Abstract

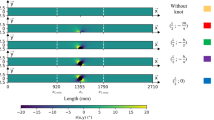

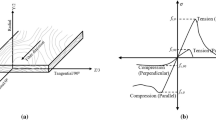

Finite element models (FEM) were used to simulate beam sections in bending with a knot. They aim at evaluating the mechanical behaviour of timber considering the effect of this singularity on resulting bending strength. By using linear elastic theory and an adapted failure criterion (Tsaï–Hill), an equivalent state can be deduced, giving information about the influence of knot on the load bearing capacity of the element. Several 2D-FEM were then developed using the free software Castem® by considering plane strain. The beam section was considered like a composite material with two materials; the wood and the knot. The slope of grain around the defect was implemented by using a simple exponential equation parameterized as a function of the radius of the singularity. The location and the size of the defect and the longitudinal modulus of elasticity of wood were investigated in this study. Results exhibit performance curves specific to bending strength. These numerical performance curves were not used to predict the bending strength but to identify some thresholds, function of the size and the location of a critical knot and the stiffness of structural beams. 188 beams with a length of 4.5 m and a cross-section of 200 × 100 mm² were tested to study the efficiency of numerical thresholds. This study shows that it is possible, by identifying only the geometrical properties of the critical defect and the stiffness of the structural beam, to improve the prediction of the bending strength of beams with a large cross-section in Maritime pine up to C40.

Similar content being viewed by others

References

Arcan M, Hashin Z, Voloshin A (1978) A method to produce uniform plane stress states with applications to fiber reinforced materials. Exp Mech 18:141–146

Bano V, Arriaga F, Soilan A, Guaita M (2011) Prediction of bending load capacity of timber beams using a finite element method simulation and grain deviation. Biosyst Eng 109:241–249

Bano V, Arriaga F, Guaita M (2013) Determination of the influence of size and position of knots on load capacity and stress distribution in timber beams of Pinus sylvestris using finite element model. Biosyst Eng 114:214–222

Bendahmane M (1988) Etude du comportement mécanique du bois avec nœuds : simulation numérique (Mechanical behaviour of wood with knots : numerical simulation), Phd Thesis, Université Bordeaux 1, France

Benoit Y (2008) Le guide des essences du bois (Guide of the wood species). ISBN 978-2-212-12086-8, FCBA Eyrolles

Buksnowitz C, Hackspiel C, Hofstetter K, Müller U, Gindl W, Teischinger A, Konnerth J (2010) Knots in trees: strain distribution in a naturally optimised structure. Wood Sci Technol 44:339–398

Chazelas JL (1990) Caractéristiques physiques et mécaniques locales du bois dans la zone des noeuds, (Physical and mechanical characteristics around knots), PhD Thesis, Université Clermont-Ferrand II, France

Coureau J-L, Cointe A, Giton M (2010) Modelling behaviour of timber from image analysis, The future of quality control for wood and wood products, Edinburgh, The final conference of COST Action E53, 4–7 May

Cramer SM, Goodman JR (1983) Model for stress analysis and strength prediction of lumber. Wood Fiber Sci 15(4):338–349

Fink G, Kohler J, Frangi A (2012) Experimental analysis of the deformation and failure behaviour of significant knot clusters. In: Proceeding of world conference on timber engineering, Auckland, New-Zealand, pp 270–279

Foley C (2003) Modeling the effects of knots in structural timber. PhD Thesis, Lund University, Sweden

Goodman JH, Bodig J (1979) Mathematical model of the tension behaviour of wood with knots and cross grain. In: Proceedings of the first international conference on wood fracture, August 14–16, 1978, Banff Alberta, Canada, pp 53–61

Grazide C (2014) Une modélisation de la résistance en flexion du Pin Maritime utilisé en construction (Modeling of timber bending strength in Maritime pine). PhD Thesis, Université de Bordeaux, France

Grazide C, Cointe A, Coureau J-L, Morel S (2015) Wood heterogeneities and failure load of timber structural elements: a statistical approach. Wood Sci Technol 49:421–440

Guindos P, Guaita M (2013) A three-dimensional wood material model to simulate the behavior of wood with any type of knot at the macro-scale. Wood Sci Technol 47:585–599

Guitard D (1987) Mécanique du matériau bois et composites (Mechanics of wood and composites), CEPAD, pp 117–123

Hoffmeyer P (1990) Failure of wood as influenced by moisture and duration load. Doctoral Thesis, State University of New-York, College of environmental Science and Forestry, Syracuse, New-York

Johansson C-J, Brundin J, Gruber R (1992) Stress grading of Swedish and German timber. A comparison of machine stress grading and three visual grading systems, Swedish National Testing and Research Institute Building Technology, Report 23, p 120

Kennedy EI (1965) Strength and related properties of woods grown in Canada, Department of forestry publication no.1104

Kunesh RH, Johnson JW (1972) Effect of single knots on tensile strength of 2 by 8 inch Douglas fir dimension lumber. For Prod J 22(1):32–36

Lanvin JD, Chatelu R, Reuling D, Joyet P (1999) Classement des bois de structure en Pin Maritime par Contrôle Non Destructif (Timber grading of Maritime pine by non-destructive tests), Proceedings of ARBORA congress “Pin Maritime”, 4–5 December 1999

Lukacevic M, Füssl J (2014) Numerical simulation tool for wooden boards with a physically based approach to identify structural failure. Eur J Wood Prod 72(4):497–508

Mihashi H, Navi P, Sunderland H, Itagaki N, Nimomoya S (1999) Micromechanics of knot’s influence on tensile strength of Japanese cedar. 1st Rilem Symposium on Timber Engineering, volume Stockholm, Sweden, pp 181–190

Pinto I (2004) Raw materials characteristics of maritime pine (Pinus pinaster Ait.) and their influence on simulated sawing yield. VTT Publications, Espoo, 533

Pugel AD (1980) Evaluation of selected mechanical properties of coniferous knotwood. PhD Thesis, University of Colorado, USA

Ranta-Maunus A, Denzler JK, Stapel P (2011) Part 2. Properties of spruce and pine tested in gradewood project, Strength of European Timber, VTT Working Paper, p 179

Roblot G, Bleron L, Meriaudeau F, Marchal R (2010) Automatic computation of the knot area ratio for machine strength grading of douglas fir and spruce timber. EJECE 14:1317–1332

Stapel P, Van De Kuilen JWG (2014a) Efficiency of visual strength grading of timber with respect to origin, species, cross section, and grading rules: a critical evaluation of the common standards. Holzforschung 68(2):203–216

Stapel P, Van De Kuilen JWG (2014b) Influence of cross-section and knot assessment on the strength of visually graded Norway Spruce. Eur J Wood Prod 72(2):213–227

Thelandersson S, Larsen HJ (2003) Timber engineering. Wiley, Oxford

Acknowledgements

The authors are grateful to the Regional Council of Aquitaine for funding of this study through the project “Morphomécanique du Pin Maritime”. The authors thank also the French National Research Agency (ANR) for supporting this study through the Xyloplate project, Equipex XYLOFOREST (ANR-10-EQPX-16).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grazide, C., Coureau, JL., Cointe, A. et al. Mechanical performance curves for the strength grading of maritime pine. Eur. J. Wood Prod. 76, 877–888 (2018). https://doi.org/10.1007/s00107-017-1241-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1241-4