Paper:

Development of Mechanical-Impedance-Varying Mechanism in Admittance Control

Toru Tsumugiwa, Miho Yura, Atsushi Kamiyoshi, and Ryuichi Yokogawa

Department of Biomedical Engineering, Faculty of Life and Medical Sciences, Doshisha University

1-3 Tatara-miyakodani, Kyotanabe, Kyoto 610-0394, Japan

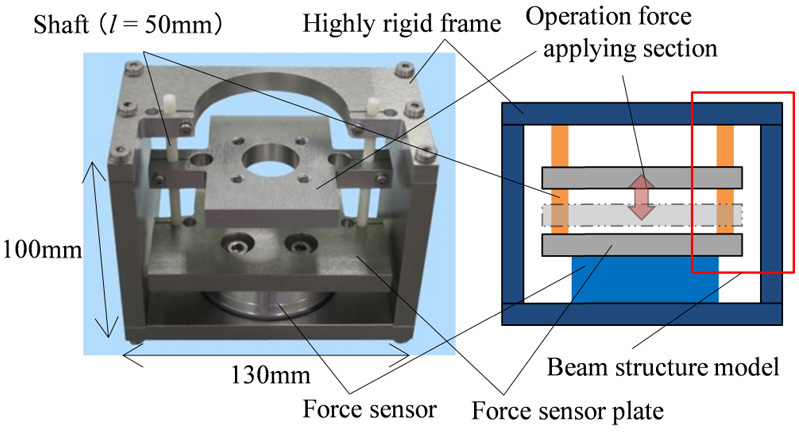

There have been numerous studies on the physical human-robot cooperative task system with impedance/admittance control in robot motion control. However, the problem of stability persists, wherein the control system becomes unstable when the robot comes into contact with a highly stiff environment. A variable impedance control strategy was proposed to circumvent this stability problem. However, a number of studies on variable impedance control are based on the variation of a parameter in the robot motion control software, and a mechanical variable impedance control has not been proposed. The purpose of this research is to propose a mechanical variable impedance control strategy using a mechanical device based on the lever principle. The proposed mechanism can adjust the magnitude of the input force to the force sensor by changing the position of application of the operating force on the beam. Adjusting the magnitude of the input force to the force sensor is equivalent to varying the impedance parameters of the robot; therefore, it is feasible to achieve mechanical variable impedance control using the proposed mechanism. In this study, the gain adjustment characteristics of the proposed mechanism were evaluated. The experimental results demonstrated that the operator can vary the impedance parameters of the robot by mechanically adjusting the input force to the force sensor and operating the robot using the proposed mechanism.

Impedance-varying mechanism

- [1] K. Kosuge, K. Furuta, and T. Yokoyama, “Virtual internal model following control of robot,” IEEE Int. Conf. on Robotics and Automation, pp. 1549-1554, January 1987.

- [2] R. J. Anderson and M. W. Spong, “Hybrid impedance control of robotic manipulators,” IEEE J. of Robotics and Automation, Vol.4, No.5, pp. 549-556, 1988.

- [3] H. Seraji, “Adaptive admittance control: an approach to explicit force control in compliant motion,” IEEE Int. Conf. on Robotics and Automation, pp. 2705-2712, August 1994.

- [4] R. Ikeura and H. Inooka, “Variable impedance control of a robot for cooperation with a human,” IEEE Int. Conf. on Robotics and Automation, pp. 3097-3102, May 1995.

- [5] H. Kazerooni, “Human power extender: an example of human-machine interaction via the transfer of power and information signals,” IEEE Int. Workshop on Advanced Motion Control, pp. 565-572, July 1998.

- [6] A. D. Santis, B. Siciliano, A. D. Luca, and A. Bicchi, “An atlas of physical human-robot interaction,” Mechanism and Machine Theory, Vol.43, No.3, pp. 253-270, 2008.

- [7] A. Campeau-Lecours, M. Otis, and C. Gosselin, “Modeling of physical human-robot interaction: Admittance controllers applied to intelligent assist devices with large payload,” Int. J. of Advanced Robotic Systems, pp. 1-12, 2016.

- [8] N. Takesue, T. Mine, R. Makino, K. Fujiwara, and H. Fujimoto, “Development of Power Assist Crane Operated by Tensional Information of Dual Wire,” J. Robot. Mechatron., Vol.25, No.6, pp. 931-938, 2013.

- [9] V. Duchaine and C. Gosselin, “Unified Robot Control Scheme for Cooperative Motion, Autonomous Motion and Contact Reaction,” J. Robot. Mechatron., Vol.23, No.4, pp. 557-566, 2011.

- [10] C. H. An and J. M. Hollerbach, “Dynamic stability issues in force control of manipulators,” IEEE Int. Conf. on Robotics and Automation, pp. 821-827, March 1987.

- [11] N. Hogan, “On the stability of manipulators performing contact tasks,” IEEE J. of Robotics and Automation, Vol.4, No.6, pp. 677-686, 1988.

- [12] D. A. Lawrence, “Impedance control stability properties in common implementations,” IEEE Int. Conf. on Robotics and Automation, pp. 1185-1190, August 1988.

- [13] S. Jung, T. C. Hsia, and R. G. Bonitz, “Force tracking impedance control of robot manipulators under unknown environment,” IEEE Trans. on Control Systems Technology, Vol.12, No.3, pp. 474-483, May 2004.

