Solar Cells for Indoor Applications: Progress and Development

Abstract

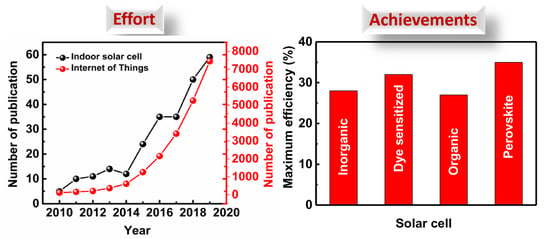

:1. Introduction

2. Sources of Indoor Light

3. PV Cells for Indoor Applications

3.1. Solar Cells Based on Inorganic Materials for Indoor Applications

3.2. DSSCs for Indoor Applications

3.3. Solar Cells Based on Organic Materials for Indoor Applications

3.4. Solar Cells for Indoor Applications Based on Perovskite Materials

4. Future Prospects

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mathews, I.; Kantareddy, S.N.; Buonassisi, T.; Peters, I.M. Technology and Market Perspective for Indoor Photovoltaic Cells. Joule 2019, 3, 1415–1426. [Google Scholar] [CrossRef]

- Liu, X.; Sánchez-Sinencio, E. A highly efficient ultralow photovoltaic power harvesting system with MPPT for internet of things smart nodes. IEEE Trans. Very Large Scale Integr. (Vlsi) Syst. 2015, 23, 3065–3075. [Google Scholar] [CrossRef]

- Kjellby, R.A.; Johnsrud, T.E.; Loetveit, S.E.; Cenkeramaddi, L.R.; Hamid, M.; Beferull-Lozano, B. Self-powered iot device for indoor applications. In the 31st International Conference on VLSI Design and 17th International Conference on Embedded Systems (VLSID), Pune, India, 6–10 January 2018; IEEE: New York, NY, USA, 2018; Volume 1, pp. 455–456. [Google Scholar]

- Jeon, K.E.; She, J.; Soonsawad, P.; Ng, P.C. Ble beacons for internet of things applications: Survey, challenges, and opportunities. Ieee Internet Things J. 2018, 5, 811–828. [Google Scholar] [CrossRef]

- Pubill, D.; Serra, J.; Verikoukis, C. Harvesting artificial light indoors to power perpetually a Wireless Sensor Network node. In the IEEE 23rd International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (CAMAD), Barcelona, Spaim, 17–19 September 2018; IEEE: New York, NY, USA, 2018; Volume 1, pp. 1–6. [Google Scholar]

- Jayakumar, H.; Lee, K.; Lee, W.S.; Raha, A.; Kim, Y.; Raghunathan, V. Powering the internet of things. In the International Symposium on Low Power Electronics and Design, LA Jolla, CA, USA, 11–13 August 2014; IEEE: New York, NY, USA, 2014; pp. 375–380. [Google Scholar]

- Kansal, A.; Hsu, J.; Zahedi, S.; Srivastava, M.B. Power management in energy harvesting sensor networks. ACM Trans. Embed. Comput. Syst. (Tecs) 2007, 6, 32-es. [Google Scholar] [CrossRef]

- Tomita, M.; Oba, S.; Himeda, Y.; Yamato, R.; Shima, K.; Kumada, T.; Xu, M.; Takezawa, H.; Mesaki, K.; Tsuda, K. Modeling, Simulation, Fabrication, and Characterization of a 10-μW/cm2 Class Si-Nanowire Thermoelectric Generator for IoT Applications. IEEE Trans. Electron. Devices 2018, 65, 5180–5188. [Google Scholar] [CrossRef]

- Yan, J.; Liao, X.; Yan, D.; Chen, Y. Review of micro thermoelectric generator. J. Microelectromechanical Syst. 2018, 27, 1–18. [Google Scholar] [CrossRef]

- Jeong, J.; Kwon, J.-H.; Lim, K.; Biswas, S.; Tibaldi, A.; Lee, S.; Oh, H.J.; Kim, J.-H.; Ko, J.; Lee, D.-W. Comparative Study of Triboelectric Nanogenerators with Differently Woven Cotton Textiles for Wearable Electronics. Polymers 2019, 11, 1443. [Google Scholar] [CrossRef] [Green Version]

- Lim, K.; Kim, D.-K.; Jeong, J.B.; Choi, S.; Biswas, S.; Tibaldi, A.; Ma, T.-Y.; Lee, S.; Kim, J.-H.; Ko, J. Enhanced output voltage of nano energy harvester with diverse textiles. Mol. Cryst. Liq. Cryst. 2019, 687, 113–117. [Google Scholar] [CrossRef]

- Biswas, S.; You, Y.-J.; Shim, J.W.; Kim, H. Utilization of poly (4-styrenesulfonic acid) doped polyaniline as a hole transport layer of organic solar cell for indoor applications. Thin Solid Films. 2020, 700, 137921. [Google Scholar] [CrossRef]

- Shin, S.-C.; Vincent, P.; Bae, J.-H.; Lee, J.J.; Nam, M.; Ko, D.-H.; Kim, H.; Shim, J.W. Quaternary indoor organic photovoltaic device demonstrating panchromatic absorption and power conversion efficiency of 10%. Dye. Pigment. 2019, 163, 48–54. [Google Scholar] [CrossRef]

- Mathews, I.; King, P.J.; Stafford, F.; Frizzell, R. Performance of III–V solar cells as indoor light energy harvesters. IEEE J. Photovolt. 2015, 6, 230–235. [Google Scholar] [CrossRef]

- Teran, A.S.; Wong, J.; Lim, W.; Kim, G.; Lee, Y.; Blaauw, D.; Phillips, J.D. AlGaAs photovoltaics for indoor energy harvesting in mm-scale wireless sensor nodes. IEEE Trans. Electron. Devices 2015, 62, 2170–2175. [Google Scholar] [CrossRef]

