Abstract

Displacement methane (CH4) by injection gases is regarded as an effective way to exploit shale gas and sequestrate carbon dioxide (CO2). In our work, the displacement of CH4 by injection gases is studied by using the grand canonical Monte Carlo (GCMC) simulation. Then, we use molecular dynamics (MD) simulation to study the adsorption occurrence behavior of CH4 in different pore size. This shale model is composed of organic and inorganic material, which is an original and comprehensive simplification for the real shale composition. The results show that both the displacement amount of CH4 and sequestration amount of CO2 see an upward trend with the increase of pore size. The CO2 molecules can replace the adsorbed CH4 from the adsorption sites directly. On the contrary, when N2 molecules are injected into the slit pores, the partial pressure of CH4 would decrease. With the increase of the pores width, the adsorption occurrence transfers from single adsorption layer to four adsorption layers. It is expected that our work can reveal the mechanisms of adsorption and displacement of shale gas, which could provide a guidance and reference for displacement exploitation of shale gas and sequestration of CO2.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Recently, the exploration and development of shale gas have received extensive attention because of the demand for resources and pollution problems [1,2,3]. Shale gas has gained tremendous attention as an unconventional gas resource [4, 5]. The main component of shale gas is CH4, which has three states in shale, i.e., adsorbed state, free state and dissolved state [6, 7]. The volume percentage of the adsorbed CH4 in the shale reservoirs could even account for 20%–85% [8, 9]. Therefore, it is significant to investigate the adsorbed CH4 in shale reservoirs for shale gas resource evaluation.

Exploration shale gas become very difficult due to the ultralow porosity and permeability shale. Right now, many methods are proposed to boost production of shale gas, for example, re-fracturing, hydro-fracturing, supercritical CO2 fracturing, injection gases, etc. Hydro-fracturing, as a method of widely application, is used to enhance permeability of unconventional reservoirs [10,11,12]. Moreover, this method could waste large amount of water and cause severe environment problems [13,14,15]. Alternatively, the new method of injection gases is regarded as a good way to improve the recovery efficiency [16,17,18]. Meanwhile, shale gases are usually stored as adsorption state in silt pore and carbon nanotube. Therefore, investigations about the displacement and diffusion of methane in silt pores are of great significance for estimating and exploiting the shale gas.

Extensive computational studies and experiments on the displacement of CH4 in shale matrix reported at present. Yang et al. [18] investigated competitive adsorption between CO2 and CH4 in Na-montmorillonites by Monto Carlo simulations, and found that the Na-montmorillonite clay shows obviously high adsorption capacity for CO2, as compared with CH4. Wu et al. [16] explored the displacement of CH4 in carbon nanochannels by using molecular dynamics simulations, and found that CO2 can displace the adsorbed CH4 directly. Akbarzadeh et al. [19] also performed MD simulations on the mixture of shale gas (methane, ethane and propone) in a nanoscale pore graphite model, and found that the most selectivity (and also recovery) of methane obtains at the methane mole fraction of 0.95. Huo et al. [20] conducted experiments to study the displacement behaviors of CH4 adsorbed on shales by CO2 injection, and found that the amount of recovered CH4 and stored CO2 increase with CO2 injection pressure. Huang et al. [21] investigated the adsorption capacities of CH4, CO2 and their mixtures on four kerogen models with different maturities by GCMC simulations. And they found that the adsorption capacity of gas molecules is related to the maturity of kerogen.

From the studies mentioned above, most of the shale models are nanosized and simplified. Because some free gases would occupy large pores and adsorbed gases would exist in organic matter and inorganic minerals. For the shale matrix, it is indispensable to simplify the complicated structure of shale matrix to deal with the complex situation. Someone argued that the structure of montmorillonite with some ions could represent the shale. However, this model still did not include the organic matter. At last, it is reasonable and appropriate to construct an all-atom shale model including inorganic silica and organic matter to investigate the displacement and diffusion of CH4 in gas shale matrix.

