The Influence of Aminoalcohols on ZnO Films’ Structure

Abstract

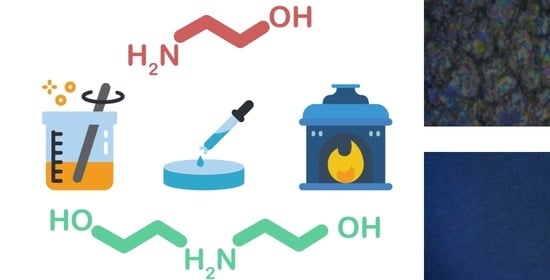

:1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Instrumental Analysis

3. Results

3.1. Layer Morphology and Structural Properties

3.2. Raman Analysis of Layers on Different Substrates

3.3. Change in Spectral Properties Depending on the Stabilizer

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ZnO | Zinc oxide |

| Zn | Zinc |

| MEA | Monoethanolamine |

| DEA | Diethanolamine |

| 0.5 MEA | 5 % of monoethanolamine |

| 1 MEA | 10 % of monoethanolamine |

| 0.5 DEA | 5 % of diethanolamine |

| 1 DEA | 10 % of diethanolamine |

| Si | Silicon |

| AlO | Sapphire |

| SiO | Quartz |

| PL | Photoluminescence |

| Zn | Zinc interstitial |

| V | Oxygen vacancy |

| V | Zinc vacancy |

References

- Khramov, A.N.; Voevodin, N.N.; Balbyshev, V.N.; Donley, M.S. Hybrid Organo-Ceramic Corrosion Protection Coatings with Encapsulated Organic Corrosion Inhibitors. Thin Solid Films 2004, 447, 549–557. [Google Scholar] [CrossRef]

- Livage, J.; Ganguli, D. Sol-Gel Electrochromic Coatings and Devices: A Review. Sol. Energy Mater. Sol. Cells 2001, 68, 365–381. [Google Scholar] [CrossRef]

- Liang, H.; Hu, Y.C.; Tao, Y.; Wu, B.; Wu, Y.; Cao, J. Existence of Ligands within Sol-Gel-Derived ZnO Films and Their Effect on Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 43116–43121. [Google Scholar] [CrossRef] [PubMed]

- Znaidi, L. Sol-Gel-Deposited ZnO Thin Films: A Review. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2010, 174, 18–30. [Google Scholar] [CrossRef]

- Hosseini Vajargah, P.; Abdizadeh, H.; Ebrahimifard, R.; Golobostanfard, M.R. Sol-Gel Derived ZnO Thin Films: Effect of Amino-Additives. Appl. Surf. Sci. 2013, 285, 732–743. [Google Scholar] [CrossRef]

- Pierre, A.C. Introduction to Sol-Gel Processing; Kluwer Academic Publisher: New York, NY, USA, 1998; ISBN 9780792381211. [Google Scholar]

- Gómez-Núnez, A.; Alonso-Gil, S.; López, C.; Roura, P.; Vilà, A. Role of Ethanolamine on the Stability of a Sol-Gel ZnO Ink. J. Phys. Chem. C 2017, 121, 23839–23846. [Google Scholar] [CrossRef]

- Yoon, S.H.; Liu, D.; Shen, D.; Park, M.; Kim, D.J. Effect of Chelating Agents on the Preferred Orientation of ZnO Films by Sol-Gel Process. J. Mater. Sci. 2008, 43, 6177–6181. [Google Scholar] [CrossRef]

- Gómez-Núñez, A.; López, C.; Alonso-Gil, S.; Roura, P.; Vilà, A. Study of a Sol-Gel Precursor and Its Evolution towards ZnO. Mater. Chem. Phys. 2015, 162, 645–651. [Google Scholar] [CrossRef]

- Thongsuriwong, K.; Amornpitoksuk, P.; Suwanboon, S. The Effect of Aminoalcohols (MEA, DEA and TEA) on Morphological Control of Nanocrystalline ZnO Powders and Its Optical Properties. J. Phys. Chem. Solids 2010, 71, 730–734. [Google Scholar] [CrossRef]

- Verma, A.; Kar, M.; Singh, D.P. Aging Effect of Diethanolamine Derived Precursor Sol on TiO2 Films Deposited at Different Annealing Temperatures. J. Sol-Gel Sci. Technol. 2010, 54, 129–138. [Google Scholar] [CrossRef]

