Abstract

High-speed optoelectronics is central to many important developments in the communication, computing, sensing, imaging, and autonomous vehicle industries. With a sharp rise of attention on energy efficiency, researchers have proposed and demonstrated innovative materials, high-speed devices, and components integrated on a single platform that exhibit ultralow power consumption and ultrawide bandwidth. Recently reported material growth and device fabrication techniques offer the potential for high-density integration of optoelectronics close to the capability and cost of conventional electronics. A tremendous synergy can be attained by integrating multiple materials with superior properties on the same chip using heterogeneous integration, heteroepitaxy, nano-heteroepitaxy, and other co-packaging strategies within the complementary metal oxide semiconductor (CMOS) ecosystem. This issue of MRS Bulletin offers an overview of the field and covers the latest developments on various ultraefficient materials, high-speed devices, their physical properties, current trends, and future directions in optoelectronics and their integration on a silicon platform.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The communication and computing industries have been the primary driving forces behind the extraordinary progress in high-speed optoelectronics that contributed to an age of information explosion over the past several decades. Enabling sustainable growth of our ever-expanding data processing and communication systems relies on low-cost optical networks at all levels to transport high-speed data with high energy efficiency. Scientific breakthroughs have recently brought tremendous momentum and an outbreak of interest in materials for ultraefficient and high-speed optoelectronic materials and devices for data processing and transport that form two key pillars of modern computing systems.1

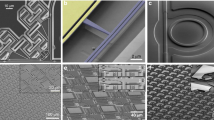

Immense progress has been made in developing high-index contrast waveguides, photonic crystals, plasmonic structures, nano-heteroepitaxy, and heterogeneous integration of multiple materials. Extremely sharp curves, bends, sophisticated splitters, and (de)-multiplexers have also been demonstrated, allowing miniaturization and a high level of device integration. Different materials have been explored, ranging from two-dimensional (2D) materials2 and topological insulators3,4 to semiconductors on various substrates for passive and active photonic devices used in telecom, datacom, sensing, light detection and ranging (LIDAR), on-chip and chip-to-chip interconnects, spectrometers, and other applications, as illustrated in Figure 1. After several decades of research, many of the materials for ultraefficient, high-speed optoelectronics have transitioned from fundamental research and development toward deployable and commercially available technologies.5

© 2009 Jeffrey Tseng @ InTouchStudios.com. Bottom: Zhou et al.66

R&D of materials for ultraefficient, high-speed optoelectronics has been driven by a wide range of applications, from data centers and telecommunications to imaging, sensing, and spectroscopy. Key optoelectronic technologies enabling such applications include tunable lasers and light-emitting diodes (LEDs), modulators, photodetectors, interconnects, and electronic-photonic co-packaging. Top-left: credit Brian Long, UCSB. Top: Mario Miscuglio and Rubab Amin, GWU, Phys.Org. Top-Right: Moody et al.50 Bottom-Left: Fathololoumi et al.69 Bottom-Right:

The primary motivation for exploring applications of optoelectronics in enhancing the performance of electronic logic, microprocessors, and memory is to continue the exponential progress that the industry has been making for more than two decades. High-speed data processing and transport form two key pillars of modern computing systems. The current trend of using multicore processors is providing a temporary respite from the stagnation of microprocessor clock frequencies.6 Still, it has created daunting challenges to programmability and ultimately drives today’s system architectures toward extreme levels of unbalanced communication-to-computation ratios.7 Limited internal heat removal capabilities, compounded with a huge deficit in chip input/output (I/O) bandwidth due to insufficient I/O interconnect density, have stalled the high-performance gains. The excessive access time of a microprocessor for communication with the off-chip main memory is among the major hurdles holding back ultrafast computing.8 Ultrafast optoelectronics offers a disruptive technology solution that can enhance the performance of communications and computation, contributing to the fundamental transformation in the field of computer architecture. Combined with photonics, optoelectronics enables ultrahigh throughput, minimal access latencies, and low power dissipation that mostly remain independent of device bandwidth and propagation distance.9

While, for a distance exceeding a few millimeters, energy efficiency for electrical signaling is typically ~5 pJ/bit (equivalent to ~5 mW/Gb/s),10 photonic communication links based on optoelectronics have shown the ability to operate at 100 fJ/bit with the potential to reduce the cost to the level of 10 fJ/bit. The application of photonics offers the prospect of increasing the DRAM bandwidth by a factor of 100 on each pin—a revolutionary leap for computing systems. The unique capability of photons for multiwavelength photonic interconnects in the DRAM input/output can continue the scalability that the semiconductor industry has been accustomed to in the last few decades, prescribed by Moore’s Law. The emergence of multicore architectures and the ever-increasing demand for information processing naturally make room for optoelectronics in the field of intrachip and interchip communications.11 This issue with three invited papers highlights some of the essential topics in ultraefficient, high-speed optoelectronics materials. Several renowned theorists and experimentalists with an in-depth understanding of the state of the art summarize advanced research on active materials for ultraefficient and high-speed optoelectronics.

Improving efficiency and speed

Conventional high-speed optoelectronics platforms are built upon two dominant material systems: (1) silicon photonics and (2) indium phosphide (InP)-based integrated photonics. Technological overlap with the heavily developed semiconductor industry, scalability up to 300-mm wafers, and seamless monolithic integration with high-speed electronics make silicon more attractive as a platform; however, InP-based systems can operate at a very high speed due to the inherent high charge-carrier mobility of the materials. Figure 2a illustrates some of the versatile functions that can be achieved on a photonic chip, including sources such as lasers, LEDs, optical modulators, and photodetectors, with more than 105 components now able to be integrated onto a single photonic-integrated circuit (PIC), as shown in Figure 2b.12

Adapted from Margalit et al.29 LEDs, light-emitting diodes.