In this work, we proposed a modified and generalized shale matrix model including inorganic silica and organic matter. Then, the mechanism of the displacement of CH4 by injection gases in shale matrix model was investigated through molecular simulations. Finally, some discussion was also addressed. In Sect. 3.1, the occurrence behaviors of CH4 in different pore size are found to become from one adsorption peak to four adsorption peaks. In Sect. 3.2, CO2 is injected into shale model to displace the adsorbed CH4. The displacement efficiency and sequestration amount of CO2 are investigated. In Sect. 3.3, the displacement CH4 by CO2 and N2 are compared and analyzed.

2 Simulation Models and Methods

2.1 Shale Models

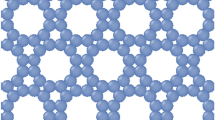

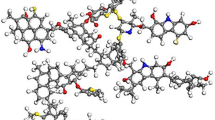

In order to construct the shale model containing inorganic minerals and organic matter, two silica sheets are used to stand for the inorganic mineral. Because the silica’s brittleness is favorable for fracture propagation. We can get the initial silica lattice from the structure database of Material Studio software [22]. Along the (1 1 0) crystallographic orientation, we can cleave a repeat unit with the thickness 3.0 nm. Generally, the polycyclic aromatic hydrocarbon is regarded as the major organic component of organic matters, especially for shale gas reservoirs. Therefore, we used methylnaphthalene molecules to stand for the organic matter in the shale matrix here.

A simulation box was constructed to (32.43 × 39.30 × c Å3), which contains two inorganic layers and two organic layers (see Fig. 1). As mentioned above, the perfect silica sheets were used to represent the inorganic layers. First, two perfect silica sheets were stacked each other in such a way as shown in Fig. 1. Then, methylnaphthalene molecules were absorbed into the interlayer space. The adsorbed methylnaphthalene molecules in slit pores were fixed [23].

2.2 Methods

GCMC simulations are carried out by SORPTION code in the MATERIAL STUDIO (MS) software developed by Accelrys Inc. The interatomic interactions are described by the force field of condensed-phase optimized molecular potential for atomistic simulation studies (COMPASS), which is a general all-atom force field. First, we took the GCMC method to investigate the displacement of CH4 by CO2. The temperature and the pressure of CH4 were 313 K and 15 MPa respectively. The acceptance or rejection of trial move is set as the Metropolis algorithm. Each equilibration procedure for CO2 and CH4 is 2 × 106. Next, CO2 was put into the slit pores with injection pressure from 0 to 110 MPa. We could get the equalized structure until the process of simulation was ended.

In order to adjust the atomic coordinates to reach a stable initial configuration, the equalized structure was minimized by using the conjugate gradient algorithm. Then, we took MD method to study the density profile of adsorbed CH4. First, the model was relaxed for 2 ns in a NVT ensemble with a time step of 1 fs. The Nose-Hoover thermostat method was used to maintain temperature. When we found that total energy of this model became time-independent, the equilibrium was arrived. In the last stage, this system experienced a simulation process of 2 ns in a NVE ensemble (constant number of atoms, isovolumetric, and constant energy conditions) with a time step of 1 fs, and the data were recorded for analysis. During these simulations, all the atoms of the shale matrix model were fixed as a rigid material.

3 Results and Discussion

3.1 Occurrence Behavior of Methane in Different Pores

The occurrence behaviors of methane in different pores are absolutely different, which is a significant aspect to reveal the adsorption behaviors of methane in shale. In this section, a series of shale model of different size pores from 10 Å to 100 Å are built. All of these shale models have undergone GCMC process to achieve the equilibrium state of adsorption, before they are subjected to MD simulations. Then, we can get some data about the density profile of CH4 in pores. Figure 2 shows the different density profiles.

Loading density profile and adsorption state of methane in different pores. (a) H = 10 Å, single adsorption layer; (b) H = 15 Å, two adsorption layers; (c) H = 25 Å, two adsorption layers and central single layer; (d) H = 40 Å, two adsorption layers and two secondary layers; (e) H = 60 Å, two adsorption layers and middle bulk phase; (f) H = 100 Å, two adsorption layers and middle bulk phase.

