Abstract

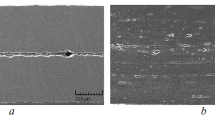

The mechanical and tribological properties of aluminum matrix composites are mainly determined by the cohesion and uniformity of the reinforcing ceramic particles. The cohesion of the reinforcing ceramic particles represents a very important issue which is mostly poor at temperatures near the melting point of aluminum and leads to inferior mechanical and tribological properties of developed aluminum matrix composites with non uniform distribution of reinforcement. The main reason for coating the particles is to improve the bonding between reinforcement and molten alloy and thus to eliminate interfacial reactions. The great enhancement in strength values of the composites in this study can be ascribed to the effective load bearing capacity of disintegrated B4C particles which are adherently bonded to the matrix alloy. Homogeneity and reduction in the particle size of B4C during the extrusion process is evidenced in the microstructural studies.

Similar content being viewed by others

References

Shabani, M.O. and A. Mazahery, A., Composites: Part B, 2013, vol. 45, pp. 185–191.

Mazahery, A. and Shabani, M.O., Ceram. Int., 2012, vol. 38, pp. 1887–1895.

Barati, M. and Claytor, G., J. Mater. Sci., 2007, vol. 39, pp. 567–576.

Alipour, G. and Sarikaya, M., J. Mater. Sci. Res., 2011, vol. 11, pp. 145–151.

Pyzik, A.J. and Aksay, I.A., Processing of ceramic and metal matrix composites, Proceedings of the International Symposium on Advances in Processing of Ceramic and Metal Matrix Composites, New York, NY, 1989, p. 269.

Pyzik, A.J. and Beaman, D.R., J. Am. Ceram. Soc., 1995, vol. 78, pp. 305–312.

Rhee, S.K., J. Am. Ceram. Soc., 1970, vol. 53, pp. 386–389.

Mazahery, A. and Shabani, M.O., Powder Technol., 2012, vol. 217, pp. 558–565.

Vugt, L.V. and Froyen, L., J. Mater. Process. Technol., 2000, vol. 104, pp. 133–144.

Irons, G.A. and Owusu-Boahen, K., Metall. Mater. Trans. B, 1995, vol. 26, pp. 980–981.

Gowri, S. and Samuel, F.H., Metall. Trans. A, 1992, vol. 23, pp. 3369–3376.

Gupta, M., Lu, L., and Ang, S.E., J. Mater. Sci., 1997, vol. 32, pp. 1261–1267.

Karnezis, P.A., Durrant, G., and Cantor, B., Mater. Charact., 1998, vol. 40, pp. 97–109.

Mazahery, A. and Shabani, M.O., Ceram. Int., 2012, vol. 38, no. 5, pp. 4263–4269.

Quaak, C.J. and Kool, W.H., Mater. Sci. Eng. A, 1994, vol. 188, pp. 277–282.

Hashim, J., Looney, L., and Hashmi, M., J. Mater. Process. Technol., 1999, vols. 92–93, pp. 1–7.

Asthana, A.J., J. of Mater. Sci. and Eng., 1998, vol. 35, pp. 1959–1980.

Leon, C.A. and Drew, R.L., J. Mater. Sci., 2000, vol. 35, pp. 4763–4768.

Davidson, A.M. and Regener, D., Compos. Sci. Technol., 2000, vol. 60, pp. 865–869.

Tham, L.M., Gupta, M., and Cheng, L., Acta Materialia, 2001, vol. 49, pp. 3243–3253.

Fard, R.R. and Akhlaghi, F., J. of Mater. Process. Technol., 2007, vols. 187–188, pp. 433–436.

Thakur, S.K., B.K. Wear, 2001, vol. 247, p. 201.

Moustafa, S.F., Badry, S.A., Sanad, A.M., and Kieback, B., Wear, 2002, vol. 253, pp. 699–710.

Zhan, Y.Z. and Zhang, G., Mater. Letters, 2003, vol. 57, pp. 4583–4591.

Cocen, U. and Onel, K., Compos. Sci. Technol., 2002, vol. 62, pp. 275–282.

McKimpson, M.G. and Scott, T.E., Mater. Sci. and Eng., 1989, vol. 107, pp. 93–106.

Ozdemir, I., Cocen, U., and Onel, K., Compos. Scie. and Technol., 2000, vol. 60, pp. 411–419.

Varma, V.K., Kamath, S.V., Kutumabarao, V.V., Mater. Sci. and Technol., 2000, vol. 17, pp. 921–936.

Zhong, L., J. of Compos. Mater., 2000, vol. 34, pp. 101–115.

Bauri, R. and Surappa, M.K., J. of Mater. Process. Technol., 2009, vol. 209, pp. 2077–2084.

Petalas, Y.G., Antonopoulos, C.G., Bountis, T.C., and Vrahatis, M.N., Phys. Lett. A, 2009, vol. 373, pp. 334–341.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Shabani, M.O., Mazahery, A. Good bonding between coated B4C particles and aluminum matrix fabricated by semisolid techniques. Russ. J. Non-ferrous Metals 54, 154–160 (2013). https://doi.org/10.3103/S1067821213020120

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821213020120