(a) Versatile functions can be achieved by combining active optoelectronic components, such as light sources, modulators, and photodetectors, with passive networks in a photonic-integrated circuit (PIC). (b) In the few decades, we have witnessed tremendous growth in the number of components integrated onto a single PIC, with more than 105 currently possible with monolithic silicon and nearly 104 with heterogeneous photonics. (b)

Early silicon photonic systems were based on hybrid integration and co-packaged devices and components to enable ultrafast optical communication channels that eliminate the high loss of electrical channels in computation, storage, and application-specific integrated circuits (ASICs). Over time, the data processing rates further improved using waveguide-connected photonic devices that were monolithically integrated and interconnected on the silicon platform. Additionally, heterogeneously integrated III–V materials helped implement on-chip light sources such as lasers and optical amplifiers.

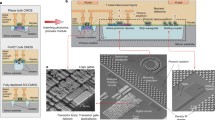

Recent trends in the semiconductor community have also focused on monolithic integration of multiple materials through heteroepitaxy for maximizing the performance of ultrafast integrated optoelectronics;13 however, incompatibility of different material systems has been the main barrier in the large-scale integration of electronics and photonics. Heteroepitaxially grown optically active high-mobility materials such as III–V and II–VI semiconductors integrated with the mainstream silicon technology can enable power-efficient, low-cost, and highly integrated ultrafast devices due to their high carrier mobilities and large optical absorption coefficients. This can open new opportunities for a wide variety of applications including intrachip, interchip, and free-space communications. Figure 3 presents two widely used material platforms for high-performance monolithically integrated optoelectronic systems on silicon. Figure 3a–b illustrates heterogeneous integration of III–V wafer via bonding on silicon-on-insulator (SOI),14,15 and Figure 3c–d shows epitaxial growth of III–V and similar optically active materials on silicon as thin films and nanostructures.16,17

Reproduced with permission from Carrara et al.;14 (b) reproduced with permission from Liang et al.;15 (c) reproduced with permission from Li et al.;16 and (d) reproduced with permission from Falub et al.17

(a) III–V-on-silicon hybrid integration technology. First, epitaxial device layers are grown on the III–V wafers. Then they are bonded to the processed silicon-on-insulator (SOI) wafers by molecular or benzocyclobutene bonding. These bonded III–V wafers are thinned using wet etching to leave the epitaxial device layers on the SOI wafers. Laser dicing is used to get smaller wafers that are then processed in III–V foundries. (b) Photograph of processed 150-mm-diameter bonded wafer showing individual device die. IR image of 150 mm III–V-on-silicon bonded wafer with complementary metal oxide semiconductor devices. (c) Scanning electron microscopy micrograph of a 300-nm-thick coalesced GaAs film grown on a patterned silicon substrate. The GaAs film is flat on the surface. (d) Self-limiting patterned growth of Ge epitaxial crystals in the form of towers on deeply patterned Si substrates. (a)

The capabilities of generating, controlling, and detecting photons by heteroepitaxially grown direct bandgap materials on a silicon substrate, which is known for its low efficiency in electron-to-photon conversion, can bring about myriad transformative opportunities that will impact a large sector of industry.18 Despite significant progress, growing materials on mismatched substrates, subsequent device fabrication, and system integration still face substantial engineering challenges and require more investigation to improve the cost–performance ratio. Researchers are still experiencing many challenges and limitations faced by the epitaxial lift-off and wafer bonding technologies: (1) Low-cost mass-manufacturable material growth and integration of various materials and devices on a single substrate. Misfit strain, threading dislocations, and thermal cracks are among the significant issues. (2) CMOS process integration with multiple dissimilar materials. Extreme physical conditions such as high temperature used in some CMOS processes are major contributors to process incompatibilities. (3) Significantly smaller substrate size for most optically active III–V materials. (4) Material issues such as the interface defects, vacancies, and traps in heteroepitaxy of lattice-mismatched materials and the resulting inconsistent device performance and inadequate reliability.

In principle, the aforementioned challenges can be circumvented by nano-heteroepitaxy that allows nanostructures of III–V materials with considerable lattice mismatch to be heteroepitaxially grown on Si. A small cross section of nanostructures enables rapid relief of effective strain energy during the growth process. Misfit dislocations limit the quality of lattice-mismatched heterojunctions in the case of planar thin-film growth. However, 0D nanostructures such as quantum dots or 1D nanostructures such as nanowires can be grown on highly lattice-mismatched substrates and still can release the mismatch strain because of inherent nanoscale geometries.19 In recent years, research groups have successfully demonstrated lasers, photodetectors, waveguides, and plasmonic devices using group III–V nano-heteroepitaxy by directly growing nanowires or transfer printing them on silicon20,21,22 to facilitate faster transmission speed, larger transmission capacity, and low power consumption. Theoretical foundations on both heteroepitaxy and nano-heteroepitaxy have been laid, and numerous experiments have been performed, placing these approaches on a sound footing.

Currently, the data traffic within and between data centers accounts for more than 85% of all global data communication.23 Directly modulated multimode vertical-cavity surface-emitting laser (VCSEL) interconnects are most commonly used in computing and data communication due to their simplicity, low cost, and energy efficiency;24 however, external modulation techniques are becoming more attractive because of higher bandwidth and longer transmission distance. For example, ultrafast (data rate of >100 Gb/s) silicon Mach–Zehnder (MZ) modulators with high reliability and low sensitivity to temperature and wavelength have been demonstrated.25 Similarly, high-Q silicon photonics microring modulators with integrated resonant cavities and slow-wave photonics crystal cavity-integrated modulators, and III–V material-based modulators on silicon have been developed. Many data center applications are designed using surface illuminated photodiodes. Recently, there has been encouraging progress in designing ultrafast photodiodes using silicon, which has inherently very low photon absorption in the near-infrared wavelength range. By designing and integrating an array of periodic photon-trapping structures in thin crystalline silicon films, normally incident beams of light are bent by almost 90º into laterally propagating modes of light along the plane of the film.26,27 Such surface structures effectively increase the propagation length of light, contributing to more than 20-fold improvement in the light absorption coefficients. This results in a broadband efficiency of >85% with ultrafast response in photodiodes. The photon-trapping structures in silicon enhance the photon density of states (DOS) while substantially reducing the optical group velocity of light compared to their counterpart without such structures. This is the reason behind significantly improved light–matter interactions and very high efficiencies in photodiodes that can offer ultrafast response above 100 Gbps.

