Abstract

Goal, Scope and Background

The automotive industry has a long history in improving the environmental performance of vehicles - fuel economy and emission improvements, introduction of recycled and renewable materials, etc. The European Union also aims at improving the environmental performance of products by reducing, in particular, waste resulting from End-of-Life Vehicles (ELVs) for example. The European Commission estimates that ELVs contribute to approximately 1 % of the total waste in Europe [9]. Other European Union strategies are considering more life cycle aspects, as well as other impacts including resource or climate change. This article is summarizing the results of a European Commission funded project (LIRECAR) that aims at identifying the environmental impacts and relevance for combinations of recycling / recovery and lightweight vehicle design options over the whole life cycle of a vehicle - i.e. manufacturing, use and recycling/recovery. Three, independent and scientific LCA experts reviewed the study according to ISO 14040. From the beginning, representatives of all Life Cycle Stakeholders have been involved (European materials & supplier associations, an environmental Non-Governmental Organization, recycler’s association).

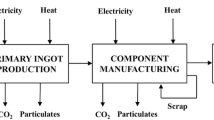

Model and System Definition

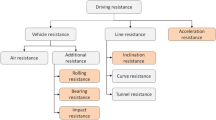

The study compared 3 sets of theoretical vehicle weight scenarios: 1000 kg reference (material range of today’s end-of-life, mid-sized vehicles produced in the early 1990’s) and 2 lightweight scenarios for 100 kg and 250 kg less weight based on reference functions (in terms of comfort, safety, etc.) and a vehicle concept. The scenarios are represented by their material range of a broad range of lightweight strategies of most European car manufacturers. In parallel, three End-of-Life (EOL) scenarios are considered: EOL today and two theoretical extreme scenarios (100% recycling, respectively, 100% recovery of shredder residue fractions that are disposed of today). The technical and economical feasibility of the studied scenarios is not taken into consideration (e.g. 100% recycling is not possible).

Results and Discussion

Significant differences between the various, studied weight scenarios were determined in several scenarios for the environmental categories of global warming, ozone depletion, photochemical oxidant creation (summer smog), abiotic resource depletion, and hazardous waste. However, these improvement potentials can be only realized under well defined conditions (e.g. material compositions, specific fuel reduction values and EOL credits) based on case-by-case assessments for improvements over the course of the life cycle. Looking at the studied scenarios, the relative contribution of the EOL phase represents 5% or less of the total life cycle impact for most selected impact categories and scenarios. The EOL technology variations studied do not impact significantly the considered environmental impacts. Exceptions include total waste, as long as stockpile goods (overburden, tailings and ore/coal processing residues) and EOL credits are considered.

Conclusions and Recommendations

LIRECAR focuses only on lightweight/recycling, questions whereas other measures (changes in safety or comfort standards, propulsion improvements for CO2, user behavior) are beyond the scope of the study. The conclusions are also not necessarily transferable to other vehicle concepts. However, for the question of end-of-life options, it can be concluded that LIRECAR cannot support any general recommendation and/or mandatory actions to improve recycling if lightweight is affected. Also, looking at each vehicle, no justification could be found for the general assumption that lightweight and recycling greatly influence the affected environmental dimension (Global Warming Potential or resource depletion and waste, respectively). LIRECAR showed that this general assumption is not true under all analyzed circumstances and not as significant as suggested. Further discussions and product development targets shall not focus on generic targets that define the approach/technology concerned with how to achieve environmental improvement (weight reduction [kg], recycling quota [%]), but on overall life cycle improvement). To enable this case-by-case assessment, exchanges of necessary information with suppliers are especially relevant.

Similar content being viewed by others

References

Thiel C, Jenssen G (2000): Comparative Life Cycle Assessment of Aluminium and Steel Bumper Carriers, SAE Technical Paper Series 2000-01-1495, Total Life Cycle Conference and Exposition, Detroit, Michigan, April 26-28, 2000, 225–230

Louis S, Wendel A (1998): Life Cycle Assessment and Design- Experience from Volvo Car Corporation, SAE technical paper series 980473, Detroit, Michigan, February 23–26, 1998, 1–6

Foglia G, Lazzari S (2001): Are Lightweight Materials Really Environmentally Friendly? A Software Tool for the Assessment of the Best Alternative Technologies in The Next Generation of Vehicles - SAE Paper n. 2001-01-3772, Proceedings of the 2001 Environmental Sus- tainability Conference and Exhibition, Graz, 463–467

Schweimer G, Levin M (2000): Life Cycle Inventory for the Golf A4, Volkswagen AG, Research, Environment and Transportation. Wolfsburg

Schmidt W-P, Beyer H-M (1998): Life Cycle Study on a Natural Fibre Reinforced Component. Proceedings of the Total Life Cycle Conference of SAE in Graz, Dec 1–3 1998, 251–258

Kaniut C, Kohler H (1995): Life Cycle Assessment (LCA) - A supporting tool for vehicle design? Life Cycle Modelling for Innovative Products and Processes edited by H. Jansen and F. Krause, Chapman & Hall, 445–458

Ridge L (1998): EUCAR - Automotive LCA Guidelines - Phase 2. In: Total Life Cycle Conference and Exposition; Graz, Austria; 12/01/ 1998-12/03/1998. SAE paper 982185, 193–204

European Commission (2003): Communication from the Commission to the council and the European Parliament - Towards a Thematic Strategy on the Sustainable Use of Natural Resources. COM(2003) 572 final, EC, Brussels

