Abstract

Scientific information on the welfare of broilers reared in alternative systems is scarce. The objective of this study was to assess the welfare of free-range broilers using the Welfare Quality® protocol. Free-range broilers reared in ten farms were observed, and measures were made in broilers of five of these farms. The collected data were transformed into scores (0-100), with higher scores indicating better welfare, except for emotional states. Prevalence percentages were calculated for the remaining data. Median (min-max) scores were 81 (63-98) for lameness, 93 (83-99) for hock burn on the farm, 100 (95-100) for plumage cleanliness, 35 (8-70) for podermatitis on the farm, 56 (26-88) for density, 53 (20-53) for dust, 34 (14-67) for litter quality, 93 (41-100) for drinkers, and 100 (100-100) for birds panting or huddling on the farm. The following average (min-max) prevalence percentages were obtained: total mortality 2.0% (1.4-7.2%), culling 0.0% (0.0-2.2%), feed withdrawal time 875 min (715-945 min), water withdrawal time 220 min (170-275 min), dead on arrival at the processing plant 0.00% (0.00-0.01%), broken wings 0%, (0-0%), inefficient stunning 3.9% (1.3-6.7%), pre-stun shock 49.3% (26.7-56.8%), hepatitis 4.5% (1.8-11.0%), bruising 9.3% (6.7-16.7%), and ascites 0% (0-0%). The negative broiler welfare points detected were pododermatitis, litter quality, density, dust, culling, feed withdrawal time, inefficient stunning, pre-stun shock, and hepatitis. The positive points identified were the absence of birds panting or huddling on the farm; low prevalence of lameness, hock lesions, dead on arrival, broken wings, and ascites; good plumage cleanliness scores, and short water withdrawal time.

Feelings; free range; protocol; scores

Evaluation of Free-Range broilers using the welfare quality® protocol

Sans ECOI; Federici JFI; Dahlke FII; Molento CFMI

IAnimal Welfare Laboratory (LABEA), Department of Animal Science, Universidade Federal do Paraná (UFPR), Brazil

IILaboratory of Poultry Production, Department of Animal Science and Rural Development, Universidade Federal de Santa Catarina (UFSC), Brazil

Correspondence Corresponding author e-mail address: Carla Forte Maiolino Molento Departamento de Zootecnia, Universidade Federal do Paraná (UFPR), LABEA – Laboratório de Bem-estar Animal. Rua dos Funcionários, 1540, Juvevê, 80035-050, Curitiba, PR, Brasil. Fone (41) 3350-5788. e-mail: carlamolento@ufpr.br

ABSTRACT

Scientific information on the welfare of broilers reared in alternative systems is scarce. The objective of this study was to assess the welfare of free-range broilers using the Welfare Quality® protocol. Free-range broilers reared in ten farms were observed, and measures were made in broilers of five of these farms. The collected data were transformed into scores (0-100), with higher scores indicating better welfare, except for emotional states. Prevalence percentages were calculated for the remaining data. Median (min-max) scores were 81 (63-98) for lameness, 93 (83-99) for hock burn on the farm, 100 (95-100) for plumage cleanliness, 35 (8-70) for podermatitis on the farm, 56 (26-88) for density, 53 (20-53) for dust, 34 (14-67) for litter quality, 93 (41-100) for drinkers, and 100 (100-100) for birds panting or huddling on the farm. The following average (min-max) prevalence percentages were obtained: total mortality 2.0% (1.4-7.2%), culling 0.0% (0.0-2.2%), feed withdrawal time 875 min (715-945 min), water withdrawal time 220 min (170-275 min), dead on arrival at the processing plant 0.00% (0.00-0.01%), broken wings 0%, (0-0%), inefficient stunning 3.9% (1.3-6.7%), pre-stun shock 49.3% (26.7-56.8%), hepatitis 4.5% (1.8-11.0%), bruising 9.3% (6.7-16.7%), and ascites 0% (0-0%). The negative broiler welfare points detected were pododermatitis, litter quality, density, dust, culling, feed withdrawal time, inefficient stunning, pre-stun shock, and hepatitis. The positive points identified were the absence of birds panting or huddling on the farm; low prevalence of lameness, hock lesions, dead on arrival, broken wings, and ascites; good plumage cleanliness scores, and short water withdrawal time.

Keywords: Feelings, free range, protocol, scores.

INTRODUCTION

The poultry industry is an important segment of the agribusiness of several countries. The Food and Agriculture Organization of the United Nations (FAO) and the Organization for Economic Co-operation and Development (OECD) estimate that, by the end of 2020, global production of poultry meat will have grown 26.3%, producing 125.5 million tons of meat, compared with the 99.3 million tons produced in 2010 (Produção Animal Avicultura, 2011). However, there has been changes in the consumption of poultry products.

New market niches have emerged, seeking for products from animals reared in systems different from those applied in industrial production. The increasing availability of organic products derived from organic systems clearly show the changes in consumer's demands. Global sales of organic foods and beverages increased 43% from 2002 to 2005. These products are currently sold in more than 120 countries, and Brazil is the eighth largest market (Willer & Yussefi, 2007). In addition to food safety, the process of purchase of animal products includes other issues (Huang, 1995; Yiridoe et al., 2005). Concerns on the ethics of production systems, specifically relative animal welfare (AW) play an important role in the decision to buy organic foods (Harper & Makatouni, 2002). The welfare of animals reared under intensive production systems, particularly poultry, has been increasingly questioned by consumers, and there is extensive literature on this issue.

Many AW critical points have been identified in industrial broiler production systems, such as skeletal disorders, locomotion problems, high stocking densities, and poor litter quality (Bessei, 2006). On the other hand, alternative production systems, such as free-range poultry production, may potentially improve bird welfare. However, there is little knowledge on the welfare of these birds.