- Addonizio, M.L.; Aronne, A.; Daliento, S.; Tari, O.; Fanelli, E.; Pernice, P. Sol-Gel Synthesis of ZnO Transparent Conductive Films: The Role of PH. Appl. Surf. Sci. 2014, 305, 194–202. [Google Scholar] [CrossRef]

- Yamashita, H.; Yoko, T.; Sakka, S. Preparation of Li2B4O7 Films with Preferential Orientation by Sol–Gel Method. J. Am. Ceram. Soc. 1991, 74, 1668–1674. [Google Scholar] [CrossRef]

- Çopuroğlu, M.; O’Brien, S.; Crean, G.M. Sol–gel synthesis, comparative characterisation, and reliability analyses of undoped and Al-doped zinc oxide thin films. Thin Solid Films 2009, 23, 6323–6326. [Google Scholar] [CrossRef]

- Khodja, S.; Touam, T.; Chelouche, A.; Boudjouan, F.; Djouadi, D.; Hadjoub, Z.; Fischer, A.; Boudrioua, A. Effects of Stabilizer Ratio on Structural, Morphological, Optical and Waveguide Properties of ZnO Nano-Structured Thin Films by a Sol-Gel Process. Superlattices Microstruct. 2014, 75, 485–495. [Google Scholar] [CrossRef]

- Yahia, I.S.; Farag, A.A.M.; Cavas, M.; Yakuphanoglu, F. Effects of Stabilizer Ratio on the Optical Constants and Optical Dispersion Parameters of ZnO Nano-Fiber Thin Films. Superlattices Microstruct. 2013, 53, 63–75. [Google Scholar] [CrossRef]

- Pubchem Website. Available online: pubchem.ncbi.nlm.nih.gov (accessed on 10 June 2022).

- Hayami, R.; Endo, N.; Abe, T.; Miyase, Y.; Sagawa, T.; Yamamoto, K.; Tsukada, S.; Gunji, T. Zinc–Diethanolamine Complex: Synthesis, Characterization, and Formation Mechanism of Zinc Oxide via Thermal Decomposition. J. Sol-Gel Sci. Technol. 2018, 87, 743–748. [Google Scholar] [CrossRef]

- Nowak, E.; Szybowicz, M.; Stachowiak, A.; Piechowiak, D.; Miklaszewski, A.; Witkowski, M.E.; Makowski, M.; Drozdowski, W. The Influence of Recrystallization on Zinc Oxide Microstructures Synthesized with Sol – Gel Method on Scintillating Properties. Crystals 2021, 11, 533. [Google Scholar] [CrossRef]

- Bachman, M. Cleaning Procedures for Silicon Wafers; UCI Integrated Nanosystems Research Facility: Irvine, CA, USA, 2002. [Google Scholar]

- Mataré, H.F. Carrier Transport at Grain Boundaries in Semiconductors. J. Appl. Phys. 1984, 56, 2605–2631. [Google Scholar] [CrossRef]

- Stahl, R.; Jung, C.; Lutz, H.D.; Kockelmann, W.; Jacobs, H. Kristallstrukturen Und Wasserstoffbrückenbindungen Bei beta-Be(OH)2 Und epsilon-Zn(OH)2. Zeitschrift für Anorg. und Allg. Chemie 1998, 624, 1130–1136. [Google Scholar] [CrossRef]

- Mousavi-Kamazani, M.; Zinatloo-Ajabshir, S.; Ghodrati, M. One-Step Sonochemical Synthesis of Zn(OH)2/ZnV3O8 Nanostructures as a Potent Material in Electrochemical Hydrogen Storage. J. Mater. Sci. Mater. Electron. 2020, 31, 17332–17338. [Google Scholar] [CrossRef]

- West, C.D. The crystal structure of rhombic ammonium nitrate. J. Am. Chem. Soc. 1932, 54, 2256–2260. [Google Scholar] [CrossRef]

- Frevel, L.K. The Crystal Structure of Ammonium Azide, NH4N3. Zeitschrift Krist. Cryst. Mater. 1936, 94, 197–211. [Google Scholar] [CrossRef]

- Ben Aziza, M.; Litaiem, Y.; Chtourou, R.; Ammar, S. The Influence of Different Stabilizers on Properties of Sol–Gel Spin-Coated Zinc Oxide Films. Brazilian J. Phys. 2021, 51, 722–730. [Google Scholar] [CrossRef]

