Figure 1.

Block diagram of the proposed tag.

Figure 1.

Block diagram of the proposed tag.

Figure 2.

Block diagram of the proposed ring oscillator.

Figure 2.

Block diagram of the proposed ring oscillator.

Figure 3.

Small-signal model of an FVF cell.

Figure 3.

Small-signal model of an FVF cell.

Figure 4.

Voltage buffer used between the temperature sensor and the ASK backscatter modulator.

Figure 4.

Voltage buffer used between the temperature sensor and the ASK backscatter modulator.

Figure 5.

Shunt regulator.

Figure 5.

Shunt regulator.

Figure 6.

Proposed current source core.

Figure 6.

Proposed current source core.

Figure 7.

Current and voltage reference. (a) Current reference. (b) Voltage reference.

Figure 7.

Current and voltage reference. (a) Current reference. (b) Voltage reference.

Figure 8.

LDO voltage regulator. (a) Schematic circuit. (b) Open-loop small-model signal.

Figure 8.

LDO voltage regulator. (a) Schematic circuit. (b) Open-loop small-model signal.

Figure 9.

Schematic circuit of the HF section.

Figure 9.

Schematic circuit of the HF section.

Figure 10.

Layout of the implemented dipole antenna.

Figure 10.

Layout of the implemented dipole antenna.

Figure 11.

Design flow chart of the proposed tag.

Figure 11.

Design flow chart of the proposed tag.

Figure 12.

Location of the current/voltage reference circuit inside the microphotography of the whole passive temperature sensor and a zoomed-in view of its layout.

Figure 12.

Location of the current/voltage reference circuit inside the microphotography of the whole passive temperature sensor and a zoomed-in view of its layout.

Figure 13.

Current/voltage reference post-layout simulation. (a) , , and DC characterization. (b) , , and transient response. (c) , , and temperature characterization. (d) DC characterization. (e) transient response. (f) temperature characterization.

Figure 13.

Current/voltage reference post-layout simulation. (a) , , and DC characterization. (b) , , and transient response. (c) , , and temperature characterization. (d) DC characterization. (e) transient response. (f) temperature characterization.

Figure 14.

Location of the proposed temperature sensor inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 14.

Location of the proposed temperature sensor inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 15.

Oscillator post-layout simulation. (a) Oscillation frequency at 25 °C. (b) Oscillation frequency temperature sweep.

Figure 15.

Oscillator post-layout simulation. (a) Oscillation frequency at 25 °C. (b) Oscillation frequency temperature sweep.

Figure 16.

Location of the LDO voltage regulator inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 16.

Location of the LDO voltage regulator inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 17.

LDO voltage regulator post-layout simulation. (a) Line regulation. (b) Load regulation. (c) Dynamic load regulation.

Figure 17.

LDO voltage regulator post-layout simulation. (a) Line regulation. (b) Load regulation. (c) Dynamic load regulation.

Figure 18.

Location of the implemented shunt regulator inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 18.

Location of the implemented shunt regulator inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 19.

Shunt regulator post-layout simulations. (a) Output voltage. (b) Delivered current.

Figure 19.

Shunt regulator post-layout simulations. (a) Output voltage. (b) Delivered current.

Figure 20.

Location of the HF section inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 20.

Location of the HF section inside the microphotography of the whole self-powered tag and a zoomed-in view of its layout.

Figure 21.

Power harvester post-layout simulation. (a) Parametric sweep for and . (b) Impedance sweep. (c) Start-up simulation. (d) Power conversion efficiency.

Figure 21.

Power harvester post-layout simulation. (a) Parametric sweep for and . (b) Impedance sweep. (c) Start-up simulation. (d) Power conversion efficiency.

Figure 22.

Post-layout simulation of the implemented ASK backscatter modulator.

Figure 22.

Post-layout simulation of the implemented ASK backscatter modulator.

Figure 23.

Layout of the implemented antenna.

Figure 23.

Layout of the implemented antenna.

Figure 24.

Antenna simulation. (a) Antenna S11 parameter. (b) Antenna impedance. (c) Radiation pattern.

Figure 24.

Antenna simulation. (a) Antenna S11 parameter. (b) Antenna impedance. (c) Radiation pattern.

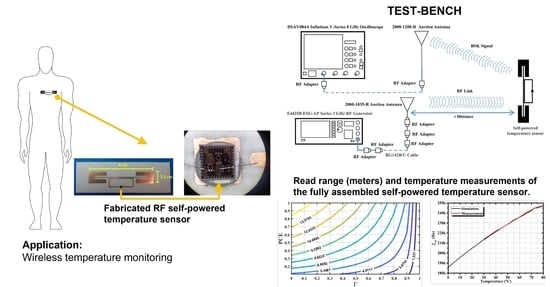

Figure 25.

Fabricated prototype of the proposed self-powered temperature sensor.

Figure 25.

Fabricated prototype of the proposed self-powered temperature sensor.

Figure 26.

Implemented PCB for low-frequency measurements.

Figure 26.

