Abstract

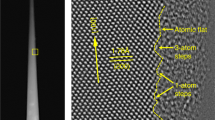

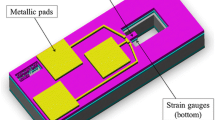

The mechanical properties of ultrananocrystalline diamond (UNCD) thin films were measured using microcantilever deflection and membrane deflection techniques. Bending tests on several free-standing UNCD cantilevers, 0.5 μm thick, 20 μm wide and 80 μm long, yielded elastic modulus values of 916–959 GPa. The tests showed good reproducibility by repeated testing on the same cantilever and by testing several cantilevers of different lengths. The largest source of error in the method was accurate measurement of film thickness. Elastic modulus measurements performed with the novel membrane deflection experiment (MDE), developed by Espinosa and co-workers, gave results similar to those from the microcantilever-based tests. Tests were performed on UNCD specimens grown by both micro and nano wafer-seeding techniques. The elastic modulus was measured to be between 930–970 GPa for the microseeding and between 945–963 GPa for the nanoseeding technique. The MDE test also provided the fracture strength, which for UNCD was found to vary from 0.89 to 2.42 GPa for the microseeded samples and from 3.95 to 5.03 for the nanoseeded samples. The narrowing of the elastic modulus variation and major increase in fracture strength is believed to result from a reduction in surface roughness, less stress concentration, when employing the nanoseeding technique. Although both methods yielded reliable values of elastic modulus, the MDE was found to be more versatile since it yielded additional information about the structure and material properties, such as strength and initial stress state.

Similar content being viewed by others

References

Bustillo, J.M., Howe, R.T., andMuller, R.S., “Surface Micromachining for Microelectromechanical Systems,”Proc. IEEE,86,1552–1574 (1998).

Sniegowski, J.J. andde Boer, M.P., “IC-compatible Polysilicon Surface Micromachining,”Annu. Rev. Mater. Res.,30,299–333 (2000).

Bhushan, B., Tribology Issues and Opportunities in MEMS, Kluwer Academic, Dordrecht (1998).

de Boer, M.P. andMayer, T.M., “Tribology of MEMS,”MRS Bulletin,4,302–304 (2001).

Gruen, D., “Nanocrystalline Diamond Films,”Annu. Rev. Mater. Sci.,29,211–259 (1999).

Gruen, D.M., Liu, S., Krauss, A.R., Luo, J., andPan, X., “Fullerenes as Precursors for Diamond Film Growth without Hydrogen or Oxygen Additions,”Appl. Phys. Lett.,64,1502–1504 (1994).

Gruen, D.M., Liu, S., Krauss, A.R. andPan, X., “Buckyball Microwave Plasmas: Fragmentation and Diamond-film Growth,”J. Appl. Phys.,75,1758–1763 (1994).

Bhattacharyya, B., Auciello, O, Birrell, J., Carlisle, J.A., Curtiss, L.A., Goyette, A.N., Gruen, D.M., Krauss, A.R., Schlueter, J., Suman, A., andZapol, P., “Synthesis and Characterization of Highly-conducting Nitrogen-Dopped Ultrananocrystalline Diamond Films,”Appl. Phys. Lett.,79,1441–1443 (2001).

Sumant, A.V., Auciello, O., Krauss, A.R., Gruen, D.M., Ersoy, D., Tucek, J., Jayatissa, A., Stach, E., Moldovan, N., Mancini, D., Busmann, H.G., and Meyer, E.M., “Fabrication of MEMS Components Based on Ultrananocrystalline Diamond Thin Films and Characterization of Mechanical Properties,” Mater. Res. Soc. Symp. Proc.,657 (2000).

Erdemir, A., Fenske, G.R., Krauss, A.R., Gruen, D.M., McCauley, T., andCsencsits, R.T., “Tribological Properties of Nanocrystalline Diamond Films,”Surf. Coat. Technol.,120–121,565–572 (1999).

Krauss, A.R., Auciello, O., Ding, M.Q., Gruen, D.M., Huang, Y., Zhirnov, V.V., Givargizov, E.I., Breskin, A., Chechen, R., Shefer, E., Konov, V., Pimenov, S., Karabutov, A., Rakhimov, A., andSuetin, N., “Electron Field Emission for Ultrananocrystalline Diamond Films,”J. Appl. Phys.,89,2958–2967 (2001).

Zapol, P., Sternberg, M., Curtiss, J., Frauenheim, T., and Druen, D.M., “Tight-binding Molecular-dynamics Simulation of Impurities in Ultrananocrystalline Diamond Grain Boundaries,” Phys. Rev. B,65 (2002).

Gruen, D.M., Krauss, A.R., Zhou, D., McCauley, T.G., andCorrigan, T.D., in Chemical Vapor Deposition, M.D. Allendorf andC. Bernard, eds, 97–25, 325–32, Electrochem. Soc., Pennington Publishers, NJ (1997).

Auciello, O., Krauss, A.R., Gruen, D.M., Busmann, H.G., Meyer, E.M., Tucek, J., Sumant, A., Jayatissa, A., Moldovan, N., Mancini, D.C., andGardos, M.N., “Two- and Three-dimensional Ultrananocrystalline Diamond (UNCD) Structures for a High Resolution Diamond-based MEMS Technology”,Mater. Res. Soc. Symp. Proc.,605,73–78 (2000).

