The Use of a Simplified Carbon Footprint Tool for Organic Waste Managers: Pros and Cons

Abstract

:1. Introduction

2. Materials and Methods

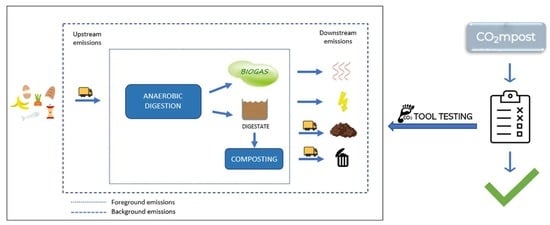

2.1. Methodology of “CO2mpost” Tool

2.2. Case Study

2.2.1. General Information on the Plant

2.2.2. GHG Accounting

3. Results

3.1. CO2 Emitted

3.2. CO2 Avoided

3.3. Key Performance Indicators

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pattara, C.; Raggi, A.; Cichelli, A. Life Cycle Assessment and Carbon Footprint in the wine supply-chain. Environ. Manag. 2012, 49, 1247–1258. [Google Scholar] [CrossRef]

- ISO. ISO 14064-1:2019. Greenhouse Gases Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Ellen Macarthur Foundation. Completing the Picture: How the Circular Economy Tackles Climate Change. 2019. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/Completing_The_Picture_How_The_Circular_Economy-_Tackles_Climate_Change_V3_26_September.pdf (accessed on 8 June 2021).

- Scrucca, F.; Barberio, G.; Fantin, V.; Porta, P.L.; Barbanera, M. Carbon Footprint: Concept, methodology and calculation. In Carbon Footprint Case Studies. Environmental Footprints and Eco-design of Products and Processes; Muthu, S.S., Ed.; Springer: Singapore, 2021; pp. 1–31. [Google Scholar]

- Wilson, A.J.S.; Orlove, B. Climate urgency: Evidence of its effects on decision making in the laboratory and the field. Curr. Opin. Environ. Sustain. 2021, 51, 65–76. [Google Scholar] [CrossRef]

- Yue, T.; Haiwen, L.; Ruyin, L.; Hong, C.; Xin, G.; Junli, L. Research trends and hotspots related to global carbon footprint based on bibliometric analysis: 2007–2018. Environ. Sci. Pollut. Res. 2020, 27, 17671–17691. [Google Scholar] [CrossRef] [PubMed]

- UNEP. UNEP Food Waste Iindex Report. 2021. Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 23 March 2021).

- Siebert, S.; Gilbert, J.; Ricci-Jürgensen, M. Compost Production in Europe. 2021. Available online: https://www.compostnetwork.info/wordpress/wp-content/uploads/190823_ECN-Compost-Production-in-Europe_final_layout-ECN.pdf (accessed on 14 January 2021).

- European Union. Taxonomy Technical Report. 2019. Available online: https://ec.europa.eu/info/sites/info/files/business_economy_euro/banking_and_finance/documents/190618-sustainable-finance-teg-report-taxonomy_en.pdf (accessed on 23 March 2021).

- Manninen, K.; Koskela, S.; Nuppunen, A.; Sorvari, J.; Nevalainen, O.; Siitonen, S. The applicability of the renewable energy directive calculation to assess the sustainability of biogas production. Energy Policy 2013, 56, 549–557. [Google Scholar] [CrossRef]

- European Commission. Sustainability of Bioenergy; Commission Staff Working Document Impact Assessment. SWD, 2016, 418 final. Part 4/4; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- De La Peña, L.; Guo, R.; Cao, X.; Ni, X.; Zhang, W. Accelerating the energy transition to achieve carbon neutrality. Resour. Conserv. Recyc. 2022, 177, 105957. [Google Scholar] [CrossRef]

- European Union. 2030 Climate & Energy Framework. 2020. Available online: https://ec.europa.eu/clima/policies/strategies/2030_en (accessed on 5 January 2021).