This study aimed at evaluating the degree of welfare of free-range broiler chickens reared in different farms in the state of Paraná, Brazil, using the Welfare Quality® Assessment Protocol for Poultry (Welfare Quality, 2009).

MATERIALS AND METHODS

Ten free-range Label Rouge broiler chicken farms were visited one and five days before birds were sent to the processing plant. All poultry houses had open sides to allow bird access to an outdoor area; during the night, birds were kept inside the house. House floor was covered with 10-cm high wood-shavings litter. Birds were exposed only to natural light. The offered feed supplied the nutritional requirements of free-range broilers, who were also fed kale, cabbage, and grass. Water was supplied ad libitum in bell drinkers. In order to apply the protocol, birds were kept inside the barn and individual birds were randomly caught to evaluate plumage cleanliness, pododermatitis on the farm, and hock burn lesions on the farm. When a farm had more than one barn, only one barn was selected for the application of the protocol.

The visited farms were located in the state of Paraná: five were located in the metropolitan region of Curitiba (region A), and the others in central region of that state (region B). Farms of both regions and the processing plants were broilers were slaughtered were visited between July and September of 2011.

Broiler welfare was assessed according to the measures of the Welfare Quality® Assessment Protocol for Poultry. Table 1 presents a brief description of the methodology applied in each measurement. The collected data were applied to the equations of the protocol, generating scores that ranged between zero and 100. Higher scores indicate better welfare. The following variables were scored: lameness, pododermatitis on the farm and at the processing plant, hock burn lesion on the farm and at the processing plant, plumage cleanliness, panting or huddling on the farm, dust, litter quality, number of drinkers, bird density, birds in outdoor areas, flight distance, breast blisters, and cachexia. Pododermatitis on the farm, hock burn lesion on the farm, and plumage cleanliness were scored at the same time in the same birds. When data that were not applied to protocol equations, their prevalence percentage was calculated, and included: total mortality, culling, pasture cover, water withdrawal time, feed withdrawal time, panting, huddling of birds in the transport crate, crate density, dead on arrival at the processing plant, broken wings, wing-flapping in the shackling line, pre-stun shock, inefficient stunning, bruising, ascites, dehydration, hepatitis, and abscesses. Qualitative behavioral assessment included positive emotional states (active, relaxed, comfortable, confident, energetic, friendly, and positively occupied) and negative emotional states (fearful, agitated, drowsy, tense, unsure, bored, scared, nervous, distressed). The medians of each emotional state were calculated per group and per farm. Medians varied between zero and 125, with zero corresponding to the absence and 125 to maximal expression of each emotional state.

Some methodological adaptations were required. Broilers of only the five farms of region B were assessed at the processing plant. This plant processed only free-range broilers and belonged to the company responsible for these farms. A total of 2,000 broilers were processed daily from Monday to Friday, between 07:00 and 11:00h. The visit to the processing plant was then standardized to the first processing day, but disease percentage was calculated based on the total number of broilers processed, according to the plant's report. According to the protocol, each measure taken at the processing plant should be recorded for 10 minutes; however, in the present study, broilers from the two first farms were assessed for five minutes and from the other three farms, for 10 minutes. It was not possible to determine the percentage of carcasses condemned for pericarditis and sepsis because these were not included in the plant's report, but the individual prevalence of the other diseases was calculated and expressed as a percentage. Only plumage cleanliness and lameness were assessed in 70-100 and 115-150 birds, respectively, as a function of the number of birds present in the barn at the time of assessment. Birds were observed only once for five minutes inside the barn for behavioral assessment. Broilers panting or huddling were observed both inside and outside the barn. The values of 0-100 result from the equations provided by the protocol. Data expressed as percentages were calculated using the descriptive analysis of the program Excel 2010.

RESULTS AND DISCUSSION

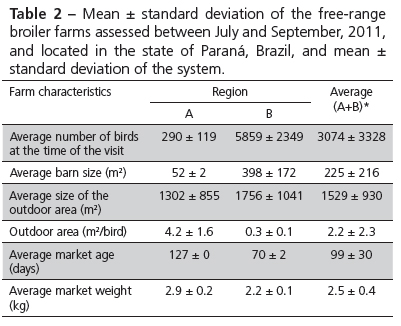

The regions rearing free-range broilers were different (Table 2), with region A characterized by smaller farms. These differences should be taken into account, as shown by the standard deviation results. This variation may be explained by the fact that the chain of free-range chicken production is more diversified that industrial broiler production, and highlights the need to be cautious when extrapolating conclusions. Results should be considered according to the context, to each specific situation.

The outdoor area available for the birds ranged between 2.3 and 5.5 m2 pasture/bird in region A and between 0.15 and 0.41 m2 in region B. According to the recommendations of the Brazilian Ministry of Agriculture, at least 3 m2 must be available per bird (Brasil, 1999). The difference in market age was due to the problems region A farmers had in finding a processing plant for their broilers.

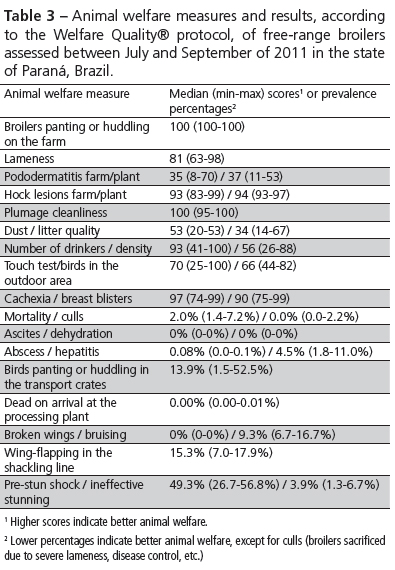

The scores and prevalence results obtained in the present study are shown in Table 3. The assessment times in six farms (two in region A and four in region B) ranged between 07:30 and 13:30 h, and in four farms (three in region A and one in region B) between 13:00 and 18:00 h. Median time for the application of the protocol on farms was 210 min (130-270 min, which is equivalent to 02:10-04:30 h), and in the processing plant was 195 min, ranging between 02:10 and 04:00 h.

