New Tendencies in Wind Energy Operation and Maintenance

Abstract

:1. Introduction

2. Materials and Method

- Operation and maintenance of wind farms (O&M): The term “operation and maintenance” is studied as a variable in itself, since it appears as a generic keyword in the research conducted.

- Failure rate and analysis (FAIL): Investigations involving issues related to equipment failures are included in this variable.

- Reliability (RELI): Reliability, availability and maintainability are attributes of the design of systems that have a significant impact on the maintenance of a developed system.

- Condition-monitoring system (C_M): This variable is the grouping of research that deals with condition monitoring. This tool searches the processes of monitoring a condition parameter in machinery, in order to identify a significant change that is indicative of a fault developing. It is an important component of predictive maintenance.

- Maintenance strategies (M_STRA): A maintenance strategy defines the rules for the sequence of planned maintenance work; therefore, the different types of maintenance under investigation are grouped in this variable.

- Maintenance and life cycle cost (M_COST): Research covering topics related to equipment costs are taken into account in this variable.

- Maintenance optimization (M_OPT): A variable that meets the keywords “optimization and maintenance processes”.

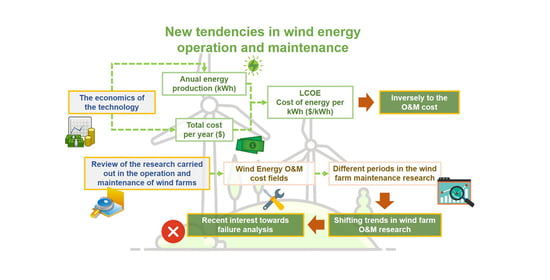

3. Overview of Wind Farm O&M Research

3.1. Operation and Maintenance (O&M) of Wind Farms

- site and seasonal asset disturbances

- stakeholder requirement trade-off

- reliability and asset deterioration challenges

- diagnostic, prognostic and information and communication technology applications

- maintenance optimization models

3.2. Failure Rate and Analysis (FAIL)

3.3. Reliability (RELI)

3.4. Condition-Monitoring System (CM)

3.5. Maintenance Strategies (M_STRA)

3.6. Maintenance and Life Cycle Cost (M_COST)

3.7. Maintenance Optimization (M_OPT)

4. Discussion

4.1. Maintenance Optimization (M_OPT)

4.2. LCOE Wind Energy vs. Research on Wind Farm Maintenance

- 1st Stage (growth): In 2007, the results obtained were less than 1000. Up to 2014, research in the field grows year by year from 785 results in 2007 to more than 3500 papers in 2013. This stage of growth in research into O&M costs in wind farms is taking place in parallel with the increase in wind projects around the world. At this stage, the scientific and technical interest in the technology was at its highest.

- 2nd Stage (stagnation): After years of constant growth, research into the maintenance of wind farms stagnates between 2014 and 2016. This period of stagnation in research into O&M costs in wind farms was influenced by the global economic crisis which began in 2007.

- 3rd Stage (growth): From 2016 onwards, research in the field increases again year by year, from more than 4000 papers in 2016 to almost 6300 results in 2019. This new phase of growth in O&M cost research is related to the growth of a social conscience in favor of the sustainability of the planet and increasing concern about the consequences of climate change.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IEA. Global Energy Review. 2020. Available online: https://www.iea.org/reports/global-energy-review-2020/renewables (accessed on 17 November 2020).

- Obane, H. Forecasting photovoltaic and wind energy capital costs in Japan: A Bayesian approach. Energy Procedia 2019, 158, 3576–3582. [Google Scholar] [CrossRef]

- Irena. Renewable Energy Technologies: Cost Analysis Series; Volume 1: Power Sector, Issue 5/5; International Renewable Energy Agency: Abu Dhabi, UAE, 2012. [Google Scholar]

- EWEA. The Economics of Wind Energy; European Wind Energy Association: Brussels, Belgium, 2009. [Google Scholar]

- Steffen, B.; Beuse, M.; Tautorat, P.; Schmidt, T.S. Experience curves for operations and maintenance costs of renewable energy technologies. Joule 2020, 4, 359–375. [Google Scholar] [CrossRef]

- El-Thalji, I.; Liyanage, J.P. On the operation and maintenance practices of wind power asset A status review and observations. J. Qual. Mainten. Eng. 2012, 18, 232–266. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, X.; Liu, M.; Zeng, J. Based on wavelet transform of fault diagnosis and analysis of wind generator transmission system. J. Basic Sci. Eng. 2011, 19 (Suppl. S1), 210–218. [Google Scholar]

- Kusiak, A.; Li, W. The prediction and diagnosis of wind turbine faults. Renew. Energy 2011, 36, 16–23. [Google Scholar] [CrossRef]

