Structure and Properties of Polyamide Fabrics with Insect-Repellent Functionality by Electrospinning and Oxygen Plasma-Treated Surface Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Electrospinning

2.3. Oxygen Plasma Treatment

2.4. Preparation of Insect-Repellent Polyamide Fabrics

2.5. Characterization of Polyamide Samples

2.5.1. Surface Morphology

2.5.2. Capillary Flow Porometry

2.5.3. Fourier Transform Infrared (FTIR)

2.5.4. X-ray Photoelectron Spectroscopy (XPS)

2.5.5. Tensile Testing

2.6. Characterization of Permethrin-Treated Polyamide Fabrics

2.6.1. Determination of Permethrin Concentrations in the Polyamide Fabrics

2.6.2. Washing Fastness of the Permethrin-Treated Polyamide Fabrics

2.6.3. Light (UV) Fastness of the Permethrin-Treated Polyamide Fabrics

2.6.4. Assessment of Insect-Repellent Performance

3. Results and Discussion

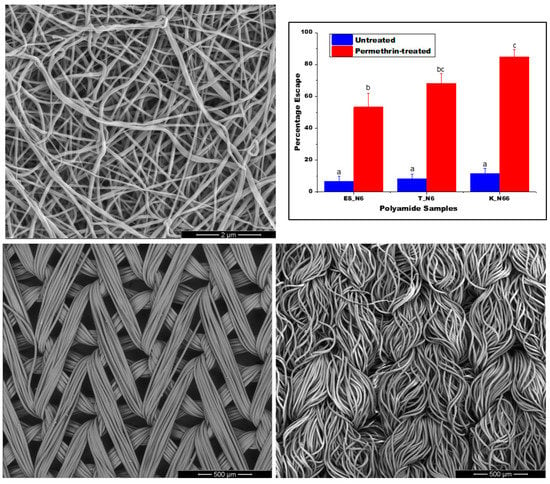

3.1. Morphology of Polyamide Fabrics

3.2. Pore Size and Distribution of Polyamide Fabrics

3.3. FTIR Spectra of As-Spun/Received Polyamide Fabrics

3.4. XPS Results of Plasma-Treated and Untreated Polyamide Samples

3.5. Tensile Properties of Polyamide Fabrics

3.6. Permethrin Contents on Polyamide Samples

3.7. Washing/Light Fastness of Permethrin-Containing Polyamide Fabrics

3.8. Contact Irritancy Assay of Mosquito Repellency

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Githeko, A.K.; Lindsay, S.W.; Confalonieri, U.E.; Patz, J.A. Climate change and vector-borne diseases: A regional analysis. Bull. World Health Organ. 2000, 78, 1136–1147. [Google Scholar]

- Faulde, M.; Uedelhoven, W. A new clothing impregnation method for personal protection against ticks and biting insects. Int. J. Med. Microbiol. 2006, 296, 225–229. [Google Scholar] [CrossRef]

- WHO. Vectors of Diseases: Hazards and Risks for Travelers—Part I. Can. Commun. Dis. Rep. 2001, 25, 189–194. [Google Scholar]

- WHO. Vectors of Diseases: Hazards and Risks for Travelers—Part II. Can. Commun. Dis. Rep. 2001, 26, 201–203. [Google Scholar]

- Kettel, M.J.; Schaefer, K.; Groll, J.; Möller, M. Nanogels with High Active β-Cyclodextrin Content as Physical Coating System with Sustained Release Properties. ACS Appl. Mater. Interfaces 2014, 6, 2300–2311. [Google Scholar] [CrossRef]

- Faulde, M.K.; Uedelhoven, W.M.; Robbins, R.G. Contact Toxicity and Residual Activity of Different Permethrin-Based Fabric Impregnation Methods for Aedes aegypti (Diptera: Culicidae), Ixodes ricinus (Acari: Ixodidae), and Lepisma saccharina (Thysanura: Lepismatidae). J. Med. Entomol. 2003, 40, 935–941. [Google Scholar] [CrossRef]

- Interlandi, J. Can Permethrin Treated Clothing Help You Avoid Mosquito Bites? Consumer Reports: Yonkers, NY, USA, 2016. [Google Scholar]

- Frances, S.P.; Cooper, R.D. Personal protective measures against mosquitoes: Insecticide-treated uniforms, bednets and tents. ADF Health 2007, 8, 50–56. [Google Scholar]

- Lestremau, F.; Willemin, M.-E.; Chatellier, C.; Desmots, S.; Brochot, C. Determination of cis-permethrin, trans-permethrin and associated metabolites in rat blood and organs by gas chromatography–ion trap mass spectrometry. Anal. Bioanal. Chem. 2014, 406, 3477–3487. [Google Scholar] [CrossRef] [Green Version]

- Agency. Available online: https://www.epa.gov/insect-repellents/repellent-treated-clothing (accessed on 15 September 2020).