Median, minimum, and maximum scores for birds panting or huddling on the farm were 100 (100-100), as shown in Table 3. In region A, temperature ranged between 11.1 and 25.5ºC, and relative humidity between 71 and 84% on the assessment days. In region B, temperature ranged between 6.3 and 32.6ºC and relative humidity between 72 and 97% (SIMEPAR, 2011). Side curtains, side openings and doors remained opened during the day to allow air into the barn and birds to move between the barn and the outdoor area. Silva et al. (2001) submitted broilers with regular feathering or naked neck to temperatures between 38 and 42ºC and observed that naked-neck bird were more resistant to heat stress. The possibility of choosing the environment may have also been beneficial to birds, as they could remain in the barn or in the outdoor area as a function of temperature changes during the day.

Lameness score median was also high (81, 63-98; Table 3) and may be attributed to the access of birds to the external environment and to their slow growth rate. Continuous exercise contributes to increase bone strength in poultry (Bizeray et al., 2000) and rapid growth rate is the main cause of locomotion problems (Bessei, 2006). The observed low number of birds panting or huddling and presenting lameness indicates good AW of the evaluated broilers.

The high hock burn lesion score median (93, 83-99) demonstrates that the incidence of this lesion was low. On the other hand, the low pododermatitis scores on the farm (35, 8-70) indicates that this was a critical AW issue (Table 3). Some pododermatitis scores presented a median of 57% (15-98%). Gouveia et al. (2009) found pododermatitis in 74.8% naked-neck broilers. The quality of the outdoor area may also influence the incidence of dermatitis. The presence of stones, high humidity, and small pasture cover area may cause damage the skin, which may be subsequently infected by bacteria (Haslam, 2011). The environment around the barns presented compacted soil and little pasture cover. The farms did not practice paddock rotation. The medians of hock burn lesion (94, 93-97) and pododermatitis (37, 11-53; Table 3) scores in the processing plant were consistent with those obtained on farms. The median of breast blister score was 90 (75-99), and considered high (Table 3). This result was equivalent to an incidence of 0.9% (0.0-2.6%) broilers with breast blisters. Gouveia et al. (2009) observed breast blisters in 18.3% naked-neck broilers and Dal Bosco et al. (2010), 0% in slow-growing broilers. Therefore, when hock burn lesions, pododermatitis, and breast blisters are taken into account, only pododermatitis may be considered an AW critical point in free-range broiler chickens.

The median of plumage cleanliness scores was excellent (100, 100-95), differently from dust scores (53, 20-53) and litter quality scores (34, 14-67; Table 3). The most critical litter quality problems were found below and around the drinkers, indicating possible wrong height or leaking. Although dust and litter quality scores were not optimal, these factors did not impair bird hygiene, as shown by plumage cleanliness. Uncontrolled dust may irritate the respiratory tract, causing bronchial inflammation (European Commission, 2000). Poor litter quality may also affect broiler health, impairing excreta absorption and promoting the proliferation of bacteria and fungi, as well as increasing gas emissions (Berg, 2004). However, it must be noted that free-range broiler chickens remain at least 50% of the day outdoors, which minimizes problems caused by dust and poor litter quality. In the present study, dust and litter were considered points that needed improvement.

The obtained drinker scores (93, 41-100) indicate that eight farms presented adequate results, but scores were low in two farms, where water availability to the birds seemed to be low (Table 3). During the rearing period, average water to feed intake ratio of industrial broilers is, on average, 1.8:1 for bell drinkers (European Commission, 2000). Chickens may survive up to 30 days without feed, with up 98% body fat and 50% body protein losses, but they cannot tolerate losing more than 20% water (Gama et al., 2008). Therefore, water availability is critical.

There was a wide variation in bird density scores in the barn (56, 26-88; Table 3).In region A, median density score was 74 (54-86), and 45 (26-59) in region B, with mean densities of 16.6±7.6 kg/m2 and 32.6±5.0 kg/m2 in regions A and B, respectively. The lower density in region A is explained by the practice of selling up to 25% of the flock during growout. The density values observed in region B are higher than the recommendation of up to 30 kg/m2 for free-range broilers (AVAL, 2010), but lower than the density applied in industrial broiler production, of up to 39 kg/m2 (UBA, 2008). However, it should be considered that the broilers in region B also had access to an outdoor area. Bessei (2004) suggests that high density is negative to broilers due to crowding, social conflicts, lack of space for exercise or locomotion activity, and physiological stress, and assumes that low density improves AW. High density was considered an AW critical point on those farms.

The median of touch test scores was high (70, 25-100; Table 3), but low scores (25) were determined on one farm in region A and two farms in region B. Hemsworth & Barnett (2000) note that the touch test of an animal reared in extensive systems is always longer compared with confined animals. The result observed in the present study is probably related to the birds' agility and the possibility of choosing the environment. The median of scores of birds in the outdoor area was 66 (44-82; Table 3), corresponding to ≥50% of birds recorded outside the barn. However, the outdoor areas provided little natural or built shelter, except for the barn. Shelter scores were 0% in one farm, <5% in three farms, 5-10% in five farms, and >20% in one farms. These results show that outdoor shelters should be improved in free-range systems, as they may intensify the use of outdoor areas and increase the behavioral repertoire of broilers.

