Abstract

Dimethyl ether (DME) is considered as a substitution of diesel oil. It can be used in diesel engines because of its high cetane number (> 55). The combustion process does not generate particle matter (PM) or sulphur oxides (SOx) pollutions. One of the methods to obtain DME is direct synthesis from a CO2 and H2 mixture. On the other hand, CO2 is an attractive reagent, which is a safe and economical source of carbon. The aim of this work was to obtain DME in the direct process from the mixture CO2 and H2 in the presence of hybrid catalyst. In these catalytic the CuO/ZrO2 was selected as a metallic function. The montmorillonite K10 modified by heteropolyacids was selected as an acidic function. The catalysts were obtained by different preparation methods and contained various types of heteropolyacids. The catalysts were characterized by following methods: BET/BJH, XRD, SEM, DCS/TG, NH3-TPD and FT-IR. The direct hydrogenation of CO2 was performed in the high pressure fixed-bed flow reactor connected online with GC equipped with TCD and FID detectors. It was shown that both synthesis method of metallic function and the type of heteropolyacids have influence on the total catalytic activity of the hybrid catalyst. The acidity and thermal stability of HPAs are identified as the most important parameters having a decisive influence on the overall catalytic activity of the samples.

Similar content being viewed by others

Introduction

In recent years, the concentration of CO2 in the atmosphere has been constantly increasing, having an impact on global climate change [1]. Therefore, a growing number of countries and researchers are interested in developing technologies to reduce CO2 emissions and developing efficient carbon dioxide utilization systems. Synthesis of CO2-derived chemicals includes synthesis of urea [2], CO [3], methane [4], methanol [5,6,7], dimethyl ether [8, 9], and other hydrocarbons [10]. Among them, dimethyl ether appears very promising because of its physicochemical properties and possibilities of applications.

Dimethyl ether (DME) is considered as a substitution of diesel oil in diesel engines due to its high cetane number (> 55). Undoubted advantage of using DME as a fuel would be a significant reduction of air pollution. During DME combustion, soot impurities are not generated, which is an important problem in engines running on traditional diesel oil. No toxic sulfur oxides are also emitted and the amount of nitrogen oxides is considerably decreased. Nowadays, dimethyl ether is produced form syngas (1), but also CO2 and H2 mixture can be used as a feedstock (2).

The DME synthesis proceeds in two steps: hydrogenation of CO/CO2 into methanol (3, 4) and subsequent dehydration of methanol into DME (5). All reactions are exothermic, therefore, low temperature facilitates shifting the reaction balance towards the products. Moreover, in accordance to the Le Chatelier’s principle an increase in pressure increases the amount of methanol produced.

Hybrid catalysts used in a direct dimethyl ether synthesis exhibit metallic and acidic functions. The metallic function is responsible for hydrogenation of carbon dioxide, whereas the acidic function contributes to dehydration of methanol. Mostly, CuO/ZnO catalysts with different additives [11,12,13] are used as the metallic functions. At the same time, zeolites [14, 15] or γ-Al2O3 [16] are commonly applied as the acidic function.

In commercial production of methanol from syngas, the catalytic system CuO/ZnO/Al2O3 is used. In this case, the elevated temperature (250–280 °C) and pressures up to 6–8 MPa are needed [17]. On the other hand, in industry production, the syngas is enriched with 5% of CO2, which causes increased activity of copper-zinc catalyst. The commercial catalytic system has low activity in synthesis of methanol from CO2 and H2 mixture under 250 °C [18] because of low reactivity of the CO2 molecule. The increase of temperature makes the CO2 activation much easier. At the same time, high reaction temperature facilitates the sintering of Cu crystals which leads to deactivation of the catalyst. Currently it is considered that copper plays a role of an active phase during catalytic synthesis of methanol. However, the type of the support must be very carefully considered, because metallic copper poorly interacts with CO2 molecule [19]. The TiO2–SiO2 modification of industrial catalyst improves CO2 conversion from 15.8 to 40.7% and yield to methanol from 3.7 to 16.7% [20]. Similarly, Inui et al. [21] claims that Ga2O3 and Pd added to CuO/ZnO/Al2O3 improves catalytic activity in both CO and CO2 hydrogenation.

