Abstract

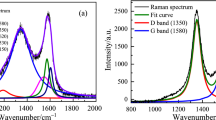

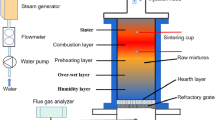

The iron and steel industry is a major emitter of pollutant gases into the atmosphere, thus greatly affecting the quality of the environment. It is therefore imperative to find alternative means of reducing the pollutant gases emitted into the atmosphere through sintering activities in the iron and steel industry. This study focuses on semicoke as an alternative sinter fuel to replace coal, coke breeze and other fuels used in iron ore sintering. Specifically, comparison between semicoke and coke breeze was made with respect to their combustion characteristics and combustion efficiency. Investigations were made based on drop tube furnace test results, thermogravimetric analyses and optical microscopy. The chemical kinetics governing the combustion mechanism of semicoke and coke breeze were also investigated. Semicoke was high in volatile, hydrogen, net calorific value and oxygen content. The relatively high volatile content, low ignition and heating temperatures, high combustion index and combustion efficiency of semicoke makes semicoke a better alternative fuel to power sinter plants. Consequently, among the semicoke sample types employed in the study, SC2 semicoke showed high combustion characteristics. This study is relevant in the iron and steel industry as it investigates the validity of combustion efficiency of semicoke.

Similar content being viewed by others

REFERENCES

Ooi, T.C., Thompson, D., Anderson, D.R., Fisher, R., Fray, T., and Zandi, M., The effect of charcoal combustion on iron-ore sintering performance and emission of persistent organic pollutants, Combust. Flame, 2011, vol. 158, no. 5, pp. 979–987.

Griffin, P.W. and Hammond, G.P., Industrial energy use and carbon emissions reduction in the iron and steel sector: a UK perspective, Appl. Energy, 2019, vol. 249, pp. 109–125.

Qu, Y., An, J., He, Y., and Zheng, J., An overview of emissions of SO2 and NOx and the long-range transport of oxidized sulfur and nitrogen pollutants in East Asia, J. Environ. Sci., 2016, vol. 44, pp. 13–25.

Tang, Y., Li, R., and Wang, S., Research progress and prospects of coal petrology and coal quality in China, Int. J. Coal Sci. Technol., 2020, vol. 7, pp. 273–287.

Zhu, D.Q., Luo, Y.H., Pan, J., and Zhou, X.L., Characterization of semicoke generated by coal-based direct reduction process of siderite, J. Centr. South Univ., 2015, vol. 22, no. 8, pp. 2914–2921.

Zhu, D., Zhou, X., Pan, J., and Luo, Y., Direct reduction and beneficiation of a refractory siderite lump, Miner. Process. Extr. Metall., 2014, vol. 123, no. 4, pp. 246–250.

Mousa, E., Wang, C., Riesbeck, J., and Larsson, M., Biomass applications in iron and steel industry: An overview of challenges and opportunities, Renewable Sustainable Energy Rev., 2016, vol. 65, pp. 1247–1266.

Ahmed, H., New trends in the application of carbon-bearing materials in blast furnace iron-making, Minerals, 2018, vol. 8, no. 12, pp. 561–571.

Gan, M., Ji, Z., Fan, X., Zhao, Y., Chen, X., and Fan, Y., Insight into the high proportion application of biomass fuel in iron ore sintering through CO-containing flue gas recirculation, J. Clean. Prod., 2019, vol. 232, pp. 1335–1347.

El-Hussiny, N.A., Khalifa, A.A., El-Midany, A.A., Ahmed, A.A., and Shalabi, M.E., Effect of replacement coke breeze by charcoal on technical operation of iron ore sintering, Int. J. Sci. Eng. Res., 2015, vol. 6, pp. 681–686.

Luo, Y.H., Zhu, D.Q., Pan, J., and Zhou, X.L., Utilization of semicoke as by-product derived from coal-based direct reduction process in iron ore sintering, Ironmaking Steelmaking, 2016, vol. 43, no. 8, pp. 628–634.

Jha, G. and Soren, S., Study on applicability of biomass in iron ore sintering process, Renewable Sustainable Energy Rev., 2017, vol. 80, pp. 399–407.

Wang, X., Wang, D., Song, M., Xin, C., and Zeng, W., Tetraethylenepentamine-modified activated semicoke for CO2 capture from flue gas, Energy Fuels, 2017, vol. 31, no. 3, pp. 3055–3061.

Zhao, J.P., Loo, C.E., and Dukino, R.D., Modeling fuel combustion in iron ore sintering, Combust. Flame, 2015, vol. 162, no. 4, pp. 1019–1034.

Yörük, C.R., Meriste, T., Sener, S., Kuusik, R., and Trikkel, A., Thermogravimetric analysis and process simulation of oxy-fuel combustion of blended fuels including oil shale, semicoke, and biomass, Int. J. Energy Res., 2018, vol. 42, no. 6, pp. 2213–2224.

Liang, W., Ning, X., Zhang, J., Li, Y., Niu, L., Jiang, C., Zhang, N., and Wang, G., Effect of Effect of ash on coal combustion performance and kinetics analysis, Combust. Sci. Technol., 2022, vol. 194, no. 4, pp. 785–800.

Jelonek, Z., Drobniak, A., Mastalerz, M., and Jelonek, I., Assessing pellet fuels quality: A novel application for reflected light microscopy, Int. J. Coal Geol., 2020, vol. 222, p. 103433.

Wang, S.J., Wu, F., Zhang, G., Zhu, P., Wang, Z.Y., Huang, C.J., and Chen, S.T., Research on the combustion characteristics of anthracite and blended coal with composite catalysts, J. Energy Inst., 2014, vol. 87, no. 2, pp. 96–101.

Wu, J., Wang, B., and Cheng, F., Thermal and kinetic characteristics of combustion of coal sludge, J. Therm. Anal. Calorim., 2017, vol. 129, no. 3, pp. 1899–1909.

Yang, G., Yang, Z., Zhang, J., Yang, Z., and Shao, J., Combustion characteristics and kinetics study of pulverized coal and semicoke, High Temp. Mater. Proc., 2019, vol. 38, pp. 783–791.

Wang, S.J., Huang, C.J., Wu, F., Zhu, P., and Zhang, G., Investigation on influence of steel industry wastes on pulverized coal combustion characteristics, J. Energy Inst., 2013, vol. 86, no. 3, pp. 167–170.

Funding

This research is financially supported by the Key Laboratory of Hubei Province for Coal Conversion and New Carbon Materials (grant no. WKDM202007) and Hubei Technological Innovation Special Fund (Grant no. 2020ZYYD019). The support of Nangang Industry Development Co. Ltd is also appreciated.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Alex Kojo Acquah, Fang, H., Wang, S. et al. Comparison Study on Combustion Characteristics between Semicoke and Coke Breeze. Coke Chem. 64, 407–416 (2021). https://doi.org/10.3103/S1068364X21090027

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X21090027