- Saeed, A.M.; Kim, H.S.; Lee, S.Y.; Shim, J.W. High indoor performance of flexible organic photovoltaics using polymer electrodes. Thin Solid Films 2020, 704, 138006. [Google Scholar] [CrossRef]

- Lucarelli, G.; Di Giacomo, F.; Zardetto, V.; Creatore, M.; Brown, T.M. Efficient light harvesting from flexible perovskite solar cells under indoor white light-emitting diode illumination. Nano Res. 2017, 10, 2130–2145. [Google Scholar] [CrossRef] [Green Version]

- Reich, N.v.; Van Sark, W.; Turkenburg, W. Charge yield potential of indoor-operated solar cells incorporated into Product Integrated Photovoltaic (PIPV). Renew. Energy 2011, 36, 642–647. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Grabham, N.J.; Beeby, S.P.; Tudor, M. The effect of the type of illumination on the energy harvesting performance of solar cells. Sol. Energy 2015, 111, 21–29. [Google Scholar] [CrossRef]

- Biswas, S.; You, Y.-J.; Vincent, P.; Bae, J.-H.; Shim, J.W.; Kim, H. Organic tandem solar cells under indoor light illumination. Prog. Photovolt. Res. Appl. 2020, 1–10. [Google Scholar] [CrossRef]

- Freitag, M.; Teuscher, J.; Saygili, Y.; Zhang, X.; Giordano, F.; Liska, P.; Hua, J.; Zakeeruddin, S.M.; Moser, J.-E.; Grätzel, M. Dye-sensitized solar cells for efficient power generation under ambient lighting. Nat. Photonics 2017, 11, 372. [Google Scholar] [CrossRef]

- Yin, H.; Ho, J.K.W.; Cheung, S.H.; Yan, R.J.; Chiu, K.L.; Hao, X.; So, S.K. Designing a ternary photovoltaic cell for indoor light harvesting with a power conversion efficiency exceeding 20%. J. Mater. Chem. A 2018, 6, 8579–8585. [Google Scholar] [CrossRef]

- Yin, H.; Chen, S.; Cheung, S.H.; Li, H.W.; Xie, Y.; Tsang, S.W.; Zhu, X.; So, S.K. Porphyrin-based thick-film bulk-heterojunction solar cells for indoor light harvesting. J. Mater. Chem. C 2018, 6, 9111–9118. [Google Scholar] [CrossRef] [Green Version]

- Mathews, I.; Kelly, G.; King, P.J.; Frizzell, R. GaAs solar cells for indoor light harvesting. In the IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; IEEE: New York, NY, USA, 2014; pp. 0510–0513. [Google Scholar]

- Teran, A.S.; Moon, E.; Lim, W.; Kim, G.; Lee, I.; Blaauw, D.; Phillips, J.D. Energy harvesting for GaAs photovoltaics under low-flux indoor lighting conditions. IEEE Trans. Electron. Devices 2016, 63, 2820–2825. [Google Scholar] [CrossRef] [PubMed]

- De Rossi, F.; Pontecorvo, T.; Brown, T.M. Characterization of photovoltaic devices for indoor light harvesting and customization of flexible dye solar cells to deliver superior efficiency under artificial lighting. Appl. Energy 2015, 156, 413–422. [Google Scholar] [CrossRef]

- Pettersson, H.; Gruszecki, T. Long-term stability of low-power dye-sensitised solar cells prepared by industrial methods. Sol. Energy Mater. Sol. Cells 2001, 70, 203–212. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Jian, Z.-H.; Huang, S.-H.; Lee, K.-M.; Kao, M.-H.; Shen, C.-H.; Shieh, J.-M.; Wang, C.-L.; Chang, C.-W.; Lin, B.-Z. Performance characterization of dye-sensitized photovoltaics under indoor lighting. J. Phys. Chem. Lett. 2017, 8, 1824–1830. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.-C.; Wang, C.-L.; Chang, C.-W.; Hsu, C.-W.; Hsiao, Y.-H.; Liu, C.-L.; Wang, C.-C.; Lin, S.-Y.; Lin, C.-Y. A large, ultra-black, efficient and cost-effective dye-sensitized solar module approaching 12% overall efficiency under 1000 lux indoor light. J. Mater. Chem. A 2018, 6, 1995–2003. [Google Scholar] [CrossRef]

- Lee, K.S.; Kang, M.G. Optimum design of dye-sensitized solar module for building-integrated photovoltaic systems. Etri J. 2017, 39, 859–865. [Google Scholar] [CrossRef] [Green Version]

- Tingare, Y.S.; Vinh, N.S.n.; Chou, H.H.; Liu, Y.C.; Long, Y.S.; Wu, T.C.; Wei, T.C.; Yeh, C.Y. New acetylene-bridged 9, 10-conjugated anthracene sensitizers: Application in outdoor and indoor dye-sensitized solar cells. Adv. Energy Mater. 2017, 7, 1700032. [Google Scholar] [CrossRef]

- Kim, S.; Saeed, A.M.; Kim, H.S.; Shim, J.W. Enhanced hole selecting behavior of WO3 interlayers for efficient indoor organic photovoltaics with high fill-factor. Appl. Surf. Sci. 2020, 527, 146840. [Google Scholar] [CrossRef]

- Aoki, Y. Photovoltaic performance of Organic Photovoltaics for indoor energy harvester. Org. Electron. 2017, 48, 194–197. [Google Scholar] [CrossRef]