Photonic interconnects provide the connectivity necessary for scaling electronic systems that are currently experiencing steady growth in transistor counts. Future applications that will demand computing systems based on numerous nodes will require new architectures with optoelectronic links for reduced cost, complexity, and power efficiency. Monolithic integration of ultrafast photonics with high-performance silicon electronics promises to eliminate expensive, complex, and power-intensive electrical links, opening doors to a continued upsurge in interconnect bandwidth.

Material platforms and devices

The exponential growth in demand for high data capacity28 has spurred innovations in telecommunications, computing, storage, networking, sensing, imaging, and metrology. These applications are a driving factor in the development of optoelectronic platforms with ultralow system-level power consumption and ultrawide bandwidth. The integration of electronics with passive and active photonics—enabled by the mature processing capabilities of the silicon CMOS ecosystem—has been essential for increasing the speed and total bandwidth, with capacities approaching >1 Tbps possible through multiplexing. This scalability is the true advantage of silicon photonics and optoelectronics, especially when considering co-packaging with other ASICs for computation, memory, and networking. At present, silicon photonic PICs are capable of >1 Tbps communications with nearly pJ/bit energy consumption.29

Traditional silicon PICs face challenges in efficiently generating, modulating, and detecting light—pointing to the need for heterogeneous integration. Beyond silicon, many other material platforms are being developed in pursuit of sub-pJ to sub-fJ energy requirements without sacrificing bandwidth, as illustrated in Figure 4. These approaches are often developed with sights set on eventual hybrid or hetero-integration with silicon photonics and co-packaged electronics. In the subsections below, we discuss a few of the key technological areas in which advanced materials are being developed to overcome the bottleneck silicon faces due to a lack of efficient active components like tunable lasers and low-noise detectors.

Ultralow power, high-speed interconnects

The two primary optical components of an interconnect are a laser and a modulator. As data rates continue to increase from 100 Gbps to beyond 10 Tbps, the integration of electronics with photonic interconnects is essential to reduce the total system power consumption and the device capacitance to achieve faster data rates. In the last few years, the evolution of energy efficiency and bandwidth has resulted in >1 Tbps data rates with <10 pJ/bit with silicon CMOS technologies, as illustrated in Figure 5. With targeted energy requirements pushing toward fJ/bit, we are seeing the transition from modular components to fully integrated semiconductor PICs that combine on-chip lasers with high-speed modulators.

Adapted from Margalit et al.29

Advances in the growth, design, and fabrication of monolithic and heterogeneous CMOS-compatible photonic and optoelectronic materials, as well as the co-packaging of electronics and photonics, has improved the total power consumption, energy/bit, and total bandwidth of photonic-integrated circuits (PICs) for communications.

Because silicon is an indirect bandgap material, it is unsuitable for achieving efficient gain for lasers. Thus, silicon PICs today mostly use separate lasers based on III–V chips fiber coupled to a silicon PIC, which avoids challenges associated with heterogeneous integration of non-lattice-matched materials as well as combining the III–V and silicon processing. A hybrid approach utilizes a III–V semiconductor end-coupled directly adjacent to a silicon PIC chip, which has enabled laser stabilization through self-injection locking of an InP/Si laser to silicon nitride microresonators30 and frequency comb generation from a high-quality-factor silicon nitride microresonator enabling hertz-linewidth lasing that could boost the rates of coherent optical communications and impact the performance of optical sensing and signal generation.31

A more nascent approach, the concept of topology has been extended from condensed-matter science into photonics, giving rise to topological insulator lasing (TIL) using topologically protected modes that provide stability even in the presence of scattering and defects.32 The topological properties give rise to single-mode lasing, robustness to fabrication imperfections, and higher slope efficiencies compared to topologically trivial analogs. The first room-temperature, non-magnetic, and electrically pumped TIL operating in the telecommunications band was demonstrated in 2021, which is based on an epitaxially grown InGaAsP/InP heterostructure patterned into a 10 × 10 network of microring cavities. Although TIL technology is not as mature as traditional semiconductor lasers, this advance opens up exciting prospects for encoding information in additional degrees of freedom, such as orbital angular momentum.33

In comparison to fiber or end coupling, which introduces loss at each interface, the direct integration of such lasers with silicon photonics and electronics can further improve the efficiency and bandwidth. Several gain media have been explored for heterogeneous integration with silicon. Germanium lasers have been demonstrated, which are quasi-lattice-matched with silicon, but their efficiency has not been practical for most applications.34 III–V materials (e.g., InP, GaAs), which have a direct bandgap, have seen tremendous progress in recent years.35 Although their integration with silicon is challenging, especially due to coupling from the III–V layer to the silicon layer, their promise is exemplified by their potential for scalability. The most common approaches are hybrid integration where the III–V laser is flip-chip bonded to the silicon chip, or heterogeneous integration, where the III–V material is directly bonded on silicon waveguides and then post-processed. Heterogeneous integration is compatible with the 300-mm CMOS process and, thus, may be more appealing in terms of scalability, as evidenced by Intel’s implementation of this technology.36

Whether the lasers are fiber, hybrid, or heterogeneous coupled to the PICs, the other critical element of photonic interconnects is the optical modulator. Numerous technologies from a wide range of materials have been developed to provide high-speed modulation. The most common approach is based on the Mach–Zehnder interferometer (MZI), which can convert microwave frequency electrical signals to intensity modulations of an injected single-frequency laser line.37 Current silicon-based MZIs typically exhibit 25 Gbps bandwidths, which can be scaled toward Tbps through multiplexing. Arrays of microring resonators have also been developed, where each ring can modulate separate frequency channels, which provides lower power consumption while retaining high bandwidth with proposed performance approaching 1 Tbps with an energy consumption of less than 20 fJ/bit.38 Whereas MZI modulators are less sensitive to temperature fluctuations, ring modulators offer better prospects in terms of footprint and scalability.

