Enhancing Oil Recovery with Hydrophilic Polymer-Coated Silica Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Silica Nanoparticles and Injection Seawater

2.2. Crude Oil and Normal Decane

2.3. Type of Porous Media

2.4. Interfacial Tension Measurement

2.5. Rock Wettability Tests

2.6. Rock Core Flooding Experiments

3. Results and Discussion

3.1. Nanoparticle Oil Recovery Performance

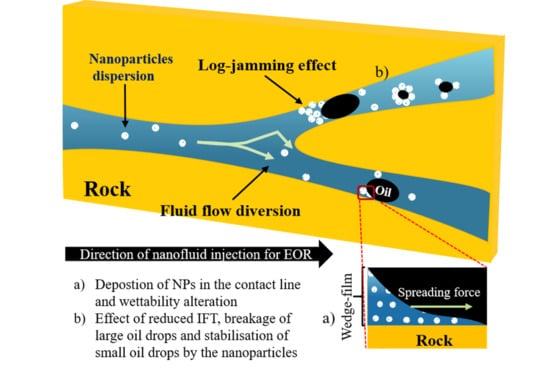

3.2. Evaluation of Nanoparticle Oil Recovery Mechanisms

3.2.1. Interfacial Tension Analysis

3.2.2. Spontaneous Imbibition Tests

3.2.3. Transport Behavior of Nanoparticles during EOR Process

4. Conclusions

- The NPs at 0.1 wt.% had a minor effect on the viscosity of the injection water; however, they showed an ability to retard the breakthrough time, resulting in a high recovery compared to the base case (waterflood).

- Hydrophilic silica nanoparticles (polymer-coated SO2) seemed to be more effective in enhancing oil recovery as secondary EOR fluids in Berea sandstone.

- Hydrophilic silica nanoparticles are capable of gradually changing the microscopic distribution of fluids due to deposition on the rock surface, changes in the surface roughness and wettability of the rock to a more water-wet condition, which could be an important mechanism for long injection periods expected at a field scale.

- Generation of in situ oil emulsion droplets in water phase could be an influencing factor on the recovery of oil for some small-size nanoparticles.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, X.; Zhang, Y.; Chen, G.; Gai, Z. Application of Nanoparticles in Enhanced Oil Recovery: A Critical Review of Recent Progress. Energies 2017, 10, 45. [Google Scholar] [CrossRef] [Green Version]

- Muggeridge, A.; Cockin, A.; Webb, K.; Frampton, H.; Collins, I.; Moulds, T.; Salino, P. Recovery rates, enhanced oil recovery and technological limits. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2014, 372, 2006. [Google Scholar] [CrossRef] [Green Version]

- Sandeep, R.; Jain, S.; Agrawal, A. Application of Nanoparticles-Based Technologies in the Oil and Gas Industry. In Nanotechnology for Energy and Environmental Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 257–277. [Google Scholar]

- Ahmadi, M.; Habibi, A.; Pourafshari, P.; Ayatollahi, S. Zeta Potential Investigation and Mathematical Modeling of Nanoparticles Deposited on the Rock Surface to Reduce Fine Migration. In SPE Middle East Oil and Gas Show and Conference; Society of Petroleum Engineers: Manama, Bahrain, 2011; p. 14. [Google Scholar]

- Bennetzen, M.V.; Mogensen, K. Novel Applications of Nanoparticles for Future Enhanced Oil Recovery. In International Petroleum Technology Conference; International Petroleum Technology Conference: Kuala Lumpur, Malaysia, 2014; p. 14. [Google Scholar]

- Negin, C.; Ali, S.; Xie, Q. Application of nanotechnology for enhancing oil recovery—A review. Petroleum 2016, 2, 324–333. [Google Scholar] [CrossRef]

- Miranda, C.R.; Lara, L.S.d.; Tonetto, B.C. Stability and Mobility of Functionalized Silica Nanoparticles for Enhanced Oil Recovery Applications. In SPE International Oilfield Nanotechnology Conference and Exhibition; Society of Petroleum Engineers: Noordwijk, The Netherlands, 2012; p. 11. [Google Scholar]

- Bera, A.; Belhaj, H. Application of nanotechnology by means of nanoparticles and nanodispersions in oil recovery-A comprehensive review. J. Nat. Gas Sci. Eng. 2016, 34, 1284–1309. [Google Scholar]

