Reflective Meta-Films with Anti-Damage Property via Field Distribution Manipulation

Abstract

:1. Introduction

2. Materials and Methods

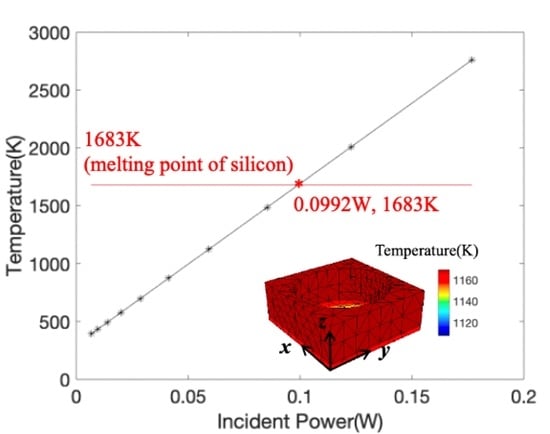

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, T.J.; Smith, D.R.; Liu, R. Metamaterials; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Zhang, L.; Mei, S.; Huang, K.; Qiu, C.-W. Advances in Full Control of Electromagnetic Waves with Metasurfaces. Adv. Opt. Mater. 2016, 4, 818–833. [Google Scholar] [CrossRef]

- Jahani, S.; Jacob, Z. All-dielectric metamaterials. Nat. Nanotechnol. 2016, 11, 23. [Google Scholar] [CrossRef]

- Glybovski, S.B.; Tretyakov, S.A.; Belov, P.A.; Kivshar, Y.S.; Simovski, C.R. Metasurfaces: From microwaves to visible. Phys. Rep. 2016, 634, 1–72. [Google Scholar] [CrossRef]

- Genevet, P.; Capasso, F.; Aieta, F.; Khorasaninejad, M.; Devlin, R. Recent advances in planar optics: From plasmonic to dielectric metasurfaces. Optica 2017, 4, 139–152. [Google Scholar] [CrossRef]

- Hou-Tong, C.; Antoinette, J.T.; Nanfang, Y. A review of metasurfaces: Physics and applications. Rep. Prog. Phys. 2016, 79, 076401. [Google Scholar]

- Chu, P.; Chen, J.; Xiong, Z.; Yi, Z. Controllable frequency conversion in the coupled time-modulated cavities with phase delay. Opt. Commun. 2020, 476, 126338. [Google Scholar] [CrossRef]

- Faraji-Dana, M.; Arbabi, E.; Arbabi, A.; Kamali, S.M.; Kwon, H.; Faraon, A. Compact folded metasurface spectrometer. Nat. Commun. 2020, 9, 4196. [Google Scholar] [CrossRef]

- Shalaev, M.I.; Sun, J.; Tsukernik, A.; Pandey, A.; Nikolskiy, K.; Litchinitser, N.M. High-Efficiency All-Dielectric Metasurfaces for Ultracompact Beam Manipulation in Transmission Mode. Nano Lett. 2015, 15, 6261–6266. [Google Scholar] [CrossRef] [Green Version]

- Xia, Z.; Qin, X.; Wu, Y.; Pan, Y.; Zhou, J.; Zhang, Z. Efficient broadband light absorption in elliptical nanohole arrays for photovoltaic application. Opt. Lett. 2015, 40, 5814–5817. [Google Scholar] [CrossRef]

- Yu, P.; Yang, H.; Chen, X.; Yi, Z.; Yao, W.; Chen, J.; Yi, Y.; Wu, P. Ultra-wideband solar absorber based on refractory titanium metal. Renew. Energy 2020, 158, 227–235. [Google Scholar] [CrossRef]

- Arbabi, A.; Horie, Y.; Bagheri, M.; Faraon, A. Dielectric metasurfaces for complete control of phase and polarization with subwavelength spatial resolution and high transmission. Nat. Nanotechnol. 2015, 10, 937. [Google Scholar] [CrossRef] [Green Version]

