Introduction: Silver alloy is one of semi-precious alloys for dental prosthesis, which has been applied remarkably in Japanese dental field. Ag-20Pd-17.7Cu-12Au alloy (G12) with Cu/Ag ratio of 0.367, which was newly developed for commercial dental silver alloy, shows an unique hardening mechanism after a simple solution treatment (ST) at relatively high temperature as well as traditionally applied Ag-20Pd-14.5Cu-12Au alloy (S12) with Cu/Ag ratio of 0.2841) [1]. However, the relationship between ST at various temperatures and the mechanical strength of G12 has not been fully investigated. Therefore, the relationship between ST and mechanical properties of G12 after ST at various temperatures was investigated systematically in this study.

Experimental Methods: Materials used in this study were hot-rolled plates of Ag-20Pd-17.7Cu-12Au alloy (G12) and Ag-20Pd-14.5Cu-12Au alloy (S12). All samples were conducted with the solution treatment(ST) at 1023~1173 K for 3.6 ks in Ar gas atmosphere followed by water quenching (WQ). Hereafter, the samples of G12 and S12 subjected to ST were designated by using temperature (e.g. G12/1123 K). In addition, some samples subjected to aging treatment (AT) at 673 K for 1.2 ks in a vacuum followed by air cooling after ST (G12/AT673 K).

Back-scattering electron (BSE) images from a scanning electron microscope (SEM) and elemental mapping by a wavelength dispersive X-rays spectrometer (WDS) were used for observation of the microstructure and the identification of phase constitution. Vickers hardness (HV), tensile and fatigue tests were performed to evaluate the mechanical strength. The corrosion potential was also measured in a 3 mass% NaCl solution to evaluate the corrosion resistance.

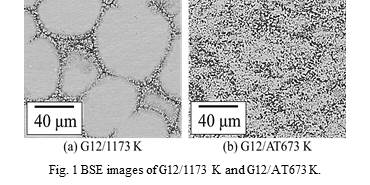

Results and Discussion: Figure 1 shows the microstructures of G12/1173 K and G12/AT673 K. The microstructure of G12/1173 K is composed of three kinds of phases with Ag-rich α2 phase (white area), Cu-rich α1 phase (light dark area) and β phase (dark area) of Pd-Cu intermetallic compound. Although the nominal melting point of G12 is around 1233 K, it seems that the high Cu concentration area like α1 phase is partially dissolved and then the α1 and β phases reprecipitate during cooling. On the other hand, the microstructure of G12/AT673 K was composed of two kinds of phases with α2 and β phases, which is a typical microstructure of AT after ST[1].

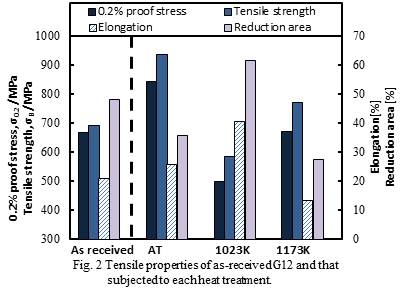

Figure 2 shows the tensile properties of as-received G12 and those subjected to various heat treatments. Both strength and ductility of G12/1173 K decrease significantly as compared with those of G12/AT673 K. It is considered that relatively early tensile failure could occur by a significant stress concentration at the grain boundaries of coarsen α2 phases. From these results, there are high possibilities of degraded tensile properties of G12 with an increase in the temperature of heat treatment more than 1173K.

Conclusions:

- Microstructure of G12 subjected to ST at relatively high temperature of 1173 K was composed of three kinds of phases with α2, α1 and β phases, and seemed to had partially dissolved area at relatively high Cu concentration.

- Strength and ductility of G12 subjected to solution treatment at restively high temperature more than 1173K decreased significantly.

References:

[1] T. Akahori, M. Niinomi, M. Nakai, H. Tsutsumi, T. Kanno, Y.H. Kim, H. Fukui, J. Japan Inst. Metals, 74(2010), pp. 337-344