- Lechêne, B.P.; Cowell, M.; Pierre, A.; Evans, J.W.; Wright, P.K.; Arias, A.C. Organic solar cells and fully printed super-capacitors optimized for indoor light energy harvesting. Nano Energy 2016, 26, 631–640. [Google Scholar] [CrossRef] [Green Version]

- Cnops, K.; Voroshazi, E.; de Ruijter, C.H.; Heremans, P.; Cheyns, D. Organic photovoltaic cell relying on energy transfer with over 20% efficiency in indoor lighting. In the IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; IEEE: New York, NY, USA, 2014; pp. 0143–0146. [Google Scholar]

- Park, S.Y.; Li, Y.; Kim, J.; Lee, T.H.; Walker, B.; Woo, H.Y.; Kim, J.Y. Alkoxybenzothiadiazole-based fullerene and nonfullerene polymer solar cells with high shunt resistance for indoor photovoltaic applications. ACS Appl. Mater. Interfaces 2018, 10, 3885–3894. [Google Scholar] [CrossRef] [PubMed]

- Cutting, C.L.; Bag, M.; Venkataraman, D. Indoor light recycling: A new home for organic photovoltaics. J. Mater. Chem. C 2016, 4, 10367–10370. [Google Scholar] [CrossRef]

- Goo, J.S.; Lee, J.-H.; Shin, S.-C.; Park, J.-S.; Shim, J.W. Undoped ZnO electrodes for low-cost indoor organic photovoltaics. J. Mater. Chem. A 2018, 6, 23464–23472. [Google Scholar] [CrossRef]

- Mori, S.; Gotanda, T.; Nakano, Y.; Saito, M.; Todori, K.; Hosoya, M. Investigation of the organic solar cell characteristics for indoor LED light applications. Jpn. J. Appl. Phys. 2015, 54, 071602. [Google Scholar] [CrossRef]

- Vincent, P.; Shim, J.W.; Bae, J.-H.; Kim, H. Optimizing the efficiency of organic solar cell under indoor light via controlling optical absorption. Mol. Cryst. Liq. Cryst. 2018, 660, 85–89. [Google Scholar] [CrossRef]

- Kim, S.; Jahandar, M.; Jeong, J.H.; Lim, D.C. Recent Progress in Solar Cell Technology for Low-Light Indoor Applica-tions. Curr. Altern. Energy 2018, 2, 1–15. [Google Scholar]

- Venkateswararao, A.; Ho, J.K.; So, S.K.; Liu, S.-W.; Wong, K.-T. Device characteristics and material developments of indoor photovoltaic devices. Mater. Sci. Eng. R Rep. 2019, 100517. [Google Scholar] [CrossRef]

- Mainville, M.; Leclerc, M. Recent Progress on Indoor Organic Photovoltaics: From Molecular Design to Production Scale. Acs Energy Lett. 2020, 5, 1186–1197. [Google Scholar] [CrossRef]

- Virtuani, A.; Lotter, E.; Powalla, M. Influence of the light source on the low-irradiance performance of Cu(In,Ga)Se2 solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 2141–2149. [Google Scholar] [CrossRef]

- Freunek, M.; Freunek, M.; Reindl, L.M. Maximum efficiencies of indoor photovoltaic devices. IEEE J. Photovolt. 2012, 3, 59–64. [Google Scholar] [CrossRef]

- Freunek, M. Indoor photovoltaics: Efficiencies measurements and design. In Solar Cell Nanotechnology; Wiley Online Library: Hoboken, NJ, USA, 2014; pp. 203–222. [Google Scholar]

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Ohl, R.S. Light-Sensitive Electric Device. U.S. Patent 2,402,662, 25 June 1946. [Google Scholar]

- Green, M.A. The path to 25% silicon solar cell efficiency: History of silicon cell evolution. Prog. Photovolt. Res. Appl. 2009, 17, 183–189. [Google Scholar] [CrossRef]

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D. Solar cell efficiency tables (Version 45). Prog. Photovolt. Res. Appl. 2015, 23, 1–9. [Google Scholar] [CrossRef]

- Green, M.A. Corrigendum to ‘Solar cell efficiency tables (version 49)’[Prog. Photovolt: Res. Appl. 2017; 25: 3–13]. Prog. Photovolt. Res. Appl. 2017, 25, 333–334. [Google Scholar] [CrossRef] [Green Version]

- Hamrick, K.B. The history of the hand-held electronic calculator. Am. Math. Mon. 1996, 103, 633–639. [Google Scholar] [CrossRef]

- Foti, M.; Tringali, C.; Battaglia, A.; Sparta, N.; Lombardo, S.; Gerardi, C. Efficient flexible thin film silicon module on plastics for indoor energy harvesting. Sol. Energy Mater. Sol. Cells 2014, 130, 490–494. [Google Scholar] [CrossRef]

- Águas, H.; Mateus, T.; Vicente, A.; Gaspar, D.; Mendes, M.J.; Schmidt, W.A.; Pereira, L.; Fortunato, E.; Martins, R. Thin film silicon photovoltaic cells on paper for flexible indoor applications. Adv. Funct. Mater. 2015, 25, 3592–3598. [Google Scholar] [CrossRef]

- Kao, M.-H.; Shen, C.-H.; Yu, P.-c.; Huang, W.-H.; Chueh, Y.-L.; Shieh, J.-M. Low-temperature growth of hydrogenated amorphous silicon carbide solar cell by inductively coupled plasma deposition toward high conversion efficiency in indoor lighting. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Bätzner, D.; Romeo, A.; Zogg, H.; Tiwari, A. CdTe/CdS Solar Cell Performance under Low Irradiance. In Proceedings of the 17-th EC PV Solar Energy Conference, Munich, Germany; 2001. [Google Scholar]

