Conclusions

-

1.

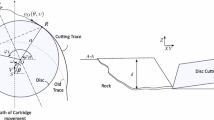

Theoretical analysis of oscillations during cutting of rocks detected the presence of three maxima in the oscillation spectrum (located in the ranges 102, 103, and 104 Hz respectively for typical cutting conditions). The first two maxima relate to inertia-free relaxation oscillations of the stick-slip type, occurring as a result of projection separation and rock microinhomogeneity; the oscillation frequencies corresponding to them are of the order v/h and v/d (v and h are cutting rate and depth; d is grain size).

-

2.

The Г-integral is invariant with cutting in a brittle regime, but under conditions of considerable plastic deformation it appeared to be a very effective tool since it made it possible to establish the main characteristic of cutting resistance (KIIc or Гc), to calculate the maximum cutting resistance Tmax, or to determine the cutter efficiency index.

Similar content being viewed by others

Literature Cited

W. Maurer, Advanced Drilling Techniques, Petroleum Publ. Co., Tulusa (1980).

G. P. Cherepanov, Mechanics of Brittle Fracture, McGraw-Hill, New York (1979).

G. P. Cherepanov, “Configuration forces in solid deformed body mechanics,” Zh. Prikl. Mat. Mekh.,49, No. 4, 593–603 (1985).

A. L. Krylovskii, “Experimental study of the frequency properties of cutting force during rock breaking by RKS cutters,” in: Machine and Equipment for Mining [in Russian], TsNIITÉI-tyazhmash, Moscow (1979).

L. B. Glatman, L. B. Shilov, and Ya. B. Gitman, “Determination of the amplitude-frequency characteristics of vibration of RKS-1 rotating cutters,” Probl. Provedeniya Gornykh Vyrabotok, No. 216, 3–5 (1983).

J. C. Jaeger and N. G. W. Cook, Fundamentals of Rock Mechanics, Chapman and Hall, London (1977).

F. P., Bowden and L. Leben, “The nature of sliding and the analysis of friction,” Proc. R. Soc.,A169, 371–391 (1939).

F. Morgen, M. Muskat, and D. W. Reed, “Friction phenomena and the stick-slip process,” J. Appl. Phys.,12, No. 2, 743–752 (1941).

J. D. Byerlee, “Theory of friction based on brittle fracture,” J. Appl. Phys.,38, No. 12, 2928–2934 (1967).

A. L. Ruina, “Theory of rate and state dependent friction,” J. Geophys. Res.,88, NB 12, 10359–10370 (1983).

J. E. Gu, J. R. Rice, A. L. Ruina, and S. T. Tse, “Slip motion and stability of a single degree of freedom elastic system with rate and state dependent friction,” J. Mech. Phys. Sol.,32, No. 3, 167–196 (1984).

J. H. Dieterich, “Mechanical behavior of crusted rocks,” Geophys. Monograph Series, American Geophysical Union, No. 24, 103–120 (1981).

A. I. Beron, A. S. Kazanskii, B. M. Leibov, and E. Z. Pozin, Coal Cutting [in Russian], Gostekhizdat, Moscow (1962).

V. D. Abezgauz, Cutting Tools of Milling Type Machines for Developing Rocks and Soils [in Russian], Mashinostroenie, Moscow (1965).

V. I. Vrublevskii, Resistance of Rocks to Failure [in Russian], Tekhnika, Kiev (1964).

I. A. Istroushko, Drilling of Hard Rocks [in Russian], Nedra, Moscow (1966).

E. I. Il'nitskaya, R. I. Teder, E. S. Vatolin, and M. F. Kuntysh, Properties of Rocks and Methods of Determining Them [in Russian], Nedra, Moscow (1969).

“Failure of rocks during drilling,” Proc. of the Third All-Union Sci.-Tech. Conf., Vols. 1 and 2 [in Russian], Minnefteprom, Moscow (1983).

M. I. Vorozhtsov, E. I. Korol'ko, G. F. Perlov, et al., “Experimental device for studying processes of rock failure by cutting with different deep drilling conditions,” Trudy VNII Burovoi Tekhniki, No. 37, 217–223 (1975).

V. V. Bundaev and V. S. Nikiforovskii, “Behavior of the failed zone in rock with a change in cutting angle and failed layer thickness,” Fiz.-Tekh. Probl. Razrab. Polezn. Iskop., No. 5, 56–59 (1984).

V. S. Nikiforovskii and E. I. Shemyakin, Dynamic Failure of Solids [in Russian], Nauka, Novosibirsk (1979).

Additional information

All-Union Scientific-Research Institute of Drilling Technology, Ministry of the Petroleum Industry, Moscow. Translated from Problemy Prochnosti, No. 8, pp. 94–102, August, 1986.

Rights and permissions

About this article

Cite this article

Cherepanov, G.P. Theory of rock cutting. Strength Mater 18, 1103–1114 (1986). https://doi.org/10.1007/BF01525361

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01525361