Ultrasound Treatment Enhanced Semidry-Milled Rice Flour Properties and Gluten-Free Rice Bread Quality

Abstract

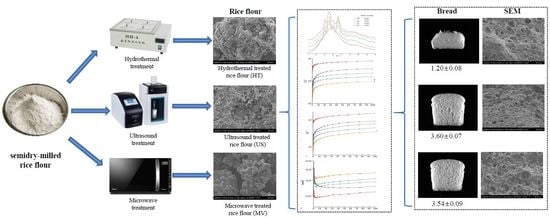

:1. Introduction

2. Results and Discussion

2.1. Particle Size, Damaged Starch (DS)

2.2. Granule Morphology

2.3. Crystal Structure

2.4. Short-Range Ordered Structure of Starch and Secondary Structure of Protein

2.5. Hydration Properties

2.6. Thermal Properties

2.7. Pasting Properties

2.8. Rheological Properties of Rice Batter

2.9. Bread Quality

2.10. Principal Component Analysis (PCA)

3. Materials and Methods

3.1. Rice Flour

3.2. Different Physical Modification Methods

3.2.1. Ultrasound Treatment

3.2.2. Microwave Treatment

3.2.3. Hydrothermal Treatment

3.3. Particle Size Distribution, Damaged Starch (DS) Content and Protein Content

3.4. Scanning Electron Microscopy (SEM)

3.5. X-ray Diffraction (XRD)

3.6. Water Hydration Property

3.7. Short-Range Ordered Structure of Starch and Secondary Structure of Protein

3.8. Differential Scanning Calorimetry (DSC)

3.9. Pasting Properties

3.10. Rheological Properties of Gels

3.11. Breadmaking Procedure

3.12. Gluten-Free Rice Bread Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Brouns, F.; van Rooy, G.; Shewry, P.; Rustgi, S.; Jonkers, D. Adverse Reactions to Wheat or Wheat Components. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1437–1452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Santos, F.G.; Aguiar, E.V.; Rosell, C.M.; Capriles, V.D. Potential of chickpea and psyllium in gluten-free breadmaking: Assessing bread's quality, sensory acceptability, and glycemic and satiety indexes. Food Hydrocoll. 2021, 113, 106487. [Google Scholar] [CrossRef]

- Solaesa, Á.G.; Villanueva, M.; Muñoz, J.M.; Ronda, F. Dry-heat treatment vs. heat-moisture treatment assisted by microwave radiation: Techno-functional and rheological modifications of rice flour. LWT-Food Sci. Technol. 2021, 141, 110851. [Google Scholar] [CrossRef]

- Sun, X.; Saleh, A.S.M.; Sun, Z.; Ge, X.; Shen, H.; Zhang, Q.; Yu, X.; Yuan, L.; Li, W. Modification of multi-scale structure, physicochemical properties, and digestibility of rice starch via microwave and cold plasma treatments. LWT-Food Sci. Technol. 2022, 153, 112483. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Halal, S.; Dias, A.R.G.; Zavareze, E.D.R. Physical modification of starch by heat-moisture treatment and annealing and their applications: A review. Carbohyd. Polym. 2021, 274, 118665. [Google Scholar] [CrossRef]

- Ruiz, E.; Srikaeo, K.; Revilla, L. Effects of Heat Moisture Treatment on Physicochemical Properties and Starch Digestibility of Rice Flours Differing in Amylose Content. Food Appl. Biosci. 2018, 6, 140–153. [Google Scholar]

- Li, Y.-D.; Xu, T.-C.; Xiao, J.-X.; Zong, A.-Z.; Qiu, B.; Jia, M.; Liu, L.-N.; Liu, W. Efficacy of potato resistant starch prepared by microwave–toughening treatment. Carbohyd. Polym. 2018, 192, 299–307. [Google Scholar] [CrossRef]

- Villanueva, M.; Harasym, J.; Muñoz, J.M.; Ronda, F. Rice flour physically modified by microwave radiation improves viscoelastic behavior of doughs and its bread-making performance. Food Hydrocoll. 2019, 90, 472–481. [Google Scholar] [CrossRef] [Green Version]