- UNFCCC. Paris Agreement. 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 5 October 2021).

- De Rosa, M.; Pizzol, M.; Schmidt, J. How methodological choices affect LCA climate impact results: The case of structural timber. Int. J. Life Cycle Assess. 2018, 23, 147–158. [Google Scholar] [CrossRef]

- Brandão, M.; Levasseur, A.; Kirschbaum, M.U.F.; Weidema, B.P.; Cowie, A.L.; Jørgensen, S.V.; Hauschild, M.Z.; Pennington, D.W.; Chomkhamsri, K. Key issues and options in accounting for carbon sequestration and temporary storage in life cycle assessment and carbon footprinting. Int. J. Life Cycle Assess. 2013, 18, 230–240. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Fullana-i-Palmer, P.; Raggi, A.; Gazulla, C.; Raugei, M.; Benveniste, G.; Anglada, M. Unresolved issues in the accounting of biogenic carbon exchanges in the wine sector. J. Clean. Prod. 2014, 82, 16–22. [Google Scholar] [CrossRef]

- Rahman, F.; O’Brien, C.; Ahamed, S.I.; Zhang, H.; Liu, L. Design and implementation of an open framework for ubiquitous carbon footprint calculator applications. Sustain. Comput. Inform. Syst. 2011, 1, 257–274. [Google Scholar] [CrossRef]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Løkke, S. Carbon Footprint. A catalyst for Life Cycle Assessment? J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef]

- United Nation. Transforming our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/2030agenda (accessed on 1 October 2021).

- Finkbeiner, M.; Neugebauer, S.; Berger, M. Carbon footprint of recycled biogenic products: The challenge of modelling CO2 removal credits. Int. J. Sustain. Eng. 2013, 6, 66–73. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is there a simplified LCA tool suitable for the agri-food industry? An assessment of selected tools. J. Clean. Prod. 2017, 149, 406–425. [Google Scholar] [CrossRef]

- European Union. Special Eurobarometer 459 “Climate Change” Report. 2017. Available online: https://op.europa.eu/en/publication-detail/-/publication/5f03345d-9f43-11e7-b92d-01aa75ed71a1/language-en (accessed on 1 December 2021).

- Harangozo, G.; Szigeti, C. Corporate carbon footprint analysis in practice—With a special focus on validity and reliability issues. J. Clean. Prod. 2017, 167, 1177–1183. [Google Scholar] [CrossRef]

- Vosooghnia, A.; Pollettini, A.; Rossi, A.; Vázquez-Rowe, I.; Francini, G. Carbon footprint of anaerobic digestion combined with ultrasonic post-treatment of agro-industrial organic residues. J. Environ. Manag. 2021, 278, 111459. [Google Scholar] [CrossRef] [PubMed]

- Møller, J.; Boldrin, A.; Christensen, T.H. Anaerobic digestion and digestate use: Accounting of greenhouse gases and global warming contribution. Waste Manag. Res. 2009, 27, 813–824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bacenetti, J.; Fiala, M. Carbon footprint of electricity from anaerobic digestion plants in Italy. Environ. Eng. Manag. J. 2015, 14, 1495–1502. [Google Scholar] [CrossRef]

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories Volume 4 Agriculture, Forestry and Other Land Use. 2006. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.html (accessed on 1 December 2021).

- Bartocci, P.; Zampilli, M.; Liberti, F.; Pistolesi, V.; Massoli, S.; Bidini, G.; Fantozzi, F. LCA analysis of food waste co-digestion. Sci. Total Environ. 2020, 709, 136187. [Google Scholar] [CrossRef]

- EPD International AB. Product Category Rules. 2020. Available online: https://test1.environdec.com/PCR (accessed on 8 October 2021).

