Abstract

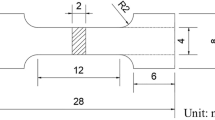

Plates of Al-(a)Si-(b)Cu-Mg-(c)Fe alloys with varying content of (mass pct) Si (a = 3, 4.5, 7.5, 9, 10, or 11), Cu (b = 0, 1, or 4), and Fe (c = 0.2, 0.5 or 0.8) were cast in sand molds with a heavy chill at one end to ensure quasi-directional solidification over a wide range of Secondary Dendrite Arm Spacing (SDAS). Statistical analysis on the size of the β-Al5FeSi, α-Al8Fe2Si, or Al2Cu intermetallics on Backscattered Electron images showed that a high Si content reduced the size of the β platelets in alloys with up to 0.5 Fe content regardless of the SDAS, whereas at small SDAS the refining effect extended up to 0.8 Fe, and involved α-phase intermetallics which replaced the beta platelets at those concentrations. At low Si contents, a high Cu level appeared to have similar refining effects as increased Si, through the formation of α-phase particles in the post-eutectic stage which agglomerated with the Al2Cu intermetallics. A high content of Si appears to make the overall refining process less critical in terms of SDAS/cooling rate.

Similar content being viewed by others

Notes

The level of Fe in these alloys (0.8 pct) was higher than that of the initial study described in Figure 1 (0.5 pct) and was carried out at a much larger (~50 µm) SDAS.

The reading of this excellent piece of work is marred by the use of an ordinal rather than the commonly used nominative phase identification scheme.

The electron-matter interaction depth[13] in pure Al, Si, Cu, and Fe for the 20 keV electrons is estimated to be 4.2, 4.7, 1.5, and 1.6 μm, respectively, although the effective BSE depth is far more less than these. Only X-ray signals (EDX/EDS) come from this much deeper region where as the backscattered electrons and secondary electrons come from the actual surface,[14,15] after the incident electron interaction, so the error due to under the surface detection seemed to be minor, especially considering the high density of the α-Al8Fe2Si and β-Al5Fe2Si phases (3695 and 3429 kg/m3, respectively).[16,17]

Ignoring the nature of the particles in favor of their size is consistent with the initial goal of this work, that of minimizing the deleterious effects of the intermetallics on the alloys ductility, which mostly are determined by particle size.[1,18,19] Actual identification of the intermetallic phases involved in the quantitative metallography was carried out as described in Appendix B.

The 0.8 Fe alloy at large SDAS is the case for some of the experiments of Reference 4.

References

[1]C.H. Caceres, I.L. Svensson, and J.A. Taylor: Int. J. Cast Met. Res. 2003, vol. 15, pp. 531–43,

C.H. Caceres and J.A. Taylor: Shaping Casting: The John Campbell Symposium, 2005, vol. 1, pp. 245–54.

C.H. Caceres and J.A. Taylor: Metall. Mater. Trans. B 2006, vol. 37B, pp. 897–903.

C.H. Caceres, B. Johannesson, J.A. Taylor, A. Canales-Nunez, M. Cardoso, and J. Talamantes: The effect of si content on the size and morphology of Fe-rich and Cu-rich intermetallics in Al-Si-Cu-Mg alloys (Minerals, Metals & Materials Soc, Warrendale, PA, 2007).

T. Sivarupan, C.H. Caceres, and J.A. Taylor: in 5th Shape Casting Symposium TMS 2014, M. Tiryakioglu, J. Campbell, and G.E. Byczynski, eds., Wiley, New York, 2014, pp. 137–43.

T. Sivarupan, C.H. Caceres, and J.A. Taylor: Materials Science Forum 2013, Light Metals Technology, vol. 765, Trans Tech Publications, Switzerland, 2013, p. 107.

O. Vorren, J.E. Evensen, and T.B. Pedersen: Trans. Am. Foundrymen’s Soc., vol. 92, 1984, pp. 459–66.

A. Gorny, J. Manickaraj, Z. Cai, and S. Shankar: J. Alloys Compd. 2013, vol. 577, pp. 103-124.

W. Khalifa, F. Samuel, and J. Gruzleski: Metallurgical and Materials Transactions A 2003, vol. 34, pp. 807-825.

M.H. Mulazimoglu, A. Zaluska, J.E. Gruzleski, and F. Paray: Metall. Mater. Trans. A 1996, vol. 27, pp. 929–36.

S. Lee, B. Kim, and S. Lee: Mater. Trans. 2011, vol. 52, pp. 1053–62.

T. Sivarupan, C.H. Caceres, and J.A. Taylor: Metall. Mater. Trans. A 2013, vol. 44A, pp. 4071–80.

K. Kanaya and S. Okayama: J. Phys. D 1972, vol. 5, pp. 43-58.

M. Kaczorowski and W.W. Gerberich: Mater. Lett. 1986, vol. 4, pp. 244-48.

F.J. Humphreys, P.J. Goodhew, and R. Beanland: Electron microscopy and analysis (Taylor & Francis, New York, 2001).

