Abstract

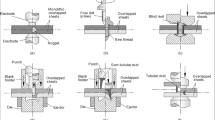

Based on a continuous trend towards lightweight design and the need of load-carrying joints between metals and fibre-reinforced plastics, Spin-Blind-Riveting (SBR) was developed at the Chair of Welding Engineering of Technische Universität Chemnitz. Through the combination of a rotated rivet and the application of a joining force, rivet connections can be fabricated without the need of predrilling the sheets. Tests were carried out with material combinations which are significant for lightweight constructions such as magnesium and aluminium alloys and glass fibre-reinforced polyamide in sheet thicknesses of 1 and 2 mm. Results show that the SBR process permits reliable rivet connections over a wide range of joining parameters. SBR joints combine high shear strength with low standard deviation of joint strength. Short joining time, high loadability and high reproducibility make Spin-Blind-Riveting an attractive new joining process for lightweight applications.

Similar content being viewed by others

References

Grandt J (1994) Blindniettechnik: Qualität und Leistungsfähigkeit moderner Blindniete. Die Bibliothek der Technik, Verl. Moderne Industrie Landsberg/Lech

Mucha J (2013) The effect of material properties and joining process parameters on behavior of self-pierce riveting joints made with the solid rivet. Mater Des 52:932–946

Duan H, Han G, Wang M (2014) Rotation friction pressing riveting of AZ31 magnesium alloy sheet. Mater Des 54:414–424

Seidlitz H, Ulke L, Kroll L. Schutzrecht DE102009013265A1. Verfahren und Werkzeuge zum Herstellen einer Mischbaugruppe

Biermann D, Liu Y (2014) Innovative flow drilling on magnesium wrought alloy AZ31. Proc Int Conf Manuf Light Components ManuLight 18(14):209–214

DIN EN 1465 (2009) Adhesives - determination of tensile lap-shear strength of bonded assemblies

(2005) D5961/D5961M-05e1 standard test method for bearing response of polymer–matrix composite laminates. Vol. 15.03. Composite materials. ASTM International. West Conshohocken, PA

Mücklich S (2008) Leichtbaupotenziale durch Einsatz von Leichtmetallen, Habilitation, Technische Universität Chemnitz

Author information

Authors and Affiliations

Corresponding authors

Additional information

Doc. IIW-2567, recommended for publication by SC-Auto “Select Committee Automotive and Road Transport.”

Rights and permissions

About this article

Cite this article

Podlesak, F., Hälsig, A., Höfer, K. et al. Spin-blind-riveting: secure joining of plastic with metal. Weld World 59, 927–932 (2015). https://doi.org/10.1007/s40194-015-0255-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0255-y