- Ding, H.; Zhang, N.; Zhang, Y.; Wei, M.; Bai, B. Experimental Data Analysis of Nanoparticles for Enhanced Oil Recovery. Ind. Eng. Chem. Res. 2019, 58, 12438–12450. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, X.; Zhong, X.; Reagen, S.; Zhang, S.; Sun, W.; Pu, H.; Zhao, J.X. Polymer nanoparticles based nano-fluid for enhanced oil recovery at harsh formation conditions. Fuel 2020, 267, 117251. [Google Scholar] [CrossRef]

- Bila, A.L. Experimental Investigation of Surface-Functionalised Silica Nanoparticles for Enhanced Oil Recovery. Ph.D. Thesis, Norwegian University of Science and Technology (NTNU), Trondheim, Norway, 2020. [Google Scholar]

- Omran, M.; Akarri, S.; Torsaeter, O. The Effect of Wettability and Flow Rate on Oil Displacement Using Polymer-Coated Silica Nanoparticles: A Microfluidic Study. Processes 2020, 8, 991. [Google Scholar] [CrossRef]

- Saigal, T.; Dong, H.; Matyjaszewski, K.; Tilton, R.D. Pickering emulsions stabilized by nanoparticles with thermally responsive grafted polymer brushes. Langmuir 2010, 26, 15200–15209. [Google Scholar] [CrossRef]

- Qi, L.; Song, C.; Wang, T.; Li, Q.; Hirasaki, G.J.; Verduzco, R. Polymer-coated nanoparticles for reversible emulsification and recovery of heavy oil. Langmuir 2018, 34, 6522–6528. [Google Scholar] [CrossRef]

- Ponnapati, R.; Karazincir, O.; Dao, E.; Ng, R.; Mohanty, K.K.; Krishnamoorti, R. Polymer-functionalized nanoparticles for improving waterflood sweep efficiency: Characterization and transport properties. Ind. Eng. Chem. Res. 2011, 50, 13030–13036. [Google Scholar] [CrossRef]

- Bila, A.; Stensen, Å.J.; Torsæter, O. Polymer-functionalized silica nanoparticles for improving water flood sweep efficiency in Berea sandstones. E3s Web Conf. 2020, 146, 02001. [Google Scholar] [CrossRef] [Green Version]

- Bila, A.; Stensen, Å.J.; Torsæter, O. Experimental Investigation of Polymer-Coated Silica Nanoparticles for Enhanced Oil Recovery. Nanomaterials 2019, 9, 882. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aziz, H.; Tunio, S.Q. Enhancing oil recovery using nanoparticles—A review. Adv. Nat. Sci. Nanosci. Nanotechnol. 2019, 10, 033001. [Google Scholar] [CrossRef]

- Tangparitkul, S.; Charpentier, T.V.J.; Pradilla, D.; Harbottle, D. Interfacial and colloidal forces governing oil droplet displacement: Implications for enhanced oil recovery. Colloids Interfaces 2018, 2, 30. [Google Scholar] [CrossRef] [Green Version]

- Chevalier, Y.; Bolzinger, M.-A. Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2013, 439, 23–34. [Google Scholar] [CrossRef]

- Afolabi, R.O.; Yusuf, E.O. Nanotechnology and global energy demand: Challenges and prospects for a paradigm shift in the oil and gas industry. J. Pet. Explor. Prod. Technol. 2019, 9, 1423–1441. [Google Scholar] [CrossRef] [Green Version]

- Roustaei, A.; Saffarzadeh, S.; Mohammadi, M. An evaluation of modified silica nanoparticles’ efficiency in enhancing oil recovery of light and intermediate oil reservoirs. Egypt. J. Pet. 2013, 22, 427–433. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Davidson, D.; Bryant, S.L.; Huh, C. Nanoparticle-Stabilized Emulsions for Applications in Enhanced Oil Recovery. In SPE Improved Oil Recovery Symposium; Society of Petroleum Engineers: Tulsa, OK, USA, 2010; p. 18. [Google Scholar]

- Adil, M.; Lee, K.; Zaid, H.M.; Latiff, N.R.A.; Alnarabiji, M.S. Experimental study on electromagnetic-assisted ZnO nanofluid flooding for enhanced oil recovery (EOR). PLoS ONE 2018, 13, e0193518. [Google Scholar] [CrossRef]

- Kim, I.; Worthen, A.J.; Johnston, K.P.; DiCarlo, D.A.; Huh, C. Size-dependent properties of silica nanoparticles for Pickering stabilization of emulsions and foams. J. Nanopart. Res. 2016, 18, 82. [Google Scholar] [CrossRef]

- Wasan, D.T.; Nikolov, A.D. Spreading of nanofluids on solids. Nature 2003, 423, 156–159. [Google Scholar] [CrossRef]