- Virtuani, A.; Lotter, E.; Powalla, M. Performance of Cu (In, Ga) Se2 solar cells under low irradiance. Thin Solid Films. 2003, 431, 443–447. [Google Scholar] [CrossRef]

- Virtuani, A.; Lotter, E.; Powalla, M.; Rau, U.; Werner, H.J. Highly resistive Cu (In, Ga) Se2 absorbers for improved low-irradiance performance of thin-film solar cells. Thin Solid Films. 2004, 451–452, 160–165. [Google Scholar] [CrossRef]

- Randall, J. Designing Indoor Solar Products: Photovoltaic Technologies for AES; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Saravanan, S.; Teja, T.K.; Dubey, R.; Kalainathan, S. Design and analysis of GaAs thin film solar cell using an efficient light trapping bottom structure. Mater. Today: Proc. 2016, 3, 2463–2467. [Google Scholar] [CrossRef]

- Mashooq, K.; Talukder, M.A. Management of light absorption in extraordinary optical transmission based ultra-thin-film tandem solar cells. J. Appl. Phys. 2016, 119, 193101. [Google Scholar] [CrossRef] [Green Version]

- Bermudez, V.; Perez-Rodriguez, A. Understanding the cell-to-module efficiency gap in Cu (In, Ga)(S, Se) 2 photovoltaics scale-up. Nat. Energy 2018, 3, 466. [Google Scholar] [CrossRef]

- O’regan, B.; Grätzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Gong, J.; Sumathy, K.; Qiao, Q.; Zhou, Z. Review on dye-sensitized solar cells (DSSCs): Advanced techniques and research trends. Renew. Sustain. Energy Rev. 2017, 68, 234–246. [Google Scholar] [CrossRef]

- Kalyanasundaram, K. Dye-Sensitized Solar Cells; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Sakamoto, R.; Katagiri, S.; Maeda, H.; Nishimori, Y.; Miyashita, S.; Nishihara, H. Electron transport dynamics in redox-molecule-terminated branched oligomer wires on Au (111). J. Am. Chem. Soc. 2015, 137, 734–741. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Pettersson, H. Dye-sensitized solar cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Barber, G.D.; Hoertz, P.G.; Lee, S.-H.A.; Abrams, N.M.; Mikulca, J.; Mallouk, T.E.; Liska, P.; Zakeeruddin, S.M.; Grätzel, M.; Ho-Baillie, A. Utilization of Direct and Diffuse Sunlight in a Dye-Sensitized Solar CellSilicon Photovoltaic Hybrid Concentrator System. J. Phys. Chem. Lett. 2011, 2, 581–585. [Google Scholar] [CrossRef]

- Higashijima, S.; Inoue, Y.; Miura, H.; Kubota, Y.; Funabiki, K.; Yoshida, T.; Matsui, M. Organic dyes containing fluorene-substituted indoline core for zinc oxide dye-sensitized solar cell. RSC Adv. 2012, 2, 2721–2724. [Google Scholar] [CrossRef]

- Kang, T.S.; Smith, A.P.; Taylor, B.E.; Durstock, M.F. Fabrication of Highly-Ordered TiO2 Nanotube Arrays and Their Use in Dye-Sensitized Solar Cells. Nano Lett. 2009, 9, 601–606. [Google Scholar] [CrossRef]

- Burnside, S.; Winkel, S.; Brooks, K.; Shklover, V.; Gra, M.; Hinsch, A.; Kinderman, R.; Bradbury, C.; Hagfeldt, A.; Pettersson, H. Deposition and characterization of screen-printed porous multi-layer thick film structures from semiconducting and conducting nanomaterials for use in photovoltaic devices. J. Mater. Sci. Mater. Electron. 2000, 11, 355–362. [Google Scholar] [CrossRef]

- Kapil, G.; Ogomi, Y.; Pandey, S.S.; Ma, T.; Hayase, S. Indoor light performance of coil type cylindrical dye sensitized solar cells. J. Nanosci. Nanotechnol. 2016, 16, 3183–3187. [Google Scholar] [CrossRef] [PubMed]

- Venkatesan, S.; Liu, I.-P.; Hung, W.-N.; Teng, H.; Lee, Y.-L. Highly efficient quasi-solid-state dye-sensitized solar cells prepared by printable electrolytes for room light applications. Chem. Eng. J. 2019, 367, 17–24. [Google Scholar] [CrossRef]

- Reddy, K.S.K.; Chen, Y.-C.; Wu, C.-C.; Hsu, C.-W.; Chang, Y.-C.; Chen, C.-M.; Yeh, C.-Y. Cosensitization of structurally simple porphyrin and anthracene-based dye for dye-sensitized solar cells. ACS Appl. Mater. Interfaces 2018, 10, 2391–2399. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-C.; Chou, H.-H.; Ho, F.-Y.; Wei, H.-J.; Wei, T.-C.; Yeh, C.-Y. A feasible scalable porphyrin dye for dye-sensitized solar cells under one sun and dim light environments. J. Mater. Chem. A 2016, 4, 11878–11887. [Google Scholar] [CrossRef]

- Chang, T.-K.; Chi, Y. Bis-tridentate Ru (ii) sensitizers with a spatially encumbered 2, 6-dipyrazolylpyridine ancillary ligand for dye-sensitized solar cells. RSC Adv. 2017, 7, 42013–42023. [Google Scholar] [CrossRef] [Green Version]