Currently, it is considered that ZrO2 addition facilitates CuO dispersion on the support surface. As a consequence, conversion of CO2 increases [22]. Fisher and Bell in their study state that ZrO2 improves copper’s catalytic activity during methanol synthesis both from CO/H2 and CO2/H2 mixtures [23]. What is more, during hydrogenation of CO2 a considerable amount of water is formed, leading to a decreased catalytic activity of Cu/ZnO/Al2O3 catalyst [24]. This effect is associated with oxidation of active copper to copper oxide.

The dehydration of methanol into DME requires acidic centers on the catalyst’s surface. The methanol molecule can be adsorbed on both Brønsted and Lewis acid centers [25]. The total concentration of acidic centers on the surface and their strength have an important influence on the catalytic activity. It is known that mainly weak and medium acid centers are responsible for dehydration of methanol, while the presence of strong acid centers favors receiving of olefins [26]. Commercial catalyst, with Al2O3 as the acidic function, rapidly loses its catalytic activity because of the hydrophilic character. Aluminum oxide adsorbs water which is formed during the reaction. This leads to blocking of the active centers on the catalyst surface, a problem that has to be overcome by high temperature [27].

Zeolites constitute yet another class of the catalysts of acidic character. The strength and the type of the acid centers on the catalyst’s surface is related to the structure of zeolite and its Si/Al ratio. Commonly, H-ZSM-5 is used because of its better hydrophobic character than Al2O3. However, due to the high reaction temperature (above 270 °C) hydrocarbons can be observed among created products. It is related to the high acidity of this zeolite. To improve its selectivity to DME and preserve high methanol conversion simultaneously, it is needed to decrease the amount of strong acid centers maintaining the total acidity at high level [28].

Heteropolyacids (HPAs) might be an interesting alternative to using Al2O3 or zeolites as the acidic function. Heteropolyacids are strong solid acids containing the Brønsted type of acid centres [29]. Two types of HPA structures are known: Keggin (XM12O40n−) and Wells–Dawson (X2M18O62n−), where X-heteroatom e.g. P, Si, etc.; M-atom addenda e.g. W, Mo, etc. In catalytic reactions, HPAs with the Keggin structure are usually used because of higher total acidity and thermal stability [30]. The acidity of Keggin HPAs is connected with the type of addenda atom: H3PW12O40 (HPW) is more acid than H3PMo12O40 (HPMo). At the same time HPAs have small specific surface area, therefore their immobilization on a high-surface support is necessary.

The aim of the studies was to obtain DME in direct route from CO2 and H2 mixture in the presence of hybrid catalyst. Promising results on the addition of ZrO2 to the commercial catalyst (CuO/ZnO2/Al2O3) were an inspiration of investigating a CuO/ZrO2 as the metallic function. The montmorillonite K10 modified by heteropolyacids was selected as the acidic component. HPAs are well known in catalysis but—to the best of our knowledge—have not been used in the direct hydrogenation of CO2 to DME yet. Therefore, our main focus was to examine the effect of the composition of the acid function of the hybrid catalyst (consisting of HPMo and HPW heteropolyacids deposited on montmorillonite K10) on the conversion and selectivity in the CO2 to DME process. In our studies HPW and HPMo were impregnated on montmorillonite K10 which is thermally resistant and has a high surface area [31].

Experimental

Preparation of hybrid catalysts

The metallic component was prepared by co-precipitation method using NaOH or citric acid as a precipitant agent in accordance with the procedure presented in our previous article [32]. On the basis of the earlier results, Cu/ZrO2 synthetized with NaOH (CZNaOH) and citric acid (CZcitric) calcinated at 350 °C was chosen as the metallic functions.