When qualitative behavioral assessment was performed, the higher medians were observed for positive emotional states (Figure 1). Medians ranged between 48 and 98 for positive emotional states and between 2 and 80 for negative emotional states. According to Duncan (2006), the concept of sentience is based on the capacity of animals to experience positive and negative emotional states. High AW degree is achieved in the absence of negative situations and affective states and in the presence of positive situations and affective states (Boissy et al., 2007). Some behaviors may promote AW, with physical, psychological, and social benefits, whereas negative behaviors may compromise the welfare of birds submitted to frustration or anxiety (Costa et al., 2012). There are few evidences of the emotional states poultry, but behaviors such as running, jumping, feeding, singing, resting, and dust-bathing are considered pleasant activities, while hunger, thirst, discomfort, pain, and feat are considered unpleasant (Appleby et al., 2004). Therefore, the predominance of positive emotional states is beneficial to birds, as observed in the present study as a function of the high medians recorded for those emotional states.

Feed withdrawal median was 875 min (715-945 min), corresponding to 11:55-15:45 h. Transport time to the processing plant was no longer than 20 min, and time at lairage ranged between 20 and 75 min. Pre-slaughter feed withdrawal times of 8-12 h are recommended for broilers (Mendes, 2001; UBA, 2008; AVAL, 2010), as body weight loss is, on average, 1.1% in hour of feed withdrawal up to 5.8% in 12 hours (Assayag Junior et al., 2005). Longer fasting time may deplete body energy reserves, impairing the animal's capacity to face stress situations (Savenije et al., 2002). Median water withdrawal time was 220 min (170-275 min), corresponding to 03:00-04:35 h. Water withdrawal is recommended at catching time (Northcutt et al., 1997), as observed in all evaluated farms. The longer the lairage time, the worse is broiler welfare (Rojas et al., 2010), and therefore the observed feed withdrawal time was considered an item to be reviewed by the farmers.

The median of cachexia scores was high (97, 74-99; Table 3), corresponding to 0.03% (0.01-0.30%) cachectic birds. This value is close to that observed by Herenda & Jakel (1994), who found 0.15% cachectic broilers reared in a free-range system. None of the broilers was condemned due to ascites (0%, 0-0%) or dehydration (0%, 0-0%; Table 3), which is considered an excellent AW result. The median incidence of abscesses (0.08, 0.0-0.1%) was low (Table 3). Jorge (2008) found 0.05% abscesses and lesions with purulent secretion in industrial broilers, which value is close to that observed in the present study. Hepatitis presented the highest prevalence among the evaluated diseases (4.5%, 1.8-11.0%; Table 3). Herenda & Jakel (1994) found lower prevalence (0.01%) in free-range broilers. Hepatitis may be caused by viruses, fungi, parasites, or non-infectious nutritional factors, but the main cause is bacterial infections (Schmidt et al., 2003). Therefore, it is important to determine the causes of the observed hepatitis, as it may impair broiler welfare.

The median of total mortality was 2.0% (1.4-7.2%), but some farms presented high mortality rates (Table 3). In farms of region A, most mortality was detected during the first weeks of the growout, and was probably due to problems in maintaining optimal barn temperatures during this period. In region B, the main mortality cause was overcrowding due to hysteria, according to barn control spreadsheets. The reason of overcrowding indicated by the farmers was the possible presence of predators inside the barns during the night, which may have caused panic. This result may be associated with the higher number of birds housed in region B compared with region A, where no overcrowding was observed. Dourado et al. (2009) observed lower mortality rate in free-range broilers (0.02%) than that recorded in the present study. Median culling rate was extremely low (0.0%, 0.0-2.2%; Table 3). However, this may not indicate adequate broiler welfare, as culling may be required to prevent unnecessary suffering (Butterworth, 2004). Therefore, mortality rates and the lack of culling should be reviewed by the farmers.

Median transport crate density was 40.3 kg/m2 (39.3-42.3 kg/m2), median broiler market weight was 2.145 kg (2.090-2.250 kg), and total transport crate areas were 4256 cm2 and 532 cm2/bird. According to the European Community (CE, 2005), broilers weighing 1.6-3.0 kg must be provided a transport area of 160 m2/kg. The calculated median density was 343 cm2/kg (334-360 cm2/kg). In general, crate density seemed to be adequate, and complied with the recommendations of the European Community (CE, 2005). Delezie et al. (2007) observed that higher crate density resulted in higher rectal temperature and higher corticosterone levels in broilers.

The median of panting or huddling birds in the transport crates was 2.6% (0.0-51.4%). A rate of 21.8% broilers with thermal discomfort was observed, out of which 11.8% were panting (high temperature in the transport crate) and 10.0% were huddling (low temperature in the transport crate). Temperature may be constant during transport, but when the truck stops, there is an imbalance (Webster et al., 1992), establishing a microclimate inside the crates (Mitchell & Kettlewell, 2004). Another item that should be considered is the discomfort caused pre-slaughter management, which may potentiate the stress animals are already experiencing (Rui et al., 2011). The observation of panting and huddling broilers in the transport crates showed that birds were suffering thermal discomfort.

The median of the number of dead on arrival at the processing plant (0.01%, 0.00-0.01%; Table 3) was low. Herenda & Jakel (1994) found 0.24% dead on arrival when evaluating free-range broilers. No broilers with broken wings were observed (0%, 0-0%; Table 3). Rates of up to 1.0% of light chickens and 3.0% of chickens heavier than 3.0 kg are considered acceptable (Grandin, 2010a). Median incidence of bruising was high (9.3%, 6.7-16.7%; Table 3), while Gouveia et al. (2009) observed only 3.7% in naked-neck broilers, particularly in the breast area. The dead on arrival and broken wing results were considered adequate, but bruising is a critical point in the free-range system.

Median wing-flapping was high (15.3%, 7.0-17.9%; Table 3). Wing-flapping is a normal reaction when broilers are hung because their position is uncomfortable (Jones & Satterlee, 1997). However, wing-flapping may also be due to excessive pressure applied by the workers of the shackling area, inexperience of the workers, high light intensity, inadequate shackling time, noise, and bends and unevenness in the line (Jones & Satterlee, 1997). The following problems were identified in the present study: Influence of natural and artificial light and noise because the shackling area was outdoors; and shackling time (>60 s) longer than the recommendations (Bedanova et al. 2007). According to Haslam (2011), no birds should flap their wings in the shackling lines. Reducing wing-flapping is important to reduce broiler stress and to make work smoother in the shackling area.

