Extraction and Characterization of Microplastics from Portuguese Industrial Effluents

Abstract

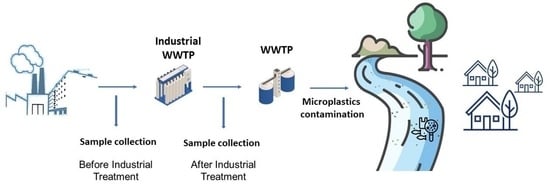

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Extraction of the Microplastics

2.3. Characterization and Quantification of Microplastics

2.4. Microplastics Identification

2.5. Statistical Analysis

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbasi, S.; Soltani, N.; Keshavarzi, B.; Moore, F.; Turner, A.; Hassanaghaei, M. Microplastics in different tissues of fish and prawn from the Musa Estuary, Persian Gulf. Chemosphere 2018, 205, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Al-Azzawi, M.S.M.; Kefer, S.; Weißer, J.; Reichel, J.; Schwaller, C.; Glas, K.; Knoop, O.; Drewes, J.E. Validation of Sample Preparation Methods for Microplastic Analysis in Wastewater Matrices—Reproducibility and Standardization. Water 2020, 12, 2445. [Google Scholar] [CrossRef]

- Aldalbahi, A.; El-Naggar, M.; El-Newehy, M.; Rahaman, M.; Hatshan, M.; Khattab, T. Effects of Technical Textiles and Synthetic Nanofibers on Environmental Pollution. Polymers 2021, 13, 155. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef]

- Antunes, J.; Frias, J.; Sobral, P. Microplastics on the Portuguese coast. Mar. Pollut. Bull. 2018, 131, 294–302. [Google Scholar] [CrossRef]

- Atugoda, T.; Vithanage, M.; Wijesekara, H.; Bolan, N.; Sarmah, A.K.; Bank, M.S.; You, S.; Ok, Y.S. Interactions between microplastics, pharmaceuticals and personal care products: Implications for vector transport. Environ. Int. 2021, 149, 106367. [Google Scholar] [CrossRef]

- Besley, A.; Vijver, M.G.; Behrens, P.; Bosker, T. A standardized method for sampling and extraction methods for quantifying microplastics in beach sand. Mar. Pollut. Bull. 2017, 114, 77–83. [Google Scholar] [CrossRef]

- Blanco, L.; Hermosilla, D.; Negro, C.; Swinnen, N.; Prieto, D.; Blanco, Á. Assessing demineralization treatments for PVC effluent reuse in the resin polymerization step. Environ. Sci. Pollut. Res. 2017, 24, 16631–16638. [Google Scholar] [CrossRef]

- Bretas Alvim, C.; Mendoza-Roca, J.A.; Bes-Piá, A. Wastewater treatment plant as microplastics release source—Quantification and identification techniques. J. Environ. Manag. 2020, 255, 109739. [Google Scholar] [CrossRef]

- Caputo, F.; Vogel, R.; Savage, J.; Vella, G.; Law, A.; Della Camera, G.; Hannon, G.; Peacock, B.; Mehn, D.; Ponti, J.; et al. Measuring particle size distribution and mass concentration of nanoplastics and microplastics: Addressing some analytical challenges in the sub-micron size range. J. Colloid Interface Sci. 2021, 588, 401–417. [Google Scholar] [CrossRef]

- Carney Almroth, B.M.; Åström, L.; Roslund, S.; Petersson, H.; Johansson, M.; Persson, N.-K. Quantifying shedding of synthetic fibers from textiles; a source of microplastics released into the environment. Environ. Sci. Pollut. Res. 2018, 25, 1191–1199. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Costa, C.Q.V.; Cruz, J.; Martins, J.; Teodósio, M.A.A.; Jockusch, S.; Ramamurthy, V.; Da Silva, J.P. Fluorescence sensing of microplastics on surfaces. Environ. Chem. Lett. 2021, 19, 1797–1802. [Google Scholar] [CrossRef]

- Da Costa, J.; Duarte, A.; Rocha-Santos, T. Microplastics—Occurrence, Fate and Behaviour in the Environment. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Deng, H.; Wei, R.; Luo, W.; Hu, L.; Li, B.; Di, Y.; Shi, H. Microplastic pollution in water and sediment in a textile industrial area. Environ. Pollut. 2020, 258, 113658. [Google Scholar] [CrossRef] [PubMed]

