Abstract

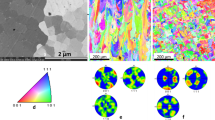

An as-built and solutionized Ni-based superalloy built by additive manufacturing through a direct metal laser sintering technique is characterized to understand the microstructural differences as compared to the as-wrought alloy. Initially, each layer undergoes rapid solidification as it is melted by the laser; however, as the part is built, the underlying layers experience a variety of heating and cooling cycles that produce significant microsegregation of niobium which allows for the formation of the deleterious δ-phase. The as-built microstructure was characterized through Vickers hardness, optical microscopy, scanning and transmission electron microscopy, electron back-scattering diffraction, x-ray diffraction, and synchrotron x-ray microLaue diffraction. The isothermal formation and growth of the δ-phase were characterized using synchrotron-based in situ small angle and wide angle x-ray scattering experiments. These experimental results are compared with multicomponent diffusion simulations that predict the phase fraction and composition. The high residual stresses and unexpected formation of the δ-phase will require further annealing treatments to be designed so as to remove these deficiencies and obtain an optimized microstructure.

Similar content being viewed by others

Notes

Certain commercial equipment, instruments, software, or materials are identified in this paper to foster understanding. Such identification does not imply recommendation or endorsement by the National Institute of Standards and Technology, nor does it imply that the materials or equipment identified are necessarily the best available for the purpose.

References

D.M. Shah and D.N. Duhl: Proc. 5th Int. Symp. Superalloys, vol 1 (1984) p. 105.

X. Xie, G. Wang, J. Dong, C. Xu, W. Cao, and R. Kennedy: Proc. 6th Int. Symp. Superalloys 718, 625, 706 Var. Deriv., vol 1, (2005), p. 179.

W. Cao and R. Kennedy: Proc. 10th Int. Symp. Superalloys 2004, vol 1 (2004) p. 91.

C.L. Thomas, T.M. Gaffney, S. Kaza, and C.H. Lee, Proc. Aero. App. Conf. (1996). doi:10.1109/AERO.1996.499663.

Y. Song, Y. Yan, R. Zhang, D. Xu, and F. Wang, J. Mater. Process. Technol. 120, 237 (2002).

K. Giannatsis and V. Dedoussis, Int. J. Adv. Des. Manuf. Technol. 40, 116 (2009).

E. Sachlos and J.T. Czernuszka, Eur. Cells Mater. 5, 29 (2003).

N.A. Waterman and P. Dickens, World Class Des. Manuf. 1, 27 (1994). doi:10.1108/09642369210056629.

ASTM, Annual Book of ASTM Standards (2010). doi:10.1520/F2792-10.

A. Simchi, F. Petzoldt, and H. Pohl, J. Mater. Process. Technol. 141, 319 (2003).

A. Simchi, Mater. Sci. Eng. A 428, 148 (2006).

G.J. Booysen, M. Truscott, J. Els, and D.J. De Beer, Innovative Dev. Des. Manuf., Proc. 5th Int. Conf. Adv. Res. Rapid Prototyping, vol 1, (2011), p. 145.

P.L. Blackwell, J. Mater. Process. Technol. 170, 240 (2005).

J. Delgado, J. Ciurana, and C.A. Rodriguez, J. Adv. Manuf. Technol. 60, 601 (2012).

J.P. Kruth, G. Levy, F. Klocke, and T. Childs, CIRP Ann. 56, 730 (2012).

Q. Jia and D. Gu, J. Alloys Compd. 585, 713 (2014).

ATI, “718Plus Alloy Datasheet, UNS NO7818.” https://www.atimetals.com/Documents/ati_718plus_tds_en_v3.pdf. Accessed 25 Aug 2015.

J. Ilavsky, P.R. Jemian, A.J. Allen, F. Zhang, L.E. Levine, and G.G. Long, J. Appl. Crystallogr. 42, 469 (2009).

J. Ilavsky, F. Zhang, A.J. Allen, L.E. Levine, P.R. Jemian, and G.G. Long, Metall. Mater. Trans. A 44, 68 (2013).

J. Ilavsky, A.J. Allen, L.E. Levine, F. Zhang, P.R. Jemian, and G.G. Long, J. Appl. Crystallogr. 45, 1318 (2012).

L. Levine, B. Larson, W. Yang, M.E. Kassner, J. Tischler, M.A. Delos-Reyes, R.J. Fields, and W. Liu, Nat. Mater. 5, 619 (2006).