Pre-stun shock median was high (49.3%, 26.7-56.8%; Table 3). The reason was that the wings touched the water of the waterbath before the heads were immersed, consequently presenting neck retraction. Pre-stun shock is an AW issue, because it is painful and may trigger broiler reactions, such as violent wing-flapping and lifting of the head (DEFRA, 2007; Haslam, 2011). Inefficient stunning median was also high (3.9%, 1.3-6.7%; Table 3), indicating that some birds were still conscious at bleeding. The European Safety Food Authority (2004) does not recommend any operations in the carcass while the animal is still conscious. Grandin (2010b) also prescribes zero tolerance for any procedure in animals showing any signs of return of consciousness. Pre-stun shock and inefficient stunning results were considered critical for the welfare of the broilers of region A.

CONCLUSIONS

Free-range broiler production presented variations between the studied regions. Region A was characterized by smaller farms. Consequently, average market age and weight were higher in broilers of this region. In addition, outdoor and barn areas of region A farms were smaller compared with those of region B. Broilers of region B were slaughtered in a processing plant owned by the same company, allowing better control of processing. Farms of both regions presented little shelter and caked soil in the outdoor area. The following improvement points were detected: pododermatitis, litter quality, dust, density, outdoor shelter, culling, panting or huddling of birds in the transport crates, feed withdrawal time, wing-flapping in the shackling line, bruising, hepatitis, pre-stun shock, and stunning. The positive aspects were the absence of panting or huddling broilers on the farms; adequate number of drinkers; flight distance; prevalence of positive emotional states; adequate transport crate density; short water withdrawal time; good plumage cleanliness scores; low prevalence of lameness, hock burn lesions, and breast blisters; low total mortality; low number of dead on arrival at the processing plant; low number of cachectic and dehydrated birds; and low incidence of abscesses, broken wings, and ascites. The identification and correction of critical points in free-range broiler production systems may improve bird welfare and increase productivity.

REFERENCES

Appleby, M.C.; Mench, J.A.; et al. Causes and effects. In: Appleby, M.C.; Mench, J.A.; Hughes, B.O. Poultry behaviour and welfare. CAB Publishing. 2004. Cap.3. p.30-44.

AVAL - Associação da Avicultura Alternativa. Norma para produção, abate e controle laboratorial de frango caipira, frango colonial, frango tipo caipira ou estilo caipira ou frango tipo ou estilo colonial certificado alternativo. 2010. Disponível em http://www.aval.org.br/. Acesso em: 01 de dez. 2011.

Assayag Junior MS, Pedroso AC, Pedroso AC, Franco SG, Bodziak S, Silva JC. Efeito da duração do jejum pré-abate sobre o peso corporal de frangos de corte aos 45 dias de idade. Braz. J. Vet. Res. Anim. Sci 2005; 42(3):188-192.

Bedanova I, Voslarova E, Chloupek P, Pistekova V, Suchy P, Blahova J, Dobsikova R, Vecerek V. Stress broilers resulting from shackling. Poultry Science 2007; 86:1065-1069.

Berg C. Pododermatitis and hock burn in broiler chickens. In: Weeks C, Butterworth A. Measuring and auditing broiler welfare. CABI Publishing. 2004. p.37-50.

Bessei, W. Stocking density. In: Weeks, C.; Butterworth, A. Measuring and auditing broiler welfare. CABI Publishing. 2004. Cap.11. p.133-144.

Bessei W. Welfare in broilers: a review. World's Poultry Science Journal 2006; 62:455-466.

Bizeray D, Leterrier C, Constantin P, Picard M, Faure JM. Early locomotor behaviour in genetic stocks of chickens with different growth rates. Applied Animal Behaviour Science 2000; 68:231-242.

Boissy A. Manteuffel G, Jensen MB. Moe RO, Spruijt B, Keeling LJ, Winckler C, Forkman B, Dimitrov I, Langbein J, Bakken M, Veissier I, Aubert A. Assessment of positive emotions in animals to improve their welfare. Physiology & Behaviour 2007. 92:375-397.

Butterworth A. Infectious disease: morbidity and mortality. In: Weeks C, Butterworth A. Measuring and auditing broiler welfare. CABI Publishing; 2004.

Brasil. Ministério da Agricultura, Pecuária e Abastecimento. Ofício Circular DOI/DIPOA n.007/99 de 19 de maio de 1999. Normatização e Comercialização de Frango Caipira ou Frango Colonial, também denominado "Frango Tipo ou Estilo Caipira" ou "Tipo ou Estilo Colonial". 1999.

Brasil. Ministério da Agricultura e do Abastecimento. Ofício Circular DOI/DIPOA n.012/12 de 01 de fevereiro de 2012. Alteração do Ofício Circular 007/1999 de 15 de maio de 1999, com redução da idade de abate disciplinada. 2012.

CE - Comunidade Europeia. Regulamento n.º 1/2005 do Conselho, de 22 de Dezembro de 2004, relativo à proteção dos animais durante o transporte e operações afins e que altera as Diretivas 64/432/CEE e 93/119/CE e o Regulamento (CE) n.º 1255/97. Jornal Oficial da União Europeia nº L 003/31 de 05/01/2005. p.0001 0037. 2005.

Costa, L.S.; Pereira, D.F.; Bueno, L.G.F.; Pandorfi, H. Some aspects of chicken behavior and welfare. Revista Brasileira de Ciência Avícola 2012; v.14, n.3. p.159-164.

Dal Bosco A, Mugnai C, Sirri F, Zamparini C, Castellini C. Assessment of a global positioning system to evaluate activities of organic chickens at pasture. Journal Applied Poultry Research 2010; 19:213-218.