- Brandão, R.F.M.; Carvalho, J.A.B.; Barbosa, F.P.M. Condition monitoring of the wind turbine generator slip ring. In Proceedings of the Universities Power Engineering Conference, London, UK, 4–7 September 2012. [Google Scholar]

- Tamilselvan, P.; Wang, Y.; Wang, P. Optimization of wind turbines operation and maintenance using failure prognosis. In Proceedings of the PHM 2012–2012 IEEE International Conference on Prognostics and Health Management: Enhancing Safety, Efficiency, Availability, and Effectiveness of Systems through PHM Technology and Application, Conference Program, Denver, CO, USA, 18–21 June 2012. [Google Scholar]

- Lau, B.C.P.; Ma, E.W.M.; Pecht, M. Review of offshore wind turbine failures and fault prognostic methods. In Proceedings of the PHM 2012–2012 IEEE International Conference on Prognostics and Health Management: Enhancing Safety, Efficiency, Availability, and Effectiveness of Systems Through PHM Technology and Application, Conference Program, Beijing, China, 23–25 May 2012. [Google Scholar]

- Hofmann, M.A. Review of decision support models for offshore wind farms with an emphasis on operation and maintenance strategies. Wind Energy 2011, 35, 1–16. [Google Scholar] [CrossRef]

- Tracht, K.; Westerholt, J.; Schuh, P. Spare parts planning for offshore wind turbines subject to restrictive maintenance conditions. Procedia Cirp. 2013, 563–568. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2013, 53, 365–376. [Google Scholar] [CrossRef]

- Aguilar, S.; Telles, G.R.; Medina, P.; Quaresma, B.; Cyrino, F.L.; Castro, R. Wind power generation: A review and a research agenda. J. Clean Prod. 2019, 218, 850–870. [Google Scholar]

- Brink, T.; Madsen, S.O.; Lutz, S. Perspectives on How Operation & Maintenance (O&M) Innovations Contribute to the Reduction of Levelized Cost of Energy (LCOE) in Offshore Wind Parks; Danish Wind Industry Association: Copenhagen, Denmark, 2015. [Google Scholar]

- Myrent, N.J.; Kusnick, J.F.; Adams, D.E.; Griffith, D.T. Pitch error and shear web disbond detection on wind turbine blades for offshore structural health and prognostics management. In Proceedings of the Collection of Technical Papers—AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Boston, MA, USA, 8–11 April 2013. [Google Scholar]

- Sainz, J.A.; Sebastián, M.A. Methodology for the maintenance centered on the reliability on facilities of low accessibility. Procedia Eng. 2013, 63, 852–860. [Google Scholar] [CrossRef] [Green Version]

- Fischer, K.; Besnard, F.; Bertling, L. Reliability-centered maintenance for wind turbines based on statistical analysis and practical experience. IEEE Trans. Energy Convers. 2012, 27, 184–195. [Google Scholar] [CrossRef] [Green Version]

- Krishna, D.G. Preventive maintenance of wind turbines using Remote Instrument Monitoring System. In Proceedings of the 2012 IEEE 5th Power India Conference PICONF 2012, Murthal, India, 19–22 December 2012. [Google Scholar]

- Faulstich, S.; Lyding, P.; Tavner, P.J. Effects of wind speed on wind turbine availability. In Proceedings of the European Wind Energy Conference and Exhibition 2011 EWEC 2011, Brussels, Belgium, 14–17 March 2011; pp. 85–88. [Google Scholar]

- Li, H.Z.; Jing, T.; Zhang, H. Arena-based modeling of the maintenance operation for a wind farm. Appl. Mech. Mater. 2013, 401–403, 2205–2208. [Google Scholar] [CrossRef]

- Godwin, J.L.; Matthews, P. Prognosis of wind turbine gearbox failures by utilising robust multivariate statistical techniques. In Proceedings of the PHM 2013—2013 IEEE International Conference on Prognostics and Health Management, Conference Proceedings, Gaithersburg, MD, USA, 24–27 June 2013. [Google Scholar]

- Li, D.; Feng, Y.; Liu, Z.; Chu, J.; Jin, Q. Reliability modeling and maintenance strategy optimization for wind power generation sets. Power Syst. Technol. 2011, 35, 122–127. [Google Scholar]

- Haddad, G.; Sandborn, P.A.; Pecht, M.G. An options approach for decision support of systems with prognostic capabilities. IEEE Trans Reliab. 2012, 61, 872–883. [Google Scholar] [CrossRef]

- Lu, D.; Qiao, W.; Gong, X.; Qu, L. Current-based fault detection for wind turbine systems via hilbert-huang transform. In Proceedings of the IEEE Power and Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013. [Google Scholar]

- Hameed, Z.; Vatn, J.; Heggset, J. Challenges in the reliability and maintainability data collection for offshore wind turbines. Renew. Energy 2011, 36, 2154–2165. [Google Scholar] [CrossRef]