- Hashemi, A.S.; Ramakrishna, S.; Aberle, G.A. Recent progress in flexible–wearable solar cells for self-powered electronic devices. Energy Environ. Sci. 2020, 13, 685. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Zakeeruddin, S.M.; Hagfeldt, A.; Grätzel, M. Direct contact of selective charge extraction layers enables high-efficiency molecular photovoltaics. Joule 2018, 2, 1108–1117. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Y.; Zhang, W.; Stojanovic, M.; Dar, M.I.; Péchy, P.; Saygili, Y.; Hagfeldt, A.; Zakeeruddin, S.M.; Grätzel, M. Electron-Affinity-Triggered Variations on the Optical and Electrical Properties of Dye Molecules Enabling Highly Efficient Dye-Sensitized Solar Cells. Angew. Chem. 2018, 130, 14321–14324. [Google Scholar] [CrossRef]

- Desta, M.B.; Vinh, N.S.; Kumar, C.P.; Chaurasia, S.; Wu, W.-T.; Lin, J.T.; Wei, T.-C.; Diau, E.W.-G. Pyrazine-incorporating panchromatic sensitizers for dye sensitized solar cells under one sun and dim light. J. Mater. Chem. A 2018, 6, 13778–13789. [Google Scholar] [CrossRef]

- Park, S.H.; Roy, A.; Beaupre, S.; Cho, S.; Coates, N.; Moon, J.S.; Moses, D.; Leclerc, M.; Lee, K.; Heeger, A.J. Bulk heterojunction solar cells with internal quantum efficiency approaching 100%. Nat. Photonics 2009, 3, 297–302. [Google Scholar] [CrossRef]

- Wang, J.; Chai, Z.; Liu, S.; Fang, M.; Chang, K.; Han, M.; Hong, L.; Han, H.; Li, Q.; Li, Z. Organic Dyes based on Tetraaryl-1, 4-dihydropyrrolo-[3, 2-b] pyrroles for Photovoltaic and Photocatalysis Applications with the Suppressed Electron Recombination. Chem. A Eur. J. 2018, 24, 18032–18042. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Michaels, H.; Roy, R.; Johansson, M.; Öberg, V.; Andruszkiewicz, A.; Zhang, X.; Freitag, M.; Johansson, J.M.E. Four-Terminal Tandem Solar Cell with Dye-Sensitized and PbS Colloidal Quantum-Dot-Based Subcells. ACS Appl. Energy Mater. 2020, 3, 3157–3161. [Google Scholar] [CrossRef] [Green Version]

- Lan, J.-L.; Wei, T.-C.; Feng, S.-P.; Wan, C.-C.; Cao, G. Effects of Iodine Content in the Electrolyte on the Charge Transfer and Power Conversion Efficiency of Dye-Sensitized Solar Cells under Low Light Intensities. J. Phys. Chem. C 2012, 116, 25727–25733. [Google Scholar] [CrossRef]

- Byrne, O.; Coughlan, A.; Surolia, P.K.; Thampi, K.R. Succinonitrile-based solid-state electrolytes for dye-sensitised solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 417–427. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.-P.; Lin, C.-A.; Wei, T.-C.; Tsai, M.-L.; Meng, Y.; Li, C.-T.; Ho, K.-C.; Wu, C.-I.; Lau, S.-P.; He, J.-H. Economical low-light photovoltaics by using the Pt-free dye-sensitized solar cell with graphene dot/PEDOT:PSS counter electrodes. Nano Energy 2015, 18, 109–117. [Google Scholar] [CrossRef]

- Li, C.-T.; Lee, C.-T.; Li, S.-R.; Lee, C.-P.; Chiu, I.T.; Vittal, R.; Wu, N.-L.; Sun, S.-S.; Ho, K.-C. Composite films of carbon black nanoparticles and sulfonated-polythiophene as flexible counter electrodes for dye-sensitized solar cells. J. Power Sources 2016, 302, 155–163. [Google Scholar] [CrossRef]

- Chiu, I.T.; Li, C.-T.; Lee, C.-P.; Chen, P.-Y.; Tseng, Y.-H.; Vittal, R.; Ho, K.-C. Nanoclimbing-wall-like CoSe2/carbon composite film for the counter electrode of a highly efficient dye-sensitized solar cell: A study on the morphology control. Nano Energy 2016, 22, 594–606. [Google Scholar] [CrossRef]

- Huang, Y.-J.; Lee, C.-P.; Pang, H.-W.; Li, C.-T.; Fan, M.-S.; Vittal, R.; Ho, K.-C. Microemulsion-controlled synthesis of CoSe2/CoSeO3 composite crystals for electrocatalysis in dye-sensitized solar cells. Mater. Today Energy 2017, 6, 189–197. [Google Scholar] [CrossRef]

- Cheng, F.; Ou, Y.; Liu, G.; Zhao, L.; Dong, B.; Wang, S.; Wen, S. Novel Quasi-Solid-State Electrolytes based on Electrospun Poly(vinylidene fluoride) Fiber Membranes for Highly Efficient and Stable Dye-Sensitized Solar Cells. Nanomaterials 2019, 9, 783. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.-P.; Teng, H. Zinc-doping in TiO2 films to enhance electron transport in dye-sensitized solar cells under low-intensity illumination. Phys. Chem. Chem. Phys. 2009, 11, 9489–9496. [Google Scholar] [CrossRef]

- Reddy, K.S.K.; Liu, Y.-C.; Chou, H.-H.; Kala, K.; Wei, T.-C.; Yeh, C.-Y. Synthesis and Characterization of Novel β-Bis(N,N-diarylamino)-Substituted Porphyrin for Dye-Sensitized Solar Cells under 1 sun and Dim Light Conditions. ACS Appl. Mater. Interfaces 2018, 10, 39970–39982. [Google Scholar] [CrossRef] [PubMed]

- Liu, I.P.; Lin, W.-H.; Tseng-Shan, C.-M.; Lee, Y.-L. Importance of Compact Blocking Layers to the Performance of Dye-Sensitized Solar Cells under Ambient Light Conditions. ACS Appl. Mater. Interfaces 2018, 10, 38900–38905. [Google Scholar] [CrossRef]

