Abstract

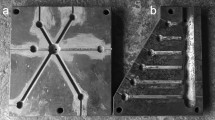

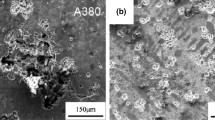

This work focuses on the determination of the hot tearing susceptibility of aluminum alloys using a Constrained Rod Casting (CRC) mold. In order to do so, a CRC mold was designed and manufactured and different alloys within the 6000 series were tested. Different criteria for the determination of the hot tearing susceptibility were proposed and evaluated. In certain alloys, the effect on the hot tearing susceptibility with the amount of certain alloying elements, grain refiner addition and metallostatic pressure was evaluated. The results obtained in this work show a good correlation to those found by other authors, as well as to the hot tearing tendency of alloys produced by direct-chill (DC) casting in our cast shop. Therefore, the use of a CRC test in order to predict how different 6000 series alloys will perform in solidification processes like DC casting shows to be a simple and cost-effective option with very good results.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Nadella R, Eskin D, Katgerrman L (2007) Role of grain refining in hot cracking and macrosegregation in direct chill cast AA 7075 billets. Institute of Materials, Minerals and Mining, Materials Science and Technology, 23(11): 1327-1335.

Eskin D (2008) Physical Metallurgy of Direct Chill Casting of Aluminum Alloys. Taylor and Francis Group.

Zhu JZ, Guo J, Samonds MT (2011) Numerical modeling of hot tearing formation in metal casting and its validations. International Journal for Numerical Methods in Engineering 87:289–308.

Campbell, J (2003) Castings. Butterworth-Heinemann, Oxford.

Beeley P (2001) Foundry Technology. Butterworth-Heinemann, Oxford.

Lin C, Aliravci C, Pekguleryuz MO (2007) Hot-Tear Susceptibility of Aluminum Wrought Alloys and the Effect of Grain Refining.Metallurgical and Materials Transactions A 38(A): 1056–1068.

Cao G, Kou S, Chang YA (2006) Hot cracking susceptibility of binary Mg–Al alloys. Magnesium Technology 57–61.

Davies, GJ (1973) Solidification and Casting. Halsted Press, University of Cambridge.

Huang H, Fu PH, Wang YX, Peng LM, Jiang HY (2014) Effect of Pouring and mold temperatures on hot tearing susceptibility of AZ91D and Mg-3Nd-0.2Zn-Zr Mg alloys. Trans. Nonferrous Met. Soc. China 24:922–929.

Drezet JM, Rappaz M (2013) Prediction of Hot Tears in DC-Cast Aluminum Billets, in: Essential Readings in Light Metals: Cast Shop for Aluminum Production, John Wiley & Sons, Inc, From Light Metals 2001, Joseph L. Anjier, Editor.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Stermann, L., Iraizoz, M. (2018). Evaluation of Hot Tearing Susceptibility of 6000 Series Aluminum Alloys Using Constrained Solidification Test. In: Martin, O. (eds) Light Metals 2018. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72284-9_52

Download citation

DOI: https://doi.org/10.1007/978-3-319-72284-9_52

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72283-2

Online ISBN: 978-3-319-72284-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)