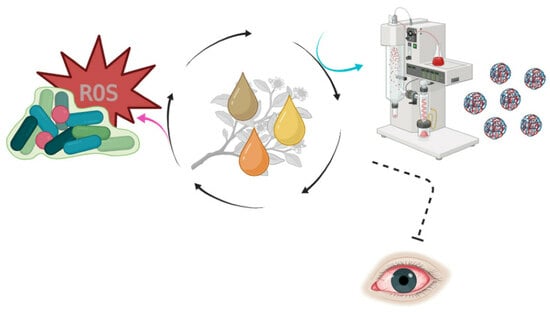

Enhancing the Functional Properties of Tea Tree Oil: In Vitro Antimicrobial Activity and Microencapsulation Strategy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. TTO Analysis

2.2.1. Gas Chromatography—Mass Spectrometry Analysis

2.2.2. Characterization and Validation of UV/Vis Method

2.3. Biological Activity of Free TTO

2.3.1. Antimicrobial Screening

Bacterial Strains

Diffusion Agar Assay

Determination of the Minimum Inhibitory Concentration (MIC) and Minimum Bactericidal Concentration (MBC)

Bacterial Kill Curves

2.3.2. Evaluation of Antibiofilm Activity

Crystal Violet Assay

MTT in Assembled Biofilms

2.4. Antioxidant Activity of TTO

2.5. Preparation of Microcapsules by Spray-Drying

2.5.1. Preparation of Emulsions

2.5.2. Spray Drying

2.5.3. Determination of Microencapsulation Yield (EY), Microencapsulation Efficiency (ME) and Oil Embedding Rate (ER)

2.5.4. Particle-Size Analyses

2.5.5. Scanning Electron Microscopy (SEM)

2.5.6. Fourier-Transform Infrared Spectroscopy (FTIR)

2.5.7. Antimicrobial Screening of Microencapsulated TTO

3. Results and Discussion

3.1. GC-MS Analysis of TTO and Encapsulated TTO

3.2. Biological and Antioxidant Activity of Free TTO

3.2.1. Antimicrobial Activity of TTO

3.2.2. MIC/MBC

3.3. Bacterial Kill Curves of Free TTO

3.4. Antibiofilm Activity of Free TTO

3.5. Antioxidant Activity

3.6. Microencapsulation of TTO

3.6.1. Microencapsulation Yield (EY), Microencapsulation Efficiency (ME), and Oil Embedding Rate (ER)

3.6.2. Particle Size and Morphological Characterization of the Microcapsules of TTO

3.7. Antimicrobial Screening of Microencapsulated TTO

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kant, R.; Kumar, A. Review on essential oil extraction from aromatic and medicinal plants: Techniques, performance and economic analysis. Sustain. Chem. Pharm. 2022, 30, 100829. [Google Scholar] [CrossRef]

- Baptista-Silva, S.; Borges, S.; Ramos, O.L.; Pintado, M.; Sarmento, B. The progress of essential oils as potential therapeutic agents: A review. J. Essent. Oil Res. 2020, 32, 279–295. [Google Scholar] [CrossRef]

- Dhifi, W.; Bellili, S.; Jazi, S.; Bahloul, N.; Mnif, W. Essential oils’ chemical characterization and investigation of some biological activities: A critical review. Medicines 2016, 3, 25. [Google Scholar] [CrossRef]

- de Sousa, D.P.; Damasceno, R.O.S.; Amorati, R.; Elshabrawy, H.A.; de Castro, R.D.; Bezerra, D.P.; Nunes, V.R.V.; Gomes, R.C.; Lima, T.C. Essential oils: Chemistry and pharmacological activities. Biomolecules 2023, 13, 1144. [Google Scholar] [CrossRef]

- Rumelt, S. Overview of Common and Less Common Ocular Infections; Intechopen: London, UK, 2016. [Google Scholar] [CrossRef]

