Calibration of Acoustic-Soil Discrete Element Model and Analysis of Influencing Factors on Accuracy

Abstract

:1. Introduction

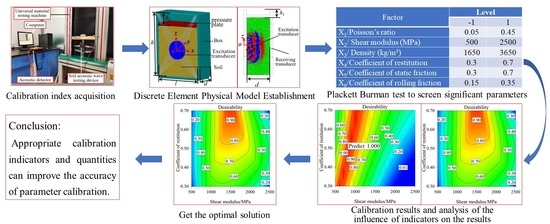

2. Materials and Methods

2.1. Actual Scene Experiment

2.2. Simulation Model Establishment

2.2.1. DEM Calculation Method

2.2.2. Discrete Element Model Building

2.2.3. Simulation Parameter Settings

2.3. Index Measurement

- (1)

- Acoustic velocity

- (2)

- Dominant frequency

2.4. Test Scheme

2.4.1. Plackett—Burman Test Scheme

2.4.2. Box—Behnken Test Scheme

3. Results and Discussion

3.1. Plackett—Burman Test Results and Sensitivity Analysis

3.2. Box—Behnken Design Test

3.2.1. Establishment of Regression Model and Significance Analysis

- (1)

- Significance analysis of acoustic wave dominant frequency Y1

- (2)

- Significance analysis of acoustic velocity Y2

3.2.2. Analysis of the Influence of the Number of Indexes on the Desirability of Calibration Results

3.2.3. Parameter Optimization and Verification of Desirability Based on Dual-Index

- (1)

- Parameter optimization for desirability

- (2)

- Validation of the optimal combination of parameters

4. Discussion

4.1. The Necessity of Constitutive Parameter Calibration

4.2. Difference of Calibration Effect

5. Conclusions

- (1)

- Based on EDEM software, the sensitivity analysis was carried out by the Plackett—Burman test. It was concluded that the sensitivity of each parameter to the dominant frequency of acoustic waves was ranked as Shear modulus, Poisson’s ratio, Coefficient of restitution, Coefficient of rolling friction, Density, and Coefficient of static friction. The order of sensitivity to acoustic velocity is Shear modulus, Poisson’s ratio, Coefficient of restitution, Coefficient of static friction, Coefficient of rolling friction, and Density.

- (2)

- Through the Box—Behnken test, the quadratic regression model of the three sensitive parameters on the dominant frequency and velocity is constructed and optimized. The optimal solutions of the two models are obtained as follows: shear modulus is 1407 MPa, Poisson’s ratio is 0.3, and coefficient of restitution is 0.79. The relative error values of the simulated dominant frequency and velocity and the actual values were 4.4% and 2.2%, respectively. It shows that the model constructed by the climbing test and the response surface test can well optimize the parameter values, and the optimal parameter combination can be used to study the acoustic wave propagation in the soil.

- (3)

- Comparing the calibration effect of the single and dual- indexes, it is found that a single index can only meet the calibrated index, while other indexes have significant errors. Moreover, the optional range of parameter values is wide and cannot be limited to a reasonable range. Dual-indexes can narrow the range of parameter values and meet the requirements of the two indexes. Therefore, the number of indexes should be increased as reasonably as possible to make the calibration effect more accurate and the parameter values more aligned with the actual materials.

- (4)

- The calibration of different scenarios is compared and discussed in this paper. It can be seen that the calibrated parameter combinations are different in different scenarios, so we should select the significant parameters according to the scenarios, then calibrate the significant parameters, and finally determine the final parameter combination.

Author Contributions

Funding

Conflicts of Interest

References

- Xu, Y.; Li, J.; Duan, J.; Song, S.; Jiang, R.; Yang, Z. Soil water content detection based on acoustic method and improved Brutsaert’s model. Geoderma 2020, 359, 114003. [Google Scholar] [CrossRef]

- Dongqing, L.; Xing, H.; Feng, M.; Yu, Z. The impact of unfrozen water content on ultrasonic wave velocity in frozen soils. Procedia Eng. 2016, 143, 1210–1217. [Google Scholar] [CrossRef]

- Gorthi, S.; Chakraborty, S.; Li, B.; Weindorf, D.C. A field-portable acoustic sensing device to measure soil moisture. Comput. Electron. Agric. 2020, 174, 105517. [Google Scholar] [CrossRef]

- Weidinger, D.M.; Ge, L.; Stephenson, R.W. Ultrasonic Pulse Velocity Tests on Compacted Soil. In Proceedings of the Characterization, Modeling, and Performance of Geomaterials, Selected Papers from the 2009 GeoHunan International Conference, Changsha, China, 3–6 August 2009; pp. 150–155. [Google Scholar]