L. Levine, C. Okoro, and R. Xu, IUCrJ. (2015). doi:10.1107/S2052252515015031.

J. Wang, B.H. Toby, P.L. Lee, L. Ribaud, S.M. Antao, C. Kirtz, M. Ramanthan, R.B. Von Dreele, and M.A. Beno, Rev. Sci. Instrum. 79, 085105 (2008).

P. Pranaam, F.J. Margetan, and R.B. Thompson, AIP Conf. Proc. 700, 1061 (2004).

O. Messe, J. Barnard, E. Pickering, P. Midgley, and C. Rae, Philos. Mag. 94, 1132 (2014).

E. Pickering, H. Mathus, A. Bhowmik, O. Messe, J. Barnard, M. Hardy, R. Krakow, K. Loehnert, H. Stone, and C. Rae, Acta Mater. 60, 2757 (2012).

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee, Metall. Mater. Trans. A 19, 453 (1988).

K. Unocic, R. Hayes, M. Mills, and G. Daehn, Metall. Mater. Trans. A 41, 409 (2010).

W. Cao, Proc. 6th Int. Symp. Superalloys 718, 625, 706 Var. Deriv, vol 1 (2005), p. 165.

R.E. Schafrik, D.D. Ward, and J.R. Groh, Proc. 5th Int. Symp. Superalloys 718, 625, 706 Var. Deriv., vol 1 (2001), p. 1.

S. Azadian, L.Y. Wei, and R. Warren, Mater. Charact. 53, 7 (2004).

H. Zhang, S. Zhang, M. Cheng, and Z. Li, Mater. Charact. 61, 49 (2010).

Y. Huang and T.G. Langdon, J. Mater. Sci. 42, 421 (2007).

J. Ilavsky and P.R. Jemian, J. Appl. Crystallogr. 42, 347 (2009).

Z. Jian and W. Hejing, Chin. J. Geochem. 22, 38 (2003).

M. Wojdry, J. Appl. Crystallogr. 43, 1126 (2010).

J.B. Nelson and D.P. Riley, Proc. Phys. Soc. Lond. 57, 160 (1945).

B. Cullity and S. Stock, Elements of X-ray Diffraction, 3rd ed. (Upper Saddle River: Prentice Hall, 2001).

G.H. Williamson and W.H. Hall, Acta Metall. 1, 22 (1953).

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, and X. Zeng, J. Alloys Compd 513, 518 (2012).

K. Amato, S. Gaytan, L. Murr, E. Martinez, P. Shindo, J. Hernandez, S. Collins, and F. Medina, Acta Mater. 60, 2229 (2012).

K. Amato, J. Hernandez, L. Murr, E. Martinez, S. Gaytan, and P. Shindo, J. Mater. Sci. Res. 1, 3 (2012).

K. Mumtz, P. Erasenthiran, and N. Hopkinson, J. Mater. Process. Technol. 195, 77 (2008).

M.C. Flemings, Metall. Trans. 5, 2121 (1974).

W. Kurz and D.J. Fischer, Fundamentals of Solidification, 1st ed. (Adermannsdorf: Trans-Tech. Publications, 1986).

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner, Metall. Trans. A 20, 1125 (1989).

S.A. David, J.M. Vitek, M. Rappaz, and L.A. Boatner, Metall. Trans. A 21, 1753 (1990).

J.M. Vitek, S.A. David, M. Rappaz, and L.A. Boatner, Int. Trends Weld. Sci. Technol., Proc. 3rd Int. Conf. Trends Weld. Res., vol 1, (1993), p. 167.

TCS Ni-Alloys database v6.1, Thermo-Calc Software, (Stockholm, 2013).

Acknowledgements

The use of the Advanced Photon Source at Argonne National Laboratory was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CG11357. Research performed in part at the NIST Center for Nanoscale Science and Technology. This material is based upon work supported by the Defense Advanced Research Projects Agency under Contract No. HROO 11-12-C-0037. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the Defense Advanced Research Projects Agency.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Idell, Y., Levine, L.E., Allen, A.J. et al. Unexpected δ-Phase Formation in Additive-Manufactured Ni-Based Superalloy. JOM 68, 950–959 (2016). https://doi.org/10.1007/s11837-015-1772-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1772-2