Abstract

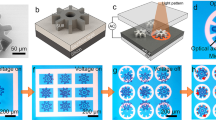

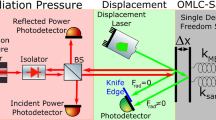

New developments based heavily on integrated-circuit-related technologies have led to rapid progress in the development of microdynamical systems. These systems are based upon the science, technology, and design of moving micromechanical devices, and are a subclass of what is known in the USA as microelectromechanical systems (MEMS). Recent rapid progress gives promise for new designs of integrated sensors, actuators, and other devices that can be combined with on-chip microcircuits to make possible high-performing, compact, portable, low-cost engineering systems. Mechanical materials for some of the microdynamical systems that have thus far been demonstrated consist of deposited thin films of polycrystalline silicon, silicon nitride, aluminum, polyimide, and tungsten among other materials. To make mechanical elements using thin-film processing, microstructures are freed from the substrate by etching a sacrificial layer of silicon dioxide. First demonstrated as a means to produce electrostatically driven, doubly supported beam bridges, this sacrificial-layer technology has proven very versatile and been used to make, among other structures, laterally vibrating doubly folded bridges, gears, springs, and impacting microvibromotors. Recently, micromirrors that consist of multiply hinged plates which fold out of the surface plane in which they are formed reaching vertical heights of mm dimensions have been demonstrated. The polycrystalline-silicon cross section for these mirrors is thinner than two micrometers. The mirrors can be moved using electrostatic comb drives or microvibromotors. Continued research on the mechanical properties of the electrical materials forming microdynamic structures (which previously had exclusively electrical uses), on the scaling of mechanical design, on tribological effects, on coatings, and on the effective uses of computer aids is now underway and promises to provide the engineering base that will exploit this promising technology.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Howe, R.T., and Muller, R.S., (1982), “Polycrystalline Silicon Micromechanical Beams,” 1982 Spring Meeting of the Electrochemical Society, Montreal, Canada, Extended Abstracts 82–1(May 9–14, 1982 ).

H.C. Nathanson, W.E. Newell, R.A. Wickstrom, and J. R. Davis, Jr., (1967), “The resonant gate transistor,” IEEE Trans. Electr. Devices, ED-14, 117–133.

Terry, S.C., (1975), “A gas chromatograph system fabricated on a silicon wafer using integrated circuit technology,” PhD dissertation, Department of Electrical Engineering, Stanford University, Stanford, CA.

Petersen, K.E., (1982), “Silicon as a mechanical material,” Proc. of the IEEE, 70, 420–457.

Howe, R.T., “Surface Micromachining,” (1985) in Micromachining and Micropackaging of Transducers, edited by C. D. Fung, Elsevier Science Publishers, New York, 169.

Kamins, T.I., (1988), Polycrystalline Silicon for Integrated Circuit Applications, Kluwer Academic Publishers, Dordrecht.

Seto, J.Y.W., (1976), Journal of Applied Physics, 47, 4780.

French, PJ., and Evans, A.G.R., (1985), Sensors and Actuators, 8

Guckel, H., and Burns, D.W., (1986), Technical Digest, IEEE Int. Electron Devices Mtg., Los Angeles, CA, 176.

Murarka, S.P., and Retajczyk, T.F. Jr., (1983), “Effect of phosphorus doping on stress in silicon and polycrystalline silicon,” Journal of Applied Physics, 54, 2069.

Choi, M.S., and E. W. Hearn, E.W. (1984), Journal of the Electrochemical Society, 131, 2443.

H. Guckel, D. W. Burns, C. R. Rutigliano, D. K. Showers, and J. Uglow, (1987), Technical Digest, Int. Conf. on Solid-State Sensors and Actuators, Tokyo, Japan, 277.

Goodenough, Frank, (1991), “Airbags Boom When IC Accelerometer Sees 50G,” Electronic Design, August 8, 1991.

W.C. Tang, T-C. H. Nguyen, and R.T. Howe, “Laterally driven polysilicon resonant microstructures,” 1989 IEEE Micro-Electro-Mechanical Systems Conference, 53–59, Salt Lake City, UT (Feb. 20–22, 1989 )

Pisano, A.P., (1989), “Resonant-structure micromotors,” 1989 IEEE MicroElectro-Mechanical Systems Conference, 44–48, Salt Lake City, UT (Feb. 20–22, 1989 )

Judy, J.W. and Muller, R.S. (1996), “Batch-Fabricated, Addressable, Magnetically Actuated Microstructures,” Solid-State Sensor and Actuator Workshop, 187–190, Transducer Research Foundation, Hilton Head Island, SC, 2–6 June 1996.

K.S.J. Pister, M.W. Judy, S.R. Burgett, and R. S. Fearing, (1992), “Microfabricated hinges,” Sensors and Actuators (A), 33.3, 249–256.

N.C. Tien, O. Solgaard, M.-H. Kiang, M. Daneman, K.Y. Lau, and R.S. Muller, (1995) “Surface-micromachined mirrors for laser-beam positioning,” Proceedings 8th International Conference on Solid-State Sensors and Actuators (Transducers ’95) and Eurosensors IX, Stockholm, Sweden, June 25–29, 1995, 352–355.

M-H. Kiang, O. Solgaard, R. S. Muller, K. Y. Lau, (1996) “Silicon-micromachined micromirrors with integrated high-precision actuators for external-cavity lasers,” IEEE Photonics Technology Letters, 8, (1996).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1997 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Muller, R.S. (1997). Microdynamical Systems. In: Bhushan, B. (eds) Micro/Nanotribology and Its Applications. NATO ASI Series, vol 330. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-5646-2_41

Download citation

DOI: https://doi.org/10.1007/978-94-011-5646-2_41

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-6381-4

Online ISBN: 978-94-011-5646-2

eBook Packages: Springer Book Archive