A single adsorption peak is founded in Fig. 2a. The distance between two solid walls of 10 Å is very close, the attractive potentials of two walls are strengthened by each other. A large amount of CH4 would accumulate in the central of the pore. The peak of adsorption layer is the second highest at 0.65 g\( \cdot \)cm−3, compare with 0.75 g\( \cdot \)cm−3 at 15 Å. Since the pore size is the narrowest in all cases, the amount of adsorption methane is limited. A small amount of methane molecules absorbed in the pore, which results in the peak of adsorption layer is not the highest. As the size of pore increases, the single adsorption layer would become two adsorption layers. The attractive potentials of two walls become weak or even disappear. Meanwhile, the peaks of adsorption layer are the highest. It can be seen from the Fig. 2b. When the distance of two walls increases to 25 Å, apart from two peaks, a central single layer appears. Two peaks near the walls are lower, around half the figure for H = 15 Å. Four peaks of adsorption layers, including two primary adsorption layers and two secondary, will appear at 40 Å [17]. Figure 2e and f show that the density of bulk phase is all keep in at 0.2 g\( \cdot \)cm−3 at the pore width of 60–100 Å. This situation illustrates that the central bulk phase will not change with the silt width increases.

In order to show the state of molecular occurrence more intuitively, we give snapshots of the adsorption model in two pore sizes. The pore sizes are set as 25 Å and 60 Å, representing mesopores and macropores respectively. Figure 3a shows that the amount of adsorbed CH4 next to the walls is much more than the bulk’s. So near the walls, two symmetrical peaks appeared. However, the center of the pore is still adsorbed with a certain amount of CH4. Correspondingly, a small peak appears in the center of the density profile graph. In contrast to, when the pores become macropores, no more peaks appear in the center of the pores. It can be seen from Fig. 3b. Because in the case of large pore, the density of methane in the central area basically does not change.

3.2 Methane Displacement by Carbon Dioxide in Different Pores

Injection gases has become a high efficient way to exploit the shale gas. CO2 and N2 are usually considered ideal gases to displace methane. Some studies find that the adsorption capacity of gases is related to the attractive potentials between gases and shale matrix atoms. Figure 4a shows the changes of loading amount of CH4 at different CO2 injection pressure in different pores. The size of pore is set 15–100 Å. Obviously, the downward trend in loading amount of CH4 is significant at different pores. As the injection pressure of CO2 increases, the loading amount of CH4 in the shale model diminishes. For injection pressure of 0–30 MPa, the loading amount of CH4 decreases quickly. When CO2 is injected, the molecules can adsorb on the walls to replace the adsorbed methane. At high pressure, there are no more adsorption sites for CO2 molecules to adsorb. The curve becomes smooth at high CO2 injection pressure. The loading amount of CH4 starts to stay stable. With the increase of the pores width, the loading amount of CH4 at different CO2 injection pressure increases obviously. Similarly, the sequestration amount of CO2 rises significantly. For the same width of pore, the figure for sequestration CO2 grows dramatically, which is shown in the Fig. 4b. Furthermore, the displacement amount of CH4 at CO2 injection pressure of 90 MPa is studied. Much more CO2 is absorbed into the pores with the increase of pore width, causing more methane to be driven out. So Fig. 4c shows that the displacement amount of CH4 is the highest in the pore size of 100 Å. Correspondingly, the sequestration amount of CO2 is also the most. It can be seen from Fig. 4d.

Displacement of methane by carbon dioxide in different pores. (Tm = 313 K, Pm = 15 MPa) (a) Loading amount of CH4 at different CO2 injection pressure; (b) Sequestration amount of CO2 at different CO2 injection pressure; (c) Displacement amount of CH4 at CO2 injection pressure of 90 MPa; (d) Sequestration amount of CO2 at CO2 injection pressure of 90 MPa.

