Abstract

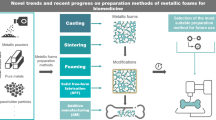

Optimized structures found in nature can be sometimes imitated in engineering structures. The recent interest in functionally graded metallic materials makes bone structures interesting because bones are naturally functionally graded1. The cellular structure of foam metals (Fig.1) is very similar to that of the cancellous bone; therefore, these metals can be considered as potential candidates for future implant applications if porosity level, size and shape, strength and biocompatibility aspects satisfy the design specifications of implants. Foam metals based on biocompatible metallic materials (e.g. Ti and Ti-6A1-4V) are expected to provide better interaction with bone. This is mainly due to higher degree of bone growth into porous surfaces and higher degree of body fluid transport through three-dimensional interconnected array of pores2 (open cell foam), leading to better interlocking between implant and bone and hence reducing or avoiding the well-known implant losening. Furthermore, the elastic modulus of foam metals can be easily tailored with porosity level to match that of natural bone, leading to a better performance by avoiding the high degree of elastic mismatch which currently exists between conventional solid metallic implants and bone.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Weiner, S., and Wagner, H. D.,1998, The material bone: structure-mechanical function relation. Annu. Rev. Mater. Sci. 28:271–298.

Pillar, R. M., 1987, Porous-surfaced metallic implants for orthopaedic applications. J Biomed. Mater. Res. 21:1–3.

Banhart, J., 2001, Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 46:559–632.

Körner, C., and Singer, R. F., 2002, Processing of metal foams-challenges and opportunities. Adv. Eng. Mater. 2:159–165.

Martin, B., Stiller, C., Buchkremer, H. P., Stöver, D., and Baur, H., 2000, High purity titanium, stainless steel and superalloy parts . Adv. Eng. Mater. 2:196–199.

Wen, C. E., Mabuchi, M., Yamada, Y., Shimojima, K., Chino, Y., and Asahina, T., 2001, Processing of biocompatible porous Ti and Mg. Script. Mat. 45:1147–1153.

Wen, C. E., Yamada, Y., Shimojima, K., Chino, Y., Asahina, T., and Mabuchi, M., 2001, Processing and mechanical properties of autogenous titanium implant materials. J Mater. Sci. 13:397–401.

Froes, F. H., 2002 Lightweight heavyweight, Metal Powder Report (www.metalpowder.net)

Clemow, A. J., Weinstein, A. M., Klawitter, J. J., Koeneman, J., and Anderson, J., 1981, Interface mechanics of porous titanium implants. J. Biomea. Mate. Res. 15: 73–82.

Chang, Y., Oka, M., Kobayashi, M., Gu, H., Li, Z., Nakamura, T., and Ikada, Y., 1996, Significance of interstitial bone ingrowth under load-bearing conditions: a comparison between solid and porous implant materials, Biomaterials 17: 1141–1148.

Gibson L. J., and Ashby F., 1997, Cellular solids: structure and properties. Cambridge University Press.

Elbir, S., Yilmaz, S., Toksoy, K., Guden, M., and Hall, I. W., 2003, SiC-particulate aluminum composite foams produced by powder compacts: Foaming and compression behavior, J. Mater. Sci. 38:4745–4755.

Weiner, S., and Wagner, H. D. ,1998, The material bone:structure-mechanical function relations. Annu. Rev. Mater. Sci. 28:271–298.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2004 Springer Science+Business Media New York

About this paper

Cite this paper

Guden, M., Celik, E., Cetiner, S., Aydin, A. (2004). Metals Foams for Biomedical Applications: Processing and Mechanical Properties. In: Hasirci, N., Hasirci, V. (eds) Biomaterials. Advances in Experimental Medicine and Biology, vol 553. Springer, Boston, MA. https://doi.org/10.1007/978-0-306-48584-8_20

Download citation

DOI: https://doi.org/10.1007/978-0-306-48584-8_20

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4757-0988-9

Online ISBN: 978-0-306-48584-8

eBook Packages: Springer Book Archive