Abstract

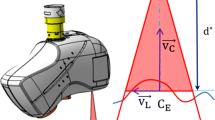

Integrating measurement operations for on-machine inspection in a 5-axis machine tool is a complex activity requiring a significant limitation of measurement time in order not to penalize the production time. When using a laser-plane sensor, time optimization must be done while keeping the quality of the acquired data. In this paper, a simulation tool is proposed to assess a given digitizing trajectory. This tool is based on the analysis of sensor configurations relatively to the geometry of the studied part.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

L. Dubreuil, Y. Quinsat, C. Lartigue, Multi-sensor approach for multi-scale machining defect detection, Joint Conference On Mechanical, June 2014, Toulouse, France, Research in Interactive Design Vol. 4

F. Poulhaon, A. Leygue, M. Rauch, J-Y. Hascoet, and F. Chinesta, Simulation-based adaptative toolpath generation in milling processes, Int. J. Machining and Machinability of Materials, 2014, 15 (3/4), pp. 263–284.

S. Larsson and Johan AP Kjellander. Path planning for laser scanning with an industrial robot. Robotics and Autonomous Systems, 2008, 56(7), pp.615–624.

Q. Wu, J. Lu, W. Zou, and D. Xu. Path planning for surface inspection on a robot-based scanning system. In Mechatronics and Automation (ICMA), IEEE International Conference on, 2015, pp. 2284–2289.

A. Bernard, M. Véron, Visibility theory applied to automatic control of 3d complex parts using plane laser sensors. CIRP Annals-Manufacturing Technology, 2000, 49(1), pp.113–118.

Prieto, F., Redarce, H., Lepage, R., and Boulanger, P., Range image accuracy improvement by acquisition planning. In Proceedings of the 12th conference on vision interface (VI’99), Trois Rivieres, Québec, Canada, 1999, pp.18–21.

Son, S., Park, H., and Lee, K. H., Automated laser scanning system for reverse engineering and inspection. International Journal of Machine Tools and Manufacture, 2002, 42(8), pp.889–897.

Yang, C. C. and Ciarallo, F. W., Optimized sensor placement for active visual inspection. Journal of Robotic Systems, 2001, 18(1), pp.1–15.

Lartigue, C., Quinsat, Y., Mehdi-Souzani, C., Zuquete-Guarato, A., and Tabibian, S., Voxel-based path planning for 3d scanning of mechanical parts. Computer-Aided Design and Applications, 2014, 11(2), pp.220–227.

Mavrinac, A., Chen, X., and Alarcon-Herrera, J. L., Semiautomatic model-based view planning for active triangulation 3-d inspection systems. Mechatronics, IEEE/ASME Transactions on, 2015, 20(2), pp.799–811.

S. Lavernhe, Y. Quinsat, C. Lartigue, Model for the prediction of 3D surface topography in 5-axis milling, International Journal of Advanced Manufacturing Technology, 2010, 51, pp. 915–924.

M. Mahmud, D. Joannic, M. Roy, A. Isheila, J.-F. Fontaine, 3D part inspection path planning of a laser scanner with control on the uncertainty, Computer-Aided Design, 2011, 43, pp. 345–355.

C. Mehdi-Souzani, Y. Quinsat, C. Lartigue, P. Bourdet, A knowledge database of qualified digitizing systems for the selection of the best system according to the application, CIRP Journal of Manufacturing Science and Technology, 2016, DOI: doi:10.1016/j.cirpj.2015.12.002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

PHAN, N.D.M., QUINSAT, Y., LARTIGUE, C. (2017). Simulation of Laser-Sensor Digitizing for On-Machine Part Inspection. In: Eynard, B., Nigrelli, V., Oliveri, S., Peris-Fajarnes, G., Rizzuti, S. (eds) Advances on Mechanics, Design Engineering and Manufacturing . Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-45781-9_31

Download citation

DOI: https://doi.org/10.1007/978-3-319-45781-9_31

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-45780-2

Online ISBN: 978-3-319-45781-9

eBook Packages: EngineeringEngineering (R0)