Abstract

All concrete structures contain reinforcement spacers, and deep sections can be affected by bleeding and segregation without displaying visible indications during casting. However, their effects on mass transport and long-term durability are not well studied. In this paper, reinforced concrete columns were prepared with plastic and cementitious spacers to achieve 50 mm cover, and compacted at different vibration frequencies and durations. 28d cured samples were extracted along the height, conditioned to equilibrium (21 °C, 75% RH or 50 °C, 7% RH), and then subjected to water absorption, electrical conduction, epoxy impregnation and fluorescence imaging. Samples from the top of the column consistently gave higher accessible porosity and mass transport compared to samples from the bottom. Presence of spacers caused additional increases in mass transport because of preferential flow through the spacer-concrete interface which is more porous and microcracked compared to bulk concrete farther away. Image analysis on cross-sections showed that the columns experienced some aggregate segregation despite care taken to avoid over-compaction. The resistance of concrete to ingress of aggressive agents decreases with increasing height due to the combined negative effects of reinforcement spacers and segregation.

Similar content being viewed by others

1 Introduction

Spacers are used in concrete structures to support reinforcement steel so that the nominal cover between the reinforcement and formwork is maintained before and after concreting [1]. Spacers are made from plastic, cementitious materials, or steel wire in many different shapes and sizes [2,3,4,5]. Design standards for concrete structures require spacers to be located at every meter (or less) along the length of reinforcing bars to ensure that the bars remain in place during concreting [6,7,8,9]. The spacers are left permanently in the structure, and so they form an essential component of reinforced concrete. As such, ideally spacers should not have a negative impact on long-term durability. However, some field observations have reported a correlation between the location of spacers and reinforcement corrosion [10,11,12,13,14].

Surprisingly, very little research has been carried out to understand the effect of spacers on the long-term durability of concrete structures. Available studies have shown that the presence of spacers can disrupt the microstructure of the cover zone and accelerate ingress of aggressive agents causing premature deterioration [15, 16]. However, a limitation of these studies is that they were based entirely on spacers supporting horizontal reinforcement (e.g. in slabs and beams). Spacers are also used to support vertical reinforcement (e.g. in columns and walls) and their effect on microstructure and transport could be different, especially in conjunction with bleeding and segregation that occurs when fresh concrete is compacted. Furthermore, in these applications, spacers are typically located on the surface exposed to the external environment.

Segregation refers to the separation of ingredients in fresh concrete such that they are no longer uniformly distributed [17,18,19]. Bleeding is a form of segregation caused by settlement of solid particles (aggregate and cement) due to gravity and upward migration of water [20]. The bleed water accumulates on the upper surface, under larger aggregate particles or reinforcing steel after the concrete has been placed and compacted, prior to setting. High vibration frequency and/or long compaction time increase the tendency for bleeding and segregation [21,22,23]. Concretes that are most susceptible to segregation and bleeding are those with large slump values, that are deficient in fines, containing angular aggregates, or inappropriately handled, placed and compacted in deep sections [20, 24, 25]. A small amount of segregation and bleeding is inevitable in freshly compacted concrete, but excessive amounts can lead to performance issues such as surface defects, excessive plastic shrinkage and reduced strength especially near the top of structural elements [20, 26,27,28].

However, no studies have been carried out to-date on the combined effects of vertical reinforcement spacers and segregation on mass transport properties of concrete. It is reasonable to suspect that the presence of spacers may disrupt the microstructure and distribution of aggregate particles in vertically cast concrete. These are the main research questions that this study seeks to address. Concrete columns with plastic or cementitious spacers vibrated at two different frequencies and durations were tested for water sorptivity, electrical conductivity and accessible porosity. The spacers were positioned near the top and bottom of the columns and segregation was analysed by measuring the area fraction of aggregate on cross-sections at different heights using image analysis. Finally, the measured properties were correlated to pore structure to establish the combined effects spacers and segregation.

2 Experimental

2.1 Materials and mix proportion

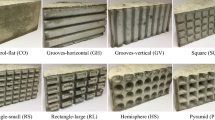

Plastic ‘A’ clip spacers (PS) and single cementitious spacers (CS) to achieve 50 mm cover were used in this study. The spacers (Fig. 1) were obtained from a major manufacturer. The plastic spacer was made of polyvinyl chloride (PVC) and has a surface area of 2560 mm2. The cementitious spacer was made of fibre-reinforced Portland cement mortar containing 50% replacement of cement with ground-granulated blastfurnace slag (GGBS) at a water/binder ratio of 0.35. The cementitious spacer has a water accessible porosity of 8.5% determined by vacuum saturation and a surface area of 1860 mm2. Single cover spacers were selected for this study because these are the most widely used spacers to support vertical reinforcements.

An ordinary Portland cement CEM I concrete mix was designed based on absolute volume method at free water/cement (w/c) ratio of 0.4. The cement complied with BS EN 197–1:2011 [29]. Thames Valley sand (< 5 mm) and gravel (< 10 mm) complying with medium grading [30] were used as fine and coarse aggregate respectively. The gravel had a specific gravity of 2.75 and 24-h absorption of 0.6%, while the sand had fineness modulus of 2.76, specific gravity of 2.51 and 24-h absorption of 0.62%. The total aggregate fraction was 70% vol. and sand to total aggregate mass ratio was 0.4. A superplasticiser (MasterGlenium SKY 920) was added to achieve good consistence and workability retention. Tap water was used as batching water, which was adjusted to account for aggregate absorption and water from the superplasticizer.

