Substrate and Passivation Techniques for Flexible Amorphous Silicon-Based X-ray Detectors

Abstract

:1. Introduction

1.1. Flexible Electronics

1.2. X-ray Source and Detector Structure and Operation

1.3. Flexible Indirect X-ray Detectors

2. Materials and Methods

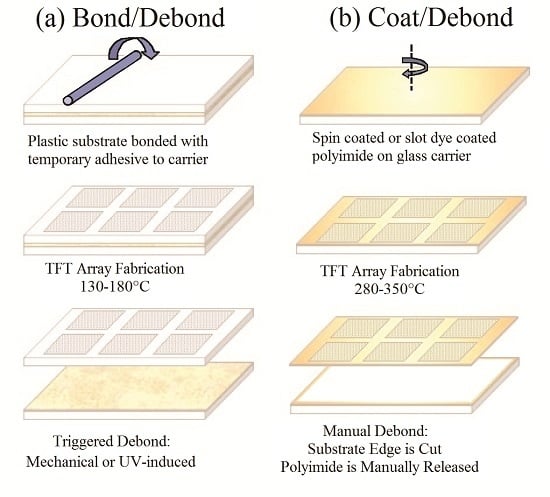

2.1. Substrate Preparation: Polyethylene Naphthalate (PEN) Bond/Debond

2.2. Substrate Preparation: Polyimide Cast and Debond Process

2.3. PIN Diode Processing and Device Structure

2.4. PIN Diode Test Setup

2.4.1. L-I-V Sweeps of 1 mm2 Diodes

2.4.2. Diode Array Testing

3. Results

3.1. L-I-V Sweep Comparison between Blanket and Pixelated Photodiodes

3.2. Effect of the Photodiode Passivation Layer

3.2.1. Dark Current vs. Time Stability

3.2.2. Effect of Diode Shape

3.2.3. Effect of a Backside Guard Ring on Humidity Sensitivity

3.2.4. Array Performance

3.2.5. PIN Diode Film Cracking

3.2.6. Effect of the Substrate: PEN vs. Polyimide

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Smith, J.; O’Brien, B.; Lee, Y.K.; Bawolek, E.; Christen, J. Application of Flexible OLED Display Technology for Electro-Optical Stimulation and/or Silencing of Neural Activity. IEEE J. Disp. Technol. 2014, 10, 514–520. [Google Scholar] [CrossRef]

- Smith, J.T.; Katchman, B.A.; Kullman, D.; Obahiagbon, U.; Lee, Y.K.; O’Brien, B.; Madabhushi, K.P.; Surampudi, V.; Raupp, G.B.; Anderson, K.S.; et al. Application of Flexible OLED Display Technology to Point-of-Care Medical Diagnostic Testing. IEEE J. Disp. Technol. 2016, 12. [Google Scholar] [CrossRef]

- Marrs, M.; Bawolek, E.; Smith, J.T.; Raupp, G.B.; Morton, D. Flexible Amorphous Silicon PIN Diode X-ray Detectors. SPIE Def. Secur. Sens. 2013, 87300C. [Google Scholar] [CrossRef]

- Zink, F.E. The AAPM/RSNA Physics Tutorial for Residents: X-ray Tubes. Radiographics 1997, 17, 1259–1268. [Google Scholar] [CrossRef] [PubMed]

- Carlton, R.R.; Adler, A.M. Principles of Radiographic Imaging: An Art and A Science, 5th ed.; Cengage Learning: Clifton Park, NY, USA, 2012; pp. 191–215. [Google Scholar]

- Schaefer-Prokop, C.; Neitzel, U.; Venema, H.W.; Uffmann, M.; Prokop, M. Digital chest radiography: An update on modern technology, dose containment and control of image quality. Eur. Radiol. 2008. [Google Scholar] [CrossRef] [PubMed]

- Kuo, T.T.; Wu, C.M.; Lu, H.H.; Chan, I.; Wang, K.; Leou, K.C. Flexible X-ray Imaging Detector Based on Direct Conversion in Amorphous Selenium. J. Vac. Sci. Technol. A 2014, 32, 1–5. [Google Scholar] [CrossRef]

- Lujan, R.A.; Street, R.A. Flexible X-ray Detector Array Fabricated with Oxide Thin-Film Transistors. IEEE Electron Device Lett. 2012, 33, 688–690. [Google Scholar] [CrossRef]

- Ng, T.N.; Wong, W.S.; Chabinyc, M.L.; Sambandan, S.; Street, R.A. Flexible Image Sensor Array with Bulk Heterojunction Organic Photodiode. Appl. Phys. Lett. 2008, 92, 1–3. [Google Scholar] [CrossRef]

- PI 2600 Series—Low Stress Applications. Product Bulletin. Available online: http://www.hdmicrosystems.com/HDMicroSystems/en_US/pdf/PI-2600_ProcessGuide.pdf (accessed on 4 April 2016).