- Amirat, Y.; Choqueuse, V.; Benbouzid, M. EEMD-based wind turbine bearing failure detection using the generator stator current homopolar component. Mech. Syst. Signal Proc. 2013, 41, 667–678. [Google Scholar] [CrossRef] [Green Version]

- Bala, S.; Pan, J.; Das, D.; Apeldoorn, O.; Ebner, S. Lowering failure rates and improving serviceability in offshore wind conversion-collection systems. In Proceedings of the PEMWA 2012—2012 IEEE Power Electronics and Machines in Wind Applications, Denver, CO, USA, 16–18 July 2012. [Google Scholar]

- Ho, T.C.Y.; Ran, L. A study on the electrical system arrangement for offshore wind turbines and factors influencing the voltage level choice. In Proceedings of the—2012 3rd IEEE International Symposium on Power Electronics for Distributed Generation Systems, PEDG 2012, Aalborg, Denmark, 25–28 June 2012; pp. 442–449. [Google Scholar]

- Tavner, P.J.; Greenwood, D.M.; Whittle, M.W.G.; Gindele, R.; Faulstich, S.; Hahn, B. Study of weather and location effects on wind turbine failure rates. Wind Energy 2013, 16, 175–187. [Google Scholar] [CrossRef]

- Mesquita, R.F.; Beleza, J.A.; Maciel, F.P. Application of neural networks for failure detection on wind turbines. In Proceedings of the 2011 IEEE PES Trondheim PowerTech: The Power of Technology for a Sustainable Society, POWERTECH 2011, Trondheim, Norway, 19–23 June 2011. [Google Scholar]

- Guo, P.; Infield, D.; Yang, X. Wind turbine gearbox condition monitoring using temperature trend analysis. IEEE Trans. Sustain. Energy 2012, 3, 124–133. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Pan, L. The research of the wind turbines reliability based on characteristics of wind energy. Adv. Mat. Res. 2013, 677, 278–281. [Google Scholar] [CrossRef]

- Boroumandjazi, G.; Saidur, R.; Rismanchi, B.; Mekhilef, S. A review on the relation between the energy and exergy efficiency analysis and the technical characteristic of the renewable energy systems. Renew. Sust. Energy Rev. 2012, 16, 3131–3135. [Google Scholar] [CrossRef]

- Pinar, J.M.; García, F.P.; Tobias, A.; Papaelias, M. Wind turbine reliability analysis. Renew. Sust. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Zafirakis, D. The influence of technical availability on the energy performance of wind farms: Overview of critical factors and development of a proxy prediction model. J. Wind Eng. Ind. Aerodyn. 2013, 115, 65–81. [Google Scholar] [CrossRef]

- Zhang, H.; Yin, Y.; Shen, H.; He, J.; Zhao, S. Generator maintenance scheduling of large-scale wind power integration considering peak shaving. Dianli Xitong Zidonghua/Autom. Electr. Power Syst. 2012, 36, 25–30. [Google Scholar]

- Gallo, G.; Ponta, L.; Cincotti, S. Profit-based O&M strategies for wind power plants. In Proceedings of the 9th International Conference on the European Energy Market EEM 12, Florence, Italy, 10–12 May 2012. [Google Scholar]

- Basirat, P.; Fazlollahtabar, H.; Mahdavi, I. System dynamics meta-modelling for reliability considerations in maintenance. Int. J. Process Manag. Benchmark. 2013, 3, 136–153. [Google Scholar] [CrossRef]

- Umashankar, S.; Kothari, D.P.; Vijayakumar, D.; Vasudevan, M.; Chillapalli, B. Cost effective fully fed wind turbine HTS generator: An alternative to existing generators in offshore wind farms. In Proceedings of the India International Conference on Power Electronics IICPE 2010, New Delhi, India, 28–30 January 2011. [Google Scholar]

- Deng, M.N.; Yu, Y.H.; Chen, L.; Zhao, H.S. Optimal maintenance interval for wind turbine gearbox. Appl. Mech. Mater. 2011, 130–134, 112–118. [Google Scholar] [CrossRef]

- Kostandyan, E.E.; Sørensen, J.D. Reliability assessment of offshore wind turbines considering faults of electrical/mechanical components. In Proceedings of the International Offshore and Polar Engineering Conference, Anchorage, Alaska, 30 June–5 July 2013; p. 402. [Google Scholar]

- De Prada, M.; Gomis-Bellmunt, O.; Sumper, A.; Bergas-Jané, J. Power generation efficiency analysis of offshore wind farms connected to a SLPC (single large power converter) operated with variable frequencies considering wake effects. Energy 2012, 37, 455–468. [Google Scholar] [CrossRef]

- Putter, H.T.; Gotz, D.; Petzold, F.; Oetjen, H. The evolution of VLF testing technologies over the past two decades. In Proceedings of the IEEE Power Engineering Society Transmission and Distribution Conference, Orlando, FL, USA, 7–10 May 2012. [Google Scholar]