Extending the bandwidth and energy efficiency is possible through heterogeneous integration with III–V materials, such as (Al)GaAs and In(Ga)P39 and lithium niobate.40 The article by Demkov and Posadas41 highlights the recent progress in integrating oxide-based materials, including LiNbO3 and BaTiO3, with silicon photonics to create linear electro-optic modulators. In both LiNbO3 and BaTiO3, the largest components of the Pockels tensor are 36 and 1300 pm/V, respectively, which is larger than most other materials. When combined with low waveguide propagation loss [<1 dB/cm] and small separation between the modulator electrodes, a modulation efficiency of VπL < 1 V cm is attainable. Thin-film LiNbO3 on silicon-on-insulator waveguides has enabled >100 Gbps data rates, which could lay the groundwork for high-speed communications, networks, and novel optical computing paradigms in the near future.

Pushing photodetection to the fundamental limit

Decades of research have been dedicated to the development of photodetectors with large bandwidth, high efficiency, and low noise for optical communications, imaging, sensing, and other applications requiring high-speed optoelectronics. Advances in detector materials and technologies have been driven primarily by the rapid improvements in optical communications and optical interconnect bandwidth exceeding 100 Gbps. As Bienfang et al.42 discuss, single-photon detector technologies, such as single-photon avalanche diodes (SPADs) and superconducting nanowire single-photon detectors (SNSPDs), are pushing the boundaries of photodetection sensitivity, leading to near-ideal energy efficiency. The ability of SPADs and SNSPDs to detect individual photons has created new opportunities for optical communications, including quantum key distribution that leverages the laws of quantum mechanics to ensure information security. Quantum communications have evolved from a burgeoning field to become a multibillion-dollar industry43—in part enabled by advances in SPAD and SNSPD technologies. In addition to communications, single-photon detectors also enable optical detection in photon-starved environments, such as remote sensing for characterizing gas concentrations and aerosols as well as long-distance LIDAR with sub-centimeter resolution.44,45

SPADs and SNSPDs can be fabricated using a wide range of materials, although specific choices can dramatically impact the device performance. For SPADs, which are avalanche diodes that operate above the breakdown voltage to produce an electrical pulse for each detector photon (ideally), material defects that introduce mid-bandgap states can introduce various noise processes. For example, deep-level charge-carrier traps can become filled during an avalanche process, and then release charge carriers at a later time, resulting in after-pulsing in the detector, which lengthens the recovery time for the SPAD to detect another photon. As a result, commercially available SPADs are typically fabricated with high-quality silicon for visible to near-infrared (NIR) detection and InGaAs/InP for NIR to telecommunications wavelengths. Because of the larger bandgap of silicon, the dark count rates are typically much lower than InGaAs. The detector circuitry can also be designed to actively quench and reset the detector to suppress after-pulsing and improve the noise performance. CMOS-compatible SPADs with integrated circuitry to reduce the capacitance, for example, have enabled sub-nanosecond recovery times leading to gigahertz count rates.46

SPADs offer an advantage in terms of size, weight, power, and cost over SNSPDs, but when considering other important performance metrics, including efficiency, noise, count rates, and timing jitter, SNSPDs outperform SPADs in all cases.47 SNSPDs can be fabricated from a variety of thin-film superconducting materials, including Nb(Ti)N, WSi, and MoSi. Typically, films <10-nm thick are grown and patterned into meandering, hairpin, or straight nanowires with widths <100 nm, resulting in critical temperatures ranging from ~2 K to 15 K. SNSPDs are inherently sensitive photodetectors, since an incident photon has an abundant amount of energy to trigger a detection event. High overall detection efficiencies across a wide spectrum, typically above 85% and reaching as high as 98%,48 are possible by embedding the detectors in an optical cavity mode matched to an optical fiber. NbN SNSPDs have been developed with a short wire length and low kinetic inductance, resulting in <3-ps timing jitter (at the expense of total detection efficiency due to a reduced overlap with the optical mode from a fiber).49 Meandered SNSPDs are typically coupled to optical fiber to improve the efficiency, but at the expense of timing jitter. Still, sub-10-ps timing jitter is possible for these structures, which also depends on whether the detector material is amorphous or nanocrystalline.

Because of the sensitivity of single-photon detectors, their integration with photonic circuitry is appealing for improving signal to noise and power consumption for on-chip photodetection. For example, SNSPDs have been integrated on various photonic waveguide platforms, including silicon, (Al)GaAs, aluminum nitride, tantalum, and lithium niobate.50 The challenge is to maintain high detector efficiency on chip when using short nanowires to reduce the kinetic inductance. One way to address this is to integrate detectors with a photonic crystal cavity, although it still remains a challenge to simultaneously optimize all performance metrics. Still, near-unity internal quantum efficiency and ultralow dark counts (millihertz rates) are routinely achieved with sub-100-ps jitter. Photonic integration of SPADs has also seen remarkable progress in recent years, although the fabrication and growth are more challenging compared to SNSPDs. Nonetheless, selective epitaxial growth of germanium on silicon, for example, has resulted in ~40% detection efficiencies in the telecom O-band, although simultaneously maintaining a low dark count rate is challenging.

Ultrathin and ultracompact devices

Although PICs significantly reduce the size, weight, and power of optoelectronic and photonic technologies compared to bulk materials, two-dimensional materials (2DMs) can further reduce the size and weight while maintaining, and often improving, the power consumption and bandwidth. A large family of 2DMs exist, most notably graphene, transition-metal dichalcogenides (TMDs), and hexagonal boron nitride (hBN), which cover a range of materials properties from conductors to semiconductors and insulators, respectively.51 One of the major advantages of 2DMs is their relaxed lattice-matching requirements: atomically thin materials or prefabricated devices can be directly transferred to other material platforms through van der Waals bonding. The relatively simple transfer techniques allow 2DMs to be directly integrated with silicon PICs to add additional or new functionality, such as laser sources, LEDs, high-speed modulators, and sensitive photodetectors.