3.3 Comparison of Methane Displacement by Nitrogen and Carbon Dioxide

Both N2 and CO2 can be used to displace gases. However, our studies find that the displacement mechanisms of these gases is different. The pore width is set 25 Å. Figure 5 shows the difference between these two gases. Figure 5a shows the loading amount of CH4 at different injection pressure. In the case of CO2 displacing CH4, the loading amount of methane decreases significantly as the partial pressure of CO2 increases, compared with the case of N2 displacing CH4. Both kinds of gases displacement have led to a sharp decline in loading amount of CH4. Correspondingly, the sequestration amount of CO2 has also increased rapidly in the cases of the displacement of methane by CO2 and N2. More CO2 will displace the methane to concentrate in the adsorbed layer, and N2 will displace less. When CO2 is added into the pores, the full of this space is filled with CO2 molecules. Then, CO2 molecules begin to occupy adsorption sites of CH4, replacing the adsorbed CH4 molecules directly. The displaced CH4 molecules return to free phase. The adsorption capacity of these three gases is sorted as follows: CO2 > CH4 > N2. In contrast to, when N2 is injected, N2 molecules cannot occupy adsorption sites of CH4. These N2 molecules can only adsorb on the vacancies due to the fact that the adsorption capacity of N2 is weaker than CH4. N2 molecules are able to displace CH4 because they can reduce the partial pressure of CH4. Once the partial pressure of CH4 decreases, CH4 molecules would be desorbed and displaced. Therefore, as CO2 and N2 are injected, the loading amount of methane all experiences a downward trend. The screenshots of different displacement processes is shown in Fig. 6.

4 Conclusion

On the basis of adsorption characteristics of CH4 on the shale model, we built a new shale model by using organic-inorganic composites. Then we used GCMC simulation to study the displacement of shale gas by CO2 and N2. The displacement mechanisms of the injection gases are investigated. Next, the occurrence behavior of methane in different pores is investigated by using the MD method. Our conclusions are listed as follows:

-

1.

With the pores width increase, the adsorption occurrence transfers from single adsorption layer to four adsorption layers. In the case of a much wide pore width, the density of the central bulk phase approaches to the same value at 0.2 g\( \cdot \)cm−3.

-

2.

To displace the adsorbed CH4, CO2 and N2 are injected and investigated. The results indicate that both of the CO2 and N2 molecules can displace the adsorbed shale gas and CO2 is sequestrated into the shale simultaneously.

-

3.

However, the displacement mechanisms of the injection gases are different. The adsorption capacity of CO2 is much stronger than that of CH4. The CO2 molecules can replace the adsorbed CH4 from the adsorption sites directly. On the contrary, when the pores are occupied by N2 molecules, these molecules can decrease the partial pressure of CH4.

It is expected these results and findings are of great importance for displacement exploitation of shale gas and sequestration of CO2.

References

Arora, V., Cai, Y.: US natural gas exports and their global impacts. Appl. Energy 120, 95–103 (2014)

Howarth, R.W., Santoro, R., Ingraffea, A.: Methane and the greenhouse-gas footprint of natural gas from shale formations. Clim. Change 106(4), 679 (2011)

Li, Y.X., Nie, H.K., Long, P.Y.: Development characteristics of organic-rich shale and strategic selection of shale gas exploration area in China. Nat. Gas. Ind. 29(12), 115–118 (2009)

Bowker, K.A.: Barnett shale gas production, Fort Worth Basin: issues and discussion. AAPG Bull. 91(4), 523–533 (2007)

Caulton, D.R., Shepson, P.B., Santoro, R.L., et al.: Toward a better understanding and quantification of methane emissions from shale gas development. Proc. Natl. Acad. Sci. 111(17), 6237–6242 (2014)

Howarth, R.W., Santoro, R., Ingraffea, A.: Methane and the greenhouse-gas footprint of natural gas from shale formations. Clim. Change 106(4), 679 (2011)

Ji, L., Zhang, T., Milliken, K.L., et al.: Experimental investigation of main controls to methane adsorption in clay-rich rocks. Appl. Geochem. 27(12), 2533–2545 (2012)