DEFRA. Department for Environment, Food and Rural Affairs. The welfare of poultry at slaughter or killing. 2007. Disponível em: http://www.defra.gov.uk/publications/files/pb13539-welfare-poultry-slaughter.pdf.

Delezie E, Swennen Q, Buyse J, Decuypere E. The effect of feed withdrawal and crating density in transit on metabolism and meat quality of broilers at slaughter weight. Poultry Science 2007; 86:1414-1423.

Dourado LRB, Sakomura NK, Nascimento DCN, Dorigan JC, Marcato SM, Fernandes JBK. Crescimento e desempenho de linhagens de pescoço pelado criadas em sistema semi-confinado. Ciência Agrotecnica 2009; 3(3):875-881.

Duncan IJH. The changing concept of animal sentiente. Applied Animal Behaviour Science 2006; 100:11-19.

European Commission. Health and Consumer Protection Directorate-General. The Welfare of chickens kept for meat production (broilers). Report for the Scientific Committee on Animal Health and Animal Welfare. 2000.

European Safety Food Authority. Welfare aspects of animal stunning and killing methods. Scientific Report of the Scientific Panel for Animal Health and Welfare on a request from the Commission related to welfare aspects of animal stunning and killing methods. 2004.

Gama NMSQ, Togashi CK, Ferreira NT, Buim MR, Guastalli EL, Fiagá DAM. Conhecendo a água utilizada para aves de produção. Biológico 2008; 70(1):43-49.

Gouveia KG, Vaz-Pires P, Martins da Costa P. Welfare assessment of broilers through examination of haematomas, foot-pad dermatitis, scratches and breast blisters at processing. Animal Welfare 2009; 18:43-48.

Grandin, T. Improving Animal Welfare: a practical approach. CAB International. 2010a.

Grandin, T. Auditing animal welfare at slaughter plants. Meat Science 2010b; 86:56-65.

Harper GC, Makatouni A. Consumer perception of organic food production and farm animal welfare. British Food Journal 2002; 104:287-299.

Haslam S. Broiler Chickens. In: Webster J. Management and welfare of farm animals. UFAW Farm Handbook. 5th 2011. p.338-364.

Hemsworth PH, Barnett JL. Human-animal interactions and animal stress. In: Moberg GP, Mench JA. The biology of animal stress. Basic principles and implications for animal welfare. CABI Publishing. 2000. p.309-336.

Herenda D, Jakel O. Poultry abattoir survey of carcass condemnation for standard, vegetarian and free range chickens. Canadian Veterinary Journal 1994; 35:293-296.

Huang, C.L. Consumer preferences and attitudes towards organically grown produce. European review of Agricultural Economics. Berlin. 1995. Disponível em: http://erae.oxfordjournals.org. Acesso em: 20 de nov. 2013.

Jones RB, Satterlee DG. Restricted visual input reduces struggling in shackled broiler chickens. Applied Animal Behaviour Science 1997; 52:109-117.

Jorge PS. Avaliação do bem-estar durante o pré-abate e abate e condição sanitária de diferentes segmentos da produção avícola. 2008. 107f. Doutorado. Universidade Estadual Paulista "Júlio de Mesquita Filho". Jaboticabal/SP.

Mendes, A.A. Jejum pré-abate em frangos de corte. Revista Brasileira de Ciência Avícola 2001; v.3, n.3.

Mitchell MA, Kettlewell PJ. Transport and handling. In: Weeks C, Butterworth A. Measuring and Auditing broiler welfare. CABI Publishing. 2004. p.145-160.

Northcutt JK, Savage SI, Vest LR. Relationship between feed withdrawal and viscera condition of broilers. Poultry Science 1997; 76:410-414.

Produção Animal Avicultura. Em 2020, a produção mundial vai alcançar 125 milhões de toneladas; 2011. n.53 - ano V. Edição de setembro.

Rojas, D.M.; Lozano, M.G.; et al. Transportation to the slaughterhouse. In: Legarreta, I.G. Handbook of Poultry Science and Technology. Vol. 1: Primary Processing. Wiley. 2010. Cap.4. p.55-68.

Rui, BR, Angrimani DSR, Silva, MAA. Pontos críticos no manejo pré-abate de frangos de corte: jejum, captura, carregamento, transporte e tempo de espera no abatedouro. Ciência Rural 2011; 41:1290-1296.

Savenije B, Lambooij E, Gerritzen MA, Venema K, Korft J. Effects of feed deprivation and transport on pre-slaughter blood metabolites, early postmortem muscle metabolites and meat quality. Poultry Science 2002; 81:699-708.

Schmidt RE, Reavill DR, Phalen DN. Pathology of pet and aviary birds. Blackwell Publishing Company. 2003.

SIMEPAR – Sistema Meteorológico do Paraná. Disponível em: http://www.simepar.br. Acesso em: 03 de jan. 2012.

Silva, M.A.N.; Silva, I.J.O.; Piedade, S.M.S.; Martins, E.; Coelho, A.A.D.; Savino, V.J.M. Resistência ao estresse calórico em frangos de corte de pescoço pelado. Revista Brasileira de Ciência Avícola. v.3. n.1. 2001.

UBA – União Brasileira de Avicultura. Protocolo de bem-estar para frangos de corte e perus. Disponível em: http://www.avisite.com.br/legislacao/anexos/protocolo_de_bem_estar_para_frangos_e_perus.pdf 2008. Acesso em: 01 de nov. 2011.

Yiridoe, E.K.; Bonti-Ankomah, S.; Martin, R.C. Comparison of consumer perceptions and preference toward organic versus conventionally produced foods: a review and update of the literature. Renewable Agriculture and Food System. v.20. n.4. p.193-205. 2005.

Webster AJF, Tuddenham A, Saville CA, Scott GB. Thermal stress on chickens in transit. British Poultry Science 1992; 34:267–277.