- Borysiewicz, M.A. ZnO as a Functional Material, a Review. Crystals 2019, 9, 505. [Google Scholar] [CrossRef]

- McCluskey, M.D.; Jokela, S.J. Defects in ZnO. J. Appl. Phys. 2009, 106, 1–13. [Google Scholar] [CrossRef]

- Bergman, L.; Chen, X.B.; Huso, J.; Morrison, J.L.; Hoeck, H. Raman Scattering of Polar Modes of ZnO Crystallites. J. Appl. Phys. 2005, 98, 093507. [Google Scholar] [CrossRef]

- Zeng, Y.; Ning, J.; Zhang, J.; Jia, Y.; Yan, C.; Wang, B.; Wang, D. Raman Analysis of E2 (High) and A1 (LO) Phonon to the Stress-Free Gan Grown on Sputtered Aln/Graphene Buffer Layer. Appl. Sci. 2020, 10, 8814. [Google Scholar] [CrossRef]

- Souissi, H.; Jabri, S.; Souissi, A.; Amiri, G.; Gemeiner, P.; Lusson, A.; Galtier, P.; Dkhil, B.; Sallet, V.; Oueslati, M.; et al. Activation of B1 Silent Raman Modes and Its Potential Origin as Source for Phonon-Assisted Replicas in Photoluminescence Response in N-Doped ZnO Nanowires. J. Appl. Phys. 2018, 123, 025705. [Google Scholar] [CrossRef]

- Krishnan, K.; Plane, R.A. Raman and Infrared Spectra of Complexes of Ethylenediamine with Zinc(II), Cadmium(II), and Mercury(II). Inorg. Chem. 1966, 5, 852–857. [Google Scholar] [CrossRef]

- Nowak, E.; Szybowicz, M.; Stachowiak, A.; Koczorowski, W.; Schulz, D.; Paprocki, K.; Fabisiak, K.; Los, S. A Comprehensive Study of Structural and Optical Properties of ZnO Bulk Crystals and Polycrystalline Films Grown by Sol-Gel Method. Appl. Phys. A Mater. Sci. Process. 2020, 126, 1–12. [Google Scholar] [CrossRef]

- Preis, W.; Sitte, W. Electrical Properties of Grain Boundaries in Interfacially Controlled Functional Ceramics. J. Electroceramics 2015, 34, 185–206. [Google Scholar] [CrossRef]

- Uklein, A.V.; Multian, V.V.; Kuz’micheva, G.M.; Linnik, R.P.; Lisnyak, V.V.; Popov, A.I.; Gayvoronsky, V.Y. Nonlinear Optical Response of Bulk ZnO Crystals with Different Content of Intrinsic Defects. Opt. Mater. Amst. 2018, 84, 738–747. [Google Scholar] [CrossRef]

- Ke, L.; Lai, S.C.; Ye, J.D.; Kaixin, V.L.; Chua, S.J. Point Defects Analysis of Zinc Oxide Thin Films Annealed at Different Temperatures with Photoluminescence, Hall Mobility, and Low Frequency Noise. J. Appl. Phys. 2010, 108, 1–6. [Google Scholar] [CrossRef]

- Sivakumar, K.; Senthil Kumar, V.; Muthukumarasamy, N.; Thambidurai, M.; Senthil, T.S. Influence of PH on ZnO Nanocrystalline Thin Films Prepared by Sol–Gel Dip Coating Method. Bull. Mater. Sci. 2011, 35, 327–331. [Google Scholar] [CrossRef]

- Boudjouan, F.; Chelouche, A.; Touam, T.; Djouadi, D.; Khodja, S.; Tazerout, M.; Ouerdane, Y.; Hadjoub, Z. Effects of Stabilizer Ratio on Photoluminescence Properties of Sol-Gel ZnO Nano-Structured Thin Films. J. Lumin. 2015, 158, 32–37. [Google Scholar] [CrossRef]

- Gómez-Núñez, A.; Alonso-Gil, S.; López, C.; Roura-Grabulosa, P.; Vilà, A. From Ethanolamine Precursor towards ZnO—How N Is Released from the Experimental and Theoretical Points of View. Nanomaterials 2019, 9, 1415. [Google Scholar] [CrossRef]