Implemented PCB for low-frequency measurements.

Figure 27.

Test-bench of the LF section.

Figure 27.

Test-bench of the LF section.

Figure 28.

Temperature measurements of the LF section. (a) vs. temperature. (b) vs. temperature. (c) Frequency of oscillation vs. temperature.

Figure 28.

Temperature measurements of the LF section. (a) vs. temperature. (b) vs. temperature. (c) Frequency of oscillation vs. temperature.

Figure 29.

Fully assembled proposed self-powered temperature sensor.

Figure 29.

Fully assembled proposed self-powered temperature sensor.

Figure 30.

RF power harvester characterization. (a) Testbench. (b) Transient measurement response.

Figure 30.

RF power harvester characterization. (a) Testbench. (b) Transient measurement response.

Figure 31.

Testbench used for read range and temperature characterization.

Figure 31.

Testbench used for read range and temperature characterization.

Figure 32.

Proposed self-powered sensor read range. (a) Measured read range for 65.62 mW irradiated power. (b) Extrapolated read range for 1 W irradiated power.

Figure 32.

Proposed self-powered sensor read range. (a) Measured read range for 65.62 mW irradiated power. (b) Extrapolated read range for 1 W irradiated power.

Figure 33.

Measured lateral sidebands by applying different temperatures in the proposed sensor. (a) Lateral sidebands generated at 35.75 °C. (b) Lateral sidebands generated at 62.5 °C. (c) Lateral sidebands generated at 72 °C.

Figure 33.

Measured lateral sidebands by applying different temperatures in the proposed sensor. (a) Lateral sidebands generated at 35.75 °C. (b) Lateral sidebands generated at 62.5 °C. (c) Lateral sidebands generated at 72 °C.

Figure 34.

Temperature measurements of the fully assembled self-powered temperature sensor.

Figure 34.

Temperature measurements of the fully assembled self-powered temperature sensor.

Figure 35.

Distribution of the power consumption of each of the subcircuits that compose the proposed sensor prototype.

Figure 35.

Distribution of the power consumption of each of the subcircuits that compose the proposed sensor prototype.

Table 1.

Elements and transistor sizes of the current source core.

Table 1.

Elements and transistor sizes of the current source core.

| Element | Value | Element | Value | Element | Value |

|---|

| (23.005 µm/1.8 µm) × 6 | | (1.8 µm/1.255 µm) | | (3.665 µm/18 µm) × 5 |

| (23.005 µm/1.8 µm) × 8 | | (1.8 µm/8.52 µm) | | (24.18 µm/14 µm) × 14 |

| (1.8 µm /0.9 µm) × 4 | | (5.4 µm/1.98 µm) × 14 | | (2.75 µm/14 µm) × 14 |

| (13.835 µm/1.8 µm) × 4 | | (5.4 µm/1.885 µm) | | (8.895 µm/1.8 µm) × 8 |

| (13.835 µm/1.8 µm) × 12 | | (46.16 µm/0.9 µm) × 40 | | (23.14 µm/1.8 µm) × 14 |

| (1.8 µm/15.395 µm) | | (5.4 µm/1.9 µm) | | 1.27 pF |

| | | | | | 0.5 pF |

Table 2.

Elements and transistor sizes of the current reference.

Table 2.

Elements and transistor sizes of the current reference.

| Element | Value | Element | Value | Element | Value |

|---|

| (23.005 µm/1.8 µm) × 6 | | (8.895 µm/1.8 µm) × 8 | | (13.835 µm/1.8 µm) × 4 |

| (23.005 µm/1.8 µm) × 8 | | (13.835 µm/1.8 µm) | | |

Table 3.

Elements and transistor sizes of the voltage reference.

Table 3.

Elements and transistor sizes of the voltage reference.

| Element | Value | Element | Value | Element | Value |

|---|

| (23.005 µm/1.8 µm) × 6 | | (8.895 µm/1.8 µm) × 8 | | (2.18 µm/9 µm) × 4 |

| (23.005 µm/1.8 µm) × 8 | | (13.835 µm/1.8 µm) × 4 | | (3.4 µm/18 µm) |

| 1.6 pF | | | | |

Table 4.

Elements and transistor sizes of the temperature sensor.

Table 4.

Elements and transistor sizes of the temperature sensor.

| Element | Value | Element | Value | Element | Value |

|---|

| (6.24 µm/1.8 µm) × 8 | | (3.265 µm/3.6 µm) × 4 | | (7.19 µm/3.6 µm) × 4 |

| (16 µm/1.8 µm) × 8 | | (3.265 µm/3.6 µm) × 6 | | (0.9 µm/0.36 µm) |

Table 5.

Elements and transistor sizes of the LDO voltage regulator.

Table 5.

Elements and transistor sizes of the LDO voltage regulator.

| Element | Value | Element | Value | Element | Value |

|---|

| (4.12 µm/1.8 µm) × 1 | | (13.835 µm/1.8 µm) × 8 | | (5.355 µm/18 µm) × 4 |

| (4.12 µm/1.8 µm) × 3 | | (12.815 µm/4.5 µm) × 4 | | 2.5 pF |

| (3.085 µm /1.8 µm) × 4 | | (32.99 µm/1.5 µm) × 40 | | 10 pF |

Table 6.