- Duan, J.; Bolan, N.; Li, Y.; Ding, S.; Atugoda, T.; Vithanage, M.; Sarkar, B.; Tsang, D.C.W.; Kirkham, M.B. Weathering of microplastics and interaction with other coexisting constituents in terrestrial and aquatic environments. Water Res. 2021, 196, 117011. [Google Scholar] [CrossRef]

- Elkhatib, D.; Oyanedel-Craver, V. A Critical Review of Extraction and Identification Methods of Microplastics in Wastewater and Drinking Water. Environ. Sci. Technol. 2020, 54, 7037–7049. [Google Scholar] [CrossRef]

- Fernando, J. Gómez, Rima Simonetta. 2019. Available online: http://www.weforum.org/agenda/2019/10/plastics-what-are-they-explainer/ (accessed on 4 May 2021).

- Gatidou, G.; Arvaniti, O.S.; Stasinakis, A.S. Review on the occurrence and fate of microplastics in Sewage Treatment Plants. J. Hazard. Mater. 2019, 367, 504–512. [Google Scholar] [CrossRef]

- Ghosh, A. Performance modifying techniques for recycled thermoplastics. Resour. Conserv. Recycl. 2021, 175, 105887. [Google Scholar] [CrossRef]

- Goldschmidt, A.; Streitberger, H.-J. BASF Handbook on Basics of Coating Technology, 2nd rev. ed.; Vincentz Network: Hannover, Germany, 2007. [Google Scholar]

- Gregory, M.R. Environmental implications of plastic debris in marine settings—Entanglement, ingestion, smothering, hangers-on, hitch-hiking and alien invasions. Phil. Trans. R. Soc. B 2009, 364, 2013–2025. [Google Scholar] [CrossRef]

- Guo, X.; Wang, J. The chemical behaviors of microplastics in marine environment: A review. Mar. Pollut. Bull. 2019, 142, 1–14. [Google Scholar] [CrossRef]

- Hale, R.; Seeley, M.; La Guardia, M.; Mai, L.; Zeng, E. A Global Perspective on Microplastics. J. Geophys. Res. Ocean. 2020, 125, e2018JC014719. [Google Scholar] [CrossRef]

- Hu, K.; Tian, W.; Yang, Y.; Nie, G.; Zhou, P.; Wang, Y.; Duan, X.; Wang, S. Microplastics remediation in aqueous systems: Strategies and technologies. Water Res. 2021, 198, 117144. [Google Scholar] [CrossRef] [PubMed]

- John, J.; Nandhini, A.R.; Velayudhaperumal Chellam, P.; Sillanpää, M. Microplastics in mangroves and coral reef ecosystems: A review. Environ. Chem. Lett. 2022, 20, 397–416. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.W.; An, Y.-J. Edible size of polyethylene microplastics and their effects on springtail behavior. Environ. Pollut. 2020, 266, 115255. [Google Scholar] [CrossRef] [PubMed]

- Koelmans, A.A.; Besseling, E.; Shim, W.J. Nanoplastics in the Aquatic Environment. Critical Review. In Marine Anthropogenic Litter; Bergmann, M., Gutow, L., Klages, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 325–340. [Google Scholar] [CrossRef] [Green Version]

- Kotwani, A.; Joshi, J.; Kaloni, D. Pharmaceutical effluent: A critical link in the interconnected ecosystem promoting antimicrobial resistance. Environ. Sci. Pollut. Res. 2021, 28, 32111–32124. [Google Scholar] [CrossRef] [PubMed]

- Lourenço, P.M.; Serra-Gonçalves, C.; Ferreira, J.L.; Catry, T.; Granadeiro, J.P. Plastic and other microfibers in sediments, macroinvertebrates and shorebirds from three intertidal wetlands of southern Europe and west Africa. Environ. Pollut. 2017, 231, 123–133. [Google Scholar] [CrossRef]

- Magalhães, S. Microplastics in Ecosystems: From Current Trends to Bio-Based Removal Strategies. Molecules 2020, 25, 3954. [Google Scholar] [CrossRef]

- Martins, J.; Sobral, P. Plastic marine debris on the Portuguese coastline: A matter of size? Mar. Pollut. Bull. 2011, 62, 2649–2653. [Google Scholar] [CrossRef]