- Kadolph, S. Chapter 8: Synthetic Fibers; Kadolph, S., Ed.; Pearson Education Inc.: New York, NY, USA, 2010. [Google Scholar]

- Pappas, D.; Bujanda, A.; Demaree, J.; Hirvonen, J.K.; Kosik, W.; Jensen, R.; McKnight, S. Surface modification of polyamide fibers and films using atmospheric plasmas. Surf. Coat. Technol. 2006, 201, 4384–4388. [Google Scholar] [CrossRef]

- Yetisen, A.K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M.R.; Hinestroza, J.P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S.-H. Nanotechnology in Textiles. ACS Nano 2016, 10, 3042–3068. [Google Scholar] [CrossRef]

- Xiang, C.; Frey, M.W.; Taylor, A.G.; Rebovich, M.E. Selective chemical absorbance in electrospun nonwovens. J. Appl. Polym. Sci. 2007, 106, 2363–2370. [Google Scholar]

- Khoobdel, M.S.; Vatandoost, H.; Rassi, Y.; Abaei, M.R.; Ladonni, H.; Mehrabi Tavana, A.; Bahrami, S.H.; Najaffi, M.E.; Mosakazemi, S.H.; Khamisabadi, K.; et al. Field Evaluation of Permethrin-treated Military Uniforms Against Anopheles stephensi and 4 species of Culex (Diptera:Culicidae) in Iran. J. Entomol. 2006, 3, 108–118. [Google Scholar]

- Eamsila, C.; Frances, S.P.; Strickman, D. Evaluation of permethrin-treated military uniforms for personal protection against malaria in northeastern Thailand. J. Am. Mosq. Control. Assoc. 1994, 10, 515–521. [Google Scholar]

- Evans, S.R.; Korch, G.W.; Lawson, M.A. Comparative Field Evaluation of Permethrin and Deet-Treated Military Uniforms for Personal Protection against Ticks (Acari). J. Med. Entomol. 1990, 27, 829–834. [Google Scholar]

- Mount, G.A.; Snoddy, E.L. Pressurized Sprays of Permethrin and deet on Clothing for Personal Protection against the Lone Star Tick and the American Dog Tick (Acari: Ixodidae) 1. J. Econ. Entomol. 1983, 76, 529–531. [Google Scholar]

- Abdelhameed, R.M.; Kamel, O.M.; Amr, A.; Rocha, J.; Silva, A.M.S. Antimosquito Activity of a Titanium–Organic Framework Supported on Fabrics. ACS Appl. Mater. Interfaces 2017, 9, 22112–22120. [Google Scholar]

- N’Guessan, R.; Knols, B.G.; Pennetier, C.; Rowland, M. DEET microencapsulation: A slow-release formulation enhancing the residual efficacy of bed nets against malaria vectors. Trans. R. Soc. Trop. Med. Hyg. 2008, 102, 259–262. [Google Scholar]

- Yao, T.T.; Wang, L.K.; Cheng, J.L.; Hu, Y.Z.; Zhao, J.H.; Zhu, G.N. Optimization of pyrethroid and repellent on fabrics against Stegomyia albopicta (=Aedes albopictus) using a microencapsulation technique. Med. Vet. Entomol. 2015, 29, 37–43. [Google Scholar]

- Abdel-Mohdy, F.A.; Fouda, M.M.G.; Rehan, M.; Ali, A.S. Repellency of controlled-release treated-cotton fabrics based on permethrin and bioallethrin against mosquitoes. J. Text. Inst. 2009, 100, 695–701. [Google Scholar]

- Abdel-Mohdy, F.; Fouda, M.M.G.; Rehan, M.; Aly, A. Repellency of controlled-release treated cotton fabrics based on cypermethrin and prallethrin. Carbohydr. Polym. 2008, 73, 92–97. [Google Scholar]

- Xiang, C.; Frey, M. Increasing Mechanical Properties of 2-D-Structured Electrospun Nylon 6 Non-Woven Fiber Mats. Materials 2016, 9, 270. [Google Scholar] [CrossRef] [Green Version]

