Abstract

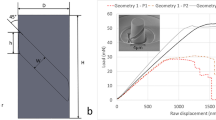

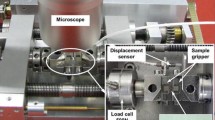

Microscale testing has enjoyed significant developments, with the majority of testing focused on tensile/compression type tests and little focus on shear testing. With the recent advances in macroscale shear testing, we developed a novel shear structure for evaluating shear properties of bulk materials and films at the microscale. The shear response in single-crystal copper oriented along the [111] direction was found to have a yield strength of ∼180 MPa. Nanocrystalline copper specimens with different orientations showed sensitivity to the film texture with a shear yield strength nearly three times that of single-crystal copper. Shear specimens were fabricated with Cu film–Si substrate interface near the middle of the shear region and compressed to fracture. The shear response showed a mixed behavior of the stiff Si substrate and softer nanocrystalline film and failed in a brittle manner, indicating a response unique to the interface.

Similar content being viewed by others

References

N.A. Fleck, G.M. Muller, M.F. Ashby, and J.W. Hutchinson: Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 42, 475–487 (1994).

W.J. Poole, M.F. Ashby, and N.A. Fleck: Micro-hardness of annealed and work-hardened copper polycrystals. Scr. Mater. 34, 559–564 (1996).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411–425 (1998).

H. Gao, Y. Huang, W.D. Nix, and J.W. Hutchinson: Mechanism-based strain gradient plasticity—I. Theory. J. Mech. Phys. Solids 47, 1239–1263 (1999).

Y. Huang, Z. Xue, H. Gao, W.D. Nix, and Z.C. Xia: A study of microindentation hardness tests by mechanism-based strain gradient plasticity. J. Mater. Res. 15, 1786–1796 (2000).

K. Durst, B. Backes, O. Franke, and M. Goken: Indentation size effect in metallic materials: Modelling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 54, 2547–2555 (2006).

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix: Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

J.R. Greer, W.C. Oliver, and W.D. Nix: Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821–1830 (2005).

D. Kiener, C. Motz, T. Schöberl, M. Jenko, and G. Dehm: Determination of mechanical properties of copper at the micron scale. Adv. Eng. Mater. 8, 1119–1125 (2006).

D. Kiener, C. Motz, and G. Dehm: Micro-compression testing: A critical discussion of experimental constraints. Mater. Sci. Eng., A 505, 79–87 (2009).

J.Y. Kim and J. Greer: Size-dependent mechanical properties of molybdenum nanopillars. Appl. Phys. Lett. 93, 101916 (2008).

C.P. Frick, B.G. Clark, S. Orso, A.S. Schneider, and E. Arzt: Size effect on strength and strain hardening of small-scale [111] nickel compression pillars. Mater. Sci. Eng., A 489, 319–329 (2008).

J.Y. Kim, D. Jang, and J.R. Greer: Tensile and compressive behavior of tungsten, molybdenum, tantalum and niobium at the nanoscale. Acta Mater. 58, 2355–2363 (2010).

A.T. Jennings, M.J. Burek, and J. Greer: Microstructure versus size: Mechanical properties of electroplated single crystalline Cu nanopillars. Phys. Rev. Lett. 104, 135503 (2010).

R. Soler, J.M. Wheeler, H.J. Chang, J. Segurado, J. Michler, J. Llorca, and J.M. Molina-Aldareguia: Understanding size effects on the strength of single crystals through high-temperature micropillar compression. Acta Mater. 81, 50–57 (2014).

B. Wu, A. Heidelberg, and J.J. Boland: Mechanical properties of ultrahigh-strength gold nanowires. Nat. Mater. 4, 525–529 (2005).

A.S. Budiman, S.M. Han, J.R. Greer, N. Tamura, J.R. Patel, and W.D. Nix: A search for evidence of strain gradient hardening in Au submicron pillars under uniaxial compression using synchrotron X-ray microdiffraction. Acta Mater. 56, 602–608 (2008).

M. Walter and O. Kraft: A new method to measure torsion moments on small-scaled specimens. Rev. Sci. Instrum. 82, 035109 (2011).

D.B. Liu, Y.M. He, J.D. Dunstan, B. Zhang, Z.P. Gan, P. Hu, and H.M. Ding: Toward a further understanding of size effects in the torsion of thin metal wires: An experimental and theoretical assessment. Int. J. Plast. 41, 30 (2013).

Y.J. Dai, Y. Huan, M. Gao, J. Dong, W. Liu, M.X. Pan, W.H. Wang, and Z.L. Bi: Development of a high-resolution micro-torsion tester for measuring the shear modulus of metallic glass fibers. Meas. Sci. Technol. 26, 025902 (2015).

J.K. Heyer, S. Brinckmann, J. Pfetzing-Micklich, and G. Eggeler: Microshear deformation of gold single crystals. Acta Mater. 62, 225 (2014).

N. Wierczorek, G. Laplanche, J-K. Heyer, A.B. Parsa, J. Pfetzing-Micklich, and G. Eggeler: Assessment of strain hardening in copper single crystals using in situ SEM microshear experiments. Acta Mater. 113, 320 (2016).

P.A. Steinmann, Y. Tardy, and H.E. Hintermann: Adhesion testing by the scratch test method: The influence of intrinsic and extrinsic parameters on the critical load. Thin Solid Films 154, 333–349 (1987).

M. Larsson, M. Olsson, P. Hedenqvist, and S. Hogmark: Mechanisms of coating failure as demonstrated by scratch and indentation testing of TiN coated HSS. Surf. Eng. 16, 436–444 (2000).

B.D. Beak, A.J. Harris, and T.W. Liskiewicz: Review of recent progress in nanoscratch testing. Tribol.-Mater., Surf. Interfaces 7, 87–96 (2013).