- Qiu, Y.; Feng, Y.; Tavner, P.; Richardson, P.; Erdos, G.; Chen, B. Wind turbine SCADA alarm analysis for improving reliability. Wind Energy 2012, 15, 951–966. [Google Scholar] [CrossRef]

- Qiao, Y.; Lu, Z.; Xu, F.; Wang, X.; Hou, Y.; Zhu, C. Study on the integrated monitoring & control platform of wind farms. Dianli Xitong Baohu yu Kongzhi/Power Syst. Prot. Control 2011, 39, 117–123. [Google Scholar]

- Hockley, C.J. Wind turbine maintenance and topical research questions. Procedia Cirp. 2013, 11, 284–286. [Google Scholar] [CrossRef] [Green Version]

- Entezami, M.; Hillmansen, S.; Weston, P.; Papaelias, M. Fault detection and diagnosis within a wind turbine mechanical braking system using condition monitoring. Renew. Energy 2012, 47, 175–182. [Google Scholar] [CrossRef]

- El-Thalji, I.; Liyanage, J.P.; Hjøllo, M. Scalable and customer-oriented life cycle costing model: A case study of an innovative vertical axis wind turbine concept (case-vawt). In Proceedings of the International Offshore and Polar Engineering Conference, Rhodes, Greece, 17 June 2012; pp. 423–425. [Google Scholar]

- Möllerström, E.; Gipe, P.; Beurskens, J.; Ottermo, F. A historical review of vertical axis wind turbines rated 100 kW and above. Renew. Sust. Energy Rev. 2019, 105, 1–13. [Google Scholar] [CrossRef]

- Mesquita, R.F.; Beleza, J.A.; Maciel, F.P. Forecast of faults in a wind turbine gearbox. In Proceedings of the 9th International Conference, ELEKTRO 2012, Rajeck Teplice, Slovakia, 21–22 May 2012; pp. 170–173. [Google Scholar]

- Wilson, G.; McMillan, D.; Ault, G. Modelling the effects of the environment on wind turbine failure modes using neural networks. In Proceedings of the International Conference on Sustainable Power Generation and Supply, SUPERGEN 2012, Hangzhou, China, 8–9 September 2012. [Google Scholar]

- Haddad, G.; Sandborn, P.; Pecht, M. A real options optimization model to meet availability requirements for offshore wind turbines. In Proceedings of the Technical Program for MFPT: The Applied Systems Health Management Conference 2011: Enabling Sustainable Systems, Virginia Beach, VA, USA, 10–12 May 2011. [Google Scholar]

- Bharadwaj, U.R.; Silberschmidt, V.V.; Wintle, J.B. A risk based approach to asset integrity management. J. Qual. Mainten. Eng. 2012, 18, 417–431. [Google Scholar] [CrossRef]

- Nielsen, J.J.; Sørensen, J.D. Challenges for risk-based maintenance planning for offshore wind turbines. In Proceedings of the International Offshore and Polar Engineering Conference, Maui, HI, USA, 19 June 2011; pp. 451–457. [Google Scholar]

- Poncela, M.; Poncela, P.; Perán, J.R. Automatic tuning of kalman filters by maximum likelihood methods for wind energy forecasting. Appl. Energy 2013, 108, 349–362. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Van Ostaeyen, J.; Duflou, J.R.; Pintelon, L. Quantifying the added value of an imperfectly performing condition monitoring system—Application to a wind turbine gearbox. Reliab. Eng. Syst. Saf. 2013, 111, 45–57. [Google Scholar] [CrossRef]

- García, F.P.; Tobias, A.M.; Pinar, J.M.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Kim, B.; Park, J.; Lee, J.; Oh, K.; Lee, J. Design and application of condition monitoring system for wind turbines. In Proceedings of the International Conference on Control, Automation and Systems, Gyeonggi-do, Korea, 26–29 October 2011; pp. 392–394. [Google Scholar]

- Byon, E.; Pérez, E.; Ding, Y.; Ntaimo, L. Simulation of wind farm operations and maintenance using discrete event system specification. Simulation 2011, 87, 1093–1117. [Google Scholar] [CrossRef]

- Cibulka, J.; Ebbesen, M.K.; Hovland, G.; Robbersmyr, K.G.; Hansen, M.R. A review on approaches for condition based maintenance in applications with induction machines located offshore. Int. J. Model. Identif. Control 2012, 33, 69–86. [Google Scholar] [CrossRef] [Green Version]

- Pican, E.; Omerdic, E.; Toal, D.; Leahy, M. Direct interconnection of offshore electricity generators. Energy 2011, 36, 1543–1553. [Google Scholar] [CrossRef] [Green Version]