- Khorasaninejad, M.; Chen, W.T.; Devlin, R.C.; Oh, J.; Zhu, A.Y.; Capasso, F. Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khorasaninejad, M.; Chen, W.T.; Oh, J.; Capasso, F. Super-Dispersive Off-Axis Meta-Lenses for Compact High Resolution Spectroscopy. Nano Lett. 2016, 16, 3732–3737. [Google Scholar] [CrossRef]

- Pu, M.; Li, X.; Guo, Y.; Ma, X.; Luo, X. Nanoapertures with ordered rotations: Symmetry transformation and wide-angle flat lensing. Opt. Express 2017, 25, 31471–31477. [Google Scholar] [CrossRef] [PubMed]

- Hail, C.U.; Poulikakos, D.; Eghlidi, H. High-Efficiency, Extreme-Numerical-Aperture Metasurfaces Based on Partial Control of the Phase of Light. Adv. Opt. Mater. 2018, 6, 1800852. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; de Lacalle, L.L.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Ray, N.J.; Yoo, J.H.; Nguyen, H.T.; Johnson, M.A.; Feigenbaum, E. Substrate-engraved antireflective nanostructured surfaces for high-power laser applications. Optica 2020, 7, 516–526. [Google Scholar] [CrossRef]

- Zhang, C.; Divitt, S.; Fan, Q.; Zhu, W.; Agrawal, A.; Xu, T.; Lezec, H.J. All-dielectric Deep Ultraviolet Metasurfaces. In CLEO: QELS_Fundamental Science 2019; Optical Society of America: New York, NY, USA, 2019; p. FM3C.3. [Google Scholar]

- Tang, F.; Ye, X.; Li, Q.; Li, H.; Yu, H.; Wu, W.; Li, B.; Zheng, W. Quadratic Meta-Reflectors Made of HfO2 Nanopillars with a Large Field of View at Infrared Wavelengths. Nanomaterials 2020, 10, 1148. [Google Scholar] [CrossRef] [PubMed]

- Moses, E.I.; Lindl, J.D.; Spaeth, M.L.; Patterson, R.W.; Sawicki, R.H.; Atherton, L.J.; Baisden, P.A.; Lagin, L.J.; Larson, D.W.; MacGowan, B.J. Overview: Development of the National Ignition Facility and the Transition to a User Facility for the Ignition Campaign and High Energy Density Scientific Research. Fusion Sci. Technol. 2016, 69, 1–24. [Google Scholar] [CrossRef]

- Rakickas, T.; Kudriašov, V.; Sirutkaitis, V.; Grigonis, R.; Gaižauskas, E. Evaluation of self-focusing influence on laser-induced damage threshold of anti-reflective coated windows. In Laser-Induced Damage in Optical Materials: 2005; International Society for Optics and Photonics: Bellingham, WA, USA, 2006; Volume 5991, p. 59911J. [Google Scholar]

- Papandrew, A.; Stolz, C.J.; Wu, Z.; Loomis, G.E.; Falabella, S. Laser conditioning characterization and damage threshold prediction of hafnia/silica multilayer mirrors by photothermal microscopy. In Laser-Induced Damage in Optical Materials: 2000; International Society for Optics and Photonics: Bellingham, WA, USA, 2001; Volume 4347, pp. 53–61. [Google Scholar]

- Gallais, L. Laser Damage of reflective optics in the sub-ps regime: Physical mechanisms and technological issues. In Laser Applications Conference 2019; Optical Society of America: New York, NY, USA, 2019; p. CM2C.3. [Google Scholar]

- Hervy, A.; Chériaux, G.; Gallais, L.; Mouricaud, D.; Djidel, S. Femtosecond laser-induced damage threshold of electron-beam deposited materials for broadband high-reflective coatings on large optics. In Pacific Rim Laser Damage 2014: Optical Materials for High-Power Lasers; International Society for Optics and Photonics: Bellingham, WA, USA, 2014; Volume 9238, p. 92380A. [Google Scholar]