D.D. Maio and S.G. Roberts: Measuring fracture toughness of coatings using FIB-machined microbeams. J. Mater. Res. 20, 299–302 (2005).

K. Matoy, T. Detzel, M. Muller, C. Motz, and G. Dehm: Interface fracture properties of thin films studied by using the micro-cantilever deflection technique. Surf. Coat. Technol. 204, 878–881 (2009).

J. Schaufler, C. Schmid, K. Durst, and M. Goken: Determination of the interfacial strength and fracture toughness of a-C:H coatings by in situ microcantilever bending. Thin Solid Films 522, 480–484 (2012).

K. Chen, Y. Mu, and W.J. Meng: A new experimental approach for evaluating the mechanical integrity of interfaces between hard coatings and substrates. MRS Commun. 4, 19–23 (2014).

Y. Mu, X. Zhang, J.W. Hutchinson, and W.J. Meng: Measuring critical stress for shear failure of interfacial regions in coating/interlayer/substrate systems through a micro-pillar testing protocol. J. Mater. Res. 32, 1421–1431 (2017).

K. Wu, J.Y. Zhang, G. Liu, P. Zhang, P.M. Cheng, J. Li, G.J. Zhang, and J. Sun: Buckling behaviors and adhesion energy of nanostructured Cu/X (X = Nb, Zr) multilayer films on a compliant substrate. Acta Mater. 61, 7889–7903 (2013).

I. Radchenko, H.P. Anwarali, S.K. Tippabhotla, and A.S. Budiman: Effects of interface shear strength during failure of semicoherent metal/metal nanolaminates: An example of accumulative rollbonded Cu/Nb. Acta Mater. 156, 125–135 (2018).

C. Mayer, N. Li, N. Mara, and N. Chawla: Micromechanical and in situ shear testing of Al–SiC nanolaminate composites in a transmission electron microscope (TEM). Mater. Sci. Eng., A 621, 229 (2015).

G.T. Gray, K.S. Vecchio, and V. Livescu: Compact forced simple-shear sample for studying shear localization in materials. Acta Mater. 103, 12 (2016).

J. Peirs, U.P. Verleysen, J. Degrieck, and F. Coghe: The use of hat-shaped specimens to study the high strain rate shear behaviour of Ti–6Al–4V. Int. J. Impact Eng. 37, 703 (2010).

C. Mayr, G. Eggeler, G.A. Webster, and G. Peter: Double shear creep testing of superalloy single crystals at temperatures above 1000 °C. Mater. Sci. Eng., A 199, 121 (1995).

J.D. Livingston: Density and distribution of dislocations in deformed copper crystals. Acta Metall. 10, 229–239 (1962).

M.A. Meyers, A. Mishra, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427 (2006).

F. Tang and J.M. Schoenung: Strain softening in nanocrystalline or ultrafine-grained metals: A mechanistic explanation. Mater. Sci. Eng., A 493, 101 (2008).

Z. You, X. Li, L. Gui, Q. Lu, T. Zhu, H. Gao, and L. Lu: Plastic anisotropy and associated deformation mechanisms in nanotwinned metals. Acta Mater. 61, 217 (2013).

O. Anderoglu, A. Misra, J. Wang, R.G. Hoagland, J.P. Hirth, and X. Zhang: Plastic flow stability of nanotwinned Cu foils. Int. J. Plast. 26, 875 (2010).

J. Wang, N. Li, O. Anderoglu, X. Zhang, A. Misra, J.Y. Huang, and J.P. Hirth: Detwinning mechanisms for growth twins in face-centered cubic metals. Acta Mater. 58, 2262 (2010).

N. Li, J. Wang, J.Y. Huang, A. Misra, and X. Zhang: Influence of slip transmission on the migration of incoherent twin boundaries in epitaxial nanotwinned Cu. Scr. Mater. 64, 149 (2011).

N. Li, J. Wang, X. Zhang, and A. Misra: In situ TEM study of dislocation-twin boundaries interaction in nanotwinned Cu films. JOM 63, 62 (2011).

A.P. Zhilyaev and T.G. Langdon: Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 53, 893–979 (2008).

V.M. Segal: Materials processing by simple shear. Mater. Sci. Eng., A 197, 157–164 (1995).

V.M. Segal: Severe plastic deformation: Simple shear versus pure shear. Mater. Sci. Eng., A 338, 331–344 (2002).

R.Z. Valiev and T.G. Langdon: Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 51, 881–981 (2006).

B. Derby: The dependence of grain size on stress during dynamic recrystallization. Acta Metall. Mater. 39, 955–962 (1991).

E. Bagherpour, F. Qods, R. Ebrahimi, and H. Miyamoto: Microstructure evolution of pure copper during a single pass of simple shear extrusion (SSE): Role of shear reversal. Mater. Sci. Eng., A 666, 324–338 (2016).

Acknowledgments

J.G.G, S.M., and N.L. acknowledge the support of the U.S. Department of Energy, Office of Nuclear Energy Fuel Cycle Research and Development Program, and the Los Alamos National Laboratory (LANL)/Laboratory Directed Research & Development (LDRD) Program. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science. Los Alamos National Laboratory, an affirmative action equal opportunity employer, is operated by Los Alamos National Security, LLC, for the National Nuclear Security Administration of the U.S. DOE under contract DE-AC52-06NA25396.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gigax, J.G., Baldwin, J.K., Sheehan, C.J. et al. Microscale shear specimens for evaluating the shear deformation in single-crystal and nanocrystalline Cu and at Cu–Si interfaces. Journal of Materials Research 34, 1574–1583 (2019). https://doi.org/10.1557/jmr.2019.104

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.104