Prior to synthesis, the commercial montmorillonite K10 (K10) was at 120 °C for 12 h. The amount of HPMo and HPW used for the synthesis was calculated to obtain theoretically one monolayer coverage of K10. The calculation was done considering the BET surface area of K10 and assumption that one Keggin unit occupies an area of 144 Å2. Both heteropolyacids were introduced via wetness impregnation method resulting in HPMo-K10 and HPW-K10 systems. After the impregnation the solid was separated, washed, and dried at 90 °C for 10 h.

The final hybrid catalysts was obtained by mechanical mixing of metallic and acidic components (grain size 0.64–1 mm) in a volume ratio 2:1.

Catalysts characterization

Specific area and porosity determination

The BET surface area, for both metallic and acidic functions were measured with nitrogen adsorption at − 196 °C on Quantachrome Autosorb-1. Prior to measurements, samples were degassed for 18 h at 100 °C under vacuum to remove adsorbed water and other surface impurities.

Crystal structure determination

Powder X-ray diffractions patterns (XRD) were collected using X’Pert PRO MDP diffractometer with Cu Kα radiation, working in Bragg–Brentano geometry. The analysis was performed between 5º and 90º in 2θ range with a measuring step 0.02º.

Morphology and surface composition

The morphology and surface composition of the synthesized samples were carried out using a high-resolution scanning electron microscope (JEOL JSM-7500F) with EDS-INCA PentaFETx3 system. Prior to the measurements, the samples were sprayed (K575X Turbo Sputter Coater) with 20 nm of chromium to increase a conductivity of the samples.

Thermal stability determination

Thermogravimetry/differential scanning calorimetry (TG-DSC) experiments were performed with a NETZSCH STA 409 thermobalance. Samples of about 20 mg were heated in air, at the rate of 10 °C/min, with endpoint at 700 °C.

Acidity measurements

The NH3 temperature-programmed desorption (NH3-TPD) measurements were carried out in quartz fixed-bed flow reactor connected online to the mass spectrometer (QMG 220 PRISMA PLUS). The signal of m/z = 16 (NH3) was monitored during TPD. Prior to TPD run, the samples (50 mg) were activated in the He flow (40 mL/min) at 350 °C for 0.5 h. Next, the reactor was cooled down to 60 °C and a 3%NH3/N2 mixture was introduced for 0.5 h. Then, the sample were flashed in the He flow (40 mL/min) to remove physisorbed NH3 and to obtain stable NH3 line. TPD was performed from 60 to 680 °C with ∆T = 10 °C/min under He flow (40 mL/min).

FT-IR spectroscopy

The FT-IR spectroscopy measurements were carried out using Excalibur series Digilab with a measure step 2 cm−1 at room temperature. Number of scans taken during a single measurement was 100. For measurement purposes, the sample was ground in a mortar and applied to the silicon plate.

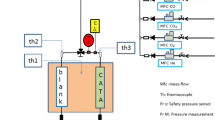

Catalytic activity tests

The hybrid catalysts were tested in the direct hydrogenation of CO2 to DME. The reaction was performed in the high pressure fixed-bed flow reactor connected online with gas chromatograph (HP 5890 Series II) equipped with TCD and FID detectors. 1 cm3 of the hybrid catalyst, with the volume ratio of metallic and acidic component equal to 2:1, was placed into the stainless reactor. Before the reaction, both the metallic and acidic function have been weighted separately and the mass of each catalyst was used to calculate STYDME (Table 3). Prior to each reaction, the pretreatment step of catalyst included reduction under atmospheric pressure in the flow of reduction mixture (5% H2/N2) equal to 60 mL/min at 200 °C for 3 h. Then, the reaction mixture (25% CO2 + 75% H2) was passed over the catalyst bed at the flow rate equal to 10 mL/min in a temperature range 200–350 °C for 12 h. Next, the temperature was decreased to 220 °C. The catalytic reaction was carried out in the flow of reaction mixture (60 mL/min) and in the temperature range from 220 to 300 °C under the pressure of 4 MPa. Gas hourly space velocity was 3600 h−1.

