Abstract

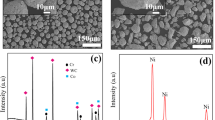

The influence of powder technology on the spraying process is growing. The use of powders of different morphologies results in a variety of coating properties. Plasma processing of ceramic composite powders underwater produces dense and spherical powders with excellent morphologies. Coatings of improved quality are produced by spraying these powders. This paper describes the concept of producing zirconia powders by a plasma process that is performed underwater. The most important parameters and standards are highlighted. Moreover, the influence of powder characteristics on coating properties will be described and some results presented.

Similar content being viewed by others

References

E.C. Subbarao, “Zirconia—An Overview,” Department of Metal- lurgical Engineering, Indian Institute of Technology, Konpur, India (1987).

R. Stevens, “Zirconia and Zirconia Ceramics,” Magnesium Elec- tron Publication No. 113, Magnesium Electron Ltd., Flemington, New Jersey, Jul (1986).

E. Lugscheider, H. Eschnauer, A. Nisch, and Z. Li, “Plasma Spray- ing of Plasma Densified Multicomponent Powders,” Proc. 12th ITSC Conf., London, The Welding Institute, Cambridge, Jun (1989).

ISO 3923, DIN 3923, “Determination of Apparent Density,” Nor- menausschuβ Pulvermetallurgie, Beuth Verlag, Berlin (1986).

ISO 4490, DIN 4490, “Determination of Flowability by Means of a Calibrated Funnel,” Normenausschuβ Pulvermetallurgie, Beuth Verlag, Berlin (1978).

ISO 3252, DIN 30900, “Terminology in the Field of Metallurgy,” Normenausschuβ Pulvermetallurgie, Beuth Verlag, Berlin (1982).

ASTM B243-288, “Standard Definitions of Terms Used in Powder Metallurgy,” ASTM, Philadelphia (1988).

ISO 3954, DIN 3954, “Powders for Powder Metallurgical Pur- poses—Sampling,” Beuth Verlag, Berlin.

E. Lugscheider, I. Rass, and C. Karsten, “Basic Investigations About the Production of Partially Stabilized ZrO2-Y2O3 Powder,” Masters thesis, Aachen University of Technology (1991).

E. Lugscheider, I. Rass, and B. Schmidt, “Basic Investigations About Influence of Powder Characteristics on Spray Drying and Underwater Plasma Densification of Stabilized Zirconia Powder,” Masters thesis, Aachen University of Technology (1990).

P. Reijnen and A.C. Firatli, “Sintering and Structural Changes in Ceramics,” Institut für Gesteinshüttenkunde, Aachen University of Technology (1984).

P. Fauchais, E. Lugscheider, and I. Rass, “Plasma Densification: Optimi- zation for Thermal Barrier Coatings in IC-Engines,” BRITE-Project P2280, Int. Thermal Spraying Conf., ITSC ’92, Orlando, ASM Interna- tional, Materials Park, to be published.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lugscheider, E., Rass, I. Underwater plasma processing of stabilized zirconia for thermal barrier coatings. JTST 1, 49–55 (1992). https://doi.org/10.1007/BF02657017

Issue Date:

DOI: https://doi.org/10.1007/BF02657017