- Sarro, W.S.; Assis, G.M.; Ferreira, G.C.S. Experimental investigation of the UPV wavelength in compacted soil. Constr. Build. Mater. 2021, 272, 121834. [Google Scholar] [CrossRef]

- Lu, C.; Li, H.; He, J.; Wang, Q.; Wang, C.; Liu, J. A Preliminary Study of Seeding Absence Detection Method for Drills on the Soil Surface of Cropland Based on Ultrasonic Wave without Soil Disturbance. J. Sens. 2019, 2019, 7434197. [Google Scholar] [CrossRef]

- Otsubo, M.; Liu, J.; Kawaguchi, Y.; Dutta, T.T.; Kuwano, R. Anisotropy of elastic wave velocity influenced by particle shape and fabric anisotropy under K0 condition. Comput. Geotech. 2020, 128, 103775. [Google Scholar] [CrossRef]

- Huang, S.; Lu, C.; Li, H.; He, J.; Wang, Q.; Yuan, P.; Wang, Y. Transmission rules of ultrasonic at the contact interface between soil medium in farmland and ultrasonic excitation transducer. Comput. Electron. Agric. 2021, 190, 106477. [Google Scholar] [CrossRef]

- Roessler, T.; Richter, C.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials–part I: Solving the problem of ambiguous parameter combinations. Powder Technol. 2019, 343, 803–812. [Google Scholar] [CrossRef]

- Richter, C.; Roessler, T.; Kunze, G.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials–Part II: Efficient optimization-based calibration. Powder Technol. 2020, 360, 967–976. [Google Scholar] [CrossRef]

- Li, P.; Ucgul, M.; Lee, S.H.; Saunders, C. A new approach for the automatic measurement of the angle of repose of granular materials with maximal least square using digital image processing. Comput. Electron. Agric. 2020, 172, 105356. [Google Scholar] [CrossRef]

- Wensrich, C.M.; Katterfeld, A. Rolling friction as a technique for modelling particle shape in DEM. Powder Technol. 2012, 217, 409–417. [Google Scholar] [CrossRef]

- Benvenuti, L.; Kloss, C.; Pirker, S. Identification of DEM simulation parameters by Artificial Neural Networks and bulk experiments. Powder Technol. 2016, 291, 456–465. [Google Scholar] [CrossRef]

- Do, H.Q.; Aragón, A.M.; Schott, D.L. A calibration framework for discrete element model parameters using genetic algorithms. Adv. Powder Technol. 2018, 29, 1393–1403. [Google Scholar] [CrossRef]

- Alonso-Marroquín, F.; Ramírez-Gómez, Á.; González-Montellano, C.; Balaam, N.; Hanaor, D.A.H.; Flores-Johnson, E.A.; Shen, L. Experimental and numerical determination of mechanical properties of polygonal wood particles and their flow analysis in silos. Granul. Matter 2013, 15, 811–826. [Google Scholar] [CrossRef]

- Marigo, M.; Stitt, E.H. Discrete element method (DEM) for industrial applications: Comments on calibration and validation for the modelling of cylindrical pellets. KONA Powder Part. J. 2015, 32, 236–252. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Els, D.N.J. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling. Comput. Electron. Agric. 2009, 65, 198–212. [Google Scholar] [CrossRef]

- Combarros, M.; Feise, H.J.; Zetzener, H.; Kwade, A. Segregation of particulate solids: Experiments and DEM simulations. Particuology 2014, 12, 25–32. [Google Scholar] [CrossRef]

- Li, Q.; Feng, M.; Zou, Z. Validation and calibration approach for discrete element simulation of burden charging in pre-reduction shaft furnace of COREX process. ISIJ Int. 2013, 53, 1365–1371. [Google Scholar] [CrossRef]

- Nakashima, H.; Shioji, Y.; Kobayashi, T.; Aoki, S.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. Determining the angle of repose of sand under low-gravity conditions using discrete element method. J. Terramech. 2011, 48, 17–26. [Google Scholar] [CrossRef]

- Zhanhua, S.O.N.G.; Hao, L.I.; Yinfa, Y.A.N.; Fuyang, T.I.A.N.; Yudao, L.I.; Fade, L.I. Calibration Method of Contact Characteristic Parameters of Soil in Mulberry Field Based on Unequal-diameter Particles DEM Theory. Trans. Chin. Soc. Agric. Mach. 2022, 53, 21–33. [Google Scholar]

