Summary

The continuous casting process employed in the steel industry is a many faceted “big” industrial problem which has given rise to many sub-problems. Here, we examine the problem involving the determination of the solid-liquid steel interface and we develop and extend a previously proposed model, which incorporates heat transfer through two layers of solid and liquid mould powder and the interface between the solid powder and the mould wall. The problem simplifies to the classical Stefan problem except that the condition on the boundary is nonlinear. Integral formulation procedures are used to establish the normalized pseudo steady state temperature as an upper bound to the normalized actual temperature. The pseudo steady state approximation yields an upper bound on the interface position, which an independent numerical enthalpy scheme confirms to be an extremely accurate approximation for the parameter values occurring in practice. The present work is important since it provides a simple method for the prediction of the solid-liquid steel interface and a bounding procedure which can be used to validate other estimates.

Similar content being viewed by others

Abbreviations

- D :

-

flux thickness atz *=0

- H :

-

enthalpy

- L :

-

latent heat of steel

- M :

-

the half thickness of the cast steel

- Q :

-

heat flux

- R :

-

interface thermal contact resistance

- S m * :

-

melting temperature of steel

- T * :

-

temperature

- T :

-

normalized temperature

- T m * :

-

melting temperature of mould powder

- T *∞ :

-

temperature of cooling water

- T w * :

-

temperature on mould wall

- T u * :

-

temperature of solid flux on its interface with mould wall

- T 0 * :

-

temperature on casting surfaceT *(0,z *)

- U :

-

casting speed

- X *(z *):

-

physical coordinate of the steel phase change boundary

- X(z) :

-

non-dimensional coordinate of the steel phase change boundary

- c :

-

specific heat of steel

- h(z *):

-

thickness of liquid flux layer

- k :

-

thermal conductivity of steel

- ks :

-

thermal conductivity of solid flux layer

- k l :

-

thermal conductivity of liquid flux layer

- m :

-

surface heat transfer coefficient

- s(z *):

-

thickness of solid flux layer

- t :

-

time

- α, β, γ:

-

positive constants given by (3.2)

- δ:

-

constant given by (3.5)

- ε:

-

coefficient of linear thermal expansion of steel

- Φ:

-

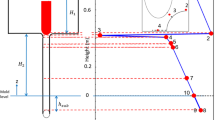

angle shown in Figure 2

- λ:

-

positive constant defined by ε(M-D)/2

- μ(z):

-

positive parameter

- θ(z *):

-

amount of contraction of steel

- ϱ:

-

density

- ξ(z):

-

positive parameter used in (5.7) and (5.8)

References

Please, C. P., Dewynne, J. N.: European study group with industry and training course in mathematical modelling. Department of Mathematics, University of Southampton, 1991.

Fowkes, N., Woods, A.: The flux of flux in a continuous steel caster. Department of Mathematics Preprint, University of Western Australia 1989.

Bland, D. R.: Flux and the continuous casting of steel. IMA J. Appl. Math.32, 89–112 (1984).

Flint, P. J.: A three dimensional finite difference model of heat transfer, fluid flow and solidification in the continuous slab caster. In: Proc. 73rd ISS Steelmaking Conf., pp. 481–490, Detroit, MI 1990.

Hong, C. P., Umeda, T., Kimura, T.: Numerical models for casting solidification. Part 1, the coupling of the boundary element and finite difference methods for solidification problems. Part 2, application of the boundary element method to solidification problems. Metall. Trans.B15, 91–107 (1984).

Laitinen, E., Neittaanmaki, P.: On numerical simulation of the continuous casting process. J. Eng. Math.22, 335–354 (1988).

Upton, E. A., Rao, T. R. S., Dauby, P. H., Knechtges, R. C.: Physical metallurgy and mathematical modelling as tools for continuous casting optimization at LTV steel. Ironmaking & Steelmaking15, 51–57 (1988).

Wu, Y.-H., Hill, J. M., Flint, P. J.: A novel finite element method for heat transfer in the continuous caster. J. Austral. Math. Soc. Ser. B35, 263–288 (1994).

Hill, J. M.: One dimensional Stefan problems: An introduction. Harlow: Longman 1987.

Dewynne, J. N., Hill, J. M.: On an integral formulation for moving boundary problems. Q. Appl. Math.41, 443–456 (1984).

Voller, V. R., Cross, M.: Accurate solutions of moving boundary problems using the enthalpy method. Int. J. Heat Mass Transfer24, 545–556 (1981).

Hill, J. M., Dewynne, J. N.: Heat conduction. Oxford: Blackwell 1987.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hill, J.M., Wu, Y.H. On a nonlinear stefan problem arising in the continuous casting of steel. Acta Mechanica 107, 183–198 (1994). https://doi.org/10.1007/BF01201828

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01201828