- Lebeaux, D.; Ghigo, J.M.; Beloin, C. Biofilm-related infections: Bridging the gap between clinical management and fundamental aspects of recalcitrance toward antibiotics. Microbiol. Mol. Biol. Rev. 2014, 78, 510–543. [Google Scholar] [CrossRef] [PubMed]

- Sosnik, A.; Seremeta, K.P. Advantages and challenges of the spray-drying technology for the production of pure drug particles and drug-loaded polymeric carriers. Adv. Colloid Interface Sci. 2015, 223, 40–54. [Google Scholar] [CrossRef] [PubMed]

- Al-Khattawi, A.; Bayly, A.; Phillips, A.; Wilson, D. The design and scale-up of spray dried particle delivery systems. Expert Opin. Drug Deliv. 2018, 15, 47–63. [Google Scholar] [CrossRef] [PubMed]

- Camera, N.A.; Reinoso, E.B.; Montironi, I.D.; Moliva, M.V.; Raviolo, J.; Ruiz Moreno, F.; Marin, C.; Camacho, N.M.; Paredes, A.J.; Morán, M.C.; et al. Spray-drying-microencapsulated Minthostachys verticillata essential oil and limonene as innovative adjuvant strategy to bovine mastitis vaccines. Res. Vet. Sci. 2022, 149, 136–150. [Google Scholar] [CrossRef]

- Sánchez-Osorno, D.M.; López-Jaramillo, M.C.; Caicedo Paz, A.V.; Villa, A.L.; Peresin, M.S.; Martínez-Galán, J.P. Recent advances in the microencapsulation of essential oils, lipids, and compound lipids through spray drying: A review. Pharmaceutics 2023, 15, 1490. [Google Scholar] [CrossRef]

- Yadav, E.; Kumar, S.; Mahant, S.; Khatkar, S.; Rao, R. Tea tree oil: A promising essential oil. J. Essent. Oil Res. 2017, 29, 201–2013. [Google Scholar] [CrossRef]

- Carson, C.F.; Hammer, K.A.; Riley, T.V. Melaleuca alternifolia (Tea Tree) oil: A review of antimicrobial and other medicinal properties. Clin. Microbiol. Rev. 2006, 19, 50–62. [Google Scholar] [CrossRef]

- ISO 4730:2017; Essential Oil of Melaleuca, Terpinen-4-ol Type (Tea Tree Oil). International Standards Organisation: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/69082.html (accessed on 15 August 2023).

- Sharifi-Rad, J.; Sureda, A.; Tenore, G.C.; Daglia, M.; Sharifi-Rad, M.; Valussi, M.; Tundis, R.; Sharifi-Rad, M.; Loizzo, M.R.; Ademiluyi, A.O.; et al. Biological activities of essential oils: From plant chemoecology to traditional healing systems. Molecules 2017, 22, 70. [Google Scholar] [CrossRef] [PubMed]

- Lam, N.S.; Long, X.; Su, X.Z.; Lu, F. Melaleuca alternifolia (tea tree) oil and its monoterpene constituents in treating protozoan and helminthic infections. Biomed. Pharmacother. 2020, 130, 110624. [Google Scholar] [CrossRef] [PubMed]

- Terzi, V.; Morcia, C.; Faccioli, P.; Valè, G.; Tacconi, G.; Malnati, M. In vitro antifungal activity of the tea tree (Melaleuca alternifolia) essential oil and its major components against plant pathogens. Lett. Appl. Microbiol. 2007, 44, 613–618. [Google Scholar] [CrossRef] [PubMed]

- Oliva, B.; Piccirilli, E.; Ceddia, T.; Pontieri, E.; Aureli, P.; Ferrini, A.M. Antimycotic activity of Melaleuca alternifolia essential oil and its major components. Lett. Appl. Microbiol. 2003, 37, 185–187. [Google Scholar] [CrossRef] [PubMed]

- Tranchida, P.Q.; Shellie, R.A.; Purcaro, G.; Conte, L.S.; Dugo, P.; Dugo, G.; Mondello, L. Analysis of fresh and aged tea tree essential oils by using GC×GC-qMS. J. Chromatogr. Sci. 2010, 48, 262–266. [Google Scholar] [CrossRef]