One example is shown in Figure 6a, where graphene can serve as an all-optical modulator.52 Due to Pauli blocking, graphene becomes transparent after pulsed optical excitation. When integrated with a plasmonic waveguide, the enhanced light–matter interaction leads to a sub-picosecond switching requiring only 35 fJ. Similar concepts have been explored with WSe2/hBN heterostructures coupled to surface plasmon polaritons, as illustrated in Figure 6b, also leading to sub-picosecond switching with ~650 fJ pulse energy.53 TMDs have also been integrated directly above silicon nitride waveguides. Using the strong electrorefractive response of monolayers, a low-loss NIR modulator was demonstrated with VπL < 0.8 V cm and a 3-dB bandwidth of 0.3 GHz.54

(a) Reproduced from Ono et al.;52 (b) reproduced from Klein et al.;53 (c) reproduced from Wu et al.;70 (d) reproduced from Ding et al.;60 and (e) reproduced from Han et al.61 SPP, surface plasmon polariton; ML, monolayer; PCC, photonic crystal cavity; PMMA, polymethyl methacrylate; VNA, vector network analyzer; FFT, fast Fourier transform; FB, frequency beating; ESA, electrical spectrum analyzer.

Materials for ultrathin and compact optoelectronics. (a) All-optical plasmonic modulator based on Pauli blocking in graphene, enabling sub-picosecond switching with 35 fJ. (b) All-optical switch based on transition-metal dichalcogenide WSe2 with sub-picosecond switching with 650 fJ. (c) Ultralow threshold (27 nW) nanolaser based on WSe2 integrated on a GaP photonic crystal membrane. (d) Ultracompact graphene photodetector with 100 GHz bandwidth and 360 mA/W responsivity. (e) Micro-electromechanical (MEMs)-actuated metalens enabling more than an order-of-magnitude focal length change and 1460-diopter change in optical power with > kilohertz rates possible.

The last few years have also resulted in promising results for 2DM sources and detectors. The first 2DM-based nanolaser was demonstrated in 2015, in which high-gain WSe2 was integrated onto a GaP photonic crystal membrane (Figure 6c).55 The large quality factor of the cavity (>104), combined with the small mode volume, yielded an ultralow lasing threshold as small as 27 nW at 130 K. Since this work, several other TMD nanolasers have been developed, including MoTe2 and MoS2/WSe2 heterostructures, which operate at room temperature.56 The ultralow threshold is appealing in terms of energy efficiency, especially compared to III–V materials,57 but several challenges remain before practical use, including total power output, electrical injection, and on-chip directed emission. Two-dimensional material photodetectors with an ultrafast response, based on graphene, were first demonstrated in 2009, and followed by chip-integrated detectors in 2013 with a responsivity of 0.1 mA W−1 with up to 20 GHz bandwidth.58,59 Since then, graphene photodetectors integrated with silicon waveguides exhibiting more than 110 GHz bandwidth have been developed,60 as shown in Figure 6d. As the demand for high bandwidth and low power consumption optical communications continues to increase, we may see 2DM technologies combined with the silicon CMOS process at large scales to meet these demands.

Beyond 2DMs, there is a growing interest in pushing the limits on tunable and programmable ultrathin optics and photonics, at least in part driven by the need for compact optical systems in various settings, including augmented and virtual reality and headset imaging technologies. One excellent example of a tunable optical element is a set of micro-electromechanical (MEMs) actuated metasurfaces that can serve as ultrathin, tunable lenses, as illustrated in Figure 6e with a MEMs Alvarez lens fabricated with a CMOS-compatible process.61 Controllable actuation with low power consumption enables modulating the focal length by up to 68 μm, resulting in more than a 103 change in the optical power with > kilohertz modulation rates possible.

Novel computing architectures with phase-change materials

Neuromorphic engineering, also known as neuromorphic computing, is a broad field that is biologically inspired to address computing design architectures to mimic neural systems.62 The implementation of neuromorphic hardware can be realized in several different ways, including oxide-based memristors,63 spintronics,64 and superconducting optoelectronics.65 In their article, Zhou et al.66 discuss how another approach, based on phase-change materials (PCMs), can efficiently overcome several limitations of traditional von Neumann computing architectures. Their premise is inspired by biological neurons, wherein data processing units within or in the direct vicinity of memory units can reduce the latency and power dissipation. The structural phase of PCMs can be controlled optically to reside in one of two states—amorphous or crystalline—that are either nearly lossless or absorptive, respectively.67 A photonic waveguide memory cell is created by integrating the PCM, such as Ge2Sb2Te5, on top of a silicon waveguide. Either through optical or electrical pulsing, heating of the PCM thin film can induce a phase transition, and the signal modulation induced by the different PCM states can mimic a biological synapse with only 60 pJ of energy consumption and an operating speed approaching 1 GHz.68 Remarkably, the PCM states are stable for more than a decade at room temperature, serving as a nonvolatile optoelectronic memory cell for in-memory and neuromorphic photonic computing. Beyond computing, the development of PCMs is a highly active research field spanning several disciplines, including optical switching and interconnects in photonics, thermal energy storage, and heat management in battery technologies.

Summary and outlook

Advances in optoelectronic materials research have fueled the rapid development of high-speed, high-efficiency, and low SWaP optical technologies and related applications, with a steep rise of attention in the last five years. Whereas initial research was motivated by potential applications in optical communications (e.g., >1 Tbps interconnects and quantum cryptography) and computing (e.g., neuromorphic, all-optical, and quantum architectures), to date, it has essentially contributed to the advancement of the fundamental science of combining multiple bulk and low-dimensional materials on a silicon platform, for both active and passive functionalities. Breakthroughs are frequently happening in many different aspects of this important area of research. Integrating several emerging materials and novel techniques such as plasmonics could give rise to the ultimate optoelectronic systems with unparallel performance. Given the long list of possible opportunities and the recent progress in remote sensing (e.g., LIDAR, magnetometry, space-based) and imaging (e.g., augmented and virtual reality, infrared vision), this field is set to remain an active area of research for years to come.

