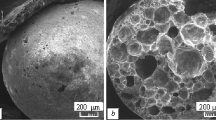

It is shown that it possible to produce heat-insulating and heat-insulating/structural refractories based on artificial ceramic binders made from thermally activated refractory clays of different compositions. The slag-alkali binder used in the new materials undergoes strengthening by a unique mechanism. An analysis is made of the granulometric composition of the slag after comminution for different lengths of time and its main granulometric characteristics are determined. The main properties and microstructure of the new heat-insulating materials are studied.

Similar content being viewed by others

References

N. A. Peretokina and V. A. Doroganov, “Development and study of the compositions of unshaped fireclay-based heat-insulating refractories and a technology for making them,” Refractories and Industrial Ceramics, 52(1), 52 – 54 (2011).

E. I. Evtushenko and N. A. Peretokina, “Production of cellular ceramic concrete on the basis of highly concentrated binder suspensions,” Izv. Vyssh. Uchebn. Zaved. Stroitel’stvo, No. 9, 28 – 31 (2007).

E. I. Evtushenko, N. A. Peretokina, V. A. Doroganov, et al., “Heat-insulating materials based on artificial ceramic binders of different compositions,” Vestnik BGTU im. V. G. Shukhova, No. 6, 149 – 151 (2013).

Yu. E. Pivinskii, T. N. Epifanova, and N. A. Peretokina, “Materials based on highly concentrated ceramic binder suspensions (CCBS). Production and properties of fine-grained foam concretes based on a quartz-glass CCBS,” Ogneupory i Tekh. Keram., No. 10, 6 – 11 (1998).

A. V. Cherevatova, “Improving the technology for making heat-resistant lightweight products with the use of highly concentrated binder systems,” Promyshlennoe i Grazhdanskoe Stroitel’stvo, No. 8, 28 – 29 (2007).

Yu. E. Pivinskii, Ceramic and Refractory Materials: Collected Works, Vol. 2 of 3, Stroiizdat SPb, St. Petersburg (2003).

V. N. Sokov, “Systems analysis of the technology used to make unfired lightweight fireclay products,” Ogneupory, No. 4, 4 (1998).

This research was carried out as part of RFFI (Russian Foundation for Basic Research) Project No. 14 – 43 – 08046 and the Program for Strategic Growth at Belgograd State Technological University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 4, pp. 34 – 37, April, 2016.

Rights and permissions

About this article

Cite this article

Peretokina, N.A., Doroganov, V.A., Grudina, V.A. et al. Heat-Insulating Properties of Refractory Materials Made with the Use of Artificial Ceramic Binders. Refract Ind Ceram 57, 189–191 (2016). https://doi.org/10.1007/s11148-016-9952-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9952-3