- Xu, Y.L.; Wang, W.; Qian, X.Z.; Yang, X.X. Quantitative Determination Method for Tea Tree Oil in Solution. Chinese Patent CN1880945A, 20 December 2006. [Google Scholar]

- CLSI. Performance Standards for Antimicrobial Disk Susceptibility Tests, 7th ed.; Clinical and Laboratory Standards Institute: Wayne, PA, USA, 2012. [Google Scholar]

- Wang, S.; Wang, H.; Ren, B.; Li, H.; Weir, M.D.; Zhou, X.; Oates, T.W.; Cheng, L.; Xu, H.H.K. Do quaternary ammonium monomers induce drug resistance in cariogenic, endodontic and periodontal bacterial species? Dent. Mater. 2017, 33, 1127–1138. [Google Scholar] [CrossRef]

- Martínez, S.R.; Palacios, Y.B.; Heredia, D.A.; Aiassa, V.; Bartolilla, A.; Durantini, A.M. Self-sterilizing 3D-printed polylactic acid surfaces soated with a BODIPY photosensitizer. ACS Appl. Mater. Interfaces 2021, 13, 11597–11608. [Google Scholar] [CrossRef]

- Martínez, S.R.; Ibarra, L.E.; Ponzio, R.A.; Forcone, M.V.; Wendel, A.B.; Chesta, C.A.; Spesia, M.B.; Palacios, R.E. Photodynamic inactivation of ESKAPE group bacterial pathogens in planktonic and biofilm cultures using metallated porphyrin-doped conjugated polymer nanoparticles. ACS Infect. Dis. 2020, 6, 2202–2213. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Mumu, S.K.; Hossain, M.M. Antimicrobial activity of tea tree oil against pathogenic bacteria and comparison of its effectiveness with eucalyptus oil, lemongrass oil and conventional antibiotics. Am. J. Microb. Res. 2018, 6, 73–78. [Google Scholar]

- Carson, C.F.; Riley, T.V. Antimicrobial activity of the major components of the essential oil of Melaleuca alternifolia. J. Appl. Bacteriol. 1995, 78, 264–269. [Google Scholar] [CrossRef] [PubMed]

- Christoph, F.; Kaulfers, P.M.; Stahl-Biskup, E. A comparative study of the in vitro antimicrobial activity of tea tree oils with special reference to the activity of β-triketones. Planta Med. 2000, 66, 556–560. [Google Scholar] [CrossRef] [PubMed]

- Griffin, S.G.; Markham, J.L.; Leach, D.N. An agar dilution method for the determination of the minimum inhibitory concentration of essential oils. J. Essent. Oil Res. 2000, 12, 249–255. [Google Scholar] [CrossRef]

- Hammer, K.A.; Carson, C.F.; Riley, T.V. Susceptibility of transient and commensal skin flora to the essential oil of Melaleuca alternifolia (tea tree oil). Am. J. Infect. Control 1996, 24, 186–189. [Google Scholar] [CrossRef]

- Banes-Marshall, L.; Cawley, P.; Phillips, C.A. In vitro activity of Melaleuca alternifolia (tea tree) oil against bacterial and Candida spp. isolates from clinical specimens. Br. J. Biomed. Sci. 2001, 58, 139–145. [Google Scholar]

- Silva, N.C.C.; Fernandes Júnior, A. Biological properties of medicinal plants: A review of their antimicrobial activity. J. Venom. Anim. Toxins Incl. Trop. Dis. 2010, 16, 402–413. [Google Scholar] [CrossRef]

- Rios, J.L.; Recio, M.C. Medicinal plants and antimicrobial activity. J. Ethnopharmacol. 2005, 100, 80–84. [Google Scholar] [CrossRef]

- Alves, E.; Faustino, M.A.; Neves, M.G.; Cunha, A.; Tome, J.; Almeida, A. An insight on bacterial cellular targets of photodynamic inactivation. Future Med. Chem. 2014, 6, 141–164. [Google Scholar] [CrossRef]