- Venkatesan, S.; Lin, W.-H.; Teng, H.; Lee, Y.-L. High-Efficiency Bifacial Dye-Sensitized Solar Cells for Application under Indoor Light Conditions. ACS Appl. Mater. Interfaces 2019, 11, 42780–42789. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, E.; Michaels, H.; Freitag, M.; Robertson, N. Synergy of co-sensitizers in a copper bipyridyl redox system for efficient and cost-effective dye-sensitized solar cells in solar and ambient light. J. Mater. Chem. A 2020, 8, 1279–1287. [Google Scholar] [CrossRef] [Green Version]

- Jen-Hsien, H.; Yu-Sheng, H.; Eric, R.; Chun-Chao, C.; Peilin, C.; Gang, L.; Chih-Wei, C.; Yang, Y. The investigation of donor-acceptor compatibility in bulk-heterojunction polymer systems. Appl. Phys. Lett. 2013, 103, 043304. [Google Scholar]

- Jin, Z.; Wang, J. A trilayer architecture for polymer photoconductors. Appl. Phys. Lett. 2013, 102, 25. [Google Scholar] [CrossRef]

- Bakar, N.; Supangat, A.; Sulaiman, K. Formation of PCDTBT: PC 71 BM p–n junction composite nanotubes via a templating method. RSC Adv. 2015, 5, 102689–102699. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, R.; Cheng, J.; Chang, Y.; Huo, M.; Yu, J.; Li, L.; Zhang, J.-P. Appropriate Donor-Acceptor Phase Separation Structure for the Enhancement of Charge Generation and Transport in Polymer Solar Cells. Polymers 2018, 10, 332. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.-C. Emerging Organic and Organic/Inorganic Hybrid Photovoltaic Devices for Specialty Applications: Low-Level-Lighting Energy Conversion and Biomedical Treatment. Adv. Opt. Mater. 2019, 7, 1800662. [Google Scholar] [CrossRef] [Green Version]

- Minnaert, B.; Veelaert, P. The Appropriateness of Organic Solar Cells for Indoor Lighting Conditions; SPIE: Bellingham, WA, USA, 2010; Volume 7722. [Google Scholar]

- Cui, Y.; Wang, Y.; Bergqvist, J.; Yao, H.; Xu, Y.; Gao, B.; Yang, C.; Zhang, S.; Inganäs, O.; Gao, F.; et al. Wide-gap non-fullerene acceptor enabling high-performance organic photovoltaic cells for indoor applications. Nat. Energy 2019, 4, 768–775. [Google Scholar] [CrossRef]

- Steim, R.; Ameri, T.; Schilinsky, P.; Waldauf, C.; Dennler, G.; Scharber, M.; Brabec, C.J. Organic photovoltaics for low light applications. Sol. Energy Mater. Sol. Cells 2011, 95, 3256–3261. [Google Scholar] [CrossRef]

- Lee, H.K.H.; Li, Z.; Durrant, J.R.; Tsoi, W.C. Is organic photovoltaics promising for indoor applications? Appl. Phys. Lett. 2016, 108, 253301. [Google Scholar] [CrossRef]

- Shin, S.-C.; Koh, C.W.; Vincent, P.; Goo, J.S.; Bae, J.-H.; Lee, J.-J.; Shin, C.; Kim, H.; Woo, H.Y.; Shim, J.W. Ultra-thick semi-crystalline photoactive donor polymer for efficient indoor organic photovoltaics. Nano Energy 2019, 58, 466–475. [Google Scholar] [CrossRef]

- Vincent, P.; Shin, S.-C.; Goo, J.S.; You, Y.-J.; Cho, B.; Lee, S.; Lee, D.-W.; Kwon, S.R.; Chung, K.-B.; Lee, J.-J.; et al. Indoor-type photovoltaics with organic solar cells through optimal design. Dye. Pigment. 2018, 159, 306–313. [Google Scholar] [CrossRef]

- Goo, J.S.; Shin, S.-C.; You, Y.-J.; Shim, J.W. Polymer surface modification to optimize inverted organic photovoltaic devices under indoor light conditions. Sol. Energy Mater. Sol. Cells 2018, 184, 31–37. [Google Scholar] [CrossRef]

- Lee, B.R.; Goo, J.S.; Kim, Y.W.; You, Y.-J.; Kim, H.; Lee, S.-K.; Shim, J.W.; Kim, T.G. Highly efficient flexible organic photovoltaics using quasi-amorphous ZnO/Ag/ZnO transparent electrodes for indoor applications. J. Power Sources 2019, 417, 61–69. [Google Scholar] [CrossRef]

- Nam, M.; Noh, H.Y.; Kang, J.-H.; Cho, J.; Min, B.K.; Shim, J.W.; Ko, D.-H. Semi-transparent quaternary organic blends for advanced photovoltaic applications. Nano Energy 2019, 58, 652–659. [Google Scholar] [CrossRef]

- Singh, R.; Shin, S.-C.; Lee, H.; Kim, M.; Shim, J.W.; Cho, K.; Lee, J.-J. Ternary Blend Strategy for Achieving High-Efficiency Organic Photovoltaic Devices for Indoor Applications. Chem. A Eur. J. 2019, 25, 6154–6161. [Google Scholar] [CrossRef]

- Vincent, P.; Shim, J.W.; Jang, J.; Kang, I.M.; Lang, P.; Bae, J.-H.; Kim, H. The Crucial Role of Quaternary Mixtures of Active Layer in Organic Indoor Solar Cells. Energies 2019, 12, 1838. [Google Scholar] [CrossRef] [Green Version]

