Abstract

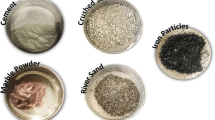

The recycling of mineral wastes is considered today an activity of utmost importance, contributing in the diversification of products, reduction of final costs, besides promoting alternative raw materials for some industrial sectors. This work focuses on the incorporation of steatite wastes in cementitious composites. A full design of experiment was carried out in order to investigate the effect of the experimental factors: fraction and particle size of steatite and compaction pressures (10 and 30 MPa) on the mechanical properties of the ceramic composites. The increase of the steatite fraction provided an increase of the bulk density and apparent porosity of the composites. Large particles of steatite provided an increase of the apparent porosity decreasing the mechanical strength. The increase of the pressing compaction decreased the apparent porosity, increasing the bulk density and the mechanical strength of the composites.

Similar content being viewed by others

References

Khaloo AR (1995) Crushed tile coarse aggregate concrete. Cem Concr Aggreg 17:119–125. doi:10.1016/0958-9465(94)00004-I

Modesto C, Bristot V, Menegali G, Brida M, Mazzuco M, Mazon A, Borba G, Virtuoso J, Gastaldon M, Oliveira AP (2003) Obtenção e caracterização de materiais cerâmicos a partir de resíduos sólidos industriais. Ceram Industr 8:14–18

Monce N, Ashjaq K (2001) Cementitious composites containing recycled tire rubber: an overview of engineering properties and potential applications. Cem Concr Aggreg 23:3–10. doi:10.1016/S0958-9465(00)00051-2

Padmini AK, Ramamurthy K, Mathews MS (2001) Behaviour of concrete with low strength bricks as lightweight coarse aggregate. Mag Concr Res 53:367–375. doi:10.1680/macr.53.6.367.40798

Binici H (2007) Effect of crushed ceramic and basaltic pumice as fine aggregates on concrete mortars properties. Constr Build Mater 21:1191–1197. doi:10.1016/j.conbuildmat.2006.06.002

Sobolev K, Türker P, Soboleva S, Iscioglu G (2007) Utilization of waste glass in ECO-cement: strength properties and microstructural observations. Waste Manag 27:971–976. doi:10.1016/j.wasman.2006.07.014

Rim KA, Ledhem A, Douzane O, Dheilly RM, Queneudec M (1999) Influence of the proportion of wood on the thermal and mechanical performances of clay-cement-wood composites. Cem Concr Compos 21:269–276. doi:10.1016/S0958-9465(99)00008-6

Pereira FR, Hotza D, Segadaes AM, Labrincha JA (2006) Ceramic formulations prepared with industrial wastes and natural sub-products. Ceram Int 32:173–179. doi:10.1016/j.ceramint.2005.01.014

Malhotra SK, Dave NG (1999) Investigations into the effect of addition of flyash and burnt clay pozzolana on certain engineering properties of cement composites. Cem Concr Compos 21:285–291. doi:10.1016/S0958-9465(99)00006-2

Senthamarai RM, Manoharan PD (2005) Concrete with ceramic waste aggregate. Cem Concr Compos 27:910–913. doi:10.1016/j.cemconcomp.2005.04.003

Menezes RR, Neves GA, Ferreira HC (2002) O estado da arte sobre o uso de resíduos como materias-pimas cerâmicas alternativas. Rev Bras Engenharia Agricola Ambiental 6:303–313

Mielcarek W, Wozny DN, Prociow K (2004) Correlation between mgsio3 phases and mechanical durability of steatite ceramics. J Eur Ceram Soc 24:3817–3821. doi:10.1016/j.jeurceramsoc.2003.12.030

White JS (1944) Particle-size distribution of steatite talc. J Am Ceram Soc 27:320–323. doi:10.1111/j.1151-2916.1944.tb14477.x

Associação Brasileira de Normas Técnicas. NBR 11578: Cimento Portland Cimento Portland Composto, Rio de Janeiro, 1991

Werkema MCC, Aguiar S (1996) Planejamento e análise de experimentos: como identificar e avaliar as principais variáveis influentes em um processo. Fundação Christiano Ottoni, Escola de Engenharia da UFMG, Belo Horizonte

Montgomery DC (1997) Introduction to statistical quality control. Wiley, USA

British Standard (2000) BS EN 12390-2: Testing hardened concrete. Making and curing specimens for strength tests

Bajza A (1983) Structure of compacted cement pastes. Cem Concr Res 13:239–245. doi:10.1016/0008-8846(83)90107-2

Acknowledgments

The author would like to thank FAPEMIG for financial support under grant no. CEX 00221/06 and an under graduation scholarship (PIBIC 2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Strecker, K., Panzera, T.H., Sabariz, A.L.R. et al. The effect of incorporation of steatite wastes on the mechanical properties of cementitious composites. Mater Struct 43, 923–932 (2010). https://doi.org/10.1617/s11527-009-9556-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-009-9556-1