- Cox, S.D.; Mann, C.M.; Markham, J.L.; Gustafson, J.E.; Warmington, J.R.; Wyllie, S.G. Determining the antimicrobial actions of tea tree oil. Molecules 2001, 6, 87–91. [Google Scholar] [CrossRef]

- Baldassarri, L.; Simpson, W.; Donelli, G.; Christensen, G. Variable fixation of staphylococcal slime by different histochemical fixatives. Eur. J. Clin. Microbiol. Infect. Dis. 1993, 12, 866–868. [Google Scholar] [CrossRef]

- Kwieciński, J.; Eick, S.; Wójcik, K. Effects of tea tree (Melaleuca alternifolia) oil on Staphylococcus aureus in biofilms and stationary growth phase. Int. J. Antimicrob. Agents 2009, 33, 343–347. [Google Scholar] [CrossRef]

- El-Tarabily, K.A.; El-Saadony, M.T.; Alagawany, M.; Arif, M.; Batiha, G.E.; Khafaga, A.F.; Elwan, H.A.M.; Elnesr, S.S.; Abd El-Hack, M.E. Using essential oils to overcome bacterial biofilm formation and their antimicrobial resistance. Saudi J. Biol. Sci. 2021, 28, 5145–5156. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Chen, F.; Wu, C.; Wang, X.; Chung, H.Y.; Jin, Z. Evaluation of antioxidant activity of Australian tea tree (Melaleuca alternifolia) oil and its components. J. Agric. Food Chem. 2004, 52, 2849–2854. [Google Scholar] [CrossRef]

- Burhan, A.M.; Abdel-Hamid, S.M.; Soliman, M.E.; Sammour, O.A. Optimisation of the microencapsulation of lavender oil by spray drying. J. Microencapsul. 2019, 36, 250–266. [Google Scholar] [CrossRef]

- Sousa, V.I.; Parente, J.F.; Marques, J.F.; Forte, M.A.; Tavares, C.J. Microencapsulation of essential oils: A review. Polymers 2022, 14, 1730. [Google Scholar] [CrossRef] [PubMed]

- Da Costa, J.M.; Borges, S.V.; Hijo, A.A.; Silva, E.K.; Marques, G.R.; Cirillo, M.Â.; de Azevedo, V.M. Matrix structure selection in the microparticles of essential oil oregano produced by spray dryer. J. Microencapsul. 2013, 30, 717–727. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, L.P.; Turatti, I.C.; Lopes, N.P.; Ferreira, J.C.; Candido, R.C.; Oliveira, W.P. Volatile retention and antifungal properties of spray-dried microparticles of Lippia sidoides essential oil. Dry. Technol. 2008, 26, 1534–1542. [Google Scholar] [CrossRef]

- Alvarenga Botrel, D.; Vilela Borges, S.; de Barros Fernandes, R.V.; Dantas Viana, A.; Gomes da Costa, J.M.; Marques, G.R. Evaluation of spray drying conditions on properties of microencapsulated oregano essential oil. Int. J. Food Sci. Technol. 2012, 47, 2289–2296. [Google Scholar] [CrossRef]

- Huang, H.J.; Yuan, W.K.; Chen, X.D. Microencapsulation based on emulsification for producing pharmaceutical products: A literature review. Dev. Chem. Eng. Min. Process. 2006, 14, 515–544. [Google Scholar] [CrossRef]

- Garcia, L.C.; Tonon, R.V.; Hubinger, M.D. Effect of homogenization pressure and oil load on the emulsion properties and the oil retention of microencapsulated basil essential oil. Dry. Technol. 2012, 30, 1413–1421. [Google Scholar] [CrossRef]

- López, A.; Castro, S.; Andina, M.J.; Ures, X.; Munguía, B.; Llabot, J.M.; Elder, H.; Dellacassa, E.; Palma, S.; Domínguez, L. Insecticidal activity of microencapsulated Schinus molle essential oil. Ind. Crops Prod. 2014, 53, 209–216. [Google Scholar] [CrossRef]