The CO2 conversion and the selectivity to DME, methanol (MeOH), CO and CH4 were calculated as follows:

The space–time-yield to DME (STYDME) was defined as follows:

where \({n}_{i}\) is the number of carbon atoms in product, \({V}_{{\mathrm{C}\mathrm{O}}_{2}}\)(cm3/min) is the volumetric rate of CO2, MDME is the molar mass of dimethyl ether and wkat is the mass of catalyst.

Results and discussion

Physicochemical characterization of the prepared catalysts

As mentioned earlier, the results presented in this publication are a continuation of the previous studies. Consequently, the physicochemical characterization of metallic components has been presented earlier [33]. It was shown that surface properties and catalytic activity strongly depend on the precipitation agent and the temperature of calcination. The metallic function prepared with NaOH shows the highest specific surface area and the highest active copper surface. At the same time the increase of the calcination temperature leads to decrease of the specific surface area and sintering of Cu crystals.

The BET surface area, total pore volume, and pore size results for acidic functions are presented in Table 1. Among them, montmorillonite K10 (252 m2/g) shows the highest specific surface area. The impregnation of K10 with HPAs leads to a decrease of the specific surface area of K10. The deposition of HPMo and HPW on K10 causes the reduction of the specific surface area to 135 m2/g and 91 m2/g, respectively.

At the same time, application of heteropolyacids on the surface of K10 causes a significant decrease of pore volume from 0.33 cm3/g (K10) to 0.08 cm3/g and 0.15 cm3/g for HPW-K10 and HPMo-K10, respectively. Moreover, the micropores appeared when HPAs were impregnated on K10.

XRD patterns of the pure montmorillonite K10, HPW-K10, and HPMo-K10 are shown in Fig. 1. Impregnation of K10 with heteropolyacids (HPW-K10 and HPMo-K10) causes a slight decrease in intensity (for 2θ = 20.8; 26.6; 42.4; 50.1°) or disappearance of some reflexes characteristic for K10 (for 2θ = 19.1; 36.5; 39.4; 45.7°). This is due to a partial reduction in crystallinity of montmorillonite K10 after application of HPW and HPMo. At the same time, low intensity reflexes appear from the heteropolyacid present in the system: 2θ = 17.8; 20.6; 34.5; 59.9; 61.9° (for HPW-K10) and 2θ = 7.9; 9.2; 17.8; 20.0; 28.3; 35.0; 36.4° (for HPMo-K10).

In order to determine the thermal stability of the acid components of the hybrid catalysts, the differential scanning calorimetry with thermogravimetry measurements were carried out. The obtained thermographs are shown in Fig. 2.

The DSC thermogram of montmorillonite K10 exhibits one explicit endothermic peak at 106 °C, which corresponds to the removal of physisorbed water. Montmorillonite K10 (black line) is thermally stable within the entire measured temperature range. The thermogram of pure HPW (gray line) shows two endothermic peaks and one exothermic peak; the endothermal peaks have maxima at 68 and 212 °C. The former one corresponds to the removal of physisorbed water and the latter one is due to the desorption of two protons and the structural oxygen with the production of water molecule according to the equation below (6) [34]:

The high temperature exothermic peak appearing at 607 °C corresponds to the collapse of the Keggin structure due to the loss of structural water [35]. The deposition of HPW on K10 results in the shift of the high-temperature exothermic peak to 565 °C (light grey line). The collapse of the Keggin structure proceeds at a lower temperature in comparison with the pure HPW. At the same time, only one endothermic peak at 106 °C is present. On the thermogram of the pure HPMo (dash dot line) two endothermic peaks with maxima at 87 °C and 128 °C are visible, which are assigned to the removal of physisorbed and structural water, respectively. At the temperature of 442 °C, an exothermic peak is present. Then, the decomposition of the Keggin structure, preceded by the removal of another water molecule, takes place. The impregnation of HPMo on K10 results in shifting the maximum of exothermic peak to 402 °C, then the thermal stability of acidic function decreases. Furthermore, also endothermic peak at 105 °C is present. The above studies clearly indicate that the acid component modified by HPW is more thermally stable than that modified by HPMo.

