Abstract

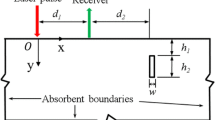

A finite-difference time-domain algorithm was applied to solve Maxwell’s equations to obtain the redistribution of an electromagnetic plane wave in the vicinity of a trailing indent crack (TIC). The roles of five geometrical parameters playing in light intensification were calculated numerically under the irradiation of a 355-nm normal incidence laser. The results show that the light intensity enhancements between the nearest neighbor pits were remarkable, which may lead to damage. The calculated results reveal that the light intensity enhancement factor (LIEF) can be up to 11.2 when TIC is on the rear-surface. With the increase of the length as well as the depth of pits, LIEF increased. Conversely, with the increase of the axis of pits, LIEF gradually declined to a stable status. It was observed that there exists an optima width or gap, which enables LIEF to be increased dramatically and then decreased gently. By comparison, results suggest that the worst cases occur when the depth and the length are both very large, especially if the width equals to 2 l and the gap equals the width. This work provides a recommended theoretical criterion for defect inspection and classification.

研究意义

在强紫外激光辐照下,熔石英元件亚表面缺陷极易诱导激光损伤.因此,缺陷诱导光场重分布的量 化,为光学元件亚表面缺陷的检测和分类提供了依据,同时也促进了高功率激光器负载能力的提高.本工作系 统研究了一类特殊的锥型划痕—trailing indent划痕对近场光调制的影响,该项工作的主要目的是为这类缺陷的检 测提供依据,以及在工程上提出控制策略.

创新要点

-

(1)

最大光强处位于坑点凸起的一侧,此处最易产生激光诱导损伤,与实验结果一致.

-

(2)

细致地研究了五个几何参数与光增强之间的关联.

-

(3)

提出了这类缺陷在工程应用上的控制策略.

Similar content being viewed by others

References

Salleo A, Taylor S T, Martin M C, et al. Laser-driven formation of a high-pressure phase in amorphous silica. Nat Mater, 2003, 2: 796–800

Li C H, Ju X, Jiang X D, et al. High resolution characterization of modifications in fused silica after exposure to low fluence 355 nm laser at different repetition frequencies. Opt Express, 2011, 19: 6439–6449

Génin F Y, Salleo A, Pistor T V, et al. Role of light intensification by cracks in optical breakdown on surfaces. J Opt Soc Am A, 2001, 18: 2607–2616

Dai W, Xiang X, Jiang Y, et al. Surface evolution and laser damage resistance of CO2 laser irradiated area of fused silica. Opt Laser Eng, 2011, 49: 273–280

Suratwala T I, Miller P E, Bude J D, et al. HF-based etching processes for improving laser damage resistance of fused silica optical surfaces. J Am Ceram Soc, 2011, 94: 416–428

Miller P E, Bude J D, Suratwala T I, et al. Fracture-induced subbandgap absorption as a precursor to optical damage on fused silica surfaces. Opt Lett, 2010, 35(16): 2702–2704

Suratwala T, Wong L, Miller P, et al. Sub-surface mechanical damage distributions during grinding of fused silica. J Non-Cryst Solids, 2006, 352: 5601–5617

Wong L, Suratwala T, Feit M D, et al. The effect of HF/NH4F etching on the morphology of surface fractures on fused silica. J Non-Cryst Solids, 2009, 355: 797–810

Li L, Xiang X, Zu X T, et al. Numerical simulation of the modulation to incident laser by the repaired damage site in a fused silica subsurface. Chin Phys B, 2011, 20: 074209

Li L, Xiang X, Zu X T, et al. Incident laser modulation of a repaired damage site with a rim in fused silica rear subsurface. Chin Phys B, 2012, 21: 044212

Hua J R, Li L, Xiang X, et al. Three-dimensional numerical simulation of light field modulation in the vicinity of inclusions in silica subsurface. Acta Phys Sin, 2011, 60: 044206

Wang F R, Liu H J, Huang J, et al. Simulation of light intensification induced by defects of polished fused silica. Chin Phys Lett, 2011, 28: 014206

Stolz C J, Feit M D, Pistor T V. Laser intensification by spherical inclusions embedded within multilayer coatings. Appl Opt, 2006, 45: 1594–1601

Qiu S G, Wolfe J E, Monterrosa A M, et al. Modeling of light intensification by conical pits within multilayer high reflector coatings. Proc SPIE, 2009, 7504: 75040M-1–75040M-9

Zhang L, Chen W, Hu L L. Systematic investigation on light intensification by typical subsurface cracks on optical glass surfaces. Appl Opt, 2013, 52: 980–989

Lawn B R. Fracture of Brittle Solids. 2nd ed. Cambridge: Cambridge University Press, 1993. 253–256

Anisimov S I, Kapeliovich B L, Perel’man T L. Electron emission from metal surfaces exposed to ultrashort laser pulses. Sov Phys JETP, 1974, 39: 375–377

Wang Y. Mechanism and experimental technique investigations of laser-induced damage by subsurface defects. Dissertation for Master Degree. Mianyang: China Academy of Engineering Physics, 2005. 23

Zhang C L, Wang Z G, Xiang X, et al. Simulation of field intensification induced by pit-shaped crack on fused silica rear-surface. Acta Phys Sin, 2012, 61: 114210

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, C., Xu, M. & Wang, C. Light intensification effect of trailing indent crack in fused silica subsurface. Sci. China Phys. Mech. Astron. 58, 1–6 (2015). https://doi.org/10.1007/s11433-014-5506-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-014-5506-1