- Shabbir, M.A.; Ahmed, W.; Latif, S.; Inam-Ur-Raheem, M.; Manzoor, M.F.; Khan, M.R.; Bilal, R.M.; Aadil, R.M. The quality behavior of ultrasound extracted sunflower oil and structural computation of potato strips appertaining to deep-frying with thermic variations. J. Food Process. Preserv. 2020, 44, e14809. [Google Scholar] [CrossRef]

- Tayyab Rashid, M.; Ahmed Jatoi, M.; Safdar, B.; Wali, A.; Muhammad Aadil, R.; Sarpong, F.; Ma, H. Modeling the drying of ultrasound and glucose pretreated sweet potatoes: The impact on phytochemical and functional groups. Ultrason. Sonochem. 2020, 68, 105226. [Google Scholar] [CrossRef]

- Cui, R.; Zhu, F. Effect of ultrasound on structural and physicochemical properties of sweetpotato and wheat flours. Ultrason. Sonochem. 2020, 66, 105118. [Google Scholar] [CrossRef]

- Li, S.; Li, Q.; Zhu, F.; Song, H.; Wang, C.; Guan, X. Effect of vacuum combined ultrasound treatment on the fine structure and physiochemical properties of rice starch. Food Hydrocoll. 2022, 124, 107198. [Google Scholar] [CrossRef]

- Qin, W.; Lin, Z.; Wang, A.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of particle size on the properties of rice flour and quality of gluten-free rice bread. LWT-Food Sci. Technol. 2021, 151, 112236. [Google Scholar] [CrossRef]

- Tong, L.-T.; Zhu, R.; Zhou, X.; Zhong, K.; Wang, L.; Liu, L.; Hu, X.; Zhou, S. Soaking time of rice in semidry flour milling was shortened by increasing the grains cracks. J. Cereal Sci. 2017, 74, 121–126. [Google Scholar] [CrossRef]

- Kaur, H.; Gill, B.S. Effect of high-intensity ultrasound treatment on nutritional, rheological and structural properties of starches obtained from different cereals. Int. J. Biol. Macromol. 2019, 126, 367–375. [Google Scholar] [CrossRef]

- Villanueva, M.; Harasym, J.; Muñoz, J.M.; Ronda, F. Microwave absorption capacity of rice flour. Impact of the radiation on rice flour microstructure, thermal and viscometric properties. J. Food Eng. 2018, 224, 156–164. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, H.; Wu, G.; Qi, X.; Wang, L.; Qian, H. Effect of structure evolution of starch in rice on the textural formation of cooked rice. Food Chem. 2020, 342, 128205. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Kong, X.; Zheng, Y.; Sun, W.; Chen, S.; Liu, D.; Zhang, H.; Fang, H.; Tian, J.; Ye, X. Controlled ultrasound treatments modify the morphology and physical properties of rice starch rather than the fine structure. Ultrason. Sonochem. 2019, 59, 104709. [Google Scholar] [CrossRef]

- Kumar, Y.; Singh, L.; Sharanagat, V.S.; Patel, A.; Kumar, K. Effect of microwave treatment (low power and varying time) on potato starch: Microstructure, thermo-functional, pasting and rheological properties. Int. J. Biol. Macromol. 2020, 155, 27–35. [Google Scholar] [CrossRef]

- Vela, A.J.; Villanueva, M.; Ronda, F. Low-frequency ultrasonication modulates the impact of annealing on physicochemical and functional properties of rice flour. Food Hydrocoll. 2021, 120, 106933. [Google Scholar] [CrossRef]

- Han, Z.; Li, Y.; Luo, D.H.; Zhao, Q.; Cheng, J.H.; Wang, J.H. Structural variations of rice starch affected by constant power microwave treatment. Food Chem. 2021, 359, 129887. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Luo, D.; Xiang, J.; Xu, W.; Xu, B.; Li, P.; Huang, J. Structural Variations of Wheat Proteins under ultrasound treatment. J. Cereal Sci. 2021, 99, 103219. [Google Scholar] [CrossRef]