The results obtained by the TPD-NH3 method are presented in Fig. 3 and Table 2.

The NH3-TPD desorption curves registered for acidic components of the hybrid catalysts are presented in Fig. 3. The obtained curves (red lines) were separated in the deconvolution process into components (green lines) with peak maxima corresponding to acid centers of a given strength. The acid sites were classified into the very weak (< 150 °C) connected with physisorption of ammonia, weak (150–250 °C), medium (250–350 °C) and strong (350–500 °C).

Due to the HPW and HPMo decomposition at 565 and 402 °C, respectively (Fig. 2) the peaks which appear above these temperatures were not included in the acidity calculation.

The unmodified montmorillonite K10 contains very weak, weak, medium and strong acidic centers within which very weak and medium acid centers dominate. Before the modification, the total concentration of acidic centers for K10 is 0.45 mmol/g, while after HPAs deposition its acidity significantly increased to 1.05 mmol/g and 1.76 mmol/g for HPMo-K10 and HPW-K10, respectively. After addition of heteropolyacids, the participation of weak acid centers enhanced.

It is worth noticing that in this case the concentration of strong acid centers significantly increased (0.483 mmol/g). At the same time, when HPMo is introduced, the medium acid centers exhibit the largest concentration (0.414 mmol/g).

In order to determine surfaces morphology, SEM analysis was done (Fig. 4).

The montmorillonite K10 (Fig. 4a) is characterized by the expanded, spongy surface. After HPW impregnation (Fig. 4b) block structures are observed. On the other hand, HPMo immobilization on K10 (Fig. 4c) leads to the appearance of fine-grained layered structures.

In order to check the interaction between metallic and acidic functions, the FTIR measurements were done. The results obtained for CZNaOH+HPMo-K10 and CZNaOH+HPW-K10 are shown in Fig. 5a, b, respectively. The displacement of the characteristic peaks coming from the Keggin anion toward lower frequency is present after mechanical mixing of metallic and acidic functions. For CZNaOH+HPMo-K10 (Fig. 5a) the following vibrations are shifted: P-Oa (from 1064 to 1045 cm−1) and Mo = Od (from 962 to 951 cm−1). Moreover, the Mo = Od vibrations (870 cm−1) disappear. For CZNaOH+HPW-K10 (Fig. 5b) the part of characteristic peaks is also shifted: vibrations related to P-Oa (from 1080 to 1060 cm−1), W = Od (from 982 to 962 cm−1) and W-Ob-W (from 889 to 893 cm−1). Also, at 1100 cm−1 a shoulder appears. This effect informs about the asymmetry of the P-Oa vibrations induced by the HPA non-conductive interactions with oxides. At the same time the peaks corresponding to the selected vibrations shift as a result of changing proton-anion interaction within HPA. This effect can result from the decrease of hydration rate or strong interaction between the Keggin anion with the active centers of the support.

The FTIR results obtained for CZNaOH+HPMo-K10 after reaction (Fig. 5a) demonstrate the absence of the characteristic peaks derived from HPMo Keggin structure. Along with the DSC thermograms (Fig. 3) this result indicates the collapse of the HPMo Keggin structure during the catalytic reaction. By contrast, the FTIR spectrum of CZNaOH+HPW-K10 (Fig. 5b) after reaction contains peaks derived from the HPW Keggin structure. However, most of them are even more shifted toward lower frequencies. This indicates changes in the HPW Keggin structure during the catalytic reaction. Therefore, HPMo is less stable than HPW under the reaction conditions. Damyanova et al. observed similar effect when heteropolyacids were impregnated on ZrO2 [35]. They observed that the temperature of HPMo decomposition decreased with the increasing amount of ZrO2 because of the strong HPMo—ZrO2 interactions. At the same time, an interplay between HPW and ZrO2 is weaker (HPW decomposition higher than 500 °C).