- Ann, M.H.; Kim, J.; Kim, M.; Alosaimi, G.; Kim, D.; Ha, N.Y.; Seidel, J.; Park, N.; Yun, J.S.; Kim, J.H. Device design rules and operation principles of high-power perovskite solar cells for indoor applications. Nano Energy 2020, 68, 104321. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Chang, J.-H.; Chiang, K.-M.; Lin, H.-L.; Hsiao, S.-Y.; Lin, H.-W. Perovskite Photovoltaics for Dim-Light Applications. Adv. Funct. Mater. 2015, 25, 7064–7070. [Google Scholar] [CrossRef]

- Chang, S.H.; Cheng, H.-M.; Chen, S.-H.; Lin, K.-F. Optical, Excitonic, and Electronic Properties of CH3NH3PbI3 Thin Films and Their Application in Photovoltaics. Perovskite Mater. Synth. CharacterisationProp. Appl. 2016, 423–443. [Google Scholar]

- Liu, Z.; He, T.; Wang, H.; Jain, S.M.; Liu, K.; Yang, J.; Zhang, N.; Liu, H.; Yuan, M. Improvement in the performance of inverted planar perovskite solar cells via the CH3NH3PbI3-xClx: ZnO bulk heterojunction. J. Power Sources 2018, 401, 303–311. [Google Scholar] [CrossRef] [Green Version]

- Raifuku, I.; Ishikawa, Y.; Ito, S.; Uraoka, Y. Characteristics of Perovskite Solar Cells under Low-Illuminance Conditions. J. Phys. Chem. C 2016, 120, 18986–18990. [Google Scholar] [CrossRef]

- Dagar, J.; Castro-Hermosa, S.; Lucarelli, G.; Cacialli, F.; Brown, T.M. Highly efficient perovskite solar cells for light harvesting under indoor illumination via solution processed SnO2/MgO composite electron transport layers. Nano Energy 2018, 49, 290–299. [Google Scholar] [CrossRef] [Green Version]

- Jagadamma, L.K.; Blaszczyk, O.; Sajjad, M.T.; Ruseckas, A.; Samuel, I.D.W. Efficient indoor p-i-n hybrid perovskite solar cells using low temperature solution processed NiO as hole extraction layers. Sol. Energy Mater. Sol. Cells 2019, 201, 110071. [Google Scholar] [CrossRef] [Green Version]

- Mathews, I.; Kantareddy, S.N.R.; Sun, S.; Layurova, M.; Thapa, J.; Correa-Baena, J.-P.; Bhattacharyya, R.; Buonassisi, T.; Sarma, S.; Peters, I.M. Self-Powered Sensors Enabled by Wide-Bandgap Perovskite Indoor Photovoltaic Cells. Adv. Funct. Mater. 2019, 29, 1904072. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Zhao, C.; Wang, Z.K.; Zhang, C.C.; Lee, H.K.; Pockett, A.; Barbé, J.; Tsoi, W.C.; Yang, Y.G.; Carnie, M.J. Interface modification by ionic liquid: A promising candidate for indoor light harvesting and stability improvement of planar perovskite solar cells. Adv. Energy Mater. 2018, 8, 1801509. [Google Scholar] [CrossRef] [Green Version]

| Reference Number | Active Material | Light Source | Luminance (Lux) | MPD 2 (µW/cm2) | PCE 3 (%) |

|---|---|---|---|---|---|

| [14] | a-Si | FL 1 | 200 | 8.10 | - |

| [14] | a-Si | FL | 1000 | 46.50 | - |

| [14] | a-Si | LED | 200 | 9.40 | - |

| [14] | a-Si | LED | 1000 | 46.40 | - |

| [14] | GaAs | FL | 200 | 13.80 | - |

| [14] | GaAs | FL | 1000 | 80.50 | - |

| [14] | GaAs | LED | 200 | 16.60 | - |

| [14] | GaAs | LED | 1000 | 92.20 | - |

| [14] | GaInP | FL | 200 | 15.60 | - |

| [14] | GaInP | FL | 1000 | 92.60 | - |

| [14] | GaInP | LED | 200 | 17.60 | - |

| [14] | GaInP | LED | 1000 | 87.20 | - |

| [15] | Al0.2Ga0.8As | LED | 580 | >100 | 21.10 |

| [53] | a-Si | FL | 100 | - | 9.10 |

| [54] | a-Si | - | - | - | 6.00–8.00 |

| [55] | a-Si | LED | 500 | - | 9.60 |

| [56] | CdS/CdTe | Halogen | - | - | 8.00 |

| [57] | CIGS | - | - | - | 3.00 |

| [58] | CIGS | FL | 100 | 2.10 | 5.80 |

| [58] | CIGS | FL | 500 | 14.90 | 8.30 |

| [58] | CIGS | FL | 1000 | 33.70 | 9.40 |

| [58] | CIGS | Halogen | 100 | 2.90 | 7.30 |

| [58] | CIGS | Halogen | 500 | 20.00 | 10.20 |

| [58] | CIGS | Halogen | 1000 | 44.90 | 11.50 |

| [62] | CIGS | LED | - | - | 2.64 |

| Reference Number | Sensitizer | Light Source | Luminance (Lux) | MPD 2 (µW/cm2) | PCE (%) 3 |

