Abstract

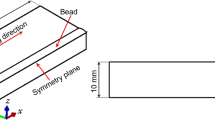

The authors proposed a switchback welding method to make stable back beads in the first layer weld during one-side multi-layer welding. In the proposed welding method, a welding torch is moved backwards and forwards like a switchback. The torch motion is important in the control of the weld pool. In this paper, the influence of the torch motion on the weld pool shape is investigated in order to find the optimum welding parameters. Firstly, fundamental welding experiments were carried out in thin plate one-side butt welding to determine the parameters of numerical simulation. Secondly, a simple numerical model for switchback welding was constructed and a heat conduction analysis was carried out, to investigate the effect of the travel speed and backward stroke distance of the torch on the weld pool. When the travel speed of the forward stroke was faster than that of the backward stroke, the weld pool length became shorter than a constant travel speed. On the other hand, if the backward stroke distance became longer than half of the forward stroke distance, continuous back beads could be obtained, regardless of such a disturbance as fluctuation of the arc length. The validity of the switchback welding method was verified by numerical simulation and fundamental experiments.

Similar content being viewed by others

References

Sugitani Y., Mao W., Ushio M.: Adaptive control of weld bead shape utilizing arc sensor in one side GMAW process with backing plate, IIW Doc. XII-1360–94, 1994.

Drews P., Starke G.: Welding in the century of information technology, Proceedings of the International Conference on ‘Advanced techniques and low cost automation’, 1994, Beijing, International Academic Publishers, pp. 3–22.

Yamamoto H., Ishihara T., Takano Y., Eguchi K., Yamane S., Oshima K.: Feed-forward control of back bead for root gap variation in V groove welding without backing plate, Quarterly Journal of the Japan Welding Society, 2002, Vol. 20, No. 4, pp. 499–505 (in Japanese).

Yamane S., Yamamoto H., Ishihara T., Kubota T., Oshima K.: Adaptive control of back bead in V-groove welding without backing plate, Science and Technology of Welding and Joining, 2004, Vol. 9, No. 2, pp. 138–148.

Jin B., Kaneko Y., Oshima K.: Control of back weld pool shape in MIG welding by using switch back method, Proceedings IEEE IAS 30th Ann. Meet., Orlando, IEEE, 1995, pp. 1835–1840.

Pardo E., Weckman D.C.: Prediction of weld pool and reinforcement dimensional transient heat transfer in GMA welding, Welding Journal, 1998, Vol. 67, pp. 150–156.

Dilthey U., Sudnik W., Mokrow O., Habedank G.: MAG-SIM for Windows, in Computer Technology in Welding Liverpool, UK, Abington Publishing, 1998, pp. 203–215.

Yamamoto T., Ohji T., Miyasaka F., Tsuji Y.: Mathematical modelling of metal active gas arc welding, Science and Technology of Welding and Joining, 2002, Vol. 7, No. 4, pp. 260–264.

Wang H.X., Sun J.S., Wei Y.H., Zheng Y.Y.: Simulation of GMAW thermal process based on string heat source model, Science and Technology of Welding and Joining, 2005, Vol. 10, No. 5, pp. 511–520.

Nakatani M., Ohji T.: Influence of pulse condition on weld penetration shape — Control method of penetration shape and welding deformation using the low frequency pulsed arc welding (Report 1), Quarterly Journal of the Japan Welding Society, 2006, Vol. 24, No. 1, pp. 52–56 (in Japanese).

Kaneko Y., Iisaka T., Yamane S., Oshima K.: Neuro-fuzzy control of weld pool in pulsed MIG welding, Quarterly Journal of the Japan Welding Society, 1994, Vol. 12, No. 3, pp. 374–378 (in Japanese).

Gao J., Wu C.: Neurofuzzy control of weld penetration in gas tungsten arc welding, Science and Technology of Welding and Joining, 2003, Vol. 8, No. 2, pp. 143–148.

Oshima K., Abe M., Kubota T.: Forced drop transfer arc welding by power source with periodically varying nonlinear characteristic, Journal of the Japan Welding Society, 1981, Vol. 50, No. 8, pp. 756–763 (in Japanese).

Oshima K., Ukita I., Abe M., Kubota T.: Effect of power source characteristic on stability and self regulation of welding arc, Trans. IEE Japan., 1981, vol. 101A, no. 1, pp. 7–14 (in Japanese).

Goldak J., Chakravarti A., Bibby M.: A new finite element model for welding heat sources, Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 1984, vol. 15B, pp. 299–305.

Fujii N., Takahashi J., Suzuki H., Yasuda K.: Comparison of strength characteristic of cast iron/mild steel welding joints by various welding process, Quarterly Journal of the Japan Welding Society, 2005, Vol. 23, No. 2, pp. 302–310 (in Japanese).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kaneko, Y., Yamane, S. & Oshima, K. Numerical Simulation of MIG Weld Pool in Switchback Welding. Weld World 53, R333–R341 (2009). https://doi.org/10.1007/BF03263476

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03263476