Data availability

No new data were generated for this article.

References

L. Chrostowski, H. Shoman, M. Hammood, H. Yun, J. Jhoja, E. Luan, S. Lin, A. Mistry, D. Witt, N.A.F. Jaeger, S. Shekhar, H. Jayatilleka, P. Jean, S.B.-de Villers, J. Cauchon, W. Shi, C. Horvath, J.N. Westwood-Bachman, K. Setzer, M. Aktary, N.S. Patrick, R.J. Bojko, A. Khavasi, X. Wang, T.F. de Lima, A.N. Tait, P.R. Prucnal, D.E. Hagan, D. Stevanovic, A.P. Knights, IEEE J. Sel. Top. Quantum Electron. 25, 8201326 (2019)

S.I. Azzam, K. Parto, G. Moody, Appl. Phys. Lett. 118, 240502 (2021)

L. Braun, G. Mussler, A. Hruban, M. Konczykowski, T. Schumann, M. Wolf, M. Münzenberg, L. Perfetti, T. Kampfrath, Nat. Commun. 7, 13259 (2016)

S.Z. Butler, S.M. Hollen, L. Cao, Y. Cui, J.A. Gupta, H.R. Gutiérrez, T.F. Heinz, S.S. Hong, J. Huang, A.F. Ismach, E. Johnston-Halperin, M. Kuno, V.V. Plashnitsa, R.D. Robinson, R.S. Ruoff, S. Salahuddin, J. Shan, L. Shi, M.G. Spencer, M. Terrones, W. Windl, J.E. Goldberger, ACS Nano 7, 2898 (2013)

O. Marshall, M. Hsu, Z. Wang, B. Kunert, C. Koos, D.V. Thourhout, Proc. IEEE 106, 2258 (2018)

S.J.B. Yoo, V. Akella, R. Amirtharajah, B. Baas, K. Bergman, S. Fan, J.S. Harris, M. Lipson, D.A.B. Miller, J. Shalf, "Balanced Computing with Nanophotonic Interconnects," LEOS 2008–21st Annual Meeting of the IEEE Lasers and Electro-Optics Society (2008), pp. 368–369

S. Shi, X. Chu, B. Li, "MG-WFBP: Efficient Data Communication for Distributed Synchronous SGD Algorithms," IEEE INFOCOM 2019-IEEE Conference on Computer Communications (2019), pp. 172–180

D. Rich, A. Bartolo, C. Gilardo, B. Le, H. Li, R. Park, R.M. Radway, M.M. Sabry Aly, H.-S.P. Wong, S. Mitra, "Heterogeneous 3D Nano-systems: The N3XT Approach?" in NANO-CHIPS 2030 (Springer, Cham, 2020), pp 127–151

C.A. Thraskias, E.N. Lallas, N. Neumann, L. Schares, B.J. Offrein, R. Henker, D. Plettemeier, F. Ellinger, J. Leuthold, I. Tomkos, IEEE Commun. Surv. Tutor. 20, 2758 (2018)

D.A.B. Miller, J. Lightwave Technol. 35, 346 (2017)

M.S. Islam, V.J. Logeeswaran, IEEE Commun. Mag. 48, 112 (2010)

D. Thomson, A. Zilkie, J.E. Bowers, T. Komljenovic, G.T. Reed, L. Vivien, D. Marris-Morini, E. Cassan, L. Virot, J.-M. Fédéli, J.-M. Hartmann, J.H. Schmid, D.-X. Xu, F. Boeuf, P. O'Brien, G.Z. Mashanovich, M. Nedeljkovic, J. Opt. 18(7), 073003 (2016)

P. Tiwari, S. Mauthe, N. Vico Trivino, P. Staudinger, M. Scherrer, P. Wen, D. Caimi, M. Sousa, H. Schmid, K.E. Moselund, Q. Ding, A. Schenk, "Scaled III-V Optoelectronic Devices on Silicon," International Conference on Numerical Simulation of Optoelectronic Devices (NUSOD) (2020), pp. 93–94

D. Carrara, A. Shen, X. Pommarede, G. Levaufre, N. Girard, D. Make, G. Glastre, J. Decobert, F. Lelarge, R. Brenot, S. Olivier, C. Jany, S. Malhouitre, B. Charbonnier, C. Kopp, G.-H. Duan, Proc. SPIE, Integrated Optics: Devices, Materials, and Technologies XXI 10106, 101060G (2017)

D. Liang, G. Roelkens, R. Baets, J.E. Bowers, Materials 3, 1782 (2010)

Q. Li, K.W. Ng, K.M. Lau, Appl. Phys. Lett. 106, 072105 (2015)

C.V. Falub, H. von Kanel, F. Isa, R. Bergamaschini, A. Marzegalli, D. Chrastina, G. Isella, E. Muller, P. Niedermann, L. Miglio, Science 335, 1330 (2012)

A.Y. Liu, J. Bowers, IEEE J. Sel. Top. Quantum Electron. 24, 6000412 (2018)

C.V. Falub, H. von Känel, F. Isa, R. Bergamaschini, A. Marzegalli, D. Chrastina, G. Isella, E. Müller, P. Niedermann, L. Miglio, Science 335, 1330 (2012)

S. Pan, V. Cao, M. Liao, Y. Lu, Z. Liu, M. Tang, S. Chen, A. Seeds, H. Liu, J. Semicond. 40, 101302 (2019)

V.J. Logeeswaran, J. Oh, A.P. Nayak, A.M. Katzenmeyer, K.H. Gilchrist, S. Grego, N.P. Kobayashi, S.-Y. Wang, A.A. Talin, N.K. Dhar, M.S. Islam, IEEE J. Sel. Top. Quantum Electron. 17, 1002 (2011)

L.N. Quan, J. Kang, C.-Z. Ning, P. Yang, Chem. Rev. 119, 9153 (2019)

