Abstract

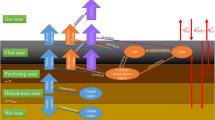

This two-part set of papers presents a study of the stress and check development inPinus radiata boards under high-temperature kiln-seasoning conditions. In the first part, a one-dimensional stress model incorporating the various strain components is developed based on a physically realistic model of drying behaviour. The drying of sapwood is assumed to be characterised by two principal stages, in which the earlier one is dominated by an evaporative front receding into the board, whereas in the later one bound water and vapour diffusion prevail. As the drying proceeds, the tracheids (pits) under water tension may cavitate randomly. This leads to a progressive fall in relative liquid permeability with moisture content. The sapwood consistently loses liquid continuity at about 60% local moisture content, significantly higher than the fibre-saturation point. The moisture in the evaporative zone is driven by a small but adequate vapour pressure difference between irreducible saturation and the fibre-saturation point which corresponds to an equilibrium moisture content of 99%. The wood is assumed to be an elasto-viscoplastic material with its mechanical properties varying with both temperature and moisture content. Under high-temperature conditions, the wood may be capable of sustaining some extent of plastic strain after passing through the yield point. Checking is assumed to occur only after the ultimate strain is exceeded.

Zusammenfassung

Diese zweiteilige Arbeit beschreibt die Spannungs- und Rißentwicklung in Kiefernbrettern unter den Bedingungen der Hochtemperatur-Trocknung. Im ersten Teil wird ein Spannungsmodell entwickelt, das die verschiedenen Dehnungskomponenten beimhaltet und auf einer physikalisch realistischen Vorstellung des Trocknungsverhaltens beruht. Es wird angenommen, daß die Trocknung des Splintholzes in zwei Stufen erfolgt: die erste ist gekennzeichnet durch eine Verdampfungsfront, die sich langsam ins Innere des Holzes zurückzieht; in der zweiten Stufe sind gebundenes Wasser und Dampfdiffusion vorherrschend, Mit fortschreitender Trocknung können die Tracheiden unter der Zugspannung des Wassers zufallsverteilt kollabieren. Dies führt zu einer fortschreitenenden Verringerung der Durchlässigkeit mit fallender Feuchte. Das Flüssigkeitskontinuum im Splintholz wird unterbrochen ab etwa 60% Holzfeuchte, d.h. deutlich über dem Fasersättingungspunkt. Die Feuchtebewegung in der Verdampfungszone wird angetrieben durch einen geringen, jedoch ausreichenden Druckunterschied zwischen nicht unterschreitbarer Sättigung und Fasersättigungspunkt, entsprechend einer Gleichgewichtsfeuchte von 99%. Das Holz wird als ein elasto-viskoplastisches Material angesehen, dessen mechanische Eigenschaften sich sowohl mit der Temperatur als auch mit der Feuchte ändern. Unter Hochtemperatur-Bedingungen kann das Holz noch einige plastische Restspannungen enthalten. Risse sollten nur entstehen, wenn die äußerste tolerierbare Spannung überschritten wird.

Similar content being viewed by others

References

Ashworth, J. C. 1977: The mathematical simulation of batch-drying of softwood timber, PhD Thesis, Department of Chemical and Process Engineering, University of Canterbury, New Zealand

Bier, H. 1986: Radiata pine in cross-grain bending. New Zealand Journal of Timber Construction. 12(1): 16–19

Bier, H.; Miller, W. R. 1990: Moisture movement, storage and handling. In: Buchanan, A. (ed): Timber Use Manual. NZ Timber Industry Federation

Bodig, J.;Jayne, B. A. 1982: Mechanics of wood and wood composites. New York: van Nostrand Reinhold Company

Carrington, A. M. 1996: High-temperature seasoning of softwood boards: determination of mechanical properties at elevated temperatures. ME Thesis, Department of Chemical and Process Engineering, University of Canterbury, New Zealand

Chen, G.; Keey, R. B.; Walker, J. C. F. 1996a: Stress development and permeability variation on drying sapwood above fibre saturation, Proceedings of 5th IUFRO Drying Conference, Quebec, Canada

