Influence of Infiltration Pressure on the Microstructure and Properties of 2D-CFRP Prepared by the Vacuum Infiltration Hot Pressing Molding Process

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

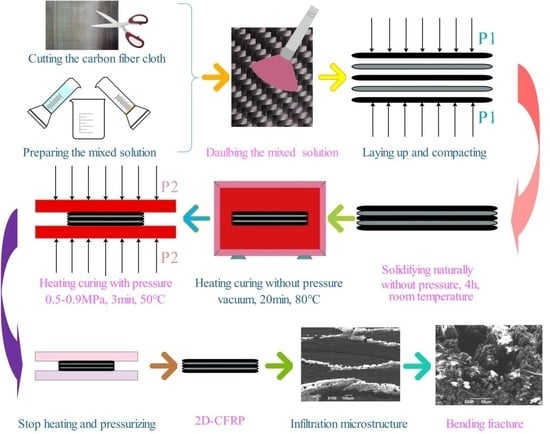

2.2.1. Vacuum Infiltration Hot Pressing Molding Process

2.2.2. Process Parameters

2.2.3. Testing and Characterization Methods

3. Experimental Results and Discussion

3.1. Influence of Infiltration Pressure on the Preparation of 2D-CFRP

3.2. Theoretical Calculation and Analysis and Summary of Experimental Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mahesh, V.H.; Md, M.I.; Shaik, J. Processing and performance of nanophased braided carbon/epoxy composites. Mat. Sci. Eng. 2010, 168, 22–29. [Google Scholar]

- Chae, H.G.; Newcomb, B.A.; Gulgunje, P.V.; Liu, Y.D.; Gupta, K.K.; Kamath, M.G.; Lyons, K.M.; Ghoshal, S.; Pramaanik, C.; Giannuzzi, L.; et al. High strength and high modulus carbon fibers. Carbon 2015, 93, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Zarrelli, M.; Russo, S.; Iannuzzo, G. Smart coatings of epoxy based CNTs designed to meet practical expectations in aeronautics. Compos. Part. B-Eng. 2018, 147, 42–46. [Google Scholar] [CrossRef]

- Wright, A.; French, M. The response of carbon fiber composites to blast loading via the Europa CAFV programme. J. Mater. Sci. 2008, 43, 6619–6629. [Google Scholar] [CrossRef]

- Qi, L.H.; Li, S.L.; Zhang, T. An analysis of the factors affecting strengthening in carbon fiber reinforced magnesium composites. Compos. Struct. 2019, 209, 328–336. [Google Scholar] [CrossRef]

- Ramani, V.; Mainak, R.; Susy, T.; Patra, A.K.; Sathiyamoorthy, D.; Tyagi, A.K. Effect of infiltration pressure and time on the porosity, structure and properties of polyacrylonitrile-fiber based carbon composites. J. Nucl. Mater. 2013, 433, 494–503. [Google Scholar]

- Masur, L.J.; Mortensen, A.; Cornie, J.A.; Flemings, M.C. Infiltration of Fibrous Preforms by a Pure Metal: Part Ⅱ. Experiment. Metall. Mater. Trans. A. 1989, 20, 2549–2557. [Google Scholar] [CrossRef]

- Mortensen, A.; Wong, T. Infiltration of Fibrous Preforms by a pure metal: Part Ⅲ. capillary phenomena. Metall. Mater. Trans. A. 1990, 21, 2257–2263. [Google Scholar] [CrossRef]

- Guan, J.T.; Qi, L.H.; Liu, J. Threshold pressure and infiltration behavior of liquid metal into fibrous preform. Trans. Nonferr. Met. Soc. China 2013, 23, 3173–3179. [Google Scholar] [CrossRef]

- Wannasin, J.; Flemings, M.C. Fabrication of metal matrix composites by a high-pressure centrifugal infiltration process. J. Mater. Process. Technol. 2005, 169, 143–149. [Google Scholar] [CrossRef]