- ISO. ISO 14040: 2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO. ISO 14044: 2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Vinci, G.; Ruggieri, R.; Billi, A.; Pagnozzi, C.; Di Loreto, M.V.; Ruggeri, M. Sustainable Management of Organic Waste and Recycling for Bioplastics: A LCA Approach for the Italian Case Study. Sustainability 2021, 13, 6385. [Google Scholar] [CrossRef]

- E4tech. Biomass and Biogas Carbon Calculator (B2C2). 2015. Available online: https://www.e4tech.com/resources/163-biomass-and-biogas-carbon-calculator-b2c2.php?filter=year%3A2015 (accessed on 23 March 2021).

- NNFCC. Biomethane & Biogas Carbon Calculator. 2015. Available online: https://www.nnfcc.co.uk/publications/tool-biomethane-carbon-calculator (accessed on 23 March 2021).

- RENERGON International AG. Anaerobic Digestion Calculator. 2021. Available online: https://www.renergon-biogas.com/en/anaerobic-digestion-calculator (accessed on 2 March 2021).

- Biogas World. Biogas Calculations. 2021. Available online: https://www.biogasworld.com/biogas-calculations (accessed on 23 March 2021).

- World Business Council for Sustainable Development (WBCSD); World Resources Institute (WRI). The Greenhouse Gas Protocol. A Corporate Accounting and Reporting Standard, Revised Edition; WBCSD: Geneva, Switzerland; WRI: Washington, DC, USA, 2004. [Google Scholar]

- ISPRA. Rapporto Rifiuti Urbani—Edizione 2020. 2020. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2020 (accessed on 29 July 2021). (in Italian)

- Consorzio Italiano Compostatori. CO2mpost v. 1.0—Tool Online per la Valutazione della CO2 Prodotta ed Evitata per le Attività di Compostaggio e Digestione Anaerobica; Manuale utente; Consorzio Italiano Compostatori: Rome, Italy, 2020. (in Italian) [Google Scholar]

- ISO. ISO 14067: 2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. ISO: Geneva, Switzerland, 2018.

- Boldrin, A.; Andersen, J.K.; Møller, J.; Favoino, E.; Christensen, T.H. Composting and compost utilization: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 800–812. [Google Scholar] [CrossRef] [Green Version]

- Kuronen, A.; Lehtovaara, M.; Jakobsson, S. Issuance Based Residual Mix Calculation Methodology; Version 1.1; Grexel Systems ltd: Helsinky, Finland, 2020; Available online: https://www.aib-net.org/facts/european-residual-mix (accessed on 21 September 2021).

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources. L 328/82. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 21 April 2021).

- Klimscheffskij, M.; Van Craenenbroeck, T.; Lehtovaara, M.; Lescot, D.; Tschernutter, A.; Raimundo, C.; Seebach, D.; Timpe, C. Residual mix calculation at the heart of reliable electricity disclosure in Europe—A case study on the effect of the RE-DISS project. Energies 2015, 8, 4667–4696. [Google Scholar] [CrossRef] [Green Version]

- Association of Issuing Bodies. European Residual Mixes 2018; Version 1.2, 2019-07-11; Association of Issuing Bodies: Brussels, Belgium, 2018. [Google Scholar]

- Ecoinvent 3.5. 2018. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-35/ecoinvent-35.html (accessed on 18 July 2021).

- Smith, A.; Brown, K.; Ogilvie, S.; Rushton, K.; Bates, J. Waste Management Options and Climate Change: Final Report. 2001. Available online: http://web.rec.org/documents/ECENA/training_programmes/2008_06_budapest/session2/16-climate_change_full_study.pdf (accessed on 16 March 2021).

- ARPAV-ORC. Benefici ambientali nell’utilizzo del compost. In Compost, una Fonte di Nuova Fertilità; Chiarion, M., Ed.; Veneto Agricoltura: Legnaro, Italy, 2009; pp. 19–26. (in Italian) [Google Scholar]

- Mainero, D.; Montoneri, E.; Boffa, V.; Montoneri, C. New Perspective from Organic Fraction Treatment: Renewable Energy and Chemicals. 2014. Available online: https://www.academia.edu/33155590/New_Perspective_From_Organic_Fraction_Treatment_Renewable_Energy_and_Chemicals (accessed on 25 March 2021).