European Commission (2003): Communication from the Commission to the council and the European Parliament - Towards a Thematic Strategy on the prevention and recycling of waste. COM (2003) 301, EC, Brussels

Bundesverband der Deutschen Industrie (1999): Die Durchführung von Ökobilanzen zur Information von Öffentlichkeit und Politik. BDI, Bonn

Department for transport (2000): Review of work on whole-life environmental impacts of vehicles: Final report; London (UK).http://www. dft.gov.uk/stellent/groups/dft roads/documents/page/dft roads 506893.hcsp

Sullivan JL, Williams RL, Yester S, Cobas-Flores E, Chubbs ST, Hentges SG, Pomper SD (1998): Life Cycle Inventory of a Generic U.S. Family Sedan- Overview of Results USCAR AMP Project. In: Society of Automotive Engineers. Total Life Cycle Conference Pro- ceedings, 1–14

Leiden University Institute of Environmental Sciences (CML): Impact assessment dec 2001.xls, version 2.5, downloadhttp://www.leidenuniv. nl/cml/lca2/index.html

International Organization for Standardization - ISO (2000): Environmental management - Life cycle assessment - Life cycle impact assessment. European standard EN ISO 14042, Geneva

International Organization for Standardization - ISO (1997): Environmental management - Life cycle assessment - Principles and framework. European standard EN ISO 14040, Geneva

Aust R (2000): Powertrain research and development - needs, trends & visions. EUCAR Conference Brussels, EUCAR, Brussels

Weidema B (1998): New developments in the methodology for life cycle assessment. In: Proceedings of the 3rd International Conference on Ecobalance. Tsukuba, 47–50

GaBi - Software and database for Life Cycle Engineering, PE Europe GmbH and IKP University of Stuttgart, April 1998

European Aluminium Association (2000): Enviommental profile report for the Euorpean aluminium industry. April 2000, EAA, Brussels

International Magnesium Association (2001): Pidgeon Process of Gold River Magnesium Corporation of Ningxia. Presentation of Mr. Li at the World Magnesium Conference, Brussels, May 2001. Document 4 dated 19.08.2001, IMA, Brussels

International Magnesium Association (2001): LCI data Magne- sium.xls. Document 6 dated 19.08.2001, IMA, Brussels

European Integrated Pollution Prevention and Control Bureau (2000): Reference Document on Best Available Techniques in the Non Ferrous Metals Industries. Brussels, May 2000

Boustead I (1997): Eco-Profiles of the European plastics industry, APME, PWMI, Brussels

Bundesamt für Umwelt, Wald und Landschaft (1998): Ökoinventare für Verpackungen. Schriftreihe Umwelt Nr. 250. BUWAL, Bern

Continental AG (1999): Produkt-Ökobilanz eines PKW-Reifens. Data provided as GaBi 3 data set. Continental AG, Hannover

BMW AG, Daimler-Benz AG, Fiat, Ford-Werke AG, Adam Opel AG, Porsche, PSA-Peugeot-Citroën, Renault, Rover Group Ltd, Volkswagen AG, AB Volvo (1998): Life Cycle Analysis - Data and Methodologies Phase 2, EUCAR Project R3. Final Report. EUCAR, Brussels

Schäper S, Gleich A, Ayres RU, Gößling-Reisemann S (ed) (2004): Sustainabiliry as Criterion to Optimize Material Selection and Product Design at AUDI AG. In: Sustainable Metals Management-Eco-efficiency in industry and science. Kluwer Academic Publishing, Dordrecht, 111–120

Castro MBG, Remmerswaal JAM, Reuter MA (2003): Life Cycle Impact Assessment of the Average Passenger Vehicle in the Netherlands. Int J LCA 8 (5) 297–304

Sullivan JL, Cobas-Flores E (2001): Full vehicle LCAs: A review. SAE- 2001-01-3725 Proceedings of the 2001 Environmental Sustainability Conference and Exhibition, Graz, 99–113

Jenseit W, Stahl H, Wollny V, Wittlinger R (2003): Recovery Options for Plastic Parts from End-of- Life Vehicles: an Eco-Efficiency Assessment; Öko-Institut: Darmstadt

Nürrenbach T, Goldhan G, Woköck A (2003): Verwertung von Kunst- stoffbauteilen aus Altautos - Analyse der Umwelteffekte nach dem LCA Prinzip und ökonomische Analyse. Fraunhofer Institut für Verfahrenstechnik und Verpackung, Freising

Goldmann D, Krinke S (2003): Sustainable ELV Treatment: Life-Cycle Assessment of the Volkswagen-SiCon Process; 4th International Conference on solid waste; Leiria, Portugal 22724.10.2003

Finkbeiner M, Ruhland K, Cetiner H, Hoffmann R, Stark B (2002): Life Cycle Design - Methods, Procedures and Examples for the Application of Life Cycle Assessment in the Automotive Product Development Process. 5th International Conference on EcoBalance (7 - 9th of Nov 2002). Tsukuba (JAPAN) 1–4

Takahashi J, Zushi H, Suzuki T, Nagai H, Kageyama K, Yoshinari H (2002): Life Cycle Assessment of Ultra Lightweight Vehicles Using CFRP. 5th International Conference on EcoBalance (7 - 9th of Nov 2002). Tsukuba (JAPAN) 1–4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schmidt, WP., Dahlqvist, E., Finkbeiner, M. et al. Life cycle assessment of lightweight and end-of-life scenarios for generic compact class passenger vehicles. Int J LCA 9, 405–416 (2004). https://doi.org/10.1007/BF02979084

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02979084