Several trial mixes were carried out to determine a viable mix at 0.4 w/c. The final mix proportions were 167 kg/m3 water, 418 kg/m3 CEM I, 728 kg/m3 sand, 1092 kg/m3 gravel and 0.75% wt. cement superplasticizer. This produced a slump of 120 mm when tested in accordance with BS EN 12,350–2: 2009 [31], which indicates a high workability mix (consistence class S3) suitable for reinforced concrete columns and walls [32, 33].

2.2 Sample preparation

Thirty-six rectangular columns (80 × 90 × 400 mm3) were cast vertically in specially fabricated timber formwork. Each column contained a high-yield steel reinforcing bar (Ø12 mm, ribbed) fixed to the formwork to achieve 50 mm cover using two spacers near the top and bottom as shown in Fig. 2. The column dimensions were selected to ensure sufficient clearance for concreting and to mimic the thickness of concrete layers placed on site, which are typically < 500 mm [24, 25]. Control reference specimens were prepared by casting columns without internal spacers. The formwork was clamped tightly using external threaded steel rods to achieve the required dimensions and to avoid leakage. Prior to casting, a thin layer of release agent was applied to internal surfaces to achieve a smooth finish and avoid defects (e.g. bugholes) that may influence the penetrability of the cover zone.

All ingredients for the concrete mix were batched by weight. Cement, sand and gravel were first dry-mixed in a 50-L capacity pan mixer for 30 s to ensure the dry solids were well-mixed before addition of water. Batch water pre-mixed with the required amount of superplasticiser was then added and mixed for a further 3 min. The columns were compacted in four uniform layers using a vibrating table (Vibtec FFT 2000 × 1000) with adjustable frequency control. This was chosen for the study since compaction of vertical elements on-site is usually carried out with external vibration rather than internal. Vibration was continued until large entrapped air bubbles ceased to appear and the surface started to glisten.

Many trials were carried out to determine the frequency and period of vibration required to achieve good compaction around rebar and spacers by visual inspection and image analysis (Sect. 2.7). This was found to be 6.5 Hz for 40 s. In another set of experiments, replicate columns were prepared in the same manner, but compacted at a higher frequency of 8.5 Hz and longer duration of 90 s to vary the degree of compaction. It should be noted that none of the samples showed visible bleeding or segregation during preparation. In addition, periodic visual checks found that the entire assembly worked well and that the spacers and rebar did not move relative to the formwork during concreting, which could otherwise influence results.

2.3 Curing and conditioning

The freshly cast columns were covered with plastic sheeting and wet hessian, and kept at room temperature for the first 24 h. Afterwards, they were demoulded and cured in a fog room at 21 °C, 100% RH for 28 days. Prior to curing, any externally exposed rebars were encased with cement grout (w/c 0.30) to prevent premature corrosion. After curing, each column was sectioned using a diamond abrasive cutter to extract two rectangular samples (80 × 90 × 90 mm3) from near the top and bottom of the column, as illustrated in Fig. 2b. These rectangular samples were used for further testing while the offcuts were discarded.

Moisture state has a huge influence on measured transport properties. Therefore, it is important to condition samples to a uniform state prior to testing to ensure meaningful results. The cut samples were conditioned to constant mass by drying at either 21 °C, 75% RH or at 50 °C, 7% RH to achieve two moisture states. The 21 °C, 75% RH regime was chosen to represent mild drying and to minimise shrinkage-induced microcracking [34] whilst the 50 °C, 7% RH regime was carried out to simulate severe drying in hot weather conditions. Drying was carried out in either an enclosed box in a temperature-controlled lab (21 ± 1 °C) or in an oven; both contained fans to circulate air and soda lime to prevent carbonation. Saturated NaCl solution was used to maintain 75% RH at 21 °C. This was monitored regularly, and salt solution replaced when required.

Samples were weighed periodically, and “equilibrium” was assumed when the mass loss was less than 0.01% per day. This required approximately 3–4 months of conditioning time. Oven-dried samples were cooled to room temperature (21 ± 1 °C) in a vacuum desiccator containing silica gel for 24 h to prevent condensation or moisture re-entering the samples during cooling, prior to testing. The mass before and after cooling was recorded and the difference was always less than 0.01%, implying constant moisture content.

2.4 Capillary absorption, accessible porosity and electrical conductivity

The conditioned samples were then tested for capillary absorption (water sorptivity) and electrical conductivity in three replicates per measurement. Absorption was carried out using conventional gravimetric measurement in a simple vertical capillary rise setup. The cast surface containing the spacer-concrete interface (Fig. 2b) was tested to simulate the direction of water ingress in real structures. Each sample was supported on two plastic rods (to allow free access of water) and then partially immersed in a tray containing shallow water to a depth of ~ 3 mm to simulate unidirectional absorption. Prior to testing, the sides of the sample were sealed with waterproof tape to prevent absorption from these surfaces.

The water uptake over time was measured with an electronic balance accurate to 0.01 g. Weighing was carried out at frequent intervals: typically 5, 10, 15, 20, 30, 40, 50 and 60 min, then every 15 min for the next hour, and then approximately every hour for the next 5 h. Subsequently, daily readings were taken until the sample approached saturation. Prior to each weighing, excess surface water was removed with dampened cloth and weighed quickly (within 30 s) without stopping the clock. The tray was covered with a loose-fitting transparent lid to prevent sample drying, but care was taken to ensure that no condensates formed underneath the lid that might drop onto the samples. Water level was maintained as required.

