Abstract

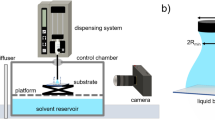

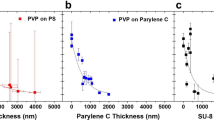

Recent work in structure–processing relationships of polymer semiconductors have demonstrated the versatility and control of thin-film microstructure offered by meniscusguided coating (MGC) techniques. Here, we analyze the qualitative and quantitative aspects of solution shearing, a model MGC method, using coating blades augmented with arrays of pillars. The pillars induce local regions of high strain rates—both shear and extensional—not otherwise possible with unmodified blades, and we use fluid mechanical simulations to model and study a variety of pillar spacings and densities. We then perform a statistical analysis of 130 simulation variables to find correlations with three dependent variables of interest: thin-film degree of crystallinity and transistor field-effect mobilities for charge-transport parallel (Μpara) and perpendicular (Μperp) to the coating direction. Our study suggests that simple fluid mechanical models can reproduce substantive correlations between the induced fluid flow and important performance metrics, providing a methodology for optimizing blade design.

Impact Statement

Polymer semiconductors have opened up a new frontier of electronics that can be flexible, stretchable, implantable, or biodegradable. While the chemical and electronic properties of these materials are important for their function as the active material in organic electronic devices, the manner by which these organic semiconductors are deposited onto a substrate can significantly influence its charge-transport properties. While a variety of techniques have been investigated to enhance charge-transport behavior, there are few reports approaching the issue in terms of the fluid dynamical considerations relevant during deposition from the solution phase. In this article, we analyze the fluid flow that occurs during thin-film deposition by solution shearing, a representative meniscusguided coating method amenable to high-throughput processing. We investigate a variety of variables related to fluid flow that can be estimated from fluid mechanical simulations of solution shearing with a coating blade patterned with a regular array of pillars used to induce higher fluid strain rates. We find correlations suggestive of underlying relationships between strain rates associated with certain directions and polymer charge-transport properties in the final deposited film. This article establishes a statistical approach using simulation data that can guide patterned blade design to enhance polymer deposition and realize high-performance devices.

Similar content being viewed by others

Acknowledgments

Use of the Stanford Synchrotron Radiation Lightsource, SLAC National Accelerator Laboratory, is supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences under Contract No. DE-AC02-76SF00515. Part of this work was performed at the Stanford Nano Shared Facilities, supported by the National Science Foundation (NSF) under Award No. ECCS-1542152. Work was also performed in part in the nano@Stanford labs, which are supported by the NSF as part of the National Nanotechnology Coordinated Infrastructure under Award No. ECCS-1542152.

Funding

The authors acknowledge support from the US Department of Energy, Office Basic Energy Sciences, Division of Materials Science and Engineering, Program on Physical Behaviors of Materials (DE-SC0016523). This work was supported in part by BASF SE. G.C.M.N.’s work was supported by the National Nanotechnology Infrastructure Network Research Experiences for Undergraduates Program via National Science Foundation Cooperative Agreement No. EECS-0335765. R.T.W. acknowledges funding from the Solar Technologies go Hybrid initiative and the Deutsche Forschungsgemeinschaft (German Research Foundation) under Germany’s Excellence Strategy EXC 2089/1-390776260.

Author information

Authors and Affiliations

Contributions

L.S., R.T.W., D.K., M.F.T., and Z.B. designed the experiments. L.S. performed all experiments and simulations. Y.D. and G.C.M.N. contributed to the patterned blade design and their fabrication. Y.D. also facilitated the blade representation in the COMSOL simulation environment. H.Y. assisted with the x-ray measurements. P.H. synthesized the semiconducting polymer. All authors discussed the results and commented on the manuscript.

Corresponding authors

Supplementary Information

Below are link to the supplementary material

Rights and permissions

About this article

Cite this article

Shaw, L., Diao, Y., Martin-Noble, G. et al. Manipulation and statistical analysis of the fluid flow of polymer semiconductor solutions during meniscus-guided coating. MRS Bulletin 46, 380–393 (2021). https://doi.org/10.1557/s43577-021-00049-9

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-021-00049-9