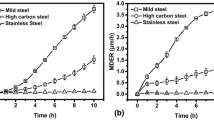

Abstract—The corrosion and cavitation resistance of high-strength economically alloyed nitrogen-bearing chromium–nickel–manganese austenitic C10Cr19Mn10Ni6Mo2N and C09Cr19Mn10Ni6Mo2Cu2N stainless steels in seawater is compared experimentally with the properties of chromium–nickel C04Cr18Ni9 and C04Cr18Ni9N steels. The resistance to pitting corrosion is tested by a chemical method in a 100-g/L FeCl3 · 6H2O solution. The overall corrosion resistance is assessed by tests in synthetic seawater (3% NaCl). The cavitation resistance in seawater is tested by means of a high-intensity cavitation system based on a Hielscher Ultrasonic UIP 1000hd ultrasound unit in 3% aqueous NaCl solution (vibration frequency 20 kHz, power 1000 W, amplitude 25 μm) for 8–36 h. After cavitation treatment, the damage and change in microhardness at the sample surface is estimated, as well as the change in phase composition and mass of the samples in the tests. According to the tests, C10Cr19Mn10Ni6Mo2N and C09Cr19Mn10Ni6Mo2Cu2N steels are free of pits after exposure to seawater and iron-chloride solution. The overall corrosion rate is lower than for chromonickel Cr18Ni9 steel. Ultrasonic cavitation may lead not only to surface damage by erosion and intensification of local corrosion but also to change in the physical and mechanical properties on account of cold working and phase transformations. The resistance to ultrasonic cavitation in seawater is greater for C10Cr19Mn10Ni6Mo2N and C09Cr19Mn10Ni6Mo2Cu2N steels, containing thermally and mechanically stable austenite, than for chromonickel steels, especially C04Cr18Ni9, which is weaker and less stable. For example, after 36-h cavitational treatment in seawater, significant changes in state are seen in C04Cr18Ni9 and C04Cr18Ni9N steels: considerable damage (etching) and hardening of the surface and also the formation of a small quantity of martensite in C04Cr18Ni9 steel. For C10Cr19Mn10Ni6Mo2N and C09Cr19Mn10Ni6Mo2Cu2N steels, the tests indicate only slight change in state of the surface and hardening.

Similar content being viewed by others

Notes

D.V. Lysov of National University of Science and Technology “MISiS” participated in these experiments.

REFERENCES

Jargelius-Pettersson, R.F.A., Application of the pitting resistance equivalent concept to some highly alloyed austenitic stainless steels, Corrosion, 1998, vol. 54, no. 2, pp. 162–168.

Gorynin, I.V., Malyshevskii, V.A., Kalinin, G.Yu., et al., Corrosion-resistant high-strength nitrogen steels, Vopr. Materialoved., 2009, no. 3 (59), pp. 7–16.

Naumenko, V.V., Shlyamnev, A.P., and Filippov, G.A., Nitrogen in austenitic stainless steels of different alloying systems, Metallurgist, 2011, vol. 55, nos. 5–6, pp. 410–418.

Mushnikova, S.Yu., Legostaev, Yu.L., Khar’kov, A.A., et al., Investigation of the effect of nitrogen on resistance to pitting corrosion of austenitic steels, Vopr. Materialoved., 2004, no. 2 (38), pp. 126–135.

Kaputkina, L.M., Smarygina, I.V., Kaputkin, D.E., Svyazhin, A.G., and Bobkov, T.V., Effect of nitrogen addition on physicochemical properties and corrosion resistance of corrosion-resistant steels, Met. Sci. Heat Treat., 2015, vol. 57, no. 7, pp. 395–401.

Janik-Czachor, M., Lunarska, E., and Szklarska-Smialowska, Z., Effect of nitrogen content in an 18Cr–5Ni–10Mn stainless steel on the pitting susceptibility in chloride solutions, Corrosion, 1975, vol. 31, no. 11, pp. 394–398.