Results of catalytic activity measurements

The obtained samples were tested in the direct CO2 hydrogenation to DME. The focus was to examine the effect of the heteropolyacids deposition on montmorillonite K10 on the conversion and selectivity in the studied process. Apart from DME, other products of the reaction, namely methanol, methane, and CO were also detected.

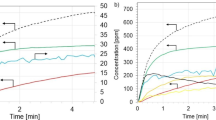

The obtained catalytic results are presented in Table 3 and Fig. 5.

The CO2 conversion increases with increasing temperature for all catalytic systems. This parameter practically does not depend on the type of acidic function. The highest CO2 conversions were obtained for the hybrid catalysts with metallic function synthesized by co-precipitation method with NaOH. As described in our previous paper [32], for the CZNaOH metallic function the active copper phase is better dispersed on the catalyst surface. This suggests that CuO in the CZNaOH component is better exposed to substrates than in the CZcitric component what results in higher CO2 conversion.

At the same time, the catalytic selectivity strongly depends on the types of both components of the hybrid system (acidic and metallic functions) as well as the temperature of the reaction.

The catalysts with unmodified acid function (CZNaOH+K10 and CZcitric+K10) lead the reaction towards methanol (at lower temperatures) and CO (at higher temperatures) as the main products. It implies that unmodified acid function (K10) does not work efficiently. The K10 surface has too low total concentration of acid sites (0.45 mmol/g) to entirely dehydrate methanol into DME. Instead of that, at higher temperatures, the endothermic RWGS reaction is favored in accordance with the reaction (7):

When the acidic component is composed of montmorillonite K10 modified with HPW, the selectivity to DME is improved, regardless of the type of metallic function.

The addition of HPW on K10 causes also a significant decrease of selectivity to methanol. The HPW impregnation on K10 surface improves dehydration of methanol. The HPW-K10 surface has the highest total acid sites concentration (1.76 mmol/g). At the same time, mainly weak and medium acid centers (0.896 mmol/g) with a lower number of strong acid centers (0.483 mmol/g) are present, what favors production of DME. However, a lot of CO is formed as a by-product.

When the acidic component is composed of montmorillonite K10 modified with HPMo, the selectivity to DME is not improved when CZcitric is used as the metallic function. When CZNaOH is used, the selectivity to DME is enhanced in the temperature range from 220 to 260 °C. The highest selectivity to DME (60.3% at 220 °C) is obtained for CZcitric+HPW-K10.

At the same time, impregnation of K10 by HPMo leads to the improved selectivity to CO and CH4. The surface of HPMo-K10 has a lot of weak and medium acid centers (0.673 mmol/g) and a little of strong acid centers (0.083 mmol/g), but total acidity is lower (1.05 mmol/g) than for HPW-K10. Furthermore, using CZcitric as metallic function favors CH4 appearance. For all catalytic systems, the amount of methanol decreases with the increase of temperature. Meantime, the quantity of CO definitely increases. This observation suggests that when the reaction temperature increases, the contribution of RWGS reaction also increases.

The most efficient catalyst in the whole temperature range is CZcitric+HPW-K10 system (Table 3). The modification of acid function with HPW always improves STYDME, regardless of the type of metallic function, in comparison with the catalysts containing unmodified acid function (K10). On the other hand, the influence of HPMo addition depends on the type of metallic function used in the catalytic system and on the temperature of the process. The STYDME increases (in comparison with catalyst containing the unmodified acid function) in the temperature range from 220 to 240 °C, but in the temperature range from 260 to 300 °C the STYDME decreases when CZNaOH is used as the metallic function. While hybrid catalyst contains CZcitric as a metallic function, the STYDME rises in the temperature range 220–260 ºC. At higher temperatures, STYDME decreases progressively. That indicates a strong interaction between the metallic and acidic components of the hybrid catalyst.