Johnson, H.E., Granick, S.: Exchange kinetics between the adsorbed state and free solution: poly (methyl methacrylate) in carbon tetrachloride. Macromolecules 23(13), 3367–3374 (1990)

Curtis, J.B.: Fractured shale-gas systems. AAPG Bull. 86(11), 1921–1938 (2002)

Clark, C., Burnham, A., Harto, C., et al.: Hydraulic fracturing and shale gas production: technology, impacts, and policy. Argonne National Laboratory (2012)

Clarkson, C.R., Haghshenas, B., Ghanizadeh, A., et al.: Nanopores to megafractures: current challenges and methods for shale gas reservoir and hydraulic fracture characterization. J. Nat. Gas Sci. Eng. 31, 612–657 (2016)

Chen, H., Carter, K.E.: Water usage for natural gas production through hydraulic fracturing in the United States from 2008 to 2014. J. Environ. Manage. 170, 152–159 (2016)

Jackson, R.E., Gorody, A.W., Mayer, B., et al.: Groundwater protection and unconventional gas extraction: the critical need for field-based hydrogeological research. Groundwater 51(4), 488–510 (2013)

Connor, J.A., Molofsky, L.J., Richardson, S.D., et al.: Environmental issues and answers related to shale gas development. In: SPE Latin American and Caribbean Health, Safety, Environment and Sustainability Conference. Society of Petroleum Engineers (2015)

Clarkson, C.R., Solano, N., Bustin, R.M., et al.: Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 103, 606–616 (2013)

Wu, H.A., Chen, J., Liu, H.: Molecular dynamics simulations about adsorption and displacement of methane in carbon nanochannels. J. Phys. Chem. C 119(24), 13652–13657 (2015)

Yu, H., Yuan, J., Guo, W., et al.: A preliminary laboratory experiment on coal bed methane displacement with carbon dioxide injection. Int. J. Coal Geol. 73(2), 156–166 (2008)

Yang, N., Liu, S., Yang, X.: Molecular simulation of preferential adsorption of CO2 over CH4 in Na-montmorillonite clay material. Appl. Surf. Sci. 356, 1262–1271 (2015)

Akbarzadeh, H., Abbaspour, M., Salemi, S., et al.: Injection of mixture of shale gases in a nanoscale pore of graphite and their displacement by CO2/N2 gases using molecular dynamics study. J. Mol. Liq. 248, 439–446 (2017)

Huo, P., Zhang, D., Yang, Z., et al.: CO2 geological sequestration: displacement behavior of shale gas methane by carbon dioxide injection. Int. J. Greenhouse Gas Control 66, 48–59 (2017)

Huang, L., Ning, Z., Wang, Q., et al.: Molecular simulation of adsorption behaviors of methane, carbon dioxide and their mixtures on kerogen: effect of kerogen maturity and moisture content. Fuel 211, 159–172 (2018)

Li, X., Xue, Q., Wu, T., et al.: Oil detachment from silica surface modified by carboxy groups in aqueous cetyltriethylammonium bromide solution. Appl. Surf. Sci. 353, 1103–1111 (2015)

Zhang, H., Cao, D.: Molecular simulation of displacement of shale gas by carbon dioxide at different geological depths. Chem. Eng. Sci. 156, 121–127 (2016)

Acknowledgements

This study was supported by the National Natural Science Foundation of China (No. 51676208) and the Fundamental Research Funds for the Central Universities (No. 18CX07012A).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Shi, J., Gong, L., Huang, Z., Yao, J. (2018). Molecular Simulation of Displacement of Methane by Injection Gases in Shale. In: Shi, Y., et al. Computational Science – ICCS 2018. ICCS 2018. Lecture Notes in Computer Science(), vol 10862. Springer, Cham. https://doi.org/10.1007/978-3-319-93713-7_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-93713-7_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-93712-0

Online ISBN: 978-3-319-93713-7

eBook Packages: Computer ScienceComputer Science (R0)