Welfare Quality. Welfare Quality® assessment protocol for poultry (broilers, laying hens). Welfare Quality® Consortium, Lalystad, Netherlands. 2009.

Willer, H.; Yussefi, M. The world of organic agriculture. Statistics and emerging trends 2007. 9th. Edition. International Federation of Organic Agriculture Movements IFOAM, Bonn, Germany & Research Institute of Organic Agriculture FiBL, Frick, Switzerland. 2007. Disponível em <http://orgprints.org/10506/1/willer-yussefi-2007-p1-44.pdf>. Acesso em: 09 de nov. 2011.

Wotton S, Wilkins LJ. Primary processing of poultry. In: Weeks C, Butterworth A. Measuring and Auditing broiler welfare. CABI Publishing. 2004. p.161-182.

Submitted: July/2012

Approved: April/2014

Text published as abstract in the Proceedings of the 46th Congress of the International Society for Applied Ethology (ISAE 2012). 31 July-4 August, Vienna, Austria.

- Appleby, M.C.; Mench, J.A.; et al. Causes and effects. In: Appleby, M.C.; Mench, J.A.; Hughes, B.O. Poultry behaviour and welfare. CAB Publishing. 2004. Cap.3. p.30-44.

- AVAL - Associação da Avicultura Alternativa. Norma para produção, abate e controle laboratorial de frango caipira, frango colonial, frango tipo caipira ou estilo caipira ou frango tipo ou estilo colonial certificado alternativo. 2010. Disponível em http://www.aval.org.br/ Acesso em: 01 de dez. 2011.

- Assayag Junior MS, Pedroso AC, Pedroso AC, Franco SG, Bodziak S, Silva JC. Efeito da duração do jejum pré-abate sobre o peso corporal de frangos de corte aos 45 dias de idade. Braz. J. Vet. Res. Anim. Sci 2005; 42(3):188-192.

- Bedanova I, Voslarova E, Chloupek P, Pistekova V, Suchy P, Blahova J, Dobsikova R, Vecerek V. Stress broilers resulting from shackling. Poultry Science 2007; 86:1065-1069.

- Berg C. Pododermatitis and hock burn in broiler chickens. In: Weeks C, Butterworth A. Measuring and auditing broiler welfare. CABI Publishing. 2004. p.37-50.

- Bessei, W. Stocking density. In: Weeks, C.; Butterworth, A. Measuring and auditing broiler welfare. CABI Publishing. 2004. Cap.11. p.133-144.

- Bessei W. Welfare in broilers: a review. World's Poultry Science Journal 2006; 62:455-466.

- Bizeray D, Leterrier C, Constantin P, Picard M, Faure JM. Early locomotor behaviour in genetic stocks of chickens with different growth rates. Applied Animal Behaviour Science 2000; 68:231-242.

- Boissy A. Manteuffel G, Jensen MB. Moe RO, Spruijt B, Keeling LJ, Winckler C, Forkman B, Dimitrov I, Langbein J, Bakken M, Veissier I, Aubert A. Assessment of positive emotions in animals to improve their welfare. Physiology & Behaviour 2007. 92:375-397.

- Butterworth A. Infectious disease: morbidity and mortality. In: Weeks C, Butterworth A. Measuring and auditing broiler welfare. CABI Publishing; 2004.

- Brasil. Ministério da Agricultura, Pecuária e Abastecimento. Ofício Circular DOI/DIPOA n.007/99 de 19 de maio de 1999. Normatização e Comercialização de Frango Caipira ou Frango Colonial, também denominado "Frango Tipo ou Estilo Caipira" ou "Tipo ou Estilo Colonial". 1999.

- Brasil. Ministério da Agricultura e do Abastecimento. Ofício Circular DOI/DIPOA n.012/12 de 01 de fevereiro de 2012. Alteração do Ofício Circular 007/1999 de 15 de maio de 1999, com redução da idade de abate disciplinada. 2012.

- CE - Comunidade Europeia. Regulamento n.º 1/2005 do Conselho, de 22 de Dezembro de 2004, relativo à proteção dos animais durante o transporte e operações afins e que altera as Diretivas 64/432/CEE e 93/119/CE e o Regulamento (CE) n.º 1255/97. Jornal Oficial da União Europeia nº L 003/31 de 05/01/2005. p.0001 – 0037. 2005.

- Costa, L.S.; Pereira, D.F.; Bueno, L.G.F.; Pandorfi, H. Some aspects of chicken behavior and welfare. Revista Brasileira de Ciência Avícola 2012; v.14, n.3. p.159-164.

- Dal Bosco A, Mugnai C, Sirri F, Zamparini C, Castellini C. Assessment of a global positioning system to evaluate activities of organic chickens at pasture. Journal Applied Poultry Research 2010; 19:213-218.

- DEFRA. Department for Environment, Food and Rural Affairs. The welfare of poultry at slaughter or killing. 2007. Disponível em: http://www.defra.gov.uk/publications/files/pb13539-welfare-poultry-slaughter.pdf

- Delezie E, Swennen Q, Buyse J, Decuypere E. The effect of feed withdrawal and crating density in transit on metabolism and meat quality of broilers at slaughter weight. Poultry Science 2007; 86:1414-1423.

- Dourado LRB, Sakomura NK, Nascimento DCN, Dorigan JC, Marcato SM, Fernandes JBK. Crescimento e desempenho de linhagens de pescoço pelado criadas em sistema semi-confinado. Ciência Agrotecnica 2009; 3(3):875-881.

- Duncan IJH. The changing concept of animal sentiente. Applied Animal Behaviour Science 2006; 100:11-19.

- European Commission. Health and Consumer Protection Directorate-General. The Welfare of chickens kept for meat production (broilers). Report for the Scientific Committee on Animal Health and Animal Welfare. 2000.