The direct comparison of the catalytic results reported in the present manuscript with data available in the literature is not straightforward. This is mostly due to significant differences between the conditions of the conducted catalytic reaction such as pressure, contact time or composition of the reaction mixture. Recently, Naik et al. reported the catalytic activity of CuO-ZnO-Al2O3 and CuO-ZnO-ZSM-5 (Si/Al = 60) catalysts (200 °C, 5 MPa, GHSV = 3000 mL/gkath) [36]. The conversion of CO2 was 15% and 29%, respectively. At the same time the selectivity to DME for catalyst containing alumina was 5% and 75% for catalyst with ZSM-5. Frusteri et al. [37] described the catalytic results for CuZnZr-MFI hybrid catalyst (240 °C, 3 MPa, GHSV = 2500 mL/gkath). In these conditions, the reported conversion of CO2 reached 19% and selectivity to DME 8.6%. Change of the acid component to FER (Si/Al = 8) (240 °C, 3 MPa, GHSV = 8800 NL/gkath) leads to slightly decreasing conversion of CO2 (17%) and increasing selectivity to DME (42%) [38]. The most efficient catalyst (CZcitric+HPW-K10) shows 47% selectivity to DME and 5% CO2 conversion. This result fits well into the activities reported above; DME is produced with relatively high selectivity, but lower conversions of CO2 are observed.

Conclusions

The direct CO2 hydrogenation to dimethyl ether (DME) was studied over hybrid catalysts. In these catalytic systems, the mixture of copper and zirconium oxides—obtained via different preparation methods—was selected the metallic component. The montmorillonite K10 modified by heteropolyacids was selected as the acidic component. Two types of heteropolyacids were chosen: phosphorus-molybdenum and phosphorus-tungsten ones.

It was shown that catalytic activity of the hybrid catalysts is a result of metallic and acid components activity. Both synthesis method of metallic function and the type of HPA have influence on the total catalytic activity of hybrid catalysts. It is due to the evolving surface properties such as specific surface area, crystallinity, and acidity. The addition of HPAs clearly influences the activity of the hybrid catalyst. The acidity and thermal stability of HPAs are identified as the most important parameters having a decisive influence on the overall catalytic activity of the samples. The results show that the phosphorous-tungsten heteropolyacid (HPW) has high surface acidity and is more stable in the reaction conditions than phosphorous-molybdenum one, therefore its presence most often had a positive effect on the catalytic performance of the studied systems. However, the final effect depends on the type of metallic function and the type of heteropolyacids.

References

Aresta M, Dibenedetto A (2007) Dalton Trans 28:2975–2992

Huang C-H, Tan C-S (2014) Aerosol Air Qual Res 14:480–499

Xu XD, Moulijn JA (1996) Energy Fuels 10:305–325

Frontera P, Macario A, Ferraro M, Antonucci P (2017) Catalysis 7:59–87

Pontzen F, Liebner W, Gronemann V, Rothaemel M, Ahlers B (2011) Catal Today 171:242–250

Olah GA (2005) Angew Chem 44:2636–2639

Arakawa H (1998) Stud Surf Sci Catal 114:19–30

Mao D, Yang W, Xia J, Zhang B, Lu G (2006) J Mol Catal A 250:138–144

Frusteri F, Cordaro M, Cannilla C, Bonura G (2015) Appl Catal B 162:57–65

Wang W, Wang S, Ma X, Gong J (2011) Chem Soc Rev 40:3369–4260

Mierczyński P, Maniecki TP, Maniukiewicz W, Jozwiak WJ (2011) Reac Kinet Mech Cat 104:139–148

Fujitani T, Saito M, Kanai Y, Watanabe T, Makamura J, Uchijima T (1995) Appl Catal A 125:199–202