|---|---|---|---|---|---|

| [71] | N719 | Philips TLD 840 FL | 250 | 69.80 | - |

| [72] | N719 | FL 1 | 1533 | 13.91 | 6.05 |

| [73] | N719 | T5 FL | 200 | 7.29 | 11.38 |

| [73] | Z907 | T5 FL | 200 | 7.84 | 12.23 |

| [74] | SK6 | T5 FL | 6000 | 366.57 | 19.46 |

| [74] | CW10 | T5 FL | 6000 | 395.46 | 20.95 |

| [74] | SK6 + CW10 | T5 FL | 6000 | 426.10 | 22.58 |

| [74] | N719 | T5 FL | 6000 | 435.86 | 23.43 |

| [75] | Y1A1 | LED | 350 | - | 19.50 |

| [76] | TF-tBu-C3F7 | T5 FL | 2400 | - | 20.37 |

| [76] | TF-tBu-C3F7 | LED | 2400 | - | 16.05 |

| [78] | XY1b + Y123 | 930 Osram FL | 500 | 132.00 | 30.80 |

| [78] | XY1b + Y123 | 930 Osram FL | 1000 | 283.00 | 31.80 |

| [79] | L350 | FL | 1000 | - | 28.40 |

| [80] | MD4 | T5 FL | 6000 | - | 8.62 |

| [80] | MD5 | T5 FL | 6000 | - | 23.17 |

| [80] | MD6 | T5 FL | 6000 | - | 16.86 |

| [80] | MD7 | T5 FL | 6000 | - | 27.17 |

| [80] | N719 | T5 FL | 6000 | - | 27.64 |

| [85] | N719 | FL | 200 | - | - |

| [92] | SK7 | T5 FL | 6000 | 335.00 | 17.70 |

| [92] | YD2 | T5 FL | 6000 | 340.00 | 20.00 |

| [92] | SK7 | LED | 6000 | 277.00 | 15.40 |

| [92] | YD2 | LED | 6000 | 296.00 | 16.50 |

| Reference Number | Active Material | Light Source | Luminance (Lux) | MPD 2 (µW/cm2) | PCE 3 (%) |

|---|---|---|---|---|---|

| [13] | PCDTBT:PTB7:PC61BM:PC71BM | LED | 500 | 18.00 | 10.60 |

| [22] | PCDTBT:PC71BM | FL 1 | 300 | 12.20 | 16.50 |

| [22] | PCDTBT:PDTSTPD:PC71BM | FL | 300 | 15.40 | 20.80 |

| [23] | P1:PC71BM | LED | 300 | 14.86 | 19.15 |

| [23] | PCDTBT:PC71BM | LED | 300 | 14.53 | 18.72 |

| [39] | PTB7-Th:PC70BM | LED | 890 | 42.6 | 11.63 |

| [39] | PTB7-Th:PC70BM | LED | 1861 | 76.2 | 10.55 |

| [102] | PBDB-TF: IO-4Cl | LED | 1000 | 78.80 | 26.00 |

| [104] | P3HT:PC71BM | FL | 300 | 4.80 | 5.80 |

| [104] | PCDTBT:PC71BM | FL | 300 | 13.90 | 16.60 |

| [104] | PTB7:PC71BM | FL | 300 | 12.20 | 14.60 |

| [105] | PPDT2FBT:PC70BM | LED | 1000 | 44.80 | 16.00 |

| [106] | P3HT:ICBA | LED | 1000 | - | 5.40 |

| [107] | P3HT:ICBA | LED | 500 | 22.78 | 13.40 |

| [108] | P3HT:ICBA | LED | 500 | 20.57 | 12.10 |

| [109] | PTB7-Th:(PBDB-T:PC70BM:ITIC-Th | LED | 1000 | - | 15.46 |

| [109] | PTB7-Th:(PBDB-T:PC70BM:ITIC-Th | FL | 1000 | - | 14.69 |

| [110] | PTB7:PC71BM:EP-PDI | LED | 500 | - | 15.68 |

| Reference Number | Active Material | Light Source | Luminance (Lux) | MPD 2 (µW/cm2) | PCE (%) 3 |

|---|---|---|---|---|---|

| [17] | CH3NH3PbI3–xClx | LED | 200 | - | 10.80 |

| [17] | CH3NH3PbI3–xClx | LED | 400 | - | 12.10 |

| [112] | CH3NH3PbI3 | LED | 200 | 12.36 | - |

| [112] | CH3NH3PbI3 | LED | 400 | 28.03 | - |

| [112] | CH3NH3PbI3 | LED | 800 | 63.79 | - |

| [112] | CH3NH3PbI3 | LED | 1600 | 147.74 | - |

| [112] | CH3NH3PbI3 | Halogen | 200 | 56.43 | - |

| [112] | CH3NH3PbI3 | Halogen | 400 | 100.97 | - |

| [112] | CH3NH3PbI3 | Halogen | 800 | 187.67 | - |

| [112] | CH3NH3PbI3 | Halogen | 1600 | 376.85 | - |

| [113] | CH3NH3PbI3−xClx | FL 1 | 100 | - | 20.90 |

| [113] | CH3NH3PbI3−xClx | FL | 600 | - | 25.10 |

| [113] | CH3NH3PbI3−xClx | FL | 1000 | - | 26.30 |

| [117] | CH3NH3PbI3 | LED | 400 | - | 26.90 |

| [118] | CH3NH3PbI2.9Cl0.1 | FL | - | 73.60 | 23.00 |

| [118] | CH3NH3PbI2.9Cl0.1 | LED | - | 457.60 | 20.80 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biswas, S.; Kim, H. Solar Cells for Indoor Applications: Progress and Development. Polymers 2020, 12, 1338. https://doi.org/10.3390/polym12061338

Biswas S, Kim H. Solar Cells for Indoor Applications: Progress and Development. Polymers. 2020; 12(6):1338. https://doi.org/10.3390/polym12061338

Chicago/Turabian StyleBiswas, Swarup, and Hyeok Kim. 2020. "Solar Cells for Indoor Applications: Progress and Development" Polymers 12, no. 6: 1338. https://doi.org/10.3390/polym12061338