- Shen, H.H.; Zhang, H.; Fan, J.K.; Xu, R.Y.; Zhang, X.M. A rock modeling method of multi-parameters fitting in EDEM. Rock Soil Mech. 2021, 42, 2298–2310. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Di Renzo, A.; Di Maio, F.P. Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem. Eng. Sci. 2004, 59, 525–541. [Google Scholar] [CrossRef]

- Huang, S.; Lu, C.; Li, H.; He, J.; Wang, Q.; Gao, Z.; Yuan, P.; Li, Y. The attenuation mechanism and regular of the acoustic wave on propagation path in farmland soil. Comput. Electron. Agric. 2022, 199, 107138. [Google Scholar] [CrossRef]

- Rianyoi, R.; Potong, R.; Ngamjarurojana, A.; Chaipanich, A. Mechanical, dielectric, ferroelectric and piezoelectric properties of 0–3 connectivity lead-free piezoelectric ceramic 0.94 Bi0. 5Na0. 5TiO3–0.06 BaTiO3/Portland cement composites. J. Mater. Sci. Mater. Electron. 2021, 32, 4695–4704. [Google Scholar] [CrossRef]

- Jiang, F. Research on the Piezoelectric Ultrasonic Nebulizer. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2014. [Google Scholar]

- Ucgul, M.; Fielke, J.M.; Saunders, C. 3D DEM tillage simulation: Validation of a hysteretic spring (plastic) contact model for a sweep tool operating in a cohesionless soil. Soil Tillage Res. 2014, 144, 220–227. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of tillage forces and soil movement of a one-third scale mouldboard plough. Biosyst. Eng. 2017, 155, 44–54. [Google Scholar] [CrossRef]

- Shi, L.; Zhao, W.; Sun, W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method. Trans. Chin. Soc. Agric. Eng. 2017, 33, 181–187. [Google Scholar]

- Rui, Z.; Dianlei, H.A.N.; Qiaoli, J.I.; Yuan, H.E.; Jianqiao, L.I. Calibration methods of sandy soil parameters in simulation of discrete element method. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 49–56. [Google Scholar]

- Huang, Y.; Hang, C.; Yuan, M.; Wang, B.; Zhu, R. Discrete element simulation and experiment on disturbance behavior of subsoiling. Trans. CSAM 2016, 47, 80–88. [Google Scholar]

- Dai, F.; Song, X.; Zhao, W.; Zhang, F.; Ma, H.; Ma, M. Simulative calibration on contact parameters of discrete elements for covering soil on whole plastic film mulching on double ridges. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2019, 50, 49–56. [Google Scholar]

| Object | Poisson’s Ratio | Shear Modulus (MPa) | Density (kg/m3) |

|---|---|---|---|

| steel | 0.25 | 7.9 × 1010 | 7860 |

| pzt | 0.32 | 7.5 × 1010 | 7900 |

| Object | Coefficient of Restitution | Coefficient of Static Friction | Coefficient of Rolling Friction |

|---|---|---|---|

| soil–steel | 0.5 | 0.5 | 0.05 |

| soil–pzt | 0.5 | 0.4 | 0.04 |

| Factor | Level | |

|---|---|---|

| −1 | 1 | |

| X1/Poisson’s ratio | 0.05 | 0.45 |

| X2/Shear modulus (MPa) | 500 | 2500 |

| X3/Density (kg/m3) | 1650 | 3650 |

| X4/Coefficient of restitution | 0.3 | 0.7 |

| X5/Coefficient of static frisction | 0.3 | 0.7 |

| X6/Coefficient of rolling friction | 0.15 | 0.35 |

| Factors and Levels | Poisson’s Ratio | Shear Modulus (MPa) | Coefficient of Restitution |

|---|---|---|---|

| −1 | 0.05 | 500 | 0.3 |

| 0 | 0.25 | 1500 | 0.5 |

| 1 | 0.45 | 2500 | 0.7 |

| No. | Experimental Level | Dominant Frequency Y1 (kHz) | Acoustic Velocity Y2 (m/s) | |||||