The cumulative absorption per unit inflow area i (g/m2) was plotted against the square-root of time t (min). For one-dimensional absorption into an unsaturated semi-infinite medium, cumulative absorption is given by \(i=S\sqrt{t}+a\), where S is the sorptivity coefficient (g/m2.min0.5) and a is a small fitting constant arising mainly from surface effects [35,36,37]. The sorptivity coefficient S was determined from the slope of the best-fit line drawn across at least ten readings taken during the first seven hours of measurement. In all cases, the R2 value of the linear regression was greater than 0.95.

Immediately after the capillary absorption test, samples were fully immersed in water and placed under vacuum for 4 h, then left submerged for 24 h to achieve saturation. The accessible porosity ϕ (%) was estimated from the mass difference between vacuum saturated surface dry condition and preconditioned state, divided by the sample volume.

The vacuum saturated-surface dry samples were then tested for bulk electrical conductivity. Samples were clamped between two larger brass plates and connected to an LCR databridge. A generous amount of a salt-free electrode gel was applied to ensure proper electrical contact between the brass plates and sample surfaces. Electrical conduction was tested in the same direction as capillary absorption through the cover in order to examine the effect of spacers. Electrical resistance R (Ω) was measured at alternating current of 1 kHz frequency to minimise polarisation effects. The resistance typically stabilises within one minute; three readings were taken and averaged. Electrical conductivity \({\sigma }_{e}\) (S/m) was then calculated as the reciprocal of electrical resistivity (\(\rho =RA/l)\), where A (m2) and l (m) are the sample cross-sectional area and length respectively.

2.5 Imaging water absorption

The imaging method described by Wu et al. [34] was used to study water ingress during capillary absorption. Following electrical conductivity measurements, samples were sectioned in half with a diamond abrasive cutter from the centre to expose the spacer and rebar, as shown in Fig. 3. The sectioning was carried out at a slow feed rate to avoid damaging the sample. The cross-sections were then conditioned at 50 °C, 7% RH and capillary absorption (sorptivity) was repeated by using water dyed with 1 wt% fluorescein (C20H12O5). The dye acts as a tracer that enhances the visibility of the water penetration front. The test was carried out in a dark room to enhance contrast and the sample cross-section was imaged regularly with a digital camera. The camera was operated at a small aperture to increase the depth of field and high ISO to obtain adequate exposure. Images were captured at 5–10 min interval for the first hour, then at 15–30 min interval for the next two hours, then hourly for the next 6 h and daily for up to 3 days. This setup mimics the sorptivity test and allows continuous imaging without disturbing the sample and water absorption process.

2.6 Epoxy impregnation and fluorescence imaging

Replicate samples were pressure impregnated with low-viscosity fluorescein-dyed epoxy resin to study preferential transport paths. This was carried out by adapting the procedures described by Wu et al. [38, 39]. Prior to impregnation, samples were dried at 40° C and the edges were sealed with several layers of adhesive waterproof tape to prevent side leakage. The sample was then evacuated and de-aired in a vacuum chamber at − 1 bar for 3 h. Epoxy was prepared by mixing the resin (Stuers EpoFix) with fluorescein dye (Struers EpoDye) at 0.05 wt. % using a magnetic stirrer for 24 h and then heated to 40 °C to reduce viscosity. The fluorescein-dyed epoxy resin was then mixed with hardener at 25:3 mass ratio. The resin was diluted with 5 wt% toluene to reduce viscosity further.

Without breaking the vacuum, the low viscosity fluorescent resin was fed into the chamber and onto the sample, covering the entire test surface (containing the spacer-concrete interface). Vacuum was then released and the sample transferred into a pressure chamber. Compressed air at 3.5 bar pressure was applied and maintained overnight to force the epoxy into the sample. After three days of curing at room temperature, the impregnated sample was sectioned in half with diamond abrasive cutter and flat ground with 120-grit SiC paper. The entire cross-section (~ 90 × 50 mm) was imaged with an optical stereo microscope (Olympus SZX10) under ultraviolet light. A series of overlapping images was captured, aligned and stitched to produce a large montage of the cross-section. Images were then analysed with Fiji/ImageJ [40] to determine the depth and spatial distribution of epoxy impregnation.

2.7 Image analysis to estimate segregation

The cut surfaces of the rectangular samples (Fig. 2b) were imaged and analysed for segregation by measuring the area fraction of exposed aggregate particles with image analysis, using a method adapted from previous studies [41,42,43]. The entire cut surface was imaged with an optical stereo microscope following the approached described in the preceding section with bright field illumination. Colour images were collected at constant magnification, brightness and contrast settings for repeatability. The aggregate particles were clearly resolved from their colour and shape information; therefore no further image processing was required to enhance contrast.

Segmentation of the aggregate particles was carried out using Fiji/ImageJ [40]. The first step was to enlarge the montage so that individual aggregate particle boundaries are clearly visible. Then, a pixel-wide line was carefully drawn onto the montage tracing the boundaries of the aggregate particles. This was done manually, and its accuracy was checked frequently by cross-referencing with the actual sample under the microscope. This is time consuming but yields accurate results (Fig. 4). Although automated edge detection methods exist, our experience found that these are less reliable when applied to complex aggregates that display a range of colour and mineralogy.

Example image analysis showing segmented aggregate particles at different heights on the same column compacted at 8.5 Hz, 90 s. (I, II, III, IV correspond to sections shown in Fig. 2b)

The smallest detectable aggregate size with this approach was 0.4 mm (diameter). Inevitably, some of the fine aggregate particles were excluded, this was estimated to be ~ 10–20% based on the particle size distribution from sieve analysis. Once all the aggregates particles were selected and accurately marked, its total area fraction (%) was calculated with image analysis as the area of the aggregate particles divided by the sample cross-sectional area. Figure 4 provides examples of segmented images with the aggregate particles marked with a yellow boundary.