Elements and transistor sizes of the shunt regulator.

Table 6.

Elements and transistor sizes of the shunt regulator.

| Element | Value | Element | Value | Element | Value |

|---|

| (11.2 µm/1.8 µm) × 25 | | (7.82 µm/45 µm) × 4 | | (7.59 µm/1.8 µm) × 10 |

| (3.62 µm/4.5 µm) × 4 | | (1.375 µm/18 µm) × 2 | | 25 |

| (0.9 µm/45 µm) | | (12.315 µm/4.5 µm) × 4 | | |

Table 7.

Elements and transistor sizes of the power harvester circuit.

Table 7.

Elements and transistor sizes of the power harvester circuit.

| Element | Value | Element | Value | Element | Value | Element | Value |

|---|

| (1.5 µm/0.18 µm) × 8 | | 1.5 nH | L | 4.18 nH | | 150 pF |

| (1.5 µm/0.18 µm) × 4 | | 0.5 pF | | 2.1 pF | | |

Table 8.

Parameters of the dipole antenna.

Table 8.

Parameters of the dipole antenna.

| Element | Value | Element | Value | Element | Value | Element | Value | Element | Value |

|---|

| 79.4 mm | | 30 mm | | 4 mm | | 11 mm | | 0.4 mm |

| 7.7 mm | | 3 mm | | 5 mm | | 1 mm | | |

| 21.7 mm | | 14 mm | | 1 mm | | 3 mm | | |

Table 9.

Comparison with previous works.

Table 9.

Comparison with previous works.

| | [43] | [44] | [49] | [41] | [50] | [47] | [48] | [42] | [51] | [52] | This Work |

|---|

| Technology | 0.35 µm | 0.35 µm | 0.25 µm | 0.18 µm | 0.18 µm | 0.18 µm | 0.18 µm | 0.13 µm | 0.13µm | 65 nm | 0.18 µm |

| | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS |

| Chip area | 2.2 × 1.8 mm | 1 × 4 mm | 1.2 mm | – | 1.2 × 2.2 mm | 1.2 × 1.2 mm | 0.9 × 1.1 mm | 0.23 mm | 0.34 mm | 1.16 × 0.94 mm | 1.06 × 0.56 mm |

| Full sensor | – | 1 × 4 mm | – | 13 × 12 cm | 5.6 × 5.0 cm | 2.5 × 0.9 cm | – | – | – | 1910 × 940 µm | 8 × 2.5 cm |

| area ** | | | | | | | | | | | |

| Wirelessly powered | YES | NO | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Incident signal | 860 MHz | 2.5 GHz | 450 MHz | 915 MHz | 13.56 MHz | 920 MHz | 902–928 MHz | 915 MHz | 900 MHz | 79 GHz | 910 MHz |

| frequency | | | | | | | | | | | |

| Wireless sensitivity | – | – | −12.3 dBm | – | −18.2 dBm | −12.3 dBm | −11 dBm | −16 dBm | −10 dBm | 5 dBm | −8.99 dBm |

| Circuitry power | 16.85 µW *** | – | 2.75 mW | – | 1.5 µW | – | 2 µW | 1.05 µW | 8.5 µW | 700 µW | 13.75 µW |

| consumption | | | | | | | | | | | |

| Temperature | 35 ∼ 45 | 20 ∼ 90 | −40 ∼ 40 | −30 ∼ 70 | 0 ∼ 100 | −25 ∼ 120 | 0 ∼ 100 | 10 ∼ 100 | 35 ∼ 42 | 32 ∼ 80 | 0 ∼ 60 |

| range (C) | | | | | | | | | | | |

| Temperature | – | 19.1 mV/C | −300 kHz/°C | 0.15 C/LSB | −666 kHz/C | 0.17 °C/LSB | 26 kHz/C | * | – | −22 MHz/C | 823.29 Hz/C |

| sensitivity | | | | | | | | | | | |

| Reader radiated | 2 W | – | 7 W | 1 W | – | 4 W | – | 4 W | – | – | 1 W |

| power (EIRP) | | | | | | | | | | | |

| Read range (m) | 2 | – | 18.3 | 0.5 | – | 3.4 | – | 10.4 | – | – | 9.5 |

| Tag-to-reader | Backscatter | 2.5 GHz OOK | 2.3 GHz | – | 402 MHz OOK | Backscatter | Backscatter | ASK | OOK | 79.1 GHz burst | ASK |

| transmission | | transmitter | transmitter | | backscatter | | | backscatter | backscatter | transmitter | backscatter |

| Communication | EPC | Own | Not | EPC | Not | EPC | EPC | Not | Not | Not | Not |

| protocol | Gen 2 | protocol | implemented | Gen 2 | implemented | Gen 2 | Gen 2 | implemented | implemented | Implemented | implemented |