|---|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | A4 | A5 | A6 | |||

| 1 | −1 | 1 | 1 | 1 | −1 | −1 | 22.2 | 563.4 |

| 2 | 1 | 1 | −1 | −1 | −1 | 1 | 20.0 | 888.9 |

| 3 | −1 | 1 | 1 | −1 | 1 | 1 | 16.4 | 727.3 |

| 4 | 1 | −1 | 1 | 1 | −1 | 1 | 11.5 | 350.9 |

| 5 | 1 | −1 | 1 | 1 | 1 | −1 | 11.1 | 354 |

| 6 | 1 | 1 | −1 | 1 | 1 | 1 | 23.3 | 754.7 |

| 7 | 1 | 1 | 1 | −1 | −1 | −1 | 23.3 | 754.7 |

| 8 | −1 | −1 | 1 | −1 | 1 | 1 | 6.8 | 347.8 |

| 9 | −1 | −1 | −1 | 1 | −1 | 1 | 8.7 | 289.9 |

| 10 | 1 | −1 | −1 | −1 | 1 | −1 | 8.6 | 434.8 |

| 11 | −1 | 1 | −1 | 1 | 1 | −1 | 20.0 | 606.1 |

| 12 | −1 | −1 | −1 | −1 | −1 | −1 | 6.8 | 363.6 |

| Source of Variance | Dominant Frequency/Y1 | Acoustic Velocity/Y2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | df | Mean Square | F | p | Sum of Squares | df | Mean Sum of Square | F | p | |

| Model | 477.62 | 6 | 79.60 | 62.15 | 0.0002 | 4.621 × 105 | 6 | 77,015.33 | 104.12 | <0.0001 |

| X1 | 23.80 | 1 | 23.80 | 18.58 | 0.0076 | 34,122.67 | 1 | 34,122.67 | 46.13 | 0.0011 |

| X2 | 428.41 | 1 | 428.41 | 334.48 | <0.0001 | 3.867 × 105 | 1 | 3.86 × 105 | 522.75 | <0.0001 |

| X3 | 1.27 | 1 | 1.27 | 0.99 | 0.3655 | 4796.00 | 1 | 4796.00 | 6.48 | 0.0515 |

| X4 | 18.50 | 1 | 18.50 | 14.44 | 0.0126 | 29,810.30 | 1 | 29,810.30 | 40.30 | 0.0014 |

| X5 | 3.31 | 1 | 3.31 | 2.58 | 0.1690 | 14.74 | 1 | 14.74 | 0.020 | 0.8932 |

| X6 | 2.34 | 1 | 2.34 | 1.83 | 0.2343 | 6669.37 | 1 | 6669.37 | 9.02 | 0.0300 |

| Residual | 6.40 | 5 | 1.28 | 3698.33 | 5 | 739.71 | ||||

| Cor Total | 484.03 | 11 | 4.658 × 105 | 11 | ||||||

| Parameters | Dominant Frequency/Y1 | Acoustic Velocity/Y2 | ||||

|---|---|---|---|---|---|---|

| Standardization Effect | Mean Sum of Square | Contribution Degree/% | Standardization Effect | Mean Sum of Square | Contribution Degree (%) | |

| X1 | 2.82 | 23.80 | 4.92 | 106.65 | 34,122.7 | 7.33 |

| X2 | 11.95 | 428.41 | 88.51 | 359.02 | 386,679 | 83.02 |

| X3 | 0.65 | 1.27 | 0.26 | −9.98 | 4796 | 1.03 |

| X4 | 2.48 | 18.51 | 3.82 | −9.68 | 29,810.30 | 6.40 |

| X5 | −1.05 | 3.31 | 0.68 | 2.22 | 14.74 | 0.003 |

| X6 | −0.88 | 2.34 | 0.48 | 47.15 | 6669.37 | 1.43 |

| No. | Factor Level Value | Dominant Frequency Y1 (kHz) | Acoustic Velocity Y2 (m/s) | ||

|---|---|---|---|---|---|

| X1 | X2 | X4 | |||

| 1 | −1 | −1 | 0 | 7.5 | 315.2 |

| 2 | 1 | −1 | 0 | 9.3 | 404 |

| 3 | −1 | 1 | 0 | 17.9 | 666.7 |

| 4 | 1 | 1 | 0 | 22.2 | 800.0 |

| 5 | −1 | 0 | −1 | 12.5 | 588.2 |

| 6 | 1 | 0 | −1 | 15.2 | 740.7 |

| 7 | −1 | 0 | 1 | 16.1 | 470.6 |

| 8 | 1 | 0 | 1 | 18.9 | 606.1 |

| 9 | 0 | −1 | −1 | 7.3 | 400 |

| 10 | 0 | 1 | −1 | 17.5 | 806.3 |

| 11 | 0 | −1 | 1 | 9.8 | 307.7 |

| 12 | 0 | 1 | 1 | 22.2 | 645.2 |

| 13 | 0 | 0 | 0 | 15.6 | 571.4 |

| 14 | 0 | 0 | 0 | 15.2 | 579.6 |

| 15 | 0 | 0 | 0 | 15.9 | 565.1 |

| 16 | 0 | 0 | 0 | 15.3 | 575.6 |

| 17 | 0 | 0 | 0 | 15.6 | 564.8 |

| Source of Variance | Dominant Frequency/Y1 | Acoustic Velocity/Y2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Free- Dom | Mean Square | F | p | Sum of Squares | Free- Dom | Mean Square | F | p | |