3 Results

3.1 Sorptivity, accessible porosity and electrical conductivity

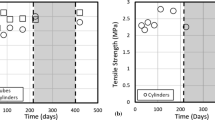

The average water sorptivity, accessible porosity and electrical conductivity are presented in Fig. 5. Error bars indicate standard errors of the average and these show that variability within replicates is generally small. The most striking observation is that in all cases, samples from the top of the column consistently produced greater accessible porosity and higher transport properties compared to samples from the bottom of the same column, even when the column was gently compacted. The difference ranged from 21 to 78% for porosity, 13–89% for sorptivity, and 29–88% for conductivity.

Increasing the vibration frequency and duration of the compaction tended to increase the porosity and transport properties of the top samples, while a corresponding decrease for the bottom samples was observed. Therefore, columns that were over-compacted showed a greater property contrast between the top and bottom. For example, the average difference in sorptivity between the top and bottom samples was 38% when compacted at 6.5 Hz and this increased to 72% at 8.5 Hz. The average difference in conductivity between the top and bottom samples was 36% (6.5 Hz) and this increased to 86% (8.5 Hz). For porosity, the corresponding values were 37% (6.5 Hz) and 55% (8.5 Hz) respectively.

3.2 Effect of spacers and drying regime

An influence of spacers can also be detected. In 37 out of 40 pairs (93%) of data, samples that contained spacers had higher porosity, sorptivity and conductivity by up to 47%, 87% and 39% compared to their respective control reference without spacers. Samples with plastic spacers showed greater increases in sorptivity and conductivity compared to cementitious spacers. Spacers produced a greater percentage increase in transport on the bottom sample compared to the top, particularly when the columns were compacted at 8.5 Hz.

Drying prior to testing had a greater impact on the measured properties than the other variables. Conditioning at 50, 7% RH increased the accessible porosity and this led to higher transport properties compared to gentle drying at 21 °C, 75% RH. Accessible porosity increased by a factor of 2.6 to 4.2 and a similar order of increase in sorptivity (3.1 to 5.5) was observed. It is worth noting that the effect of sample position, compaction and spacer occurred regardless of whether the sample was gently dried or severely dried.

However, severe drying exacerbated the effect of spacers, particularly for plastic spacers. For example, the sorptivity of 50 °C, 7% RH dried samples with plastic spacers increased by an average of 43% and 82% for the top and bottom respectively, compared to the control. The corresponding values for cementitious spacers were 26% and 32% respectively. Furthermore, the cumulative absorption against square-root of time plots samples showed a slight non-linear (sigmoidal) behaviour. This anomalous behavior did not occur in gently-dried samples and is attributed to drying-induced microcracking [34, 44].

3.3 Imaging water absorption

Figure 6 shows example images of a sample with cementitious spacer captured during water absorption from initial exposure up to 72 h, following the procedure described in Sect. 2.5. The addition of fluorescein dye enhances the visibility of the wetted regions and the sharp absorption front. The time series images show the change in water penetration depth and spatial distribution. It can be seen that absorption occurs slightly faster through the cementitious spacer than the surrounding bulk concrete. However, water uptake is dominated by absorption at the spacer-concrete interface. Within the bulk concrete, absorbed water advances in an uneven manner that is influenced by the amount and distribution of coarse aggregate particles [45]. Image analysis was carried out to measure the wetted area. The penetration front was traced, then the wetted area segmented, measured and plotted against root-time. Example cumulative absorption plots are shown in Fig. 7. These show remarkable resemblance to the cumulative absorption plots from gravimetric measurements. Therefore, the wetted region seen on the images is believed to be a good representation of actual water penetration.

3.4 Epoxy impregnation and fluorescence imaging.

Figure 8 shows example fluorescence images of samples that have been pressure impregnated with fluorescein-dyed epoxy resin. Figure 9 presents the maximum depth and total area of epoxy impregnation measured with image analysis. The results show that the presence of a spacer increases the local epoxy penetration compared to areas farther away. Samples containing plastic spacers had the highest epoxy penetration, followed by samples with cementitious spacers. Preferential impregnation occurred along the spacer-concrete interface, within the cementitious spacer itself or through the concrete nestled inside plastic spacer, but was less evident along the aggregate-paste interfacial transition zone (ITZ).

Distinct differences between the top and bottom samples can also be observed. Top samples experienced much greater epoxy impregnation (full thickness) compared to bottom samples, particularly when the columns were compacted at 8.5 Hz. For samples with cementitious spacers, penetration occurred predominantly on the underside, which is probably more porous and microcracked because of pockets of trapped bleed water and plastic settlement of fresh concrete. In contrast, settlement of aggregate particles on the topside of the spacer means that the interface here is likely to be denser. This is less evident for plastic spacers, presumably because their shape and orientation allow fresh concrete to flow through the spacer, therefore trapping less bleed water or aggregate particles.

3.5 Segregation

Figure 10 presents the aggregate content measured with image analysis (Sect. 2.7) for all samples. Top samples consistently had lower aggregate content compared to the bottom. The difference in aggregate content between the top and bottom samples ranged from 2 to 28% (absolute), and this increased with increasing compaction. Therefore, all samples experienced some amount of segregation. Columns that were compacted at higher frequency and for longer duration showed a greater amount of segregation. Samples with cementitious spacers experienced the highest degree of segregation for both compaction regimes. Image analysis of the aggregate size found that the top surface contained mainly fine aggregate particles (see Fig. 4), while the lowest surface contained mainly coarse aggregate particles with a similar particle size distribution to that of the gravel used in the concrete mix.