- Mahdi, A.A.; Mohammed, J.K.; Al-Ansi, W.; Ghaleb, A.D.S.; Al-Maqtari, Q.A.; Ma, M.; Ahmed, M.I.; Wang, H. Microencapsulation of fingered citron extract with gum arabic, modified starch, whey protein, and maltodextrin using spray drying. Int. J. Biol. Macromol. 2020, 152, 1125–1134. [Google Scholar] [CrossRef] [PubMed]

- Suna, Z.; Yanga, C.; Eggersdorferc, M.; Cuic, J.; Lic, Y.; Haic, M.; Chena, D.; Weitzc, D.A. A general strategy for one-step fabrication of biocompatible microcapsules with controlled active release. Chin. Chem. Lett. 2020, 31, 249–252. [Google Scholar] [CrossRef]

| Agar Diffusion Method (mm) 1 | |||||

|---|---|---|---|---|---|

| Microorganism | TTO 2 % v/v | ||||

| 100 | 50 | 25 | 12.5 | 6.25 | |

| S. aureus | 31 ± 2 | 25 ± 2 | 18 ± 2 | 14 ± 1 | NH 3 |

| S. aureus ATCC | 29 ± 2 | 23 ± 1 | 15 ± 3 | 12 ± 2 | 10 ± 1 |

| Staphylococcus spp. negative coagulase | 31 ± 1 | 18 ± 3 | 11 ± 2 | NH | NH |

| Corynebacterium spp. | 21 ± 1 | 16 ± 1 | 14 ± 1 | 11 ± 2 | 8 ± 2 |

| MIC | MBC | |

|---|---|---|

| Microorganism | ||

| S. aureus | 0.2% v/v (1.8 mg/mL) | 0.4% v/v (3.5 mg/mL) |

| S. aureus ATCC | 0.2% v/v (1.8 mg/mL) | 0.4% v/v (3.5 mg/mL) |

| Staphylococcus spp. negative coagulase | 0.4% v/v (3.5 mg/mL) | 0.8% v/v (7.0 mg/mL) |

| Corynebacterium spp. | 0.4% v/v (3.5 mg/mL) | - * |

| Particle Size (μm) | ||||

|---|---|---|---|---|

| Average D10 | Average D50 | Average D90 | Average Span | |

| Formulation 1 | 6.17 ± 0.10 | 9.00 ± 0.20 | 12.90 ± 0.30 | 0.740 ± 0.002 |

| Formulation 2 | 5.96 ± 0.09 | 8.56 ± 0.10 | 12.20 ± 0.30 | 0.720 ± 0.003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manzanelli, F.A.; Ravetti, S.; Brignone, S.G.; Garro, A.G.; Martínez, S.R.; Vallejo, M.G.; Palma, S.D. Enhancing the Functional Properties of Tea Tree Oil: In Vitro Antimicrobial Activity and Microencapsulation Strategy. Pharmaceutics 2023, 15, 2489. https://doi.org/10.3390/pharmaceutics15102489

Manzanelli FA, Ravetti S, Brignone SG, Garro AG, Martínez SR, Vallejo MG, Palma SD. Enhancing the Functional Properties of Tea Tree Oil: In Vitro Antimicrobial Activity and Microencapsulation Strategy. Pharmaceutics. 2023; 15(10):2489. https://doi.org/10.3390/pharmaceutics15102489

Chicago/Turabian StyleManzanelli, Franco Antonio, Soledad Ravetti, Sofia Gisella Brignone, Ariel Gustavo Garro, Sol Romina Martínez, Mariana Guadalupe Vallejo, and Santiago Daniel Palma. 2023. "Enhancing the Functional Properties of Tea Tree Oil: In Vitro Antimicrobial Activity and Microencapsulation Strategy" Pharmaceutics 15, no. 10: 2489. https://doi.org/10.3390/pharmaceutics15102489