Abstract

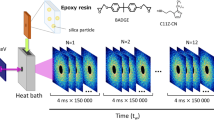

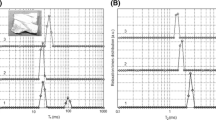

To analyze a curing process of epoxy resin in terms of molecular motion, we adapted a pulsed NMR method. Three kinds of 1H spin-spin relaxation times (T2L (long), T2S (short) and T2M (intermediate)) were estimated from observed solid echo train signals as the curing process proceeded. A short T2S value below 20 ms suggests the existence of a motion-restricted chain, that is, cured elements of resin, and its fraction, PS, sigmoidally increased with the curing time. On the other hand, the fraction of T2L, PL, decreased with the reaction time reciprocally against PS, suggesting the disappearance of highly mobile molecules raised from pre-cured resin. The spin-lattice relaxation time, T1, was also measured to check another aspect of molecular motion in the process. T1 of the mixed epoxy resin and curing agent gradually increased just after mixing both of them. This corresponds to an increment of a less-mobile fraction, of which the correction time is more than 10–6 s, and also means that the occurrence of a network structure whose mobility is strongly restricted by chemically bonded bridges between the epoxy resin and curing agent. The time courses of these parameters coincided with those of IR peaks pertinent to the curing reaction. Therefore, pulsed NMR is a useful tool to monitor the hardening process of epoxy resin in real time non-distractively in terms of the molecular motion of protons.

Similar content being viewed by others

References

C. G. Fry and A. C. Lind, Macromolecules, 1988, 21, 1292.

A. Hale and C. W. Macosako, Macromolecules, 1991, 24, 2610.

A. Shefer and M. Gottlib, Macromolecules, 1992, 25, 4036.

E. Butta, A. Livi, G. Levita, and P. A. Rolla, J. Polym. Sci., Part B: Polym. Phys., 1995, 331, 2253.

I. Mondragon, I. Quintard, and C. B. Bucknalol, Plast., Rubber Compos. Process Appl., 1995, 23, 331.

G. M. Maistrus and C. B. Buknal, Polym. Eng. Sci., 1994, 34(20), 1519.

K. Yanaguchi, pre-print of Japan Society of Anal. Chem., 1998, 10, 47.

B. Blümich, S. Anferova, K. Kremer, S. Shama, V. Hermann, and A. Segre, Spectroscopy, 2003, 18(2), 18.

B. Blümich, V. Anferov, S. Anferova, M. Klein, R. Fechte, M. Adamas, and F. Casanova, Magn. Reson. Eng., 2002, 15(4), 255.

K. Fujimoto, T. Nishi, and R. Kado, Polym. J., 1972, 3, 448.

R. Folland and A. Charlesby, J. Polym. Sci., Part C: Polym. Lett., 1978, 16, 104.

R. Folland, J. H. Stern, and A. Charlesby, J. Polym. Sci., Part A: Polym. Chem., 1978, 16, 339.

I. Kamel and A. Charlesby, J. Polym. Sci., Part B: Polym. Phys., 1981, 19, 803.

T. Nishi and T. Rikiishi, Polym. Preprints Jpn., 1978, 27, 1707.

T. Kurotu, Polym. J., 1986, 18, 859.

T. Kurotu, Polym. J., 1987, 19, 285.

H. Kimoto, A. Fukuda, A. Asano, and T. Kurotsu, Anal. Sci., 2005, 21, 315.

H. Kimoto, T. Uemura, and T. Kurotsu, Mem. Nat. Def. Acd., 2003, 43, 1.

H. Serizawa, M. Ito, T. Kanamoto, K. Tanaka, and A. Nomura, Polym. J., 1982, 14, 149.

S. Kaufman, J. Polym. Sci., Part A: Polym. Chem., 1982, 14, 149.

G. C. Munie and J. Jonas, J. Polym. Sci., Part A: Polym. Chem., 1980, 18, 1061.

R. P. Cocker, D. L. Chadwick, D. J. Dare, and R. E. Challis, Int. J. Adhes. Adhes., 1998, 18, 319.

A. Bloembergen, E. M. Purcell, and R. V. Pound, Phys. Rev., 1948, 78, 679.

The temperature dependence of the curing agent was almost the same as that of the pre-cured resin. The softening point ranges from –10 to 35°C. Over 35°C, only a component of PL was observed.

This is one of the important properties of epoxy resin for the practical purposes, being tolerate to a high temperature.

S. K. Soh and D. C. Sundberg, J. Polym. Sci., Part A: Polym. Chem., 1982, 20, 1299.

S. K. Soh and D. C. Sundberg, J. Polym. Sci., Part A: Polym. Chem., 1982, 20, 1315.

S. K. Soh and D. C. Sundberg, J. Polym. Sci., Part A: Polym. Chem., 1982, 20, 1331.

S. K. Soh and D. C. Sundberg, J. Polym. Sci., Part A: Polym. Chem., 1982, 20, 1345.

I. T. Smith, J. Appl. Chem., 1960, 10, 95.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kimoto, H., Tanaka, C., Yaginuma, M. et al. Pulsed NMR Study of the Curing Process of Epoxy Resin. ANAL. SCI. 24, 915–920 (2008). https://doi.org/10.2116/analsci.24.915

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2116/analsci.24.915