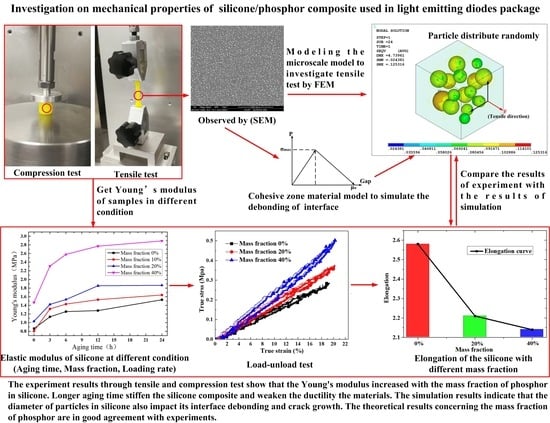

Investigation of Mechanical Properties of Silicone/Phosphor Composite Used in Light Emitting Diodes Package

Abstract

:1. Introduction

2. Experiment Preparation

3. Numerical Simulation

4. Discussion

4.1. Experimental Results

4.1.1. SEM Observation

4.1.2. Mechanical Test Results

4.2. Numerical Simulation Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, K.; Luo, X. Optical Analysis of an 80-W Lighting-Emitting-Diode Street Lamp. Opt. Eng. 2008, 47, 013002. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, S. Status and Prospects for Phosphor Bases White LED Packaging. Front. Optoelectron. China 2009, 2, 119–140. [Google Scholar] [CrossRef]

- Schubert, E.F.; Kim, J.K. Solid-state light sources getting smart. Science 2005, 308, 1274–1278. [Google Scholar] [CrossRef] [PubMed]

- Pimputkar, S.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Prospects for led lighting. Nat. Photon. 2009, 3, 180–182. [Google Scholar] [CrossRef]

- Liu, S.; Luo, X. LED Packaging for Lighting Applications: Design, Manufacturing and Testing; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Yang, Y.; Shi, H.-Q.; Li, W.-N.; Xiao, H.-M.; Luo, Y.-S.; Fu, S.-Y.; Liu, T. Tunable photoluminescent properties of novel transparent CdSe-QD/silicone nanocomposites. Compos. Sci. Technol. 2011, 71, 1652–1658. [Google Scholar] [CrossRef]

- Yang, C.H.; Bhongale, C.J.; Chou, C.H.; Yang, S.H.; Lo, C.N.; Chen, T.M.; Hsu, C.-S. Synthesis and light emitting properties of sulfide-containing polyfluorenes and their nanocomposites with CdSe nanocrystals: A simple process to suppress ketodefect. Polymer 2007, 48, 116–128. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Q.; Chen, Z.; Chen, R.; Chen, Z.; Jiao, F.; Chen, M.; Luo, X.; Liu, S. Comparison of LED Package Reliability under Thermal Cycling and Thermal Shock Conditions by Experimental Testing and Finite Element Simulation. In Proceedings of the Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 31 May–3 June 2011; pp. 454–459. [Google Scholar]

- Zhaohui, C.; Qin, Z. Fluid-solid coupling thermo-mechanical analysis of high power LED package during thermal shock testing. Microelectron. Reliab. 2012, 52, 1726–1734. [Google Scholar]

- Chen, Z.; Zhang, Q.; Wang, K.; Luo, X.; Liu, S. Reliability test and failure analysis of high power LED packages. J. Semicond. 2011, 32, 53–56. [Google Scholar] [CrossRef]

- Chen, Z.; Luo, X.; Liu, S. Thermal analysis of 3D packaging with a simplified thermal resistance network model and finite Element Simulation. In Proceedings of the 11th International Conference on Eletronic Packaging Technology & High Density Packaging, Xi’an, China, 16–19 August 2010; pp. 737–741. [Google Scholar]

- Chen, X.; Wang, S.; Cao, C.; Liu, S. Influence of phosphor amount on microstructure and damage evolution of siliconephosphor composite in light-emitting diodes packaging. Compos. Sci. Technol. 2015, 107, 98–106. [Google Scholar] [CrossRef]

- Meneghini, M.; Dal Lago, M.; Trivellin, N.; Mura, G.; Vanzi, M.; Meneghesso, G. Chip and package-related degradation of high power white LEDs. Microelectron. Reliab. 2012, 52, 804–812. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. Part B 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, T.; Chen, S.; Liu, Q. The approximate formula of normal distribution intergral and its application in experimental result determination. Adv. Meas. Lab. Manag. 2009, 3, 21–23. [Google Scholar]

- Alfano, G.; Crisfield, M.A. Finite Element Interface Models for the Delamination Anaylsis of Laminated Composites: Mechanical and Computational Issues. Int. J. Numer. Methods Eng. 2001, 50, 1701–1736. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Young’s Modulus | Poisson’s Patio |

|---|---|---|---|

| Silicone | 1.15 | 3.1 | 0.48 |

| Phosphor | 4.88 | 335,000 | 0.28 |

| Cumulative probability | Diameter (μm) | Cumulative probability | Diameter (μm) |

|---|---|---|---|

| 5% | ≤10.1933 | 60% | ≤18.6325 |

| 10% | ≤11.5801 | 70% | ≤20.2879 |

| 20% | ≤13.3915 | 80% | ≤22.4957 |

| 30% | ≤14.6582 | 90% | ≤26.1263 |

| 40% | ≤15.9145 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Zhu, F.; Fan, J.; Tao, J.; Lin, X.; Wang, F.; Shi, L. Investigation of Mechanical Properties of Silicone/Phosphor Composite Used in Light Emitting Diodes Package. Polymers 2018, 10, 195. https://doi.org/10.3390/polym10020195

Pan Y, Zhu F, Fan J, Tao J, Lin X, Wang F, Shi L. Investigation of Mechanical Properties of Silicone/Phosphor Composite Used in Light Emitting Diodes Package. Polymers. 2018; 10(2):195. https://doi.org/10.3390/polym10020195

Chicago/Turabian StylePan, Yongjun, Fulong Zhu, Jiajie Fan, Jiaquan Tao, Xinxin Lin, Fengren Wang, and Lang Shi. 2018. "Investigation of Mechanical Properties of Silicone/Phosphor Composite Used in Light Emitting Diodes Package" Polymers 10, no. 2: 195. https://doi.org/10.3390/polym10020195