- European Safety Food Authority. Welfare aspects of animal stunning and killing methods. Scientific Report of the Scientific Panel for Animal Health and Welfare on a request from the Commission related to welfare aspects of animal stunning and killing methods. 2004.

- Gama NMSQ, Togashi CK, Ferreira NT, Buim MR, Guastalli EL, Fiagá DAM. Conhecendo a água utilizada para aves de produção. Biológico 2008; 70(1):43-49.

- Gouveia KG, Vaz-Pires P, Martins da Costa P. Welfare assessment of broilers through examination of haematomas, foot-pad dermatitis, scratches and breast blisters at processing. Animal Welfare 2009; 18:43-48.

- Grandin, T. Improving Animal Welfare: a practical approach. CAB International. 2010a.

- Grandin, T. Auditing animal welfare at slaughter plants. Meat Science 2010b; 86:56-65.

- Harper GC, Makatouni A. Consumer perception of organic food production and farm animal welfare. British Food Journal 2002; 104:287-299.

- Haslam S. Broiler Chickens. In: Webster J. Management and welfare of farm animals. UFAW Farm Handbook. 5th 2011. p.338-364.

- Hemsworth PH, Barnett JL. Human-animal interactions and animal stress. In: Moberg GP, Mench JA. The biology of animal stress. Basic principles and implications for animal welfare. CABI Publishing. 2000. p.309-336.

- Herenda D, Jakel O. Poultry abattoir survey of carcass condemnation for standard, vegetarian and free range chickens. Canadian Veterinary Journal 1994; 35:293-296.

- Huang, C.L. Consumer preferences and attitudes towards organically grown produce. European review of Agricultural Economics. Berlin. 1995. Disponível em: http://erae.oxfordjournals.org Acesso em: 20 de nov. 2013.

- Jones RB, Satterlee DG. Restricted visual input reduces struggling in shackled broiler chickens. Applied Animal Behaviour Science 1997; 52:109-117.

- Jorge PS. Avaliação do bem-estar durante o pré-abate e abate e condição sanitária de diferentes segmentos da produção avícola. 2008. 107f. Doutorado. Universidade Estadual Paulista "Júlio de Mesquita Filho". Jaboticabal/SP.

- Mendes, A.A. Jejum pré-abate em frangos de corte. Revista Brasileira de Ciência Avícola 2001; v.3, n.3.

- Mitchell MA, Kettlewell PJ. Transport and handling. In: Weeks C, Butterworth A. Measuring and Auditing broiler welfare. CABI Publishing. 2004. p.145-160.

- Northcutt JK, Savage SI, Vest LR. Relationship between feed withdrawal and viscera condition of broilers. Poultry Science 1997; 76:410-414.

- Produção Animal Avicultura. Em 2020, a produção mundial vai alcançar 125 milhões de toneladas; 2011. n.53 - ano V. Edição de setembro.

- Rojas, D.M.; Lozano, M.G.; et al. Transportation to the slaughterhouse. In: Legarreta, I.G. Handbook of Poultry Science and Technology. Vol. 1: Primary Processing. Wiley. 2010. Cap.4. p.55-68.

- Rui, BR, Angrimani DSR, Silva, MAA. Pontos críticos no manejo pré-abate de frangos de corte: jejum, captura, carregamento, transporte e tempo de espera no abatedouro. Ciência Rural 2011; 41:1290-1296.

- Savenije B, Lambooij E, Gerritzen MA, Venema K, Korft J. Effects of feed deprivation and transport on pre-slaughter blood metabolites, early postmortem muscle metabolites and meat quality. Poultry Science 2002; 81:699-708.

- Schmidt RE, Reavill DR, Phalen DN. Pathology of pet and aviary birds. Blackwell Publishing Company. 2003.

- SIMEPAR – Sistema Meteorológico do Paraná. Disponível em: http://www.simepar.br Acesso em: 03 de jan. 2012.

» link - Silva, M.A.N.; Silva, I.J.O.; Piedade, S.M.S.; Martins, E.; Coelho, A.A.D.; Savino, V.J.M. Resistência ao estresse calórico em frangos de corte de pescoço pelado. Revista Brasileira de Ciência Avícola. v.3. n.1. 2001.

- UBA – União Brasileira de Avicultura. Protocolo de bem-estar para frangos de corte e perus. Disponível em: http://www.avisite.com.br/legislacao/anexos/protocolo_de_bem_estar_para_frangos_e_perus.pdf 2008 Acesso em: 01 de nov. 2011.

- Yiridoe, E.K.; Bonti-Ankomah, S.; Martin, R.C. Comparison of consumer perceptions and preference toward organic versus conventionally produced foods: a review and update of the literature. Renewable Agriculture and Food System. v.20. n.4. p.193-205. 2005.

- Webster AJF, Tuddenham A, Saville CA, Scott GB. Thermal stress on chickens in transit. British Poultry Science 1992; 34:267–277.

- Welfare Quality. Welfare Quality® assessment protocol for poultry (broilers, laying hens). Welfare Quality® Consortium, Lalystad, Netherlands. 2009.

- Willer, H.; Yussefi, M. The world of organic agriculture. Statistics and emerging trends 2007. 9th Edition. International Federation of Organic Agriculture Movements IFOAM, Bonn, Germany & Research Institute of Organic Agriculture FiBL, Frick, Switzerland. 2007. Disponível em <http://orgprints.org/10506/1/willer-yussefi-2007-p1-44.pdf>. Acesso em: 09 de nov. 2011.

- Wotton S, Wilkins LJ. Primary processing of poultry. In: Weeks C, Butterworth A. Measuring and Auditing broiler welfare. CABI Publishing. 2004. p.161-182.

Corresponding author e-mail address:

Publication Dates

-

Publication in this collection

01 Oct 2014 -

Date of issue

Sept 2014

History

-

Received

July 2012 -

Accepted

Apr 2014