- Khattara, A.; Becherif, M.; Ayad, M.Y.; Bahri, M.; Aboubou, A. Optimal number of DFIG wind turbines in farm using pareto genetic algorithm to minimize cost and turbines fault effect. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013. [Google Scholar]

- Barberá, L.; Guerrero, A.; Crespo, A.; González-Prida, V.; Guillén, A.; Gómez, J.; Sola, A. State of the art of maintenance applied to wind turbines. Chem. Eng. Trans. 2013, 33, 931–936. [Google Scholar]

- Moon, D.; Kim, S.; Kim, S. A fault detection system for wind power generator based on intelligent clustering method. J. Inst. Control Robot. Syst. 2013, 19, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Kusiak, A.; Verma, A. A data-mining approach to monitoring wind turbines. IEEE Trans. Sustain. Energy 2012, 3, 150–157. [Google Scholar] [CrossRef]

- Byon, E. Wind turbine operations and maintenance: A tractable approximation of dynamic decision making. Iie Trans. 2013, 45, 1188–1201. [Google Scholar] [CrossRef]

- Sheng, S.; Veers, P. Wind turbine drivetrain condition monitoring—An overview. In Proceedings of the Technical Program for MFPT: The Applied Systems Health Management Conference 2011: Enabling Sustainable Systems, Virginia Beach, VA, USA, 10–12 May 2011. [Google Scholar]

- Hamilton, A.; Quail, F. Detailed state of the art review for the different online/inline oil analysis techniques in context of wind turbine gearboxes. J. Tribol. 2011, 133, 044001. [Google Scholar] [CrossRef] [Green Version]

- Wiesent, B.R.; Dorigo, D.G.; Şimşek, Ö.; Koch, A.W. Linear variable filter based oil condition monitoring systems for offshore windturbines. In Proceedings of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 20 September 2011. [Google Scholar]

- Sánchez, L.; Couso, I. Singular spectral analysis of ill-known signals and its application to predictive maintenance of windmills with SCADA records. Soft Comput. 2012, 16, 755–768. [Google Scholar] [CrossRef]

- Su, C.; Zhou, X. Condition-based maintenance optimization for wind turbines based on semi-markov decision process. Jixie Gongcheng Xuebao/J. Mech. Eng. 2012, 48, 44–49. [Google Scholar] [CrossRef]

- Andrawus, J.A.; MacKay, L. Offshore wind turbine blade coating deterioration maintenance model. Wind Energy 2011, 35, 551–560. [Google Scholar] [CrossRef]

- Soua, S.; Van Lieshout, P.; Perera, A.; Gan, T.; Bridge, B. Determination of the combined vibrational and acoustic emission signature of a wind turbine gearbox and generator shaft in service as a pre-requisite for effective condition monitoring. Renew. Energy 2013, 51, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Florea, G.; Paraschiv, A.; Cimpoesu, E. Wind Farm Noise Monitoring Used for Predictive Maintenance. In Proceedings of the Information Control Problems in Manufacturing, Bucharest, Romania, 23–25 May 2012; IFAC Proceedings Volumes. Volume 45, pp. 1822–1827. [Google Scholar]

- Barszcz, T.; Jablonski, A. Aspects of automatization of wind farm monitoring on the example of a diagnostic center. In Proceedings of the Structural Health Monitoring 2011: Condition-Based Maintenance and Intelligent Structures—Proceedings of the 8th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 13–15 September 2011; pp. 2603–2610. [Google Scholar]

- Sheldon, J.S.; Watson, M.J.; Byington, C.S. Integrating oil health and vibration diagnostics for reliable wind turbine health predictions. In Proceedings of the ASME Turbo Expo, New York, NY, USA, 3 May 2011; pp. 939–948. [Google Scholar]

- Hoveskog, M.; Halila, F. Business Model Innovation–The Case of a Learning Network Approach to O&M Solutions in the Swedish Wind Energy Industry; Sage Publications: Halmstad, Sweden, 2016. [Google Scholar]

- Carlos, S.; Sánchez, A.; Martorell, S.; Marton, I. Onshore wind farms maintenance optimization using a stochastic model. Math. Comput. Model. 2013, 57, 1884–1890. [Google Scholar] [CrossRef]

- Moore, M. The testing methodologies of service aged medium voltage power cables as applied to an operating wind farm. In Proceedings of the 2011 Electrical Insulation Conference, EIC 2011, Annapolis, MD, USA, 5–8 June 2011; pp. 423–429. [Google Scholar]

- Fischer, K.; Besnard, F.; Bertling, L. A limited-scope reliability-centred maintenance analysis of wind turbines. In Proceedings of the European Wind Energy Conference and Exhibition 2011, EWEC 2011, Brussels, Belgium, 14–17 March 2011; pp. 89–93. [Google Scholar]