- Mason, S.A.; Garneau, D.; Sutton, R.; Chu, Y.; Ehmann, K.; Barnes, J.; Fink, P.; Papazissimos, D.; Rogers, D.L. Microplastic pollution is widely detected in US municipal wastewater treatment plant effluent. Environ. Pollut. 2016, 218, 1045–1054. [Google Scholar] [CrossRef]

- Misra, A.; Zambrzycki, C.; Kloker, G.; Kotyrba, A.; Anjass, M.H.; Franco Castillo, I.; Mitchell, S.G.; Güttel, R.; Streb, C. Water Purification and Microplastics Removal Using Magnetic Polyoxometalate-Supported Ionic Liquid Phases (magPOM-SILPs). Angew. Chem. Int. Ed. 2020, 59, 1601–1605. [Google Scholar] [CrossRef] [Green Version]

- Nan, M.I.; Lakatos, E.; Giurgi, G.-I.; Szolga, L.; Po, R.; Terec, A.; Jungsuttiwong, S.; Grosu, I.; Roncali, J. Mono- and di-substituted pyrene-based donor-π-acceptor systems with phenyl and thienyl π-conjugating bridges. Dye. Pigment. 2020, 181, 108527. [Google Scholar] [CrossRef]

- Chias, J.; Hoffman, J. Consumo de Plástico em Portugal: Estamos no Bom Caminho? 2019. National Geographic. Available online: https://www.natgeo.pt/planeta-ou-plastico/2019/02/consumo-de-plastico-em-portugal-estamos-no-bom-caminho (accessed on 13 May 2022).

- Nuelle, M.-T.; Dekiff, J.H.; Remy, D.; Fries, E. A new analytical approach for monitoring microplastics in marine sediments. Environ. Pollut. 2014, 184, 161–169. [Google Scholar] [CrossRef] [PubMed]

- O’Kelly, B.C.; El-Zein, A.; Liu, X.; Patel, A.; Fei, X.; Sharma, S.; Mohammad, A.; Goli, V.S.N.S.; Wang, J.J.; Li, D.; et al. Microplastics in soils: An environmental geotechnics perspective. Environ. Geotech. 2021, 8, 586–618. [Google Scholar] [CrossRef]

- Park, J.H.; Jang, M.D.; Shin, M.J. Solvatochromic hydrogen bond donor acidity of cyclodextrins and reversed-phase liquid chromatographic retention of small molecules on a β-cyclodextrin-bonded silica stationary phase. J. Chromatogr. A 1992, 595, 45–52. [Google Scholar] [CrossRef]

- Peets, P.; Leito, I.; Pelt, J.; Vahur, S. Identification and classification of textile fibres using ATR-FT-IR spectroscopy with chemometric methods. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 173, 175–181. [Google Scholar] [CrossRef]

- Prata, J.C.; da Costa, J.P.; Lopes, I.; Duarte, A.C.; Rocha-Santos, T. Environmental status of (micro)plastics contamination in Portugal. Ecotoxicol. Environ. Saf. 2020, 200, 110753. [Google Scholar] [CrossRef]

- Prata, J.C.; Reis, V.; Matos, J.T.V.; da Costa, J.P.; Duarte, A.C.; Rocha-Santos, T. A new approach for routine quantification of microplastics using Nile Red and automated software (MP-VAT). Sci. Total Environ. 2019, 690, 1277–1283. [Google Scholar] [CrossRef]

- Rodríguez-Narvaez, O.M.; Goonetilleke, A.; Perez, L.; Bandala, E.R. Engineered technologies for the separation and degradation of microplastics in water: A review. Chem. Eng. J. 2021, 414, 128692. [Google Scholar] [CrossRef]

- Sancataldo, G.; Ferrara, V.; Bonomo, F.P.; Martino, D.F.C.; Licciardi, M.; Pignataro, B.G.; Vetri, V. Identification of microplastics using 4-dimethylamino-4′-nitrostilbene solvatochromic fluorescence. Microsc. Res. Tech. 2021, 84, 2820–2831. [Google Scholar] [CrossRef]

- Schell, T.; Hurley, R.; Nizzetto, L.; Rico, A.; Vighi, M. Spatio-temporal distribution of microplastics in a Mediterranean river catchment: The importance of wastewater as an environmental pathway. J. Hazard. Mater. 2021, 420, 126481. [Google Scholar] [CrossRef]

- Thompson, R.C. Lost at Sea: Where Is All the Plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef]

