Abstract

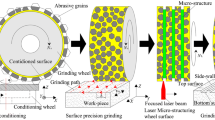

A novel approach of high-performance grinding is proposed using developed diamond wheels, to obtain minimally damaged surface layer in silicon wafers. For this reason, resin bond diamond wheels are specifically developed with lanthanum oxide (La2O3), magnesium oxide (MgO), and ceria (CeO2) as additives, respectively. The wheels contain grains with a mesh number of 20,000 and a volume fraction of diamond grains of 37.5%. The diamond wheel with ceria additives demonstrates the best grinding performance in terms of surface integrity and roughness. It allows to generate an amorphous surface layer of 43 nm in thickness, without grinding damage beneath in a silicon wafer. This is different from previous reports, in which an amorphous layer is at the top, followed by a damaged crystalline layer underneath induced by a diamond wheel. Below the amorphous layer is the pristine crystalline lattice, which is confirmed using the high-resolution transmission electron microscopy (HRTEM). The ceria wheel results in a surface roughness R a of 0.88 nm and a peak-to-valley (PV) value of 8.3 nm over an area of 70 × 50 μm2 on a Si wafer at a feed rate of 15 μm/min.

Similar content being viewed by others

References

Pei ZJ, Fisher GR, Liu J (2008) Grinding of silicon wafers: a review from historical perspectives. Int J Mach Tools Manuf 48:1297–1307

Dai JB, Ding WF, Zhang LC, Xu JH, Su HH (2015) Understanding the effects of grinding speed and undeformed chip thickness on the chip formation in high-speed grinding. Int J Adv Manuf Technol 81:995–1005

Segal M (2012) Material history learning from silicon. Nature 483:S43–S44

Zhang ZY, Wang B, Zhou P, Guo DM, Kang RK, Zhang B (2016) A novel approach of chemical mechanical polishing using environment-friendly slurry for mercury cadmium telluride semiconductors. Sci Rep 6:22466

Zhang ZY, Yang S, Guo DM, Yuan BY, Guo XG, Zhang B, Huo YX (2015) Deformation twinning evolution from a single crystal in a face-centered-cubic ternary alloy. Sci Rep 5:11290

Zhang ZY, Huo FW, Wu YQ, Huang H (2011) Grinding of silicon wafers using an ultrafine diamond wheel of a hybrid bond material. Int J Mach Tools Manuf 51:18–24

Zhang ZY, Wang B, Kang RK, Zhang B, Guo DM (2015) Changes in surface layer of silicon wafers from diamond scratching. CIRP Ann Manuf Technol 64:349–352

Zhang ZY, Guo DM, Wang B, Kang RK, Zhang B (2015) A novel approach of high speed scratching on silicon wafers at nanoscale depths of cut. Sci Rep 5:16395

Ding WF, Xu JH, Chen ZZ, Yang CY, Song CJ, Fu YC (2013) Fabrication and performance of porous metal-bonded CBN grinding wheels using alumina bubble particles as pore-forming agents. Int J Adv Manuf Technol 67:1309–1315

Ma CY, Ding WF, Xu JH, Fu YC (2015) Influence of alumina bubble particles on microstructure and mechanical strength in porous Cu-Sn-Ti metals. Mater Des 65:50–56

Zarudi I, Zou J, Zhang LC (2003) Microstructures of phases in indented silicon: a high resolution characterization. Appl Phys Lett 82:874–876

Wong S, Haberl B, Williams JS, Bradby JE (2015) Phase transformation as the single-mode mechanical deformation of silicon. Appl Phys Lett 106:252103

Takagi M, Onodera K, Matsumuro A, Iwata H, Sasaki K, Saka H (2008) TEM and HRTEM observations of microstructural change of silicon single crystal scratched under very small loading forces by AFM. Mater Trans 49:1298–1302

Gassilloud R, Ballif C, Gasser P, Buerki G, Michler J (2005) Deformation mechanisms of silicon during nanoscratching. Phys Status Solidi A Appl Mater 202:2858–2869

Wu YQ, Huang H, Zou J, Zhang LC, Dell JM (2010) Nanoscratch-induced phase transformation of monocrystalline Si. Scripta Mater 63:847–850

Zhang ZY, Huo FW, Zhang XZ, Guo DM (2012) Fabrication and size prediction of crystalline nanoparticles of silicon induced by nanogrinding with ultrafine diamond grits. Scripta Mater 67:657–660

Zhang ZY, Huo YX, Guo DM (2013) A model for nanogrinding based on direct evidence of ground chips of silicon wafers. Sci China Technol Sci 56:2099–2108

Zhou L, Eda H, Shimizu J, Kamiya S, Iwase H, Kimura S (2006) Defect-free fabrication for single crystal silicon substrate by chemo-mechanical grinding. CIRP Ann Manuf Technol 55:313–316

Pineiro A, Black A, Medina J, Dieguez E, Parra V (2013) The use of potassium peroxidisulphate and Oxone (R) as oxidizers for the chemical mechanical polishing of silicon wafers. Wear 303:446–450

Rajendran A, Takahashi Y, Koyama M, Kubo M, Miyamoto A (2005) Tight-binding quantum chemical molecular dynamics simulation of mechano-chemical reactions during chemical-mechanical polishing process of SiO2 surface by CeO2 particle. Appl Surf Sci 244:34–38

Hoshino T, Kurata Y, Terasaki Y, Susa K (2001) Mechanism of polishing of SiO2 films by CeO2 particles. J Non-Cryst Solids 283:129–136

Feng XD, Sayle DC, Wang ZL, Paras MS, Santora B, Sutorik AC, Sayle TXT, Yang Y, Ding Y, Wang XD, Her YS (2006) Converting ceria polyhedral nanoparticles into single-crystal nanospheres. Science 312:1504–1508

Zhang ZY, Lu XC, Han BL, Luo JB (2007) Rare earth effect on the microstructure and wear resistance of Ni-based coatings. Mater Sci Eng A 454:194–202

Zhang ZY, Lu XC, Han BL, Luo JB (2007) Rare earth effect on microstructure, mechanical and tribological properties of CoCrW coatings. Mater Sci Eng A 444:92–98

Gao S, Dong ZG, Kang RK, Guo DM (2013) Design and evaluation of soft abrasive grinding wheels for silicon wafers. Proc Inst Mech Eng Part B J Eng Manuf 227:578–586

Malkin S, Guo CS (2008) Grinding technology: theory and applications of machining with abrasives, vol 2 . Industrial Press, New York, pp 14–15Ch 2

Ebrahimi F, Kalwani L (1999) Fracture anisotropy in silicon single crystal. Mater Sci Eng A 268:116–126

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Huang, S., Wang, S. et al. A novel approach of high-performance grinding using developed diamond wheels. Int J Adv Manuf Technol 91, 3315–3326 (2017). https://doi.org/10.1007/s00170-017-0037-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0037-3