- [14] S. P. Buerger and N. Hogan, “Complementary stability and loop shaping for improved human-robot interaction,” IEEE Trans. on Robotics, Vol.23, No.2, pp. 232-244, April 2007.

- [15] Z. Doulgeri and G. Iliadis, “Stability of a contact task for a robotic arm modelled as a switched system,” IET Control Theory Appl., Vol.1, No.3, pp. 844-853, 2007.

- [16] E. Magrini, F. Flacco, and A. De Luca, “Control of generalized contact motion and force in physical human-robot interaction,” IEEE Int. Conf. on Robotics and Automation, pp. 2298-2304, May 2015.

- [17] D. Vincent and C. M. Gosselin, “General model of human-robot cooperation using a novel velocity based variable impedance control,” Second Joint EuroHaptics Conf. and Symp. on Haptic Interfaces for Virtual Environment and Teleoperator Systems, pp. 446-451, March 2007.

- [18] A. Lecours, B. Mayer-St-Onge, and C. Gosselin, “Variable admittance control of a four-degree-of-freedom intelligent assist device,” IEEE Int. Conf. on Robotics and Automation, pp. 3903-3908, May 2012.

- [19] F. Ficuciello, L. Villani, and B. Siciliano, “Variable impedance control of redundant manipulators for intuitive human-robot physical interaction,” IEEE Trans. on Robotics, Vol.31, No.4, pp. 850-863, May 2015.

- [20] K. Kronander and A. Billard, “Stability considerations for variable impedance control,” IEEE Trans. on Robotics, Vol.32, No.5, pp. 1298-1305, September 2016.

- [21] C. T. Landi, F. Ferraguti, L. Sabattini, C. Secchi, and C. Fantuzzi, “Admittance control parameter adaptation for physical human-robot interaction,” IEEE Int. Conf. on Robotics and Automation, pp. 2911-2916, February 2017.

- [22] M. M. Rahman, R. Ikeura, and K. Mizutani, “Investigation of the impedance characteristics of human arm for development of robots to cooperate with humans,” JSME Int. J., Series C, Vol.45, No.2, pp. 510-518, 2002.

- [23] D. Vincent, M. Boris, G. Dalong, and G. Clement, “Stable and intuitive control of an intelligent assist device,” IEEE Trans. on Haptics, Vol.5, No.2, pp. 148-159, June 2012.

- [24] B. Jangho, K. Jongheyon, and H. Daehie, “Variable impedance control with stiffness for human-robot cooperation system,” 15th Int. Conf. on Control, Automation and Systems, pp. 1231-1233, October 2015.

- [25] J. W. Jeong, P. H. Chang, and K. B. Park, “Sensorless and modeless estimation of external force using time delay estimation: application to impedance control,” J. of Mechanical Science and Technology, Vol.25, No.8, pp. 2051-2059, 2011.

- [26] T. Murakami, R. Nakamura, F. Yu, and K. Ohnishi, “Force sensorless impedance control by disturbance observer,” IEEE Power Conversion Conf., pp. 352-357, April 1993.

- [27] H. Seki, M. Iso, and Y. Hori, “How to design force sensorless power assist robot considering environmental characteristics – position control based or force control based –,” IEEE Int. Conf. on Industrial Electronics, pp. 2255-2260, March 2002.

- [28] E. D. Whiney, “Quasi-static assembly of compliantly supported rigid parts,” J. of Dynamic Systems, Measurement, and Control, Vol.104, No.1, pp. 65-77, 1982.

- [29] H. Kazerooni, “Direct-drive, active compliant end-effector,” IEEE J. of Robotics and Automation, Vol.4, No.3, pp. 324-333, 1988.

- [30] A. Sharon, N. Hogan, and D. E. Hardt, “High bandwidth force regulation and inertia reduction using a macro/micro manipulator system,” IEEE Int. Conf. on Robotics and Automation, pp. 126-132, April 1988.

- [31] A. Lopes and F. Almeida, “A force-impedance controlled industrial robot using an active robotic auxiliary device,” Robotics and Computer-Integrated Manufacturing, pp. 299-309, 2008.

- [32] L. D. Pascal, H. Jacques-Michel, A. Muhammad, and G. Clement, “Low-impedance physical human-robot interaction using an active-passive dynamics decoupling,” IEEE Robotics and Automation Letters, Vol.1, No.2, pp. 938-945, 2016.

- [33] L. D. Pascal, L. Thierry, F. Simon, A. Muhammad, and G. Clement, “A low-impedance manipulator for human-robot cooperation based on underactuated redundancy,” IEEE/ASME Trans. on Mechatronics, Vol.22, No.3, pp. 1401-1411, January 2017.

- [34] B. Vanderborght, A. Albu-Schaeffer, A. Bicchi, E. Burdet, D. G. Caldwell, R. Carloni, M. Catalano, O. Eiberger, W. Friedl, G. Ganesh, M. Garabini, M. Grebenstein, G. Grioli, S. Haddadin, H. Hoppner, A. Jafari, M. Laffranchi, D. Lefeber, F. Petit, S. Stramigioli, N. Tsagarakis, M. Van Damme, R. Van Ham, L. C. Visser, and S. Wolf, “Variable impedance actuators: A review,” Robotics and Autonomous Systems, Vol.61, Issue 12, pp. 1601-1614, 2013.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.