| Model | 317.31 | 9 | 35.26 | 593.97 | <0.0001 | 3.536 × 105 | 9 | 39,293.07 | 385.86 | <0.0001 |

| X1 | 16.82 | 1 | 16.82 | 283.37 | <0.0001 | 32,525.25 | 1 | 32,525.25 | 319.40 | <0.0001 |

| X2 | 263.35 | 1 | 263.35 | 4436.72 | <0.0001 | 2.78 × 105 | 1 | 2.78 × 105 | 2729.96 | <0.0001 |

| X4 | 26.28 | 1 | 26.28 | 442.76 | <0.0001 | 31,953.92 | 1 | 31,953.92 | 313.79 | <0.0001 |

| X1X2 | 1.56 | 1 | 1.56 | 26.32 | 0.0014 | 495.06 | 1 | 495.06 | 4.86 | 0.0633 |

| X1X4 | 2.5 × 10−3 | 1 | 2.5 × 10−3 | 0.042 | 0.8432 | 72.25 | 1 | 72.25 | 0.71 | 0.4274 |

| X2X4 | 1.21 | 1 | 1.21 | 20.39 | 0.0027 | 1183.36 | 1 | 1183.36 | 11.62 | 0.0113 |

| X12 | 0.034 | 1 | 0.034 | 0.57 | 0.4732 | 1423.58 | 1 | 1423.58 | 13.98 | 0.0073 |

| X22 | 8.08 | 1 | 8.08 | 136.07 | <0.0001 | 7862.40 | 1 | 7862.40 | 77.21 | <0.0001 |

| X42 | 0.018 | 1 | 0.018 | 0.30 | 0.6011 | 577.61 | 1 | 577.61 | 5.67 | 0.0488 |

| Residual | 0.42 | 7 | 0.059 | 712.82 | 7 | 101.83 | ||||

| Lack of Fit | 0.11 | 3 | 0.036 | 0.47 | 0.7221 | 544.74 | 3 | 181.58 | 4.32 | 0.0957 |

| Pure Error | 0.31 | 4 | 0.077 | 168.08 | 4 | 42.02 | ||||

| Cor Total | 317.72 | 16 | 3.544 × 105 | 16 | ||||||

| Optimization Index Type (Target Value) | Dominant Frequency (18 kHz) | Acoustic Velocity (507 m/s) | Dominant Frequency (18 kHz) Acoustic Velocity (507 m/s) | |

|---|---|---|---|---|

| Optimal parameter combination of fitting model prediction | Poisson’s ratio | 0.25 | 0.09 | 0.3 |

| Shear Modulus (MPa) | 1836 | 1165 | 1407 | |

| Coefficient of restitution | 0.56 | 0.37 | 0.79 | |

| Fitting model prediction | Dominant frequency (kHz) | 18 | / | 18 |

| Acoustic velocity (m/s) | / | 507 | 507 | |

| Simulation verification | Dominant frequency (kHz) | 17.5 | 11.6 | 17.2 |

| Acoustic velocity (m/s) | 634.9 | 506.3 | 493.8 | |

| Error between simulation verification and experimental | Dominant frequency (%) | 2.80 | 35.60 | 4.4 |

| Acoustic velocity (%) | 25.20 | 0.14 | 2.60 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Lu, C.; Li, H.; He, J.; Wang, Q.; Yuan, P.; Xu, J.; Jiang, S.; He, D. Calibration of Acoustic-Soil Discrete Element Model and Analysis of Influencing Factors on Accuracy. Remote Sens. 2023, 15, 943. https://doi.org/10.3390/rs15040943

Huang S, Lu C, Li H, He J, Wang Q, Yuan P, Xu J, Jiang S, He D. Calibration of Acoustic-Soil Discrete Element Model and Analysis of Influencing Factors on Accuracy. Remote Sensing. 2023; 15(4):943. https://doi.org/10.3390/rs15040943

Chicago/Turabian StyleHuang, Shenghai, Caiyun Lu, Hongwen Li, Jin He, Qingjie Wang, Panpan Yuan, Jing Xu, Shan Jiang, and Dong He. 2023. "Calibration of Acoustic-Soil Discrete Element Model and Analysis of Influencing Factors on Accuracy" Remote Sensing 15, no. 4: 943. https://doi.org/10.3390/rs15040943