3.6 Correlations between transport, porosity and aggregate content

Figure 11 shows correlations between accessible porosity, water sorptivity, electrical conductivity and aggregate content for all samples tested in this study. Here the data for porosity, sorptivity and conductivity for each series were normalised to their respective control (no spacer, bottom sample) so that these can be plotted on the same axis for ease of comparison. The plots show positive correlations between transport and porosity, consistent with the fact that water absorption and electrical conduction occur through accessible pores and cracks. In contrast, aggregate content is negatively correlated to porosity since the aggregate particles are effectively non-porous relative to cement paste. It is worth noting that the slopes of the correlations are steeper for samples that were compacted at 8.5 Hz. This shows that these samples experience a greater change in transport properties and aggregate fraction as a result of segregation along the column.

Correlation between porosity and a transport properties (sorptivity, conductivity); b aggregate content. Data for porosity sorptivity and conductivity were normalised to the control sample. Circles (○) represent control samples, triangles (△) and diamonds (◇) represent samples with plastic and cementitious spacers respectively

4 Discussion

4.1 Influence of spacers

The spacers used in this study are either non-porous or have low porosity compared to the surrounding concrete. Therefore, their presence should reduce mass transport of hardened concrete. But our tests show that samples with spacers have higher water sorptivity and electrical conductivity compared to the control, irrespective of sample position, degree of compaction and drying regime. Fluorescence imaging shows that spacers increase mass transport because of preferential flow along the spacer-concrete interface, which is more porous and micro-cracked [15, 16] than the bulk concrete. Preferential transport also takes place through the concrete nestled within plastic spacer. This occurred despite the care taken during sample preparation to ensure good placement and compaction of concrete around spacers.

Samples containing plastic spacers are most sensitive to drying because of the weak bond, poor thermal compatibility and differential volume changes between plastic and concrete. Plastic has a smooth non-porous surface that does not encourage adhesion to concrete. The thermal expansion coefficient for polyvinyl chloride is about 10 × to 15 × higher than that of concrete [17, 46], therefore plastic spacers undergo a greater expansion on heating and contraction on cooling compared to cementitious spacers or the surrounding concrete. This produces stress concentrations that lead to de-bonding of the spacer-concrete interface, exacerbated by shrinkage of the concrete (drying or autogenous). Microcracking occurred despite the fact that the plastic spacer is already perforated by over 25% of the gross plane area to mitigate these effects.

Our findings are consistent with the data reported in previous studies on similar spacer types, but used for supporting horizontal reinforcements. For example, it was observed that spacers increased sorptivity by an average of 27% and 42% for CEM I concretes [15] and blended concretes [16] respectively. These are in line with the values found in the current study. Microstructural analyses showed that the spacer-concrete interface is deficient in cement (owing to poor particle packing), and contains excess porosity and microcracking. The microstructural gradients are similar to the aggregate-paste ITZ [47,48,49] or the steel–concrete interface [50,51,52]. However, spacers span the concrete cover and expose embedded steel to external species. In contrast, porous ITZ is separated by dense bulk paste and so its overall effect on bulk transport is small [53,54,55,56,57].

4.2 Influence of bleeding and segregation

Several competing factors occur when concrete experiences bleeding and segregation. On the whole, top samples consistently showed greater porosity and transport properties compared to bottom samples because water tends to rise while denser constituents (coarse aggregate and cement particles) settle when fresh concrete is compacted. This creates a gradient in w/c ratio and aggregate content along the length of the column. However, excess bleed water near the surface will be lost to evaporation and this has been shown to reduce overall w/c ratio and porosity [58]. Some of the bleed water will be trapped beneath spacers, causing a highly porous interface to form (Fig. 8), but settlement of aggregate and cement particles produces the opposite effect on the top side of spacers.

Top samples not only contain less aggregate, but also more paste with higher water content and therefore greater tendency to shrink on drying. The shrinkage is restrained by spacer and aggregate particles, producing radial and tangential stresses, and microcracking when local tensile strength is exceeded. In contrast, bottom samples have the lowest porosity and transport properties because they contain lower w/c ratio, less cement paste and greater aggregate content. Furthermore, aggregate particles act as obstacles that increase the tortuosity of the pore structure [45], presenting another factor influencing transport. As such, the correlation between transport and porosity is not straightforward. The change in gradient seen in Fig. 11 shows that the effect of bleeding and segregation on transport is more severe when samples are compacted at higher vibration frequency and longer duration.

4.3 Comparison to other studies

Although it is well-known that concrete experiences segregation on compaction, very few studies have characterised its effect on mass transport. Lab-based studies are often carried out on small samples (for convenience) that would be less likely to display segregation. However, measurements on 100ϕ × 250 mm cylinders have found that samples extracted from the top produced higher diffusion, permeability, sorptivity and electrical conductivity than those from the bottom, for a range of concrete types and curing conditions [57, 59]. This was attributed to slight gradients in w/c ratio and/or aggregate content due to bleeding and/or segregation, but no further tests were carried out to verify this. The reported difference (top–bottom) ranged from 7 to 38% for accessible porosity, 9% to 37% for sorptivity, and 8% to 41% for electrical conductivity, which are within the range observed in this study for columns that were gently compacted.