- Nguyen, T.H.; Prinz, A.; Noll, J. Proactive maintenance of offshore wind turbine blades using knowledge-based force analysis. In Proceedings of the 3rd International Conference on Innovative Computing Technology, INTECH 2013, London, UK, 29–31 August 2013; p. 239. [Google Scholar]

- Douard, F.; Domecq, C.; Lair, W. A probabilistic approach to introduce risk measurement indicators to an offshore wind project evaluation—Improvement to an existing tool. In Proceedings of the 11th International Probabilistic Safety Assessment and Management Conference and the Annual European Safety and Reliability Conference 2012, Helsinki, Finland, 25–29 June 2012; pp. 358–364. [Google Scholar]

- Pérez, E.; Ntaimo, L.; Ding, Y. Simulation of wind farm operations and maintenance. In Proceedings of the ASME Turbo Expo, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Kusiak, A.; Verma, A. Analyzing bearing faults in wind turbines: A data-mining approach. Renew. Energy 2012, 48, 110–116. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, J.; Wang, K.; Chen, H. One-sample prediction for the failure number of lognormal distribution in the future time interval. Xitong Gongcheng Lilun Yu Shijian/Syst. Eng. Theory Pract. 2013, 33, 785–790. [Google Scholar]

- Besnard, F.; Patriksson, M.; Strömberg, A.; Wojciechowski, A.; Fischer, K.; Bertling, L. A stochastic model for opportunistic maintenance planning of offshore wind farms. In Proceedings of the IEEE PES Trondheim PowerTech: The Power of Technology for a Sustainable Society, Trondheim, Norway, 19–23 June 2011. [Google Scholar]

- Lin, Z.; Cevasco, D.; Collu, M. A methodology to develo reduced-order models to support the operation and maintenance of offshore wind turbines. Appl. Energy 2020, 259, 114228. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, Z.; Guo, B. Optimal opportunistic maintenance model of multi-unit systems. J. Syst. Eng. Electron. 2013, 24, 811–817. [Google Scholar] [CrossRef]

- Arvesen, A.; Birkeland, C.; Hertwich, E.G. The importance of ships and spare parts in LCAs of offshore wind power. Environ. Sci. Technol. 2013, 47, 2948–2956. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Besnard, F.; Fischer, K.; Tjernberg, L.B. A model for the optimization of the maintenance support organization for offshore wind farms. IEEE Trans. Sustain. Energy 2013, 4, 443–450. [Google Scholar] [CrossRef]

- Knudsen, O.Ø.; Bjørgum, A.; Døssland, L.T. Low maintenance coating systems for constructions with long lifetime. Int. Corros. Conf. 2012, 5, 3618–3626. [Google Scholar]

- Knudsen, O.O.; Bjørgum, A.; Døssland, L.T. Long-life, low-maintenance coating systems. Mater. Perform. 2012, 51, 54–59. [Google Scholar]

- Tracht, K.; Schuh, P.; Maier, J. Stochastic influences on the maintenance processes of wind energy turbines. Zwf Z. Für Wirtsch. Fabr. 2012, 107, 99–103. [Google Scholar] [CrossRef]

- Pattison, D.; Xie, W.; Quail, F. The WINDY domain-a challenging real-world application of integrated planning and scheduling. In Proceedings of the 23rd International Conference on Automated Planning and Scheduling (ICAPS), Rome, Italy, 10–14 June 2013; pp. 462–466. [Google Scholar]

- Liu, W.; Xie, C.; Wen, J.; Wang, J.; Li, J. Multi-objective decision making method for maintenance scheduling of transmission network. Dianwang Jishu/Power Syst. Technol. 2013, 37, 471–476. [Google Scholar]

- Wu, Y.; Bing, H.; Lou, S. A unit maintenance scheduling model considering peak regulation pressure balance for power system containing wind farms. Dianwang Jishu/Power Syst. Technol. 2012, 36, 94–100. [Google Scholar]

- Kovács, A.; Erdos, G.; Monostori, L.; Viharos, Z.J. Scheduling the maintenance of wind farms for minimizing production loss. Ifac Proc. Vol. 2011, 44, 14802–14807. [Google Scholar] [CrossRef] [Green Version]

- Kovács, A.; Erds, G.; Viharos, Z.J.; Monostori, L.A. System for the detailed scheduling of wind farm maintenance. Cirp Ann. Manuf. Technol. 2011, 60, 497–501. [Google Scholar]

- Amiri, R.; Wang, B. A generic framework for wind power forecasting. In Proceedings of the IECON 2011—37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; pp. 796–801. [Google Scholar]

- Watada, J.; Tai, Y.; Wang, Y.; Choi, J.; Shiota, M. Service cost optimization in supply balance of sustainable power generation. In Proceedings of the PICMET ‘11: Technology Management in the Energy Smart World (PICMET), Portland, OR, USA, 31 July–4 August 2011. [Google Scholar]