Chen, G.; Keey, R. B.; Walker, J. C. F. 1996b: Moisture content profiles in sapwood boards on drying. Proceedings of 10th International Drying Symposium, Krakow, Poland

Forest Products Laboratory, USDA. 1987: Handbook of wood and wood-based materials for engineers, architects and builders. New York: Hemisphere Publishing Co

Grossman, P. U. A.;Armstrong, L. D.;Kingston, R. S. T. 1969: An assessment of research in wood rheology. Wood Science and Technol 3: 324–328

Hinds, H. V.;Reid, J. S. 1957: Forest trees and timbers of New Zealand. Wellington: Government Printer

Hisada, T. 1979–1981: Creep and set behaviour of wood relating to kiln drying. (In Japanese), J. of Japan Wood Res. Soc., Part I and II, 25(II): 688–706, Part III, 264(4): 233–240, Part IV, 26(8): 51–526, Part V and VI, 27(5): 381–296.

Hisada, T. 1986: Creep and set behavior of wood relating to kiln drying. (In Japanese), Bull. Fort. & Fort. Prod. Res. Inst. 355: 31–130

Keey, R. B. 1992: Drying of loose and particulate materials. New York: Hemisphere Publishing Corporation

Lesse, P. F. 1972: Osmotic stress in wood. Part I: The analogy between thermal and swelling stress. Wood Science and Technol. 6: 204–214

Lesse, P. F.;Kingston, R. S. T. 1972: Osmotic stress in wood. Part II: On the computation of drying stress in wood. Wood Science and Technol. 6: 272–283

Morgan, K.;Thomas, H. R.;Lewis, R. W. 1982: Numerical modeling of stress reversal in timber drying. Wood Science. 15(2): 139–149

New Zealand Ministry of Forestry; New Zealand Forest Research Institute. 1996: Producing quality kiln-dried timber in New Zealand

Oliver, A. R. 1991: A model of the behaviour of wood as it dries (with special reference to Eucalypt materials). Research Report CM91-1, Civil and Mechanical Engineering Department, University of Tasmania, Australia

Pang, S.;Langrish, T. A. G.;Keey, R. B. 1994: Moisture movement in softwood timber at elevated temperatures. Drying Technol. 12(8): 1897–1914.

Ranta-Maunus, A. 1993: Rheological behaviour of wood in directions perpendicular to the grain. Materials and Structures. 26: 362–369

Schniewind, A. P. 1989: Concise encyclopedia of wood and wood-based materials. Oxford: Pergamon Press

Siau, J.F. 1984: Transport processes in wood. Berlin: Springer Verlag

Siimes, F. E. 1967: The effect of specific gravity, moisture content, temperature and heating time on the tension and compression strength and elasticity properties perpendicular to the grain of Finnish pine, spruce and birch wood and the significance of these factors on the checking of timber at kiln drying. Research Report, VTT Julkaisu 84 Publication, Helsinki

Stanish, M. A.;Schajer, G. S.;Kayihan, F. 1986: A mathematical model of drying for hygroscopic porous media. AIChEJ. 32(8): 1301–1311

Thelandersson, S.; Moren, T. 1990: Tensile stresses and cracking in drying timber. IUFRO Meeting. New Brunswick, Canada

Tiemenn, H. D. 1906: Effect of moisture upon the strength and stiffness of wood. USDA For. Serv. Bull, 70: 70

Wu, Q.;Milota, M. R. 1994: Effect of creep and mechano-sorptive effect on stress development during drying. Drying Technol. 12(8): 2057–2085.

Yokota, T.;Tarkow, H. 1962: Changes in dimension on heating green wood. Forest Products Journal, 12(1): 43–45

Author information

Authors and Affiliations

Additional information

This word is supported by a research grant from the New Zealand Foundation for Research, Science and Technology (UOC Contract 501)

Rights and permissions

About this article

Cite this article

Chen, G., Keey, R.B. & Walker, J.C.F. The drying stress and check development on high-temperature kiln seasoning of sapwoodPinus radiata boards. Holz als Roh- und Werkstoff 55, 59–64 (1997). https://doi.org/10.1007/BF02990517

Issue Date:

DOI: https://doi.org/10.1007/BF02990517