Abstract

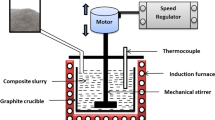

AA 2024 alloy has been melted and cast in a permanent cast iron mould in the form of 18 mm Φ fingers. The synthesis of AA2024 alloy − 5wt.% fly ash composite was made by stir cast technique. A uniform distribution of fly ash particles in the matrix phase was obtained. Good bonding between the matrix and reinforcement was also achieved. Dry sliding wear behavior of the alloy and the composite has been investigated using a pin-on-disc wear tester. The investigation was carried out at a fixed sliding velocity of 2.0 m/s, track diameter of 60 mm and load ranging from 0.5 kgf to 1.5 kgf (4.9–14.7 N). SEM studies were carried out to assess the wear behavior of the alloy and the composite. The composite showed better wear resistance than the base alloy for the lower loads. However, for the higher loads and longer sliding distances, the wear in the composite was extensive due to the existence of fractured and dislodged fly ash particles in the alloy matrix.

Similar content being viewed by others

References

Rohatgi P.K., In: Invited silver anniversary lecture by American Foundry Society, AFS Transactions, 01-133 (2001), 633.

Rohatgi P.K., Gupta N., Daoud A., ASM handbook; Casting: vol. 15; ASM International; 2008, p.1149–1164.

Rohatgi P.K., Liu Y., Ray S., ASM handbook. Friction, lubrication, and wear technology, vol. 18. ASM International; 1992 p.801–811.

Sannino A.P., Rack H.J., Wear, 189 (1995), 1.

Deuis R.L., Subramanina C., Yellup J.M., Compos Sci Technol., 57 (1997), 415.

Seah K.H.W., Hemanth J., Sharma S.C., Materials and Design, 24(2) (2003), 87.

Siddiquea R., Noumoweb A., Conservation and Recycling, 53 (2008), 27.

Belger M.A., Rohatgi P.K., Gupta N., TMS annual meeting, (2006), p. 95–204.

Sulaiman S., Sayuti M., Samin R., J. of Materials Processing Technology, 201 (2008), 731.

Rohatgi P.K., Schultz B.F., Daoud A., Zhang W.W., Tribology International, 43 (2010), 455.

Sun Zhiqiang, Di Zhang, Li Guobin, Materials and Design, 26 (2005), 454.

Hemanth J., Materials and Design, 30 (2009), 323.

Kumar V., Abraham Zacharia K., Sharma P., Fly Ash Utilization: Indian Scenario & Case Studies. http://www.tifac.org.in/news/flyindia.htm as on 15 April 2007.

Matsunaga T., Kim J.K., Hardcastle S., Rohatgi P.K., Materials Science and Engineering-A, 325 (2002), 333.

Ramachandra M., Radhakrishna K., Wear, 262 (2007), 1450.

Ramachandra M., Radhakrishna K., Journal of Materials Science, 40 (2005), 5989.

Sudrashan, Surappa M.K., Wear, 256 (2008), 349.

Mondal D.P., Das S., NIDHI JHA., 30 (2009), 2563.

Quinn T.J.F., J. Appl. Phys., 13 (1962), 33.

Zhang J., Alpas A. T., Acta. Mater, 45 (1997), 513.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Babu Rao, J., Venkata Rao, D., Siva Prasad, K. et al. Dry sliding wear behaviour of fly ash particles reinforced AA 2024 composites. Mater Sci-Pol 30, 204–211 (2012). https://doi.org/10.2478/s13536-012-0026-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s13536-012-0026-z