Moldovan, N., Auciello, O., Sumant, A.V., Carlisle, J.A., Divan, R., Gruen, D.M., Krauss, A.R., Mancini, D.C., Jayatissa, A., andTucek, J., “Ultrananocrystalline Diamond Thin Films for MEMS and Moving Mechanical Assembly Devices,” International Symposium on Micromachining and Microfabrication 22–25 October 2001, San Francisco, CA, Proc. SPIE,4557,288–298 (2001).

Nix, W.D., “Mechanical Properties of Thin Films,”Metall. Trans. A,20,2217–2245 (1989).

Brotzen, F.R., “Mechanical Testing of Thin Films,”Int. Mater. Rev.,39,24–45 (1994).

Kraft, O. andVolkert, C., “Mechanical Testing of Thing Films and Small Structures,”Adv. Eng. Mater.,3,99–110 (2001).

Weihs, T.P., Hong, S., Bravman, J.C., andNix, W.D., “Mechanical Deflection of Cantilever Microbeams: A New Technique for Testing the Mechanical Properties of Thin Films,”J. Mater. Res.,3,931–942 (1988).

Schweitz, J.-A., “Mechanical Characterization of Thin Films by Micromechanical Techniques,”MRS Bull.,17,34–45 (1992).

Kraft, O., Schwaiger, R., andNix, W.D., “Measurement of Mechanical Properties in Small Dimensions by Microbeam Deflection,”Mater. Res. Soc. Symp. Proc.,518,39–44 (1998).

Espinosa, H.D., Fischer, M., Zhu, Y., and Lee, S., “3-D Computational Modeling of RF MEMS Switches,” Proceedings of the 4th International Conference on Modeling and Simulation of Microsystems, M. Laudon and B. Romanowicz, eds, 402–405 (2001).

Espinosa, H.D., Prorok, B.C., Zhu, Y., and Fischer, M., “An Investigation of Plasticity in MEMS Materials,” Proceedings of InterPACK '01, 8–13 July, Kauai, Hawaii, USA (2001).

Espinosa, H.D., Prorok, B.C., and Fischer, M., “A Novel Experimental Technique for Testing Thin Films and MEMS Materials,” Proceedings of the SEM Annual Conference on Experimental and Applied Mechanics, 4–6 June, Portland, Oregon, 446–449 (2001).

Espinosa, H.D., Prorok, B.C., andFischer, M., “A Methodology for Determining Mechanical Properties of Free-standing Thin Films and MEMS Materials,”Journal of the Mechanics and Physics of Solids,51,47–67 (2003).

Fischer, M., “MEMS Materials Testing,”Master Thesis, Purdue University, West Lafayette, IN (1999).

Burenkov, Y.A. andNikanorov, S.P., “Temperature Dependence of the Elastic Constants of Silicon,”Sov. Phys.-Solid State,16,963–964 (1974).

Peterson, K.E., “Silicon as a Mechanical Material,” Proc. IEEE,70 (5) (1982).

Sharpe, W.N., Jr., Jackson, K., Coles, G., and LaVan, D.A., “Mechanical Properties of Different Polysilicons,” ASME Symposium on Micro-Electro-Mechanical Systems (MEMS), Orlando, FL, Vol. 2 (2000).

Jackson, K.M., Bucheit, T.E., and LaVan, D.A., “Fracture Toughness of Thin Film Polysilicon Used in MEMS Devices,” Proceedings of the MEMS. Society of Experimental Mechanics, 11–15 (2001).

Lohner, K.A., Chen, K.-S., Ayon, A.A., andSpearing, S.M., “Microfabricated Silicon Carbide Microengine Structures,”Mater. Res. Soc. Symp. Proc.,546,85–90 (1999).

Henshall, J.L., Rowcliffe, D.J., and Edington, J.W., “Fracture Toughness of Single Crystal Silicon Carbide,” J. Am. Ceram. Soc.,60 (1977).

Coles, G., Sharpe, W.N., Jr., and Edwards, R.L., “Mechanical Properties of Silicon Nitride,” Proceedings of MEMS: Mechanics and Measurement Symposium, Society of Experimental Mechanics, 1–4 (2001).

Christiansen, S., Albrecht, M., and Strunk, H.P., “Mechanical Properties and Microstructural Analysis of a Diamond-like Carbon Coating on an Alumina/glass Composite,” J. Mater. Res.,11 (8) (1996).

Auciello, O., Gruen, D.M., Krauss, A.R., Jayatissa, A., Sumant, A., Tucek, J., Mancini, D.C., Moldovan, N., Erdemir A., Ersoy, D., Gardos, M.N., Busmann, H.G., and Meyer, E.M., SPIE 2000 Symposium on “Smart Materials and MEMS,” Melbourne, Australia, 13–15 December, Proc. SPIE (2001).

Bobji, M.S. andBiswas, S.K., “Deconvolution of Hardness from Data Obtained from Nanoindentation of Rough Surfaces,”J. Mater. Res.,14,2259–2268 (1999).

Krauss, A.R., Auciello, O., Gruen, D.M., Jayatissa, A., Sumant, A., Tucek, J., Mancini, D.C., Moldovan, N., Erdemir, A., Ersoy, D., Gardos, M.N., Busmann, H.G., Meyer, E.M., andDing, M.Q., “Ultrananocrystalline Diamond Thin Films for MEMS and Moving Mechanical Assembly Devices,”Diam. Relat. Mater.,10,1952–1961 (2001).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Espinosa, H.D., Prorok, B.C., Peng, B. et al. Mechanical properties of ultrananocrystalline diamond thin films relevant to MEMS/NEMS devices. Experimental Mechanics 43, 256–268 (2003). https://doi.org/10.1007/BF02410524

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02410524