- Li, C.; Sun, Y.; Song, X.; Zhang, X.; Shi, Z.; Wang, F.; Ye, X.; Chen, S.; Sun, L.; Huang, J. Capping a glass thin layer on the etched surface via plasma chemical vapor deposition for improving the laser damage performance of fused silica. Opt. Express 2019, 27, 2268–2280. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Dai, H.; Zhang, X.; Luo, D.; Sun, X. Flexible cholesteric films with super-reflectivity and high stability based on a multi-layer helical structure. J. Mater. Chem. C 2017, 5, 10828–10833. [Google Scholar] [CrossRef]

- Hamamoto, K.; Shoki, T.; Ikebe, Y. Substrate Equipped with Multi-Layer Reflection Film, Reflection-Type Mask Blank, reflection-Type Mask, and Semiconductor Device Manufacturing Process. U.S. Patent Application No. 16/754,306, 1 October 2020. [Google Scholar]

- Manes, K.; Spaeth, M.; Adams, J.; Bowers, M. Damage Mechanisms Avoided or Managed for NIF Large Optics. Fusion Sci. Technol. 2016, 69, 146–249. [Google Scholar] [CrossRef]

- Laixi, S.; Jin, H.; Hongjie, L.; Xin, Y.; Jingjun, W.; Xiaodong, J.; Liming, Y.; Wanguo, Z.; Weidong, W. Combination of reaction ion etching and dynamic chemical etching for improving laser damage resistance of fused silica optical surfaces. Opt. Lett. 2016, 41, 4464. [Google Scholar]

- Pickering, T.; Shanks, K.; Sundaram, S. Modelling technique and analysis of porous anti-reflective coatings for reducing wide angle reflectance of thin-film solar cells. J. Opt. 2021, 23, 025901. [Google Scholar] [CrossRef]

- Ye, X.; Hu, X.; Tang, F.; Wu, J.; Yang, L.; Huang, J.; Zheng, W. Laser Field Manipulation and Laser Damage Resistance Property of Nanotextures on Fused Silica Optics. Results Phys. 2020, 18, 103262. [Google Scholar] [CrossRef]

- Yu, H.; Tang, F.; Wu, J.; Yi, Z.; Ye, X.; Wang, Y. Meta-Deflectors Made of Dielectric Nanohole Arrays with Anti-Damage Potential. Photonics 2021, 8, 107. [Google Scholar] [CrossRef]

- Sun, S.; Zhou, Z.; Zhang, C.; Gao, Y.; Duan, Z.; Xiao, S.; Song, Q. All-Dielectric Full-Color Printing with TiO2 Metasurfaces. ACS Nano 2017, 11, 4445–4452. [Google Scholar] [CrossRef] [PubMed]

- Cho, E.-H.; Kim, H.-S.; Cheong, B.-H.; Oleg, P.; Xianyua, W.; Sohn, J.-S.; Ma, D.-J.; Choi, H.-Y.; Park, N.-C.; Park, Y.-P. Two-dimensional photonic crystal color filter development. Opt. Express 2009, 17, 8621–8629. [Google Scholar] [CrossRef] [PubMed]

- Born, N.; Schneider, L.; Balzer, J.; Al-Naib, I.; Singh, R.; Velauthapillai, A.; Scheller, M.; Moloney, J.V.; Koch, M. Multi-band metamaterials with a distinguished angular sensitivity. In Proceedings of the 2015 40th International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), Hong Kong, China, 23–28 August 2015; IEEE: New York, NY, USA, 2015; pp. 1–2. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Tang, F.; Chen, J.; Yi, Z.; Ye, X.; Wang, Y. Reflective Meta-Films with Anti-Damage Property via Field Distribution Manipulation. Coatings 2021, 11, 640. https://doi.org/10.3390/coatings11060640

Yu H, Tang F, Chen J, Yi Z, Ye X, Wang Y. Reflective Meta-Films with Anti-Damage Property via Field Distribution Manipulation. Coatings. 2021; 11(6):640. https://doi.org/10.3390/coatings11060640

Chicago/Turabian StyleYu, Haichao, Feng Tang, Jun Chen, Zao Yi, Xin Ye, and Yiqun Wang. 2021. "Reflective Meta-Films with Anti-Damage Property via Field Distribution Manipulation" Coatings 11, no. 6: 640. https://doi.org/10.3390/coatings11060640