S. Kumar, G. Papen, K. Schmidtke, C. Xie, "Intra-data Center Interconnects, Networking, and Architectures," in Optical Fiber Telecommunications VII (Academic Press, 2020), pp. 627–672

M. Krainak, M. Stephen, E. Troupaki, S. Tedder, B. Reyna, J. Klamkin, H. Zhao, B. Song, J. Fridlander, M. Tran, J.E. Bowers, K. Bergman, M. Lipson, A. Rizzo, I. Datta, N. Abrams, S. Mookherjea, S.-T. Ho, Q. Bei, Y. Huang, Y. Tu, B. Moslehi, J. Harris, A. Matsko, A. Savchenkov, G. Liu, R. Proietti, S.J.B. Yoo, L. Johansson, C. Dorrer, F.R. Arteaga-Sierra, J. Qiao, S. Gong, T. Gu, O.J. Ohanian III, X. Ni, Y. Ding, Y. Duan, H. Dalir, R.T. Chen, V.J. Sorger, T. Komljenovic, Proc. SPIE 10899, 108990F (2019)

A. Samani, M. Chagnon, D. Patel, V. Veerasubramanian, S. Ghosh, M. Osman, Q. Zhong, D.V. Plant, IEEE Photonics J. 7, 7901413 (2015)

G. Crosnier, D. Sanchez, S. Bouchoule, P. Monnier, G. Beaudoin, I. Sagnes, R. Raj, F. Raineri, Nat. Photonics 11, 301 (2017)

K. Zang, X. Jiang, Y. Huo, X. Ding, M. Morea, X. Chen, C.-Y. Lu, J. Ma, M. Zhou, Z. Xia, Z. Yu, T.I. Kamins, Q. Zhang, J.S. Harris, Nat. Commun. 8, 628 (2017)

D. Reinsel, J. Gantz, J. Rydning, The Digitization of the World From Edge to Core (International Data Corp., Framingham, 2018)

N. Margalit, C. Xiang, S.M. Bowers, A. Bjorlin, R. Blum, J.E. Bowers, Appl. Phys. Lett. 118, 220501 (2021)

X. Chao, L. Junqiu, G. Joel, C. Lin, W.R. Ning, W. Wenle, P. Jonathan, X. Weiqiang, Z. Zeyu, R. Johann, S. Jennifer, T.J. Kippenberg, J.E. Bowers, Science 373, 99 (2021)

W. Jin, Q.-F. Yang, L. Chang, B. Shen, H. Wang, M.A. Leal, L. Wu, M. Gao, A. Feshali, M. Paniccia, K.J. Vahala, J.E. Bowers, Nat. Photonics 15, 346 (2021)

M.A. Bandres, S. Wittek, G. Harari, M. Parto, J. Ren, M. Segev, D.N. Christodoulides, M. Khajavikhan, Science 359, eaar4005 (2018)

G. Harari, M.A. Bandres, Y. Lumer, M.C. Rechtsman, T.D. Chong, M. Khajavikhan, D.N. Christodoulides, M. Segev, Science 359, eaar4003 (2018)

J. Liu, X. Sun, R. Camacho-Aguilera, L.C. Kimerling, J. Michel, Opt. Lett. 35, 679 (2010)

M.A. Tran, D. Huang, J.E. Bowers, APL Photonics 4, 111101 (2019)

R. Jones, P. Doussiere, J.B. Driscoll, W. Lin, H. Yu, Y. Akulova, T. Komljenovic, J.E. Bowers, IEEE Nanotechnol. Mag. 13, 17 (2019)

L. Liao, D. Samara-Rubio, M. Morse, A. Liu, D. Hodge, D. Rubin, U.D. Keil, T. Franck, Opt. Express 13, 3129 (2005)

A. Malik, S. Liu, E. Timurdogan, M. Harrington, A. Netherton, M. Saeidi, D.J. Blumenthal, L. Theogarajan, M. Watts, J.E. Bowers, Optical Fiber Communication Conference (2021), paper W6A.3

L. Chang, G. Cole, G. Moody, J.E. Bowers, Opt. Photonics News 33, 24 (2022)

M. Zhang, C. Wang, P. Kharel, D. Zhu, M. Loncar, Optica 8, 652 (2021)

A.A. Demkov, A.B. Posadas, MRS Bull. 47(5) (2022)

J. Bienfang, V. Zwiller, S. Steinhauer, MRS Bull. 47(5) (2022)

Global Quantum Cryptography Market Size, Status, and Forecast (January 2022)

K. Morimoto, A. Ardelean, M.-L. Wu, A.C. Ulku, I.M. Antolovic, C. Bruschini, E. Charbon, Optica 7, 346 (2020)

A. McCarthy, N.J. Krichel, N.R. Gemmell, X. Ren, M.G. Tanner, S.N. Dorenbos, V. Zwiller, R.H. Hadfield, G.S. Buller, Opt. Express 21, 8904 (2013)

F. Severini, I. Cusini, D. Berretta, K. Pasquinelli, A. Incoronato, F. Villa, IEEE J. Sel. Top. Quantum Electron. 28, 3802808 (2022)

A.L. Migdall, S.V. Polyakov, J. Fan, J.C. Bienfang, Single-Photon Generation and Detection: Physics and Applications (Academic Press, New York, 2013)

D.V. Reddy, R.R. Nerem, S.W. Nam, R.P. Mirin, V. Verma, Optica 7, 1649 (2020)

B. Korzh, Q.-Y. Zhao, J.P. Allmaras, S. Frasca, T.M. Autry, E.A. Bersin, A.D. Beyer, R.M. Briggs, B. Bumble, M. Colangelo, G.M. Crouch, A.E. Dane, T. Gerrits, A.E. Lita, F. Marsili, G. Moody, C. Peña, E. Ramirez, J.D. Rezac, N. Sinclair, M.J. Stevens, A.E. Velasco, V.B. Verma, E.E. Wollman, S. Xie, D. Zhu, P.D. Hale, M. Spiropulu, K.L. Silverman, R.P. Mirin, S.W. Nam, A.G. Kozorezov, M.D. Shaw, K.K. Berggren, Nat. Photonics 14, 250 (2020)