- Hu, H.; Wu, J.; Li-Chan, E.C.Y.; Zhu, L.; Zhang, F.; Xu, X.; Fan, G.; Wang, L.; Huang, X.; Pan, S. Effects of ultrasound on structural and physical properties of soy protein isolate (SPI) dispersions. Food Hydrocoll. 2013, 30, 647–655. [Google Scholar] [CrossRef]

- Vela, A.J.; Villanueva, M.; Solaesa, Á.G.; Ronda, F. Impact of high-intensity ultrasound waves on structural, functional, thermal and rheological properties of rice flour and its biopolymers structural features. Food Hydrocoll. 2021, 113, 106480. [Google Scholar] [CrossRef]

- Luo, D.; Wu, R.; Zhang, J.; Zhang, K.; Xu, B.; Li, P.; Yuan, Y.; Li, X. Effects of ultrasound assisted dough fermentation on the quality of steamed bread. J. Cereal Sci. 2018, 83, 147–152. [Google Scholar] [CrossRef]

- Lee, Y.T.; Shim, M.J.; Goh, H.K.; Mok, C.; Puligundla, P. Effect of jet milling on the physicochemical properties, pasting properties, and in vitro starch digestibility of germinated brown rice flour. Food Chem. 2019, 282, 164–168. [Google Scholar] [CrossRef] [PubMed]

- Sujka, M.; Jamroz, J. Ultrasound-treated starch: SEM and TEM imaging, and functional behaviour. Food Hydrocoll. 2013, 31, 413–419. [Google Scholar] [CrossRef]

- Mohammad Amini, A.; Razavi, S.M.; Mortazavi, S.A. Morphological, physicochemical, and viscoelastic properties of sonicated corn starch. Carbohyd. Polym. 2015, 122, 282–292. [Google Scholar] [CrossRef]

- Chi, C.; Li, X.; Lu, P.; Miao, S.; Zhang, Y.; Chen, L. Dry heating and annealing treatment synergistically modulate starch structure and digestibility. Int. J. Biol. Macromol. 2019, 137, 554–561. [Google Scholar] [CrossRef]

- Yang, Q.Y.; Lu, X.X.; Chen, Y.Z.; Luo, Z.G.; Xiao, Z.G. Fine structure, crystalline and physicochemical properties of waxy corn starch treated by ultrasound irradiation. Ultrason. Sonochem. 2019, 51, 350–358. [Google Scholar] [CrossRef]

- Meadows, Pasting Process in Rice Flour Using Rapid Visco Analyser Curves and First Derivatives. Cereal Chem. 2002, 79, 559–562. [CrossRef]

- Qin, W.; Lin, Z.; Wang, A.; Xiao, T.; He, Y.; Chen, Z.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of damaged starch on the properties of rice flour and quality attributes of gluten-free rice bread. J. Cereal Sci. 2021, 101, 103296. [Google Scholar] [CrossRef]

- Renzetti, S.; Rosell, C.M. Role of enzymes in improving the functionality of proteins in non-wheat dough systems. J. Cereal Sci. 2016, 67, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Monroy, Y.; Rivero, S.; García, M.A. Microstructural and techno-functional properties of cassava starch modified by ultrasound. Ultrason. Sonochem. 2018, 42, 795–804. [Google Scholar] [CrossRef]

- Crockett, R.; Ie, P.; Vodovotz, Y. How do xanthan and hydroxypropyl methylcellulose individually affect the physicochemical properties in a model gluten-free dough? J. Food Sci. 2011, 76, E274–E282. [Google Scholar] [CrossRef]