- Uddin, S.; Fowler, S.W.; Saeed, T.; Naji, A.; Al-Jandal, N. Standardized protocols for microplastics determinations in environmental samples from the Gulf and marginal seas. Mar. Pollut. Bull. 2020, 158, 111374. [Google Scholar] [CrossRef]

- Ugwu, K.; Herrera, A.; Gómez, M. Microplastics in marine biota: A review. Mar. Pollut. Bull. 2021, 169, 112540. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.; Lambert, S. (Eds.) Freshwater Microplastics: Emerging Environmental Contaminants? In The Handbook of Environmental Chemistry; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef] [Green Version]

- Wei, S.; Luo, H.; Zou, J.; Chen, J.; Pan, X.; Rousseau, D.P.L.; Li, J. Characteristics and removal of microplastics in rural domestic wastewater treatment facilities of China. Sci. Total Environ. 2020, 739, 139935. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Liang, T.; Hu, W.; Du, M.; Zhang, S.; Zhang, Y.; Anslyn, E.V.; Sun, X. Chemically Triggered Click and Declick Reactions: Application in Synthesis and Degradation of Thermosetting Plastics. ACS Macro Lett. 2021, 10, 1125–1131. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wang, J.; Liu, X.; Qu, F.; Wang, X.; Wang, X.; Li, Y.; Sun, Y. Microplastics in the environment: A review of analytical methods, distribution, and biological effects. TrAC Trends Anal. Chem. 2019, 111, 62–72. [Google Scholar] [CrossRef]

- Ziajahromi, S.; Neale, P.A.; Rintoul, L.; Leusch, F.D.L. Wastewater treatment plants as a pathway for microplastics: Development of a new approach to sample wastewater-based microplastics. Water Res. 2017, 112, 93–99. [Google Scholar] [CrossRef]

- Prata, J.C.; da Costa, J.P.; Duarte, A.C.; Rocha-Santos, T. Methods for sampling and detection of microplastics in water and sediment: A critical review. TrAC Trends Anal. Chem. 2018, 110, 150–159. [Google Scholar] [CrossRef]

- Gulmine, J.; Janissek, P.; Heise, H.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Pandey, M.; Joshi, G.M.; Mukherjee, A.; Thomas, P. Electrical properties and thermal degradation of poly(vinyl chloride)/polyvinylidene fluoride/ZnO polymer nanocomposites. Polym. Int. 2016, 65, 1098–1106. [Google Scholar] [CrossRef]

| Industries | Before Treatment (mV) | After Treatment (mV) |

|---|---|---|

| Resin | −13.13 (±0.90) * | −4.93 (±0.24) |

| Paint | −3.94 (±0.21) | −6.20 (±0.18) |

| Pharmaceutical | 8.47 (±1.07) | −9.90 (±0.70) |

| PVC | −12.30 (±0.56) * | −7.89 (±0.08) |

| Textile | −28.30 (±1.47) | −31.13 (±1.40) |

| Before in-House WWTP (g MPs/100 mL Effluent) | After in-House WWTP (g MPs/100 mL Effluent) | MPs Released after in-House WWTP (g MPs/Ton Effluent) | |

|---|---|---|---|

| Resins | 0.044 ± 0.020 | 0.004 ± 0.002 | 41.66 |

| Paint | 0.172 ± 0.095 | 0.009 ± 0.004 | 89.01 |

| Pharmaceutical | 0.004 ± 0.003 | 0.002 ± 0.002 | 24.69 |

| PVC | 0.029 ± 0.001 | 0.007 ± 0.006 | 70.58 |

| Textile | 0.002 ± 0.002 | 0.002 ± 0.002 | 15.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magalhães, S.; Alves, L.; Romano, A.; Medronho, B.; Rasteiro, M.d.G. Extraction and Characterization of Microplastics from Portuguese Industrial Effluents. Polymers 2022, 14, 2902. https://doi.org/10.3390/polym14142902

Magalhães S, Alves L, Romano A, Medronho B, Rasteiro MdG. Extraction and Characterization of Microplastics from Portuguese Industrial Effluents. Polymers. 2022; 14(14):2902. https://doi.org/10.3390/polym14142902

Chicago/Turabian StyleMagalhães, Solange, Luís Alves, Anabela Romano, Bruno Medronho, and Maria da Graça Rasteiro. 2022. "Extraction and Characterization of Microplastics from Portuguese Industrial Effluents" Polymers 14, no. 14: 2902. https://doi.org/10.3390/polym14142902