- Chengara, A.; Nikolov, A.D.; Wasan, D.T.; Trokhymchuk, A.; Henderson, D. Spreading of nanofluids driven by the structural disjoining pressure gradient. J. Colloid Interface Sci. 2004, 280, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Spildo, K.; Skauge, A.; Aarra, M.G.; Tweheyo, M.T. A New Polymer Application for North Sea Reservoirs. SPE Reserv. Eval. Eng. 2009, 12, 427–432. [Google Scholar] [CrossRef]

- Skauge, T.; Spildo, K.; Skauge, A. Nano-sized Particles For EOR. In SPE Improved Oil Recovery Symposium; Society of Petroleum Engineers: Tulsa, OK, USA, 2010; p. 10. [Google Scholar]

- Bila, A.; Stensen, J.Å.; Torsæter, O. Experimental Evaluation of Oil Recovery Mechanisms Using a Variety of Surface-Modified Silica Nanoparticles in the Injection Water. In SPE Norway One Day Seminar; Society of Petroleum Engineers: Bergen, Norway, 2019; p. 19. [Google Scholar]

- Kokubun, M.A.E.; Radu, F.A.; Keilegavlen, E.; Kumar, K.; Spildo, K. Transport of Polymer Particles in Oil–Water Flow in Porous Media: Enhancing Oil Recovery. Transp. Porous Media 2019, 126, 501–519. [Google Scholar] [CrossRef] [Green Version]

- Anderson, W.G. Wettability Literature Survey Part 5: The Effects of Wettability on Relative Permeability. J. Pet. Technol. 1987, 39, 1453–1468. [Google Scholar] [CrossRef]

- Nazari Moghaddam, R.; Bahramian, A.; Fakhroueian, Z.; Karimi, A.; Arya, S. Comparative Study of Using Nanoparticles for Enhanced Oil Recovery: Wettability Alteration of Carbonate Rocks. Energy Fuels 2015, 29, 2111–2119. [Google Scholar] [CrossRef]

- Cuiec, L. Rock/Crude-Oil Interactions and Wettability: An Attempt To Understand Their Interrelation. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Houston, TX, USA, 1984; p. 14. [Google Scholar]

- Ramakrishnan, T.S.; Cappiello, A. A new technique to measure static and dynamic properties of a partially saturated porous medium. Chem. Eng. Sci. 1991, 46, 1157–1163. [Google Scholar] [CrossRef]

- Heaviside, J.; Black, C.J.J. Fundamentals of Relative Permeability: Experimental and Theoretical Considerations. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: San Francisco, CA, USA, 1983; p. 17. [Google Scholar]

- Youssif, M.I.; El-Maghraby, R.M.; Saleh, S.M.; Elgibaly, A. Silica nanofluid flooding for enhanced oil recovery in sandstone rocks. Egypt. J. Pet. 2018, 27, 105–110. [Google Scholar] [CrossRef]

- Satter, A.; Iqbal, G.M. 7-Reservoir Life Cycle and Role of Industry Professionals. In Reservoir Engineering; Gulf Professional Publishing: Boston, MA, USA, 2016; pp. 127–136. [Google Scholar]

- Green, D.W.; Willhite, G.P. Enhanced Oil Recovery; Henry, L., Ed.; Doherty Memorial Fund of AIME; Society of Petroleum Engineers: Houston, TX, USA, 1998; Volume 6. [Google Scholar]

- Sydansk, R.D.; Romero-Zeron, L. Reservoir Conformance Improvement; Society of Petroleum Engineers Richardson: Houston, TX, USA, 2011. [Google Scholar]

- Wang, X.; Xiao, S.; Zhang, Z.; He, J. Displacement of nanofluids in silica nanopores: Influenced by wettability of nanoparticles and oil components. Environ. Sci. Nano 2018, 5, 2641–2650. [Google Scholar] [CrossRef]

- Rezaei, N.; Firoozabadi, A. Macro-and Microscale Waterflooding Performances of Crudes which form w/o Emulsions upon Mixing with Brines. Energy Fuels 2014, 28, 2092–2103. [Google Scholar] [CrossRef]

- Torsater, O.; Engeset, B.; Hendraningrat, L.; Suwarno, S. Improved Oil Recovery by Nanofluids Flooding: An Experimental Study. In SPE Kuwait International Petroleum Conference and Exhibition; Society of Petroleum Engineers: Kuwait City, Kuwait, 2012; p. 9. [Google Scholar]