- Marston, K.; Khouryieh, H.; Aramouni, F. Effect of heat treatment of sorghum flour on the functional properties of gluten-free bread and cake. LWT-Food Sci. Technol. 2016, 65, 637–644. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Villanueva, M. Rheological Properties of Gluten-Free Bread Doughs: Relationship with Bread Quality. In Advances in Food Rheology and Its Applications; Ahmed, J., Ptaszek, P., Basu, S., Eds.; Woodhead Publishing: Cambridge, UK, 2017; Chapter 12; pp. 297–334. [Google Scholar]

- Roman, L.; Reguilon, M.P.; Gomez, M.; Martinez, M.M. Intermediate length amylose increases the crumb hardness of rice flour gluten-free breads. Food Hydrocoll. 2020, 100, 105451. [Google Scholar] [CrossRef]

- Bourekoua, H.; Benatallah, L.; Zidoune, M.N.; Rosell, C.M. Developing gluten free bakery improvers by hydrothermal treatment of rice and corn flours. LWT-Food Sci. Technol. 2016, 73, 342–350. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Oh, I.; Jeong, S.; Lee, S. Particle size effect of rice flour in a rice-zein noodle system for gluten-free noodles slit from sheeted doughs. J. Cereal Sci. 2019, 86, 48–53. [Google Scholar] [CrossRef]

- Boulemkahel, S.; Betoret, E.; Benatallah, L.; Rosell, C.M. Effect of low pressures homogenization on the physico-chemical and functional properties of rice flour. Food Hydrocoll. 2021, 112, 106373. [Google Scholar] [CrossRef]

- Pongjaruvat, W.; Methacanon, P.; Seetapan, N.; Fuongfuchat, A.; Gamonpilas, C. Influence of pregelatinised tapioca starch and transglutaminase on dough rheology and quality of gluten-free jasmine rice breads. Food Hydrocoll. 2014, 36, 143–150. [Google Scholar] [CrossRef]

| Sample | WF | SF | HT | MW | US |

|---|---|---|---|---|---|

| D50 (µm) | 50.7 ± 0.8c | 59.4 ± 0.2a | 37.7 ± 1.1d | 57.0 ± 1.2b | 17.1 ± 0.9e |

| Damage starch content (g/100 g) | 2.06 ± 0.12d | 3.96 ± 0.04c | 24.41 ± 1.60a | 3.33 ± 0.07cd | 9.91 ± 0.20b |

| R1047/1022 | 1.34 ± 0.15ab | 1.18 ± 0.05cd | 1.28 ± 0.10bc | 1.14 ± 0.03d | 1.44 ± 0.23a |

| β-Sheet (%) | 26.8 ± 0.7c | 30.8 ± 0.2b | 30.0 ± 0.5b | 35.0 ± 0.3a | 30.1 ± 0.3b |

| α-Helix (%) | 25.6 ± 0.5c | 27.7 ± 0.4b | 15.2 ± 0.5d | 28.1 ± 0.3b | 31.7 ± 0.7a |

| β-Turn (%) | 27.1 ± 0.4a | 21.0 ± 0.6b | 27.4 ± 0.5a | 18.6 ± 0.2c | 18.3 ± 0.7c |

| Random coil (%) | 20.5 ± 0.4b | 20.4 ± 0.6b | 27.4 ± 0.4a | 18.3 ± 0.2c | 19.9 ± 0.7bc |

| Sample | WF | SF | HT | MW | US |

|---|---|---|---|---|---|

| Hydration properties | |||||

| WAI (g/g) | 3.05 ± 0.20c | 3.00 ± 0.10c | 10.54 ± 0.08a | 3.81 ± 0.12b | 3.74 ± 0.44b |

| WS (%) | 2.45 ± 0.49b | 2.14 ± 0.76b | 4.33 ± 0.44a | 1.93 ± 0.29b | 3.42 ± 0.22a |

| SP (g/g) | 3.13 ± 0.21c | 3.07 ± 0.07c | 11.02 ± 0.03a | 3.89 ± 0.12b | 3.88 ± 0.46b |