- Gómez-Núñez, A.; Roura, P.; López, C.; Vilà, A. Comparison of the Thermal Decomposition Processes of Several Aminoalcohol-Based ZnO Inks with One Containing Ethanolamine. Appl. Surf. Sci. 2015, 381, 48–53. [Google Scholar] [CrossRef]

- Copuroglu, M.; Koh, L.H.K.; O’Brien, S.; Crean, G.M. Comparative Characterisation of Zinc Oxide Thin Films Prepared from Zinc Acetate with or without Water of Hydration via the Sol-Gel Method. J. Sol-Gel Sci. Technol. 2009, 52, 432–438. [Google Scholar] [CrossRef]

- Bekkari, R.; Jaber, B.; Labrim, H.; Ouafi, M.; Zayyoun, N.; Laânab, L. Effect of Solvents and Stabilizer Molar Ratio on the Growth Orientation of Sol-Gel-Derived ZnO Thin Films. Int. J. Photoenergy 2019, 2019, 3164043. [Google Scholar] [CrossRef]

- Liu, Q.; Ren, W.; Zhang, Y.; Zhang, Y.X. Hydrogenated Carboxylated Nitrile Rubber/Modified Zinc Carbonate Basic Composites with Photoluminescence Properties. Eur. Polym. J. 2011, 47, 1135–1141. [Google Scholar] [CrossRef]

- Ben Wannes, H.; Zaghouani, R.B.; Ouertani, R.; Araújo, A.; Mendes, M.J.; Aguas, H.; Fortunato, E.; Martins, R.; Dimassi, W. Study of the Stabilizer Influence on the Structural and Optical Properties of Sol-Gel Spin Coated Zinc Oxide Films. Mater. Sci. Semicond. Process. 2018, 74, 80–87. [Google Scholar] [CrossRef]

| AlO | Si | |

|---|---|---|

| 0.5 MEA | 90 ± 39 nm | 119 ± 38 nm |

| 1 MEA | 121 ± 40 nm | 82 ± 36 nm |

| 0.5 DEA | 116 ± 49 nm | 74 ± 34 nm |

| 1 DEA | 91 ± 40 nm | 72 ± 32 nm |

| AlO | Si | SiO | |

|---|---|---|---|

| 0.5 MEA | 18 ± 3 µm | 20 ± 3 µm | 15 ± 2 µm |

| 1 MEA | 17 ± 3 µm | 20 ± 3 µm | |

| 0.5 DEA | 11 ± 3 µm | 11 ± 3 µm | 10 ± 3 µm |

| 1 DEA | 5 ± 3 µm | 12 ± 3 µm |

| AlO | a (Å) | c (Å) | c/a | (c/a) |

|---|---|---|---|---|

| 0.5 MEA | 3.2455 | 5.1919 | 1.5997 | 0.0014 |

| 1 MEA | 3.2471 | 5.1982 | 1.6009 | 0.0013 |

| 0.5 DEA | 3.2354 | 5.1947 | 1.6056 | 0.0001 |

| 1 DEA | 3.2452 | |||

| Si | a (Å) | c (Å) | c/a | (c/a) |

| 0.5 MEA | 3.2436 | 5.1910 | 1.6004 | 0.0017 |

| 1 MEA | 3.2432 | 5.1964 | 1.6022 | 0.0010 |

| 0.5 DEA | 3.2454 | 5.3327 | 1.6431 | 0.0021 |

| 1 DEA | 3.2447 | 5.3318 | 1.6432 | 0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowak, E.; Chłopocka, E.; Szybowicz, M.; Stachowiak, A.; Koczorowski, W.; Piechowiak, D.; Miklaszewski, A. The Influence of Aminoalcohols on ZnO Films’ Structure. Gels 2022, 8, 512. https://doi.org/10.3390/gels8080512

Nowak E, Chłopocka E, Szybowicz M, Stachowiak A, Koczorowski W, Piechowiak D, Miklaszewski A. The Influence of Aminoalcohols on ZnO Films’ Structure. Gels. 2022; 8(8):512. https://doi.org/10.3390/gels8080512

Chicago/Turabian StyleNowak, Ewelina, Edyta Chłopocka, Mirosław Szybowicz, Alicja Stachowiak, Wojciech Koczorowski, Daria Piechowiak, and Andrzej Miklaszewski. 2022. "The Influence of Aminoalcohols on ZnO Films’ Structure" Gels 8, no. 8: 512. https://doi.org/10.3390/gels8080512