- Yip, J.; Chan, K.; Sin, K.M.; Lau, K.S. Low temperature plasma-treated nylon fabrics. J. Mater. Process. Technol. 2002, 123, 5–12. [Google Scholar] [CrossRef]

- Jena, A.; Gupta, K. Characterization of pore structure of filtration media containing hydrophobic and hydrophilic pores. Fluid Part. Sep. J. 2002, 14, 227–241. [Google Scholar]

- NIST 98. National Institute of Standards and Technology in 98 Mass Spectral Libraries; Agilent Technologies: Santa Clara, CA, USA, 2000. [Google Scholar]

- Annandarajah, C.; Norris, E.J.; Funk, R.; Xiang, C.; Grewell, D.; Coats, J.R.; Mishek, D.; Maloy, B. Biobased plastics with insect-repellent functionality. Polym. Eng. Sci. 2019, 59, E460–E467. [Google Scholar] [CrossRef]

- Grieco, J.P.; Achee, N.L.; Sardelis, M.R.; Chauhan, K.R.; Roberts, D.R. A novel high-throughput screening system to evaluate the behavioral response of adult mosquitoes to chemicals. J. Am. Mosq. Control. Assoc. 2005, 21, 404–411. [Google Scholar]

- Upadhyay, D.J.; Cui, N.-Y.; Anderson, C.; Brown, N. A comparative study of the surface activation of polyamides using an air dielectric barrier discharge. Colloids Surf. A Physicochem. Eng. Asp. 2004, 248, 47–56. [Google Scholar] [CrossRef]

- Achee, N.L.; Sardelis, M.R.; Dusfour, I.; Chauhan, K.R.; Grieco, J.P. Characterization of Spatial Repellent, Contact Irritant, and Toxicant Chemical Actions of Standard Vector Control Compounds. J. Am. Mosq. Control. Assoc. 2009, 25, 156–167. [Google Scholar]

| Samples | Mean Flow Pore Diameter (um) |

|---|---|

| ES_N6 | 0.23 ± 0.05 |

| K_N66 | 27.6 ± 1.0 |

| T_N6 | 143.2 ± 0.2 |

| Polyamide Samples | O1s/C1s | O1s Increasing after Plasma (%) | |

|---|---|---|---|

| Untreated | Plasma | ||

| ES_N6 | 0.192 | 0.263 | 31 |

| K_N66 | 0.216 | 0.309 | 30 |

| T_N6 | 0.897 | 0.998 | 16 |

| Samples | Ultimate Tensile Strength (MPa) | Elongation at Failure (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| K_N66 | 6.12 a | 898.8 c | 1.87 f |

| T_N6 | 25.65 b | 252.84 d | 21.03 g |

| ES_N6 | 17.4 b | 74.85 e | 32.48 g |

| Samples | Capture Efficiencies (%) |

|---|---|

| I-ES_N6 | 98.4 ± 22.8 |

| P-ES_N6 | 35.6 ± 2 |

| P-K_N66 | 16.4 ± 1.6 |

| P-T_N6 | 17.6 ± 4 |

| A-ES_N6 | 47.6 ± 16 |

| A-K_N66 | 14 ± 4.4 |

| A-T_N6 | 25.6 ± 6 |

| Permethrin-Treated Fabrics | Knockdown in Viewing Chamber | Knockdown in Exposure Chamber |

|---|---|---|

| ES_N6 | 1.67 ± 1.67 | 0 ± 0 |

| T_N6 | 5 ± 3.42 | 0 ± 0 |

| K_N66 | 20 ± 4.47 | 1.67 ± 1.67 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, C.; Etrick, N.R.; Frey, M.W.; Norris, E.J.; Coats, J.R. Structure and Properties of Polyamide Fabrics with Insect-Repellent Functionality by Electrospinning and Oxygen Plasma-Treated Surface Coating. Polymers 2020, 12, 2196. https://doi.org/10.3390/polym12102196

Xiang C, Etrick NR, Frey MW, Norris EJ, Coats JR. Structure and Properties of Polyamide Fabrics with Insect-Repellent Functionality by Electrospinning and Oxygen Plasma-Treated Surface Coating. Polymers. 2020; 12(10):2196. https://doi.org/10.3390/polym12102196

Chicago/Turabian StyleXiang, Chunhui, Nicholas R. Etrick, Margaret W. Frey, Edmund J. Norris, and Joel R. Coats. 2020. "Structure and Properties of Polyamide Fabrics with Insect-Repellent Functionality by Electrospinning and Oxygen Plasma-Treated Surface Coating" Polymers 12, no. 10: 2196. https://doi.org/10.3390/polym12102196