| Thermal properties | |||||

| To (°C) | 62.47 ± 0.11a | 60.78 ± 0.45b | - | 60.18 ± 0.06b | 62.10 ± 0.74a |

| Tp (°C) | 69.02 ± 0.03a | 67.36 ± 0.17b | - | 66.76 ± 0.17b | 66.75 ± 0.75b |

| Te (°C) | 79.98 ± 0.00a | 79.32 ± 0.40bc | - | 76.26 ± 2.74cd | 74.33 ± 0.43d |

| ∆H (J·g−1) | 8.48 ± 0.02a | 7.63 ± 0.19bc | - | 7.85 ± 0.17b | 7.33 ± 0.30c |

| ∆T (°C) | 17.51 ± 0.11a | 18.54 ± 0.36a | - | 16.09 ± 2.77a | 12.22 ± 0.56b |

| Pasting properties | |||||

| PV (cP) | 4144 ± 23a | 4209 ± 46a | 3276 ± 78b | 4067 ± 113a | 2498 ± 122c |

| TV (cP) | 2580 ± 8a | 2300 ± 54b | 2449 ± 60a | 2506 ± 10a | 1731 ± 86c |

| BD (cP) | 1564 ± 15b | 1909 ± 13a | 829 ± 39c | 1561 ± 103b | 768 ± 36c |

| FV (cP) | 4218 ± 7a | 3853 ± 52b | 3901 ± 90b | 4182 ± 52a | 3099 ± 95c |

| SB (cP) | 1638 ± 1ab | 1553 ± 7bc | 1452 ± 81cd | 1677 ± 43a | 1369 ± 29e |

| Sample | Specific Volume (mL/g) | Hardness (g) | Resilence (%) | Cohesion | Springiness (%) | Gumminess | Chewiness |

|---|---|---|---|---|---|---|---|

| WF | 3.72 ± 0.12a | 48.59 ± 2.8b | 47.18 ± 1.6a | 0.89 ± 0.01a | 165.74 ± 5.5a | 44.15 ± 2.8bc | 68.62 ± 4.3b |

| SF | 3.14 ± 0.10b | 51.30 ± 4.7b | 42.73 ± 1.7b | 0.83 ± 0.01b | 97.39 ± 1.8b | 49.61 ± 5.1b | 49.74 ± 6.2bc |

| HT | 1.18 ± 0.07c | 701.70 ± 125.5a | 33.54 ± 2.1c | 0.66 ± 0.02e | 81.23 ± 6.2c | 468.40 ± 21.3a | 442.94 ± 58.9a |

| MW | 3.51 ± 0.19a | 46.06 ± 5.2b | 30.73 ± 0.9d | 0.74 ± 0.02d | 93.78 ± 2.7b | 38.81 ± 4.7cd | 35.91 ± 4.7c |

| US | 3.63 ± 0.08a | 42.27 ± 4.0b | 32.41 ± 1.4d | 0.78 ± 0.02c | 101.35 ± 6.6b | 32.62 ± 3.4d | 31.29 ± 2.8c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, W.; Xi, H.; Wang, A.; Gong, X.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L. Ultrasound Treatment Enhanced Semidry-Milled Rice Flour Properties and Gluten-Free Rice Bread Quality. Molecules 2022, 27, 5403. https://doi.org/10.3390/molecules27175403

Qin W, Xi H, Wang A, Gong X, Chen Z, He Y, Wang L, Liu L, Wang F, Tong L. Ultrasound Treatment Enhanced Semidry-Milled Rice Flour Properties and Gluten-Free Rice Bread Quality. Molecules. 2022; 27(17):5403. https://doi.org/10.3390/molecules27175403

Chicago/Turabian StyleQin, Wanyu, Huihan Xi, Aixia Wang, Xue Gong, Zhiying Chen, Yue He, Lili Wang, Liya Liu, Fengzhong Wang, and Litao Tong. 2022. "Ultrasound Treatment Enhanced Semidry-Milled Rice Flour Properties and Gluten-Free Rice Bread Quality" Molecules 27, no. 17: 5403. https://doi.org/10.3390/molecules27175403