There have been no previous studies on the combined effect of spacers and segregation on transport properties of concrete elements. However, this can be compared to that of horizontal reinforcing steel bars located in upper sections of concrete elements, known as the “top-bar effect”. Backscattered electron imaging carried out by Horne et al. [51] showed that the steel–concrete interface beneath reinforcing steel has greater porosity than that above due to bleeding and segregation. Other studies have suggested that the risk of corrosion increases with height of the concrete section due to increase in porosity and decrease in steel–concrete interface quality [60,61,62,63].

4.4 Implications

All structural concrete contains reinforcement spacers and deep sections can be affected by bleeding and segregation without displaying visible external signs. However, their effects on mass transport of hardened concrete and long-term durability are not well appreciated. It is uncommon, indeed difficult, to test for segregation in real structures (unless cores are taken) and there are currently no requirements for performance testing to ensure spacers in concrete do not adversely impact durability. This study shows that concrete near the top is more porous and prone to ingress of aggressive species that can cause premature degradation. The presence of spacers exacerbates this, and the potential increased corrosion risk of underlying reinforcement is a particular concern. These are undesirable effects, but seldom considered in research, design or construction. For example, design codes [64] for reinforced concrete structures recommend a 30% reduction in bond stress when calculating the anchorage length of top bars in deep sections to account for bleeding and segregation effects, but there are no such provisions for durability. More work is needed to test a wider range of concretes, degrees of compaction and spacer types, in particularly from field structures to establish the significance of these effects on long-term durability.

5 Conclusions

This paper presented experimental data to study the effects of spacers and segregation on the mass transport properties of vertically cast reinforced concrete columns (80 × 90 × 400 mm3) made from CEM I concrete mix at 0.40 w/c. Samples extracted from the columns were tested. Variables include sample position (top, bottom), compaction frequency (6.5 Hz, 8.5 Hz) and duration (40 s, 90 s), spacer type (cementitious, plastic) and conditioning regime (21 °C, 75% RH and 50 °C, 7% RH). The main findings are:

-

(a)

Samples near the top of the column consistently gave higher accessible porosity and transport properties compared to those from the bottom, even when they were gently compacted and showed no visible signs of bleeding or segregation during casting. The difference ranged from 21 to 78% for porosity, 13–89% for water sorptivity, and 29–88% for electrical conductivity.

-

(b)

Image analysis of sample cross-sections showed that top samples contained lower aggregate fraction and greater cement paste compared to bottom samples. Therefore, bleeding and segregation have inevitably occurred, resulting in gradients in microstructure and transport properties along the height of the columns.

-

(c)

The top–bottom property contrast increased with increasing vibration frequency and duration. For example, the average difference in transport property between top and bottom samples was 34% when gently compacted and this increased to 76% when compacted at 8.5 Hz. Similar trends were observed for accessible porosity and aggregate content.

-

(d)

Samples containing reinforcement spacers showed higher porosity, sorptivity and conductivity, regardless of the position, compaction and conditioning regime. Spacers increased transport by up to 87% (average ~ 30%) when compared to the respective control (no spacers) taken at the same height of replicate columns. The negative effect of spacers increased with severe drying, particularly for plastic spacers.

-

(e)

Fluorescence imaging showed that the negative effect of spacers is caused by preferential transport through the spacer-concrete interface that is more porous and microcracked compared to bulk concrete farther away. Preferential transport also takes place through the concrete nestled within plastic spacers. These dominant flow paths span the concrete cover and expose reinforcing steel to aggressive species, increasing the risk of premature corrosion or degradation of surrounding concrete.

-

(f)

The resistance to aggressive species decreases with height of the concrete due to small amounts of bleeding and segregation that inevitably occurred when compacted. The presence of a reinforcement spacer further exacerbates this. These effects are not currently recognised by most researchers or practitioners.

References

BS EN 7973-1: 2001 (2001) Spacers and chairs for steel reinforcement and their specification. Part 1: Product performance requirements. BSI Standards Publication, London

King ES, Dakin JM (2001) CIRIA C568: Specifying, detailing and achieving cover to reinforcement. Construction Industry Research and Information Association, London

Shaw C (2007) Cover to reinforcement: getting it right. The Structural Engineer. p. 31–35

Barnes R (2012) Concrete Advice No. 43: Spacers and visual concrete. Concrete Society, London

CRSI (2011) Placing reinforcing bars: recommended practices, 9th edn. Concrete Reinforcing Steel Institute, Schaumburg

BS EN 7973-2: 2001 (2001) Spacers and chairs for steel reinforcement and their specification. Part 2: fixing and application of spacers and chairs and tying of reinforcement. BSI Standards Publication, London

BS EN 13670: 2010 (2010) Execution of concrete structures. BSI Standards Publications, London

ACI SP-66 (04): ACI Detailing manual (2004). American Concrete Institute, Michigan

ACI 315-99 (1999): Details and detailing of concrete reinforcement (1999). American Concrete Institute, Michigan

Kawahigashi T, Kuzume K, Miyagawa T (1999) Deterioration process and estimation of durability of reinforced concrete beams in long-term exposure to marine environment. In: Proceedings of Japan society of civil engineers. p. 71–84

Vik OTK (2002) The role of bar supports in combating corrosion in reinforced concrete. Paper presented at the the Sixth international conference on short and medium span bridges, Vancouver, Canada

Kenai S, Bahar R (2003) Evaluation and repair of Algiers new airport building. Cement Concr Compos 25(6):633–641. https://doi.org/10.1016/s0958-9465(02)00077-x

Shaw P, Materialrontgen A, Kutti T (2003) Field measurement and experience of chloride induced of reinforcement in submerged structures. AB Fardig Betong, Goteborg, Sweden