- Vick, B.D.; Almas, L.K. Developing wind and/or solar powered crop irrigation systems for the great plains. Appl Eng Agric. 2011, 27, 235–245. [Google Scholar] [CrossRef]

- Butler, S.; O’Connor, F.; Farren, D.; Ringwood, J.V. A feasibility study into prognostics for the main bearing of a wind turbine. In Proceedings of the IEEE International Conference on Control Applications, Dubrovnik, Croatia, 3–5 October 2012; pp. 1092–1097. [Google Scholar]

- Espejo, A.; Mínguez, R.; Tomás, A.; Menéndez, M.; Méndez, F.J.; Losada, I.J. Directional calibrated wind and wave reanalysis databases using instrumental data for optimal design of off-shore wind farms. In Proceedings of the OCEANS 2011 IEEE, Santander, Spain, 6–9 June 2011. [Google Scholar]

- Amirat, Y.; Choqueuse, V.; Benbouzid, M. Wind turbine bearing failure detection using generator stator current homopolar component ensemble empirical mode decomposition. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Montreal, QC, Canada, 25–28 October 2012; pp. 3937–3942. [Google Scholar]

- Ding, F.; Tian, Z. Opportunistic maintenance for wind farms considering multi-level imperfect maintenance thresholds. Renew. Energy 2012, 45, 175–182. [Google Scholar] [CrossRef]

- Carvalho, M.; Pinto, E.M.; Telhada, J. Maintenance costs of a pitch control device of a wind turbine. Lect. Notes Eng. Comput. Sci. 2013, 3, 569. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, J.J.; Sørensen, J.D. On risk-based operation and maintenance of offshore wind turbine components. Reliab. Eng. Syst. Saf. 2011, 96, 218–229. [Google Scholar] [CrossRef]

- Izquierdo, J.; Crespo, A.; Uribetxebarria, J.; Erguido, A. On the importance of assessing the operational context impact on maintenance management for life cycle cost of wind projects. Renew. Energy 2020, 153, 1100–1110. [Google Scholar] [CrossRef]

- Kabalci, E. Development of a feasibility prediction tool for solar power plant installation analyses. Appl. Energy 2011, 88, 4078–4086. [Google Scholar] [CrossRef]

- Shafiee, M.; Patriksson, M.; Stromberg, A.B.; Bertling, L. A redundancy optimization model applied to offshore wind turbine power converters. In Proceedings of the 2013 IEEE Grenoble Conference PowerTech, POWERTECH 2013, Grenoble, France, 16–20 June 2013. [Google Scholar]

- Islam, M.R.; Guo, Y.; Zhu, J. A transformer-less compact and light wind turbine generating system for offshore wind farms. In Proceedings of the 2012 IEEE International Conference on Power and Energy, Kota Kinabalu, Malaysia, 2–5 December 2012; pp. 605–610. [Google Scholar]

- Mipoung, O.D.; Lopes, L.A.C.; Pillay, P. Power estimation of induction generators fed from wind turbines. In Proceedings of the Conference Record—IAS Annual Meeting (IEEE Industry Applications Society), Orlando, FL, USA, 9–13 October 2011. [Google Scholar]

- Abeywardena, H.; Atputharajah, A.; Ekanayake, J.B. Novel technique to smooth power output of a wound rotor induction generator based wind turbine. In Proceedings of the 2011 6th International Conference on Industrial and Information Systems, ICIIS 2011—Conference Proceedings, Kandy, Sri Lanka, 16–19 August 2011; pp. 517–521. [Google Scholar]

- Zavvos, A.; McDonald, A.S.; Mueller, M. Structural optimisation tools for iron cored permanent magnet generators for large direct drive wind turbines. In Proceedings of the IET Conference on Renewable Power Generation (RPG 2011), Edinburgh, UK, 6–8 September 2011. [Google Scholar]

- Islam, M.R.; Guo, Y.; Zhu, J. A novel medium-voltage converter system for compact and light wind turbine generators. In Proceedings of the 2012 22nd Australasian Universities Power Engineering Conference: “Green Smart Grid Systems”, AUPEC 2012, Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Beltrán, J.; Guerrero, J.J.; Melero, J.J.; Llombart, A. Detection of nacelle anemometer faults in a wind farm minimizing the uncertainty. Wind Energy 2013, 16, 939–952. [Google Scholar] [CrossRef]

- Benmessaoud, T.; Mohammedi, K.; Smaili, Y. Influence of maintenance on the performance of a wind farm. Prz. Elektrotechniczny 2013, 89, 174–178. [Google Scholar]

- Hameed, Z.; Wang, K. Development of optimal maintenance strategies for offshore wind turbine by using artificial neural network. Wind Energy 2012, 36, 353–364. [Google Scholar] [CrossRef]

