Abstract

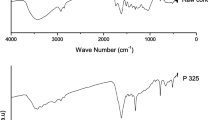

Biomass low temperature pyrolysis is a thermo-chemical treatment method that is earmarked by an pyrolysis temperature ranging from 200 to 300°C (under anoxic, heating rates ≤ 50°C/min). This paper investigates the low temperature pyrolysis properties of the raw biomass, including mulberry branch and wood chips, which collected from Jiangsu, China was carried out in a self-designed continuous pyrolysis facility. The experiments were carried out at pyrolysis temperatures of 250 ~ 300°C and residence time of 10 ~ 30 min. The results show that the mass yield of mulberry branch charcoal decreased with the increasing of the pyrolysis temperature and residence time, and the pyrolysis temperature has a significant effect on low temperature pyrolysis than the residence time. The fixed carbon and elemental carbon content of the biomass charcoals increased and volatile matters, hydrogen and oxygen contents of biomass charcoals decreased with the increasing of the pyrolysis temperature and residence time, which results in the decreasing of H/C and O/C ratios. The energy density continues to increase with increase in the pyrolysis temperature and residence time. After the pre-treatment, the biomass charcoal compared with raw biomass gained a high energy density and the improvement of hydrophobicity (OH groups are responsible for hydrogen bonding with water). SEM micrographs of mulberry branch and mulberry branch charcoals show that the porosity and the degree of thermal degradation increase with increasing of the pyrolysis temperature. After based on a systematic consideration, the operating condition of 275°C and 10 min was recommended.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Prins MJ, Ptasinski KJ, Janssen FJJG. More efficient biomass gasification via torrefaction. Energy. 2006;31(15):3458–70.

Phanphanich M, Mani S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour Technol. 2010;102(2):1246–53.

Bergman PCA. Combined torrefaction and pelletisation: The TOP process Energy research Centre of the Netherlands (ECN), Unit ECN Biomass, ECN Report: ECN-C-05-073.

Prins MJ, Frans KJP, Janssen JJG. Torrefaction of wood. Part 1: Weight loss kinetics. J Anal Appl Pyrolysis. 2006;77(1):28–34.

Lipinsky ES, Arcate JR, Reed TB. Enhanced wood fuels via torrefaction. Fuel Chem Div Preprints. 2002;47(1):408.

Bergman PCA, Kiel JHA. Torrefaction for biomass upgrading. Energy research Centre of the Netherlands (ECN), Unit ECN Biomass, ECN Report: ECN-RX-05-180.

Fonseca FF, Luengo CA, Suárez JA, et al. Wood briquette torrefaction. Energy Sustain Dev. 2005;9(3):19–22.

Arias B, Pevida C, Fermoso J, et al. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process Technol. 2008;89(2):169–75.

Almeida G, Brito JO, Perré P. Alterations in energy properties of eucalyptus wood and bark subjected to torrefaction: the potential of mass loss as a synthetic indicator. Bioresour Technol. 2010;101(24):9778–84.

Sami M, Annamalai K, Wooldridge M. Cofiring of coal and biomass fuel blends. Prog Energy Combust Sci. 2001;27(2):171–214.

Pimchuai A, Dutta A, Basu P. Torrefaction of agriculture residue to enhance combustible properties. Energy Fuel. 2010;24(9):4638–45.

Schell DJ, Harwood C. Milling of lignocellulosic biomass: results of pilotscale testing. Appl Biochem Biotechnol. 1994;45–46:159–68.

Acknowledgment

This work was supported by National Natural Science Foundation of China (51076067) and Jiangsu Provincial Natural Science Foundation of China (BK2010081).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg & Tsinghua University Press

About this paper

Cite this paper

Wang, Q., Shu, T., Lu, F., Lu, P. (2013). Experimental Study on Low Temperature Pyrolysis of Forestry Residues. In: Qi, H., Zhao, B. (eds) Cleaner Combustion and Sustainable World. ISCC 2011. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-30445-3_94

Download citation

DOI: https://doi.org/10.1007/978-3-642-30445-3_94

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-30444-6

Online ISBN: 978-3-642-30445-3

eBook Packages: EnergyEnergy (R0)