- Zhang, H.; Ramakrishnan, T.S.; Nikolov, A.; Wasan, D. Enhanced oil recovery driven by nanofilm structural disjoining pressure: Flooding experiments and microvisualization. Energy Fuels 2016, 30, 2771–2779. [Google Scholar] [CrossRef]

- Binks, B.P. Particles as surfactants—Similarities and differences. Curr. Opin. Colloid Interface Sci. 2002, 7, 21–41. [Google Scholar] [CrossRef]

- Bizmark, N.; Ioannidis, M.A.; Henneke, D.E. Irreversible adsorption-driven assembly of nanoparticles at fluid interfaces revealed by a dynamic surface tension probe. Langmuir 2014, 30, 710–717. [Google Scholar] [CrossRef] [PubMed]

- Behera, U.S.; Sangwai, J.S. Interaction of Nanoparticles with Reservoir Fluids and Rocks for Enhanced Oil Recovery. In Nanotechnology for Energy and Environmental Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 299–328. [Google Scholar]

- Chatzis, I.; Kuntamukkula, M.S.; Morrow, N.R. Effect of capillary number on the microstructure of residual oil in strongly water-wet sandstones. SPE Reserv. Eng. 1988, 3, 902–912. [Google Scholar] [CrossRef]

- ShamsiJazeyi, H.; Miller, C.A.; Wong, M.S.; Tour, J.M.; Verduzco, R. Polymer-coated nanoparticles for enhanced oil recovery. J. Appl. Polym. Sci. 2014, 131, 15. [Google Scholar] [CrossRef]

| Nanofluid (NF) | Basis | Modification | Concentration (wt.%) | Size (nm) |

|---|---|---|---|---|

| 1 | SiO2 (sol–gel cationic) | Polymer | 38.6 | 107 |

| 2 | SiO2 (sol–gel anionic) | Polymer | 26.0 | 32 |

| 3 | SiO2/Al2O3/MOX | Polymer | 21.6 | 218 |

| 4 | SiO2/Al2O3/MOX | Polymer | 25.5 | 145 |

| Salts | NaCl | KCl | NaHCO3 | Na2SO4 | CaCl2·6H2O | MgCl2·6H2O | Sr2·6H2O |

|---|---|---|---|---|---|---|---|

| wt.% | 25.50 | 0.72 | 0.22 | 4.06 | 1.62 | 3.16 | 0.02 |

| NF | Core # | VP (mL) | Swi (%) | Water Flood | Nanofluid Flood | ED (%) | Total RF (%) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| RF (%) | Sor1 (%) | RF (%) | (%) | Sor2 (%) | ||||||

| NF-1 | M1 | 11.8 | 33.93 | 43.1 | 37.61 | 4.6 | 5.9 | 35.55 | 8.11 | 47.7 |

| M2 | 12.0 | 24.22 | 38.9 | 46.29 | 7.3 | 40.83 | 11.79 | 46.2 | ||

| NF-2 | M3 | 11.7 | 24.68 | 41.7 | 43.91 | 7.4 | 7.2 | 38.36 | 12.67 | 49.1 |

| M4 | 12.2 | 20.68 | 39.4 | 48.05 | 7.0 | 42.52 | 11.50 | 46.4 | ||

| NF-3 | M5 | 11.4 | 20.78 | 40.7 | 43.07 | 8.7 | 9.2 | 36.78 | 14.63 | 49.4 |

| M6 | 11.1 | 20.73 | 37.9 | 49.22 | 9.8 | 41.47 | 15.74 | 47.7 | ||

| NF-4 | M7 | 8.1 | 23.97 | 35.1 | 49.35 | 9.5 | 8.1 | 42.14 | 20.71 | 44.6 |

| M8 | 8.3 | 18.40 | 40.6 | 48.48 | 6.6 | 43.09 | 11.14 | 47.2 | ||

| Average | 39.7 | 45.75 | 40.00 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bila, A.; Torsæter, O. Enhancing Oil Recovery with Hydrophilic Polymer-Coated Silica Nanoparticles. Energies 2020, 13, 5720. https://doi.org/10.3390/en13215720

Bila A, Torsæter O. Enhancing Oil Recovery with Hydrophilic Polymer-Coated Silica Nanoparticles. Energies. 2020; 13(21):5720. https://doi.org/10.3390/en13215720

Chicago/Turabian StyleBila, Alberto, and Ole Torsæter. 2020. "Enhancing Oil Recovery with Hydrophilic Polymer-Coated Silica Nanoparticles" Energies 13, no. 21: 5720. https://doi.org/10.3390/en13215720