G. Moody, V.J. Sorger, D.J. Blumenthal, P.W. Juodawlkis, W. Loh, C. Sorace-Agaskar, A.E. Jones, K.C. Balram, J.C.F. Matthews, A. Laing, M. Davanco, L. Chang, J.E. Bowers, N. Quack, C. Galland, I. Aharonovich, M.A. Wolff, C. Schuck, N. Sinclair, M. Lončar, T. Komljenovic, D. Weld, S. Mookherjea, S. Buckley, M. Radulaski, S. Reitzenstein, B. Pingault, B. Machielse, D. Mukhopadhyay, A. Akimov, A. Zheltikov, G.S. Agarwal, K. Srinivasan, J. Lu, H.X. Tang, W. Jiang, T.P. McKenna, A.H. Safavi-Naeini, S. Steinhauer, A.W. Elshaari, V. Zwiller, P.S. Davids, N. Martinez, M. Gehl, J. Chiaverini, K.K. Mehta, J. Romero, N.B. Lingaraju, A.M. Weiner, D. Peace, R. Cernansky, M. Lobino, E. Diamanti, L.T. Vidarte, R.M. Camacho, J. Phys. Photonics 4, 012501 (2022)

R. Mas-Balleste, C. Gomez-Navarro, J. Gomez-Herrero, F. Zamora, Nanoscale 3, 20 (2011)

M. Ono, M. Hata, M. Tsunekawa, K. Nozaki, H. Sumikura, H. Chiba, M. Notomi, Nat. Photonics 14, 37 (2020)

M. Klein, B.H. Badada, R. Binder, A. Alfrey, M. McKie, M.R. Koehler, D.G. Mandrus, T. Taniguchi, K. Watanabe, B.J. LeRoy, J.R. Schaibley, Nat. Commun. 10, 3264 (2019)

I. Datta, S.H. Chae, G.R. Bhatt, M.A. Tadayon, B. Li, Y. Yu, C. Park, J. Park, L. Cao, D.N. Basov, J. Hone, M. Lipson, Nat. Photonics 14, 256 (2020)

S. Wu, S. Buckley, J.R. Schaibley, L. Feng, J. Yan, D.G. Mandrus, F. Hatami, W. Yao, J. Vučković, A. Majumdar, X. Xu, Nature 520, 69 (2015)

Z. Cheng, R. Cao, K. Wei, Y. Yao, X. Liu, J. Kang, J. Dong, Z. Shi, H. Zhang, X. Zhang, Adv. Sci. 8, 2003834 (2021)

G. Moody, M. Segnon, I. Sagnes, R. Braive, A. Beveratos, I. Robert-Philip, N. Belabas, F. Jahnke, K.L. Silverman, R.P. Mirin, M.J. Stevens, C. Gies, Optica 5, 395 (2018)

F. Xia, T. Mueller, Y.-M. Lin, A. Valdes-Garcia, P. Avouris, Nat. Nanotechnol. 4, 839 (2009)

X. Gan, R.-J. Shiue, Y. Gao, I. Meric, T.F. Heinz, K. Shepard, J. Hone, S. Assefa, D. Englund, Nat. Photonics 7, 883 (2013)

Y. Ding, Z. Cheng, X. Zhu, K. Yvind, J. Dong, M. Galili, H. Hu, N.A. Mortensen, S. Xiao, L.K. Oxenløwe, Nanophotonics 9, 317 (2020)

Z. Han, S. Colburn, A. Majumdar, K.F. Böhringer, Microsyst. Nanoeng. 6, 79 (2020)

D. Markovic, A. Mizrahi, D. Querlioz, J. Grollier, Nat. Rev. Phys. 2, 499 (2020)

A.K. Maan, D.A. Jayadevi, A.P. James, IEEE Trans. Neural Netw. Learn. Syst. 28, 1734 (2016)

J. Grollier, D. Querlioz, K.Y. Camsari, K. Everschor-Sitte, S. Fukami, M.D. Stiles, Nat. Electron. 3, 360 (2020)

J.M. Shainline, S.M. Buckley, R.P. Mirin, S.W. Nam, Phys. Rev. Appl. 7, 034013 (2017)

W. Zhou, N. Farmakidis, J. Feldmann, X. Li, J. Tan, Y. He, C.D. Wright, W.H.P. Pernice, H. Bhaskaran, MRS Bull. 47(5) (2022)

C.D. Wright, H. Bhaskaran, W.H.P. Pernice, MRS Bull. 44(9), 721 (2019)

X. Li, N. Youngblood, Z. Cheng, S. Carrillo, E. Gemo, W.H.P. Pernice, C.D. Wright, H. Bhaskaran, Optica 7, 218 (2020)

S. Fathololoumi, D. Hui, S. Jadhav, K. Nguyen, M.N. Sakib, Z. Li, H. Mahalingam, S. Amiralizadeh, N.N. Tang, H. Frish, L. Liao, Proc. SPIE, Silicon Photonics XVI 11691, 116910A (2021). https://doi.org/10.1117/12.2577314

S. Wu, S. Buckley, J.R. Schaibley, L. Feng, J. Yan, D.G. Mandrus, F. Hatami, W. Yao, J. Vučković, A. Majumdar, X. Xu, Nature 520, 69 (2015). https://doi.org/10.1038/nature14290

Funding

G.M. gratefully acknowledges support from the UC Santa Barbara NSF Quantum Foundry funded via the Q-AMASE-i program under Award No. DMR-1906325 and from the Air Force Office of Scientific Research (AFOSR) via the Young Investigator Research Program (YIP) under Award No. FA9550-20-1-0150. M.S.I. acknowledges support from CITRIS and the Banatao Institute at the University of California and W&W Sens Devices Inc., Los Altos, Calif.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moody, G., Islam, M.S. Materials for ultra-efficient, high-speed optoelectronics. MRS Bulletin 47, 475–484 (2022). https://doi.org/10.1557/s43577-022-00337-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-022-00337-y