- Sinha, Y.; Steel, J.A.; Andrawus, J.A.; Gibson, K. A SMART software package for maintenance optimisation of offshore wind turbines. Wind Energy 2013, 37, 569–577. [Google Scholar] [CrossRef]

- Vatn, J. A state based model for opportunity based maintenance. In Proceedings of the 11th International Probabilistic Safety Assessment and Management Conference and the Annual European Safety and Reliability Conference, Helsinki, Finland, 26–29 September 2012; pp. 1–4. [Google Scholar]

- Zhao, R.; Shen, W.; Knudsen, T.; Bak, T. Fatigue distribution optimization for offshore wind farms using intelligent agent control. Wind Energy 2012, 15, 927–944. [Google Scholar] [CrossRef] [Green Version]

- Rauer, R.; Münsterberg, T.; Jahn, C. Quantity and type forecasting tool for offshore wind power plant spare parts. Computational methods in marine engineering. In Proceedings of the V International Conference on Computational Methods in Marine Engineering, Hamburg, Germany, 29–31 May 2013; p. 652. [Google Scholar]

- Feuchtwang, J.; Infield, D. Offshore wind turbine maintenance access: A closed-form probabilistic method for calculating delays caused by sea-state. Wind Energy 2013, 16, 1049–1066. [Google Scholar] [CrossRef]

- Dinwoodie, I.; Catterson, V.M.; McMillan, D. Wave height forecasting to improve off-shore access and maintenance scheduling. In Proceedings of the IEEE Power and Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013. [Google Scholar]

- O’Connor, M.; Lewis, T.; Dalton, G. Weather window analysis of irish and portuguese wave data with relevance to operations and maintenance of marine renewables. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Nantes, France, 9–14 June 2013. [Google Scholar]

- Hameed, Z.; Vatn, J. Role of grouping in the development of an overall maintenance optimization framework for offshore wind turbines. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2012, 226, 584–601. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy Statistics 2020; International Renewable Energy Agency: Abu Dhabi, UAE, 2020. [Google Scholar]

- IRENA. Renewable Power Generation Costs in 2017; International Renewable Energy Agency: Abu Dhabi, UAE, 2018. [Google Scholar]

| Measure | Year | |||||

|---|---|---|---|---|---|---|

| 2008 | 2010 | 2012 | 2014 | 2016 | 2018 | |

| Capacity (MW) | 1.20 × 105 | 1.81 × 105 | 2.67 × 105 | 3.49 × 105 | 4.67 × 105 | 5.63 × 105 |

| Production (GWh) | 2.18 × 105 | 3.43 × 105 | 5.26 × 105 | 7.13 × 105 | 9.56 × 105 | 1.26 × 105 |

| Number of Articles in Scopus | 1014 | 1558 | 2255 | 2448 | 2597 | 3167 |

| Group | Number of Keywords | Keywords |

|---|---|---|

| O&M | 1 | Operation and maintenance |

| FAIL | 1 | Failure rate |

| 2 | Fault detection | |

| 3 | Failure of gearboxes | |

| 4 | Failure analysis | |

| 5 | Failure | |

| 6 | Failure (mechanical) | |

| RELI | 1 | Reliability |

| 2 | Availability | |

| 3 | Maintainability | |

| 4 | Profitability | |

| 5 | Reliability analysis | |

| C_M | 1 | Condition monitoring |

| 2 | Condition-monitoring systems | |

| 3 | Algorithms | |

| 4 | Condition-based maintenance | |

| M_STRA | 1 | Maintenance strategies |

| 2 | Low maintenance | |

| 3 | Turbine maintenance | |

| 4 | Maintenance planning | |

| 5 | Maintenance free | |

| 6 | Preventive maintenance | |

| 7 | Predictive maintenance | |

| 8 | Maintenance activity | |

| 9 | Maintenance action | |

| M_COST | 1 | Maintenance cost |

| 2 | Costs | |

| 3 | Investment | |

| 4 | Cost–benefit analysis | |

| 5 | Investment | |

| 6 | Life cycle costs | |

| M_OPT | 1 | Optimization |

| 2 | Maintenance optimization |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, Á.M.; Orosa, J.A.; Vergara, D.; Fernández-Arias, P. New Tendencies in Wind Energy Operation and Maintenance. Appl. Sci. 2021, 11, 1386. https://doi.org/10.3390/app11041386

Costa ÁM, Orosa JA, Vergara D, Fernández-Arias P. New Tendencies in Wind Energy Operation and Maintenance. Applied Sciences. 2021; 11(4):1386. https://doi.org/10.3390/app11041386

Chicago/Turabian StyleCosta, Ángel M., José A. Orosa, Diego Vergara, and Pablo Fernández-Arias. 2021. "New Tendencies in Wind Energy Operation and Maintenance" Applied Sciences 11, no. 4: 1386. https://doi.org/10.3390/app11041386