- Teonex® Q51 Datasheet. Available online: http://www.synflex.com/en/produkte_pdf/?id=19&areaid=flaechenisolierstoffe (accessed on 10 April 2016).

- Petersen, K. Silicon as a Mechanical Material. IEEE Proc. 1982, 70, 420–456. [Google Scholar] [CrossRef]

- General Properties of Si, Ge, SiGe, SiO2 and Si3N4. Available online: http://www.virginiasemi.com/pdf/generalpropertiesSi62002.pdf (accessed on 7 April 2016).

- Raupp, G.B.; O’Rourke, S.M.; O’Brien, B.P.; Ageno, S.K.; Loy, D.E.; Bawolek, E.J.; Allee, D.R.; Venugopal, S.M.; Kaminski, J.; Bottesch, D.; et al. Low-temperarature Amorphous-silicon Backplane Technology Development for Flexible Display in a Manufacturing Pilot-line Environment. JSID 2007, 15, 445–454. [Google Scholar] [CrossRef]

- Haq, J.; Ageno, S.; Raupp, G.B.; Vogt, B.D.; Loy, D. Temporary Bond-debond Process for Manufacture of Flexible Electronics: Impact of Adhesive and Carrier Properties on Performance. J. Appl. Phys. 2010, 108, 114917. [Google Scholar] [CrossRef]

- French, I.; George, D.; Kretz, T.; Templier, F.; Lifka, H. Flexible Displays and Electronics Made in AM-LCD Facilities by the EPLaR™ Process. SID Symp. Dig. Tech. Pap. 2007, 38, 1680–1683. [Google Scholar] [CrossRef]

- Marrs, M.A.; Bawolek, E.J.; O’Brien, B.P.; Smith, J.T.; Strnad, M.; Morton, D.C. Flexible Amorphous Silicon PIN Diode Sensor Array Process Compatible with Indium Gallium Zinc Oxide Transistors. SID Symp. Dig. Tech. Pap. 2013, 44, 455–457. [Google Scholar] [CrossRef]

- Theil, J.A.; Snyder, R.; Hula, D.; Lindahl, K.; Haddad, H.; Roland, J. a-Si:H Photodiode Technology for Advanced CMOS Active Pixel Sensor Imagers. J. Non-Cryst. Solids 2002, 299, 1234–1239. [Google Scholar] [CrossRef]

- Dadu, M.; Kapoor, A.; Tripathi, K. Effect of Operating Current Dependent Series Resistance on the Fill Factor of a Solar Cell. Sol. Energy Mater. Sol. Cells 2002, 71, 213–218. [Google Scholar] [CrossRef]

- Series Resistance. Available online: http://www.pveducation.org/pvcdrom/solar-cell-operation/series-resistance (accessed on 18 May 2016).

- Street, R.A. Technology and Applications of Amorphous Silicon; Springer-Verlag: Berlin, Germany, 2000; pp. 147–221. [Google Scholar]

- Nam, H.G.; Shin, M.S.; Cha, K.H.; Cho, N.I. Fabrication of a Silicon PIN Diode for Radiation Detection. J. Korean Phys. Soc. 2006, 48, 1514–1519. [Google Scholar] [CrossRef]

- Cygan, P.; Zheng, J.; Yen, S.; Jow, T. Thermal treatment of polyethylene-2,6-naphthalate (PEN) film and its influence on the morphology and dielectric strength. Conf. Electr. Insul. Dielectr. Phenom. 1993, 630–635. [Google Scholar] [CrossRef]

| HD Microsystems PI 2611 | DuPont Teonex Q51 PEN | Silicon | Units | |

|---|---|---|---|---|

| Tensile Strength | 350 | 274.6 | 7000 | MPa |

| Glass Transition Temperature | 360 | 121 | - | °C |

| Continuous Operation Temperature | - | 180 | - | °C |

| Melting Temperature | 620 (decomposes) | 269 | 1415 | °C |

| Coefficient of Thermal Expansion | 3 | 13 | 2.6 | ppm/°C |

| Dielectric Constant | 2.9 | 3 | 11.9 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marrs, M.A.; Raupp, G.B. Substrate and Passivation Techniques for Flexible Amorphous Silicon-Based X-ray Detectors. Sensors 2016, 16, 1162. https://doi.org/10.3390/s16081162

Marrs MA, Raupp GB. Substrate and Passivation Techniques for Flexible Amorphous Silicon-Based X-ray Detectors. Sensors. 2016; 16(8):1162. https://doi.org/10.3390/s16081162

Chicago/Turabian StyleMarrs, Michael A., and Gregory B. Raupp. 2016. "Substrate and Passivation Techniques for Flexible Amorphous Silicon-Based X-ray Detectors" Sensors 16, no. 8: 1162. https://doi.org/10.3390/s16081162