- Liu, H.N.; Miyahara, H.; Ogi, K. Fabrication of Al2O3 continuous fiber reinforced Al-Cu alloy by axial infiltration process. Mater. Sci. Technol.-Lond 1998, 14, 292–298. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Ren, X.Y.; Shi, Y.; Yan, H.T.; Liu, Y.B.; Chen, G.M. Method of Vacuum Infiltration and Thermo Compression Curing of Carbon Fiber Composites. CN109049761A, December 2018. [Google Scholar]

- Yu, S.R.; He, Z.M. Theoretical analysis of the infiltration pressure of squeeze infiltration MMCs and application. Acta Mater. Compos. Sin. 1995, 12, 15–20. [Google Scholar]

- Li, C.; Wang, Y.J.; Qin, K.; Li, S.L. The Research status of the wetting of metal/ceramic in the high temperature self-lubricating materials. Int. J. Mater. Sci. Appl. 2016, 5, 108–112. [Google Scholar]

- Hu, L.X.; Yang, Y.W.; Luo, S.J.; Xu, X.Y. Investigation on the dynamics of infiltration of liquid aluminum into an alumina fibrous perform. J. Mater. Process. Technol. 1999, 94, 227–230. [Google Scholar]

- Lin, X.T.; Chu, S.J.; Wang, H.W. Design of counter pressure infiltration and solidification equipment of metal matrix composite. China Mech. Eng. 1996, 7, 53–55. [Google Scholar]

- Ma, Y.Q.; Li, S.S.; Wang, J.; Ju, L.Y.; Liu, X.M. Influence of defects on bending properties of 2D-700/E44 composites prepared by improved compression molding process. Materials 2018, 11, 2132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.; Wang, Y.M.; Yang, Q.; Feng, L.J.; Yang, R. Study on tensile behavior of SiC/TC17 composites. Acta. Metall. Sin. 2015, 52, 1025–1037. [Google Scholar]

- Zhao, S.; Yang, Z.C.; Zhou, X.G. Fracture behavior of SiC/SiC composites with different interfaces. J. Inorg. Mater. 2016, 31, 58–62. [Google Scholar]

- Gao, F.; Boniface, L.; Ogin, S.L.; Smith, P.A.; Greaves, R.P. Damage accumulation in woven-fabric CFRP laminates under tensile loading: Part 1. Observations of damage accumulation. Compos. Sci. Technol. 1999, 59, 123–126. [Google Scholar] [CrossRef]

- Billy, M.A.; Kwon, Y.W.; Pollak, R.D. Study of Composite interface fracture and crack growth monitoring using carbon nanotubes. Appl. Compos. Mater. 2010, 17, 347–362. [Google Scholar] [CrossRef]

| Curing Mixed Ratio/ Mass Ratio | Natural Curing Time /h | Pressure-Free Heating Curing Temperature/°C | Pressure-Free Heating Curing Time/min | Pressure Heating Curing Temperature/°C | Pressure Heating Curing Pressure/MPa | Pressure Heating Curing Time/min |

|---|---|---|---|---|---|---|

| 5:1 | 4 | 80 | 20 | 50 | 0.5-0.9 | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Zhao, Y.; Zhang, Y.; Wang, J.; Chen, Y.; Li, K.; Ju, L.; Yu, Y. Influence of Infiltration Pressure on the Microstructure and Properties of 2D-CFRP Prepared by the Vacuum Infiltration Hot Pressing Molding Process. Polymers 2019, 11, 2014. https://doi.org/10.3390/polym11122014

Ma Y, Zhao Y, Zhang Y, Wang J, Chen Y, Li K, Ju L, Yu Y. Influence of Infiltration Pressure on the Microstructure and Properties of 2D-CFRP Prepared by the Vacuum Infiltration Hot Pressing Molding Process. Polymers. 2019; 11(12):2014. https://doi.org/10.3390/polym11122014

Chicago/Turabian StyleMa, Yuqin, Yatao Zhao, Yun Zhang, Jie Wang, Yi Chen, Kaifu Li, Luyan Ju, and Ying Yu. 2019. "Influence of Infiltration Pressure on the Microstructure and Properties of 2D-CFRP Prepared by the Vacuum Infiltration Hot Pressing Molding Process" Polymers 11, no. 12: 2014. https://doi.org/10.3390/polym11122014