- ISO. ISO/TR 14049: 2012; Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 to Goal and Scope Definition and Inventory Analysis. ISO: Geneva, Switzerland, 2012.

- ISPRA. Italian Greenhouse Gas Inventory 1990–2017. National Inventory Report 2019. 2019. Available online: https://www.ruminantia.it/ispra-pubblicato-litalian-greenhouse-gas-inventory-1990-2017-national-inventory-report-2019 (accessed on 28 June 2021).

- Rillo, E.; Studio Fieschi & Soci Srl, Turin, Italy. Personal Communication, 2022.

- MiSE. Decreto 2 marzo 2018 sulla Promozione dell’uso del Biometano e Degli Altri Biocarburanti Avanzati nel Settore dei Trasporti; GU Serie Generale n.65 del 19-03-2018; Ministero dello Sviluppo Economico: Rome, Italy, 2018. (in Italian) [Google Scholar]

- Östergren, K.; Scherhaufer, S.; De Menna, F.; Herrero, L.G.; Gollnow, S.; Davis, J.; Vittuari, M. Simplified LCA & LCC of Food Waste Valorization, Description of Standardised Models for the Valorisation Spreadsheet Tool for Life-Cycle Assessment and Life-Cycle Costing; REFRESH Deliverable 5.4; 2018. Available online: https://eu-refresh.org/simplified-lca-lcc-food-waste-valorisation.html (accessed on 12 October 2021).

- Wardenaar, T.; van Ruijven, T.; Beltran, A.M.; Vad, K.; Guinée, J.; Heijungs, R. Differences between LCA for analysis and LCA for policy: A case study on the consequences of allocation choices in bio-energy policies. Int. J. Life Cycle Assess. 2012, 17, 1059–1067. [Google Scholar] [CrossRef] [Green Version]

- Cobo, S.; Dominguez-Ramos, A.; Irabien, A. From linear to circular integrated waste management systems: A review of methodological approaches. Resour. Conserv. Recy. 2018, 135, 279–295. [Google Scholar] [CrossRef]

- Neri, E.; Passarini, F.; Cespi, D.; Zoffoli, F.; Vassura, I. Sustainability of a bio-waste treatment plant: Impact evolution resulting from technological improvements. J. Clean. Prod. 2017, 171, 1006–1019. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Edwards, R.; Junginger, M.; Moro, A.; Rocco, M.; Shen, L. Reviewing ISO compliant multifunctionality practices in environmental life cycle modelling. Energies 2020, 13, 3579. [Google Scholar] [CrossRef]

- European Union. Proposal for a directive of the European Parliament and of the Council amending Directive (EU) 2018/2001 of the European Parliament and of the Council, Regulation (EU) 2018/1999 of the European Parliament and of the Council and Directive 98/70/EC of the European Parliament and of the Council as regards the promotion of energy from renewable sources, and repealing Council Directive (EU) 2015/652. COM (2021) 557 final. 2021. Available online: https://ec.europa.eu/info/sites/default/files/amendment-renewable-energy-directive-2030-climate-target-with-annexes_en.pdf (accessed on 13 October 2021).

- Giuntoli, J.; Agostini, A.; Edwards, R.; Marelli, L. Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions. Calculated According to the Methodology set in COM, 2016, 767; Version 2; Publications Office of the European Union: Luxembourg, 2017; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC104759 (accessed on 2 December 2021).

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recyc. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. 2008. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/2018-07-05 (accessed on 14 March 2021).