R.N. Corby and P.J. Black: Acta Crystallogr. Sect. B 1977, vol. 33, pp. 3468–75.

V. Hansen, B. Hauback, M. Sundberg, C. Romming, and J. Gjonnes: Acta Crystallogr. Sect. B 1998, vol. 54, pp. 351–57.

A. Couture: Int. Cast Met. J. 1981, vol. 6, pp. 9-17,

P.N. Crepeau: Trans. Am. Foundrymen’s Soc., vol. 103, 1995, pp. 361–66.

J.A. Taylor: Proc. Mater. Sci. 2012, vol. 1, pp. 19-33.

Y. Awano and Y. Shimizu: Trans. Am. Foundrymen’s Soc. 1990, vol. 98, pp. 889–95

Y.H. Cho, H.C. Lee, K.H. Oh, and A.K. Dahle: Metall. Mater. Trans. A 2008, vol. 39A, pp. 2435-48.

L. Bäckerud, G. Chai, and J. Tamminen: Solidification Characteristics of Aluminum Alloys, AFS/Skanaluminium Publications, Des Plaines, IL, 1990.

C.M. Dinnis, J.A. Taylor, and A.K. Dahle: Materials Forum 28, 2004, vol. 28, pp. 1016–21.

[25]C.M. Dinnis, J.A. Taylor, and A.K. Dahle: Scripta Materialia 2005, vol. 53, pp. 955–58.

X.J. Cao and J. Campbell: Mater. Trans. 2006, vol. 47, pp. 1303–12.

A.M. Samuel, F.H. Samuel, and H.W. Doty: J. Mater. Sci. 1996, vol. 31, pp. 5529–39.

L. Liu, A.M.A. Mohamed, F.H. Samuel, A.M. Samuel, H.W. Doty, and S. Valtierra: Metall. Mater. Trans. A 2009, vol. 40A, pp. 2457–69.

A. Day and P. Trimby: User Manual-Chanel 5, HKL Technology 2001, vol. 1, p. 104. http://caf.ua.edu/wp-content/uploads/docs/JEOL-7000F-Oxford_Channel_5_User_Manual.pdf.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 1, 2014.

Appendices

Appendix A: BSE Images Used for Quantitative Metallography

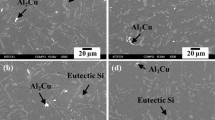

Figures A-1 through A-5 show the micrographs used to extract the images of the intermetallics for the quantitative analysis shown in Figures 5 and 6. Examples of extracted images are shown in Figure A-6 for the 0.2 Fe alloys at both 30 and 50 μm SDAS. Figure A-7 shows the original micrographs of the extracted particles of Figure 7. Figure A-8 shows the effect of Sr-modification on the AlSiFe alloy.

Appendix B: Phase Identification

In alloys with known chemical compositions, the intermetallic particles are normally characterized by their size, color (in optical micrographs), and morphology.[20,25-28] When the composition is an issue, for sizes smaller than 2 µm, it is a challenge to accurately find the chemical composition using Energy-Dispersive X-ray spectroscopy (EDX/EDS) due to the electron–matter interaction volume errors. The Electron Backscatter Diffraction (EBSD) technique, is a feasible option to identify the phases with acceptable confidence (i.e., with a mean angular deviation, <1 deg[29]) and was thus selected for the present work. Examples are given below.

The bright regions in Figures B-1(a) and (b) are script- and plate-like intermetallic phases on secondary electron images of one of the alloys studied. The EDS point analysis, the EDS map, and the EBSD analysis of Figures B-2 through B-4, respectively, exemplify script-like and plate-like particles identified as α- and β-phase intermetallics.

Electron and EDS maps of an area containing script-like intermetallics (Al-9Si-0.8Fe alloy, SDAS = 25 μm). The wt pct of each element matched the nominal values for the α-Al8Fe2Si intermetallic. The EBSD point analysis also confirmed the crystallography as the hexagonal α-Al8Fe2Si.[16] (α-Al8Fe2Si, hexagonal; space group p63/mmc(194) with a = 12.404 b = 12.404 c = 26.234, α = 90 β = 90 γ = 120.)

EBSD map of an area containing plate-like β-Al5FeSi plates layered on the electron image; EBSP’s (backscatter electron diffraction pattern) matched[17] to β-Al5FeSi plates (green); EBSD band contrast and Euler color maps are shown on the right. Bottom row: EDS quant map of Al, Si, and Fe (respectively). Alloy: 0.8 Fe, 11 Si alloy SDAS 50 µm. (β-Al5FeSi, monoclinic; space group 2/m with a = 6.16760 b = 6.1661 c = 20.8093, β = 91.)

Rights and permissions

About this article

Cite this article

Sivarupan, T., Taylor, J.A. & Cáceres, C.H. SDAS, Si and Cu Content, and the Size of Intermetallics in Al-Si-Cu-Mg-Fe Alloys. Metall Mater Trans A 46, 2082–2107 (2015). https://doi.org/10.1007/s11661-015-2808-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2808-5