Tang L, Utgenannt P (2009) A field study of critical chloride content in reinforced concrete with blended binder. Mater Corros 60(8):617–622

Alzyoud S, Wong HS, Buenfeld NR (2016) Influence of reinforcement spacers on mass transport properties and durability of concrete structures. Cem Concr Res 87:31–44. https://doi.org/10.1016/j.cemconres.2016.05.006

Muslim F, Wong HS, Choo TH, Buenfeld NR (2020) Influence of supplementary cementitious materials on microstructure and transport properties of spacer-concrete interface. Cement and Concrete Research

Neville AM (2011) Properties of Concrete, 5th edn. Pearson, Harlow

Mehta PK, Monteiro PJM (2013) Concrete: microstructure, properties, and materials. McGraw-Hill Education, New York

ACI 309.1R-08: Behaviour of fresh concrete during vibration (2008). American Concrete Institute, Michigan

Kosmatka SH (2006) Bleed water. In: Lamond JF, Pielert JH (eds) Significance of tests and properties of concrete and concrete-making materials. ASTM International, West Conshohocken, pp 99–122

Ahmad K, Smalley IJ (1973) Observation of particle segregation in vibrated granular systems. Powder Technol 8:69–75

Williams JC (1976) The segregation of particulate materials. Rev Powder Technol 15(2):245–251. https://doi.org/10.1016/0032-5910(76)80053-8

Safawi MI, Iwaki I, Miura T (2004) The segregation tendency in the vibration of high fluidity concrete. Cem Concr Res 34(2):219–226. https://doi.org/10.1016/S0008-8846(03)00249-7

CS164 (2016) Concrete practice—guidance on the practical aspects of concreting. good concrete guide 8. The Concrete Society, Surrey

ACI 309R-05 (2005) Guide for consolidation of concrete. American Concrete Institute, Michigan

ACI 309.2R-15 (2015) Guide to identification and control of visible surface effects of consolidation on formed concrete surfaces. American Concrete Institute, Michigan

Ozyildirim C, Carino NJ (2006) Concrete strength testing. In: Lamond JF, Pielert JH (eds) Significance of tests and properties of concrete and concrete-making Materials. ASTM International, West Conshohocken, pp 125–140

Panesar DK, Shindman B (2012) The effect of segregation on transport and durability properties of self consolidating concrete. Cem Concr Res 42(2):252–264. https://doi.org/10.1016/j.cemconres.2011.09.011

BS EN 197-1:2011 (2011) Cement. Composition, specifications and conformity criteria for common cements. BSI Standards Publication, London

BS EN 12620:2002+A1:2008 (2002) Aggregates for concrete. BSI Standards Publication, London

BS EN 12350-2: 2009 (2009) Testing fresh concrete. Part 2: Slump-test (2009). BSI Standards Publication, London

BS EN 206: 2013+A1: 2016 (2013) Concrete. Specification, performance, production and conformity. BSI Standards Publication, London

BS 8500-1: 2015 + A2: 2019 (2015) Concrete. Complementary British Standard to BS EN 206. Method of specifying and guidance for the specifier. BSI Standards Publication, London

Wu Z, Wong HS, Chen C, Buenfeld NR (2019) Anomalous water absorption in cement-based materials caused by drying shrinkage induced microcracks. Cem Concr Res 115:90–104. https://doi.org/10.1016/j.cemconres.2018.10.006

Hall C (1977) Water movement in porous building materials—I. Unsaturated flow theory and its applications. Build Environ 12(2):117–125

Hall C (1989) Water sorptivity of mortars and concretes: a review. Mag Concr Res 41(147):51–61. https://doi.org/10.1680/macr.1989.41.147.51

Hall C, Hoff WD (2012) Water transport in brick, stone and concrete, 2nd edn. CRC Press, New York

Wu Z, Wong HS, Buenfeld NR (2015) Influence of drying-induced microcracking and related size effects on mass transport properties of concrete. Cem Concr Res 68:35–48. https://doi.org/10.1016/j.cemconres.2014.10.018

Wu Z, Wong HS, Buenfeld NR (2017) Transport properties of concrete after drying-wetting regimes to elucidate the effects of moisture content, hysteresis and microcracking. Cem Concr Res 98:136–154. https://doi.org/10.1016/j.cemconres.2017.04.006

Schindelin J, Arganda-Carreras I, Frise E, Kaynig V, Longair M, Pietzsch T, Preibisch S, Rueden C, Saalfeld S, Schmid B, Tinevez J-Y, White DJ, Hartenstein V, Eliceiri K, Tomancak P, Cardona A (2012) Fiji: an open-source platform for biological-image analysis. Nat Meth 9(7):676–682

Picka J, Jaiswal S, Igusa T, Karr A, Shah S (2000) Quantitative description of coarse aggregate volume fraction gradients. Cem, Concr Aggreg 22(2):133–141. https://doi.org/10.1520/CCA10473J

Roussel N (2006) A theoretical frame to study stability of fresh concrete. Mater Struct 39(1):81–91. https://doi.org/10.1617/s11527-005-9036-1

Breul P, Geoffray J-M, Haddani Y (2008) On-site concrete segregation estimation using image analysis. J Adv Concr Technol 6(1):171–180. https://doi.org/10.3151/jact.6.171

Wong HS, Buenfeld NR, Hill J, Harris AW (2007) Mass transport properties of mature wasteform grouts. Adv Cem Res 19(1):35–46. https://doi.org/10.1680/adcr.2007.19.1.35

