Abstract

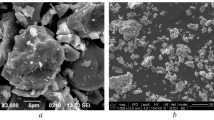

Elevated temperature compression testing has been conducted in air at 1200 and 1300K with strain rates varying from ∼10−4 to ∼10−7sec−1 on NiAl-TiB2 particulate composites. These materials, which consisted of a B2 crystal structure intermetallic Ni-50at% Al matrix and from 0 to 30 vol % of approximately 1 μm diameter TiB2 particles, were fabricated by XD synthesis and hot pressed to full density. Flow strength of the composites increased with volume fraction of the strengthening phase with NiAl-30TiB2 being approximately three times stronger than NiAl. Comparison of the light optical and transmission electron microstructures of asreceived and tested samples revealed that reactions did not occur between the two phases, and NiAl-TiB2 interfaces were not cracked during deformation. Additional transmission electron microscopy indicated that the particles stabilize a vastly different microstructure in the NiAl matrix of the composites than that formed in unreinforced NiAl.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

E. M. Grala, in “Mechanical Properties of Intermetallic Compounds”, edited by J. H. Westbrook (Wiley, New York, 1960) pp. 358–404.

A. G. Rozner and R. J. Wasilewski, J. Inst. Met. 94 (1966) 169–175.

A. Ball and R. E. Smallman, Acta Metall. 14 (1966) 1349–1355.

R. R. Vandervoort, A. K. Mukherjee and J. E. Dorn, Trans. ASM 59 (1966) 930–944.

L. A. Hocking, P. R. Strutt and R. D. Dodd, J. Inst. Met. 99 (1971) 98–101.

W. J. Yang and R. A. Dodd, Met. Sci J. 7 (1973) 41–47.

J. D. Whittenberger, Mater. Sci. Engng 57 (1983) 77–85.

Idem, J. Mater. Sci. 22 (1987) 394–402.

Idem, ibid. 23 (1987) 235–240.

Idem, NASA, TM 101382 (1988).

K. Vedula, V. Pathare, I. Aslanidis and R. H. Titran, in “High-Temperature Ordered Intermetallic Alloys”, edited by C. C. Koch, C. T. Liu and N. S. Stoloff, (Materials Research Society, Pittsburgh, PA, 1984) pp. 411–21.

M. Sherman and K. Vedula, J. Mater. Sci 21 (1986) 1974–1980.

R. K. Viswanadham, S. K. Mannan and B. Sprissler, “Nickel Aluminide/Titanium Diboride Composites” Martin Marietta Laboratories TR 87-66c, 1987.

J. R. Ramberg and W. S. Williams, J. Mater. Sci. 22 (1987) 1815–1826.

D. Broussaud, H. Pastor, R. Meyer and A. Accary, in “Modern Developments in Powder Metallurgy”, edited by H. H. Hausner and W. E. Smith, (Metal Powder Industries Federation & American Powder Metallurgy Institute, Princeton, NJ, 1974) pp. 589–603.

J. D. Whittenberger, Mater. Sci. Engng 73 (1985) 87–96.

R. W. Clark and J. D. Whittenberger, “Thermal Expansion 8”, edited by T. A. Hahn (Plenum Press, New York, 1984) pp. 189–96.

High Temperature Materials — Mechanical, Electronic and Thermophysical Properties Information Analysis Center, Purdue University, West Lafayette, IN 47906.

L. M. Brown, in “Fatigue and Creep of Composite Materials”, edited by H. Lilholt and R. Talreja, (Riso National Laboratory, Roskilde, Denmark, 1982) pp. 1–18.

O. D. Sherby, R. H. Klundt and A. K. Miller, Met. Trans 8A (1977) 843–850.

S. V. Raj and G. M. Pharr, Mater. Sci. Engng 81 (1986) 217–237.

D. L. Bacon, U. F. Kocks and R. O. Scattergood, Phil. Mag. 28 (1973) 1241–1263.

R. W. Lund and W. D. Nix, Acta Metall. 24 (1976) 469–481.

M. R. Harmouche and A. Wolfenden, J. Test. Eval. 15 (1987) 101–104.

S. V. Raj, Scripta Metall. 20 (1986) 1333–1338.

C. A. Barrett, “The Effect of 0.1 Atomic Percent Zirconium on the Cyclic Oxidation Resistance of β-NiAl”, submitted to Ox. of Metals.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Whittenberger, J.D., Viswanadham, R.K., Mannan, S.K. et al. Elevated temperature slow plastic deformation of NiAl-TiB2 particulate composites at 1200 and 1300K. J Mater Sci 25, 35–44 (1990). https://doi.org/10.1007/BF00544181

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00544181