Ladera R, Perez-Alonso FJ, Gonzales-Carballo JM, Ojeda M, Rojas S, Fierro JLG (2013) Appl Catal A 142–143:241–248

Hassanpour S, Yaripour F, Taghizadeh M (2010) Fuel Process Technol 91:1212–1221

Ereña J, Garoña R, Arandes JM, Aguayo T, Bilbao J (2005) Catal Today 107–108:467–473

Venugopal A, Palgunadi J, Dog JK, Joo OS, Shin CH (2009) J Mol Catal A 302:20–27

Skrzypek J, Słoczyński J, Ledakowicz St (1994) Methanol synthesis—science and engineering. Polish Scientific Publishers, Warsaw

Saito M, Fujitani T, Tacheuchi M, Watanabe T (1996) Appl Catal A 138:311–318

Yang Y, White MG, Liu P (2012) J Phys Chem C 116:248–256

Zhang L, Zhan Y, Chen S (2012) Appl Catal A 415:118–123

Inui T, Hara H, Takeguchi T, Kim J-B (1997) Catal Today 36:25–32

Yang C, Ma Z, Zhao N, Wei W, Hu T, Sun Y (2006) Catal Today 115:222–227

Bell AT, Fisher IA (1997) J Catal 172:222–237

Nowak P, Lachowska M, Skrzypek J (1991) Chem Eng Sci 46:3324–3325

Wu Y, Ye X, Yang X, Wang X, Chu W, Hu Y (1996) Ind Eng Chem Res 35:2546–2560

Yaripour F, Baghaei F, Schmidt I, Perregaard J (2005) Catal Commun 6:147–152

Xu M, Lunsford JH, Goodman DW, Bhattacharyya A (1997) Appl Catal A 149:289–301

Khandan N, Kazemeini M, Aghaziarati M (2008) Appl Catal A 349:6–12

Okuhara T, Mizuno N, Misono M (2001) Appl Catal A 222:63

Timofeeva MN (2003) Appl Catal A 256:19–35

Pacuła A, Pamin K, Kryściak-Czerwenka J, Olejniczak Z, Gil B, Bielańska E, Dula R, Serwicka EM, Drelinkiewicz A (2015) Appl Catal A 498:192–204

Kornas A, Grabowski R, Śliwa M, Samson K, Ruggiero-Mikołajczyk M, Żelazny A (2017) Reac Kinet Mech Cat 121:317–327

Janik MJ, Bardin BB, Davis RJ, Neurock M (2006) J Phys Chem B 110:4170–4178

Xian-e C, Daichun D, Jianping N, Youming J, Jing Z, Yixiang Q (1997) Thermochim Acta 292:45–50

Damyanova S, Gomez LM, Banares MA, Fierro JLG (2000) Chem Mater 12:501–510

Naik SP, Ryu T, Bui V, Miller JD, Drinnan NB, Zmierczak W (2011) Chem Eng 167:362–368

Frusteri F, Bonura G, Cannilla C, Drago Ferrante G, Aloise A, Catizzone E, Migliori M, Giordano G (2015) Appl Catal B 176–177:522–531

Bonura G, Migliori M, Frusteri L, Cannilla C, Catizzone E, Giordano G, Frusteri F (2018) J CO2 Util 24:398–406

Acknowledgements

Authors would like to thank for the financial support within OPUS Project No. 2012/05/B/ST4/00071 founded by the National Science Centre of Poland and to the satutory funds of the Jerzy Haber Institute of Catalysis and Surface Chemistry, PAS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kornas, A., Śliwa, M., Ruggiero-Mikołajczyk, M. et al. Direct hydrogenation of CO2 to dimethyl ether (DME) over hybrid catalysts containing CuO/ZrO2 as a metallic function and heteropolyacids as an acidic function. Reac Kinet Mech Cat 130, 179–194 (2020). https://doi.org/10.1007/s11144-020-01778-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-020-01778-9