Dehghanpoor Abyaneh S, Wong HS, Buenfeld NR (2014) Computational investigation of capillary absorption in concrete using a three-dimensional mesoscale approach. Comput Mater Sci 87:54–64. https://doi.org/10.1016/j.commatsci.2014.01.058

Patrick S (2005) Practical guide to polyvinyl chloride. Rapra Technology, Shropshire

Larbi JA (1993) Microstructure of the interfacial zone around aggregate particles in concrete. Heron 38(1):69

Ollivier JP, Maso JC, Bourdette B (1995) Interfacial transition zone in concrete. Adv Cem Based Mater 2(1):30–38. https://doi.org/10.1016/1065-7355(95)90037-3

Scrivener KL, Crumbie AK, Laugesen P (2004) The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci 12(4):411–421. https://doi.org/10.1023/B:INTS.0000042339.92990.4c

Glass GK, Yang R, Dickhaus T, Buenfeld NR (2001) Backscattered electron imaging of the steel-concrete interface. Corros Sci 43(4):605–610. https://doi.org/10.1016/S0010-938X(00)00146-3

Horne AT, Richardson IG, Brydson RMD (2007) Quantitative analysis of the microstructure of interfaces in steel reinforced concrete. Cem Concr Res 37(12):1613–1623. https://doi.org/10.1016/j.cemconres.2007.08.026

Angst UM, Geiker MR, Michel A, Gehlen C, Wong H, Isgor OB, Elsener B, Hansson CM, François R, Hornbostel K, Polder R, Alonso MC, Sanchez M, Correia MJ, Criado M, Sagüés A, Buenfeld N (2017) The steel–concrete interface. Mater Struct 50(2):143. https://doi.org/10.1617/s11527-017-1010-1

Buenfeld NR, Okundi E (1998) Effect of cement content on transport in concrete. Mag of Concr Res 50(4):339–351. https://doi.org/10.1680/macr.1998.50.4.339

Bentz D, Garboczi E, Lagergren E (1998) Multi-scale microstructural modeling of concrete diffusivity: identification of significant varibles. Cem, Concr Aggreg 20(1):129–139

Delagrave A, Bigas JP, Ollivier JP, Marchand J, Pigeon M (1997) Influence of the interfacial zone on the chloride diffusivity of mortars. Adv Cem Based Mater 5(3):86–92. https://doi.org/10.1016/S1065-7355(96)00008-9

Delagrave A, Marchand J, Pigeon M (1998) Influence of microstructure on the tritiated water diffusivity of mortars. Adv Cem Based Mater 7(2):60–65. https://doi.org/10.1016/S1065-7355(97)00029-1

Wong HS, Zobel M, Buenfeld NR, Zimmerman RW (2009) Influence of the interfacial transition zone and microcracking on the diffusivity, permeability and sorptivity of cement-based materials after drying. Mag Concr Res 61(8):571–589. https://doi.org/10.1680/macr.2008.61.8.571

Wong HS, Matter K, Buenfeld NR (2013) Estimating the original cement content and water–cement ratio of Portland cement concrete and mortar using backscattered electron microscopy. Mag Concr Res 65(11):693–706. https://doi.org/10.1680/macr.12.00201

Wong HS, Pappas AM, Zimmerman RW, Buenfeld NR (2011) Effect of entrained air voids on the microstructure and mass transport properties of concrete. Cem Concr Res 41(10):1067–1077. https://doi.org/10.1016/j.cemconres.2011.06.013

Soylev TA, François R (2003) Quality of steel–concrete interface and corrosion of reinforcing steel. Cem Concr Res 33(9):1407–1415. https://doi.org/10.1016/S0008-8846(03)00087-5

Uddin T, Otsuki N, Hisada M (1999) Corrosion of steel bars with respect to orientation in concrete. ACI Mater J 96(2):154–159. https://doi.org/10.14359/439

Zhang R, Castel A, François R (2011) Influence of steel–concrete interface defects owing to the top-bar effect on the chloride-induced corrosion of reinforcement. Mag Concr Res 63(10):773–781. https://doi.org/10.1680/macr.2011.63.10.773

Angst UM, Geiker MR, Alonso MC, Polder R, Isgor OB, Elsener B, Wong H, Michel A, Hornbostel K, Gehlen C, François R, Sanchez M, Criado M, Sørensen H, Hansson C, Pillai R, Mundra S, Gulikers J, Raupach M, Pacheco J, Sagüés A (2019) The effect of the steel–concrete interface on chloride-induced corrosion initiation in concrete: a critical review by RILEM TC 262-SCI. Mater Struct 52(4):88. https://doi.org/10.1617/s11527-019-1387-0

BS EN 1992-1-1: 2004 (2004) Eurocode 2: Design of concrete structures. General rules and rules for buildings. BSI Standards Publication, London

Acknowledgements

F. Muslim gratefully acknowledges the Indonesian Endowment for Education (LPDP) for funding her PhD at Imperial College London. We thank Mr. Andrew Morris, Dr Marcus Yio and Ms. Marwa El-Fassi for their assistance with the laboratory work. The research leading to this publication benefitted from EPSRC funding under grant No. EP/R010161/1 and from support from the UKCRIC Coordination Node, EPSRC grant number EP/R017727/1, which funds UKCRIC’s ongoing coordination.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Muslim, F., Wong, H.S., Cheng, G. et al. Combined effects of vertical spacers and segregation on mass transport properties of reinforced concrete. Mater Struct 53, 151 (2020). https://doi.org/10.1617/s11527-020-01591-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01591-9