- Dolci, G.; Rigamonti, L.; Grosso, M. Life cycle assessment of the food waste management with a focus on the collection bag. Waste Manag. Res. 2021, 39, 1317–1327. [Google Scholar] [CrossRef]

- Feiz, R.; Johansson, M.; Lindkvist, E.; Moestedt, J.; Påledal, S.N.; Svensson, N. Key performance indicators for biogas production—Methodological insights on the life-cycle analysis of biogas production from source-separated food waste. Energy 2020, 200, 117462. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Mancini, E.; Negro, V.; Mainero, D.; Raggi, A. Analisi di uno strumento di carbon footprint per il compostaggio e la digestione anaerobica. In Innovazione e Circolarità—Il Contributo del Life Cycle Thinking nel Green Deal per la Neutralità Cclimatica. Proceedings of the Italian LCA Network Conference, Reggio Calabria, Italy, 22–24 September 2021; forthcoming.

| Type of Activity | Emission Factor | Source |

|---|---|---|

| Energy consumption | ||

| Italian electricity residual mix | 0.596 kg CO2 eq/kWh | [47] |

| Renewable resources | ||

| hydropower | 0.0062 CO2 eq/kWh | [48] |

| photovoltaic | 0.069 CO2 eq/kWh | [48] |

| wind power | 0.017 CO2 eq/kWh | [48] |

| geothermal | 0.074 CO2 eq/kWh | [48] |

| other renewable resources | 0.265 CO2 eq/kWh | [48] |

| Fossil resources | ||

| natural gas | 2.60 kg CO2 eq/m3 | [48] |

| LPG—liquefied petroleum gas | 0.935 kg CO2 eq/kg | [48] |

| diesel oil | 0.268 kg CO2 eq/kg | [48] |

| gasoline | 0.258 kg CO2 eq/kg | [48] |

| Auxiliary materials consumption | ||

| polyelectrolytes | 0.332 kg CO2 eq/kg | [48] |

| sulphuric acid | 0.116 kg CO2 eq/kg | [48] |

| iron (III) chloride | 0.831 kg CO2 eq/kg | [48] |

| amine oxide | 4.830 kg CO2 eq/kg | [48] |

| lubricating oil | 1.270 kg CO2 eq/kg | [48] |

| Direct emissions | ||

| methane, biogenic | 27.8 kg CO2 eq/kg | [48] |

| dinitrogen monoxide | 265 kg CO2 eq/kg | [48] |

| direct emissions for biogas combustion | 0.0296 kg CO2 eq/m3 | [48] |

| Waste treatment | ||

| residual waste (to landfill) | 0.097 kg CO2 eq/kg | Calculated by the tool developer |

| WtE | 0.038 kg CO2 eq/kg | [48] |

| wastewater treatment | 0.49 kg CO2 eq/m3 | [48] |

| Transport | ||

| in input/in output | 0.163 kg CO2 eq/tkm | [48] |

| Compost | ||

| avoided unit of peat | 0.823 kg CO2 eq/kg | [49,50] |

| avoided unit of nitrogen (N) fertiliser | 5.290 kg CO2 eq/kg | [49,50] |

| avoided unit of phosphorus (P) fertiliser | 0.520 kg CO2 eq/kg | [49,50] |

| Avoided unit of potassium (K) fertiliser | 0.380 kg CO2 eq/kg | [49,50] |

| avoided waste in MBT before landfilling | 0.104 kg CO2 eq/kg | Calculated by the tool developer |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mancini, E.; Negro, V.; Mainero, D.; Raggi, A. The Use of a Simplified Carbon Footprint Tool for Organic Waste Managers: Pros and Cons. Sustainability 2022, 14, 1951. https://doi.org/10.3390/su14041951

Mancini E, Negro V, Mainero D, Raggi A. The Use of a Simplified Carbon Footprint Tool for Organic Waste Managers: Pros and Cons. Sustainability. 2022; 14(4):1951. https://doi.org/10.3390/su14041951

Chicago/Turabian StyleMancini, Eliana, Viviana Negro, Davide Mainero, and Andrea Raggi. 2022. "The Use of a Simplified Carbon Footprint Tool for Organic Waste Managers: Pros and Cons" Sustainability 14, no. 4: 1951. https://doi.org/10.3390/su14041951