Azuma, S., Miyuki, H., and Kudo, T., Effect of alloying nitrogen on crevice corrosion of austenitic stainless steels, ISIJ Int., 1996, vol. 36, no. 7, pp. 793–798.

Loable, C., Viçosa, I.N., Mesquita, T.J., Mantel, M., Nogueira, R.P., Berthom, G., Chauveau, E., and Roche, V., Synergy between molybdenum and nitrogen on the pitting corrosion and passive film resistance of austenitic stainless steels as a pH-dependent effect, Mater. Chem. Phys., 2017, vol. 186, pp. 237–245.

Kozyrev, S.P., Gidroabrazivnyi iznos metallov pri kavitatsii (Hydroabrasive Wear of Metals during Cavitation), Moscow: Mashinostroenie, 1971.

Georgievskaya, E.P., Kavitatsionnaya eroziya grebnykh vintov i metody bor’by s nei (Cavitation Erosion of Propellers and Its Prevention), Leningrad: Sudostroenie, 1978.

Lauterborn, W., Cavitation and coherent optics, in Cavitation and Inhomogeneities in Underwater Acoustics, Berlin: Springer-Verlag, 1980, pp. 3–12.

Prikhod’ko, V.M., Aleksandrov, V.A., Fatyukhin, D.S., and Petrova, L.G., Effect of ultrasonic cavitation on nitrided steel surface layer condition, Met. Sci. Heat Treat., 2015, vol. 57, nos. 5–6, pp. 300–303.

Prikhod’ko, V.M., Ul’trazvukovye tekhnologii pri proizvodstve, ekspluatatsii i remonte transportnoi tekhniki (Ultrasonic Technologies in the Production, Operation and Reparation of Transport Equipment), Moscow: Tekhpoligraftsentr, 2003.

Merson, D.L. and Lindrov, M.L., Effect of cavitation on structural steels surface destruction, Vektor Nauki Tol’yatt. Gos. Univ., 2010, no. 3, pp. 43–45.

Pearsall, J.S., Cavitation (Mechanics Engineering Monograph), London: Mills & Boon, 1972.

Agranat, B.A., Dubrovin, M.N., Khavskii, N.N., et al., Osnovy fiziki i tekhniki ul’trazvuka (Basics of Ultrasound Physics and Technology), Moscow: Vysshaya Shkola, 1987.

Shestoperov, V.Yu., Cavitation destruction of materials and the criteria for assessment their erosion resistance, Tr. Nizhegorod. Gos. Tekh. Univ. im. R.E. Alekseeva, 2013, no. 5 (102), pp. 79–83.

Kaputkina, L.M., Svyazhin, A.G., Smarygina, I.V., Kindop, V.E., and Bazhenov, V.E., High-strength corrosion-resistant cryogenic steel alloyed with nitrogen, Metallurgist, 2016, vol. 60, no. 7, pp. 802–809.

Kaputkina, L.M., Svyazhin, A.G., Smarygina, I.V., and Kindop, V.E., Influence of nitrogen and copper on hardening of austenitic chromium-nickel-manganese stainless steel, CIS Iron Steel Rev., 2016, vol. 11, pp. 30–34.

Kaputkina, L.M., Svyazhin, A.G., Smarygina, I.V., and Bobkov, T.V., Corrosion resistance of high-strength austenitic chromium–nickel–manganese steel containing nitrogen, Steel Transl., 2016, vol. 46, no. 9, pp. 644–650.

ACKNOWLEDGMENTS

Financial support was provided by the Russian Ministry of Education and Science (project RFMEFI57514X0071).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Kaputkina, L.M., Svyazhin, A.G., Smarygina, I.V. et al. Corrosion and Cavitation Resistance of High-Strength Austenitic Nitrogen Stainless Steels in Seawater. Steel